Static Structural Analysis on Different Topology Optimization Transtibial Prosthetic Socket Leg

Corresponding email: sirhazwan@gmail.com

Published at : 05 Feb 2024

Volume : IJtech

Vol 15, No 2 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i2.6711

Norli, M.H.M., Sukimi, A.K.A., Ramlee, M.H., Mahmud, J., Abdullah, A.H., 2024. Static Structural Analysis on Different Topology Optimization Transtibial Prosthetic Socket Leg. International Journal of Technology. Volume 15(2), pp. 455-462

| Mohd Hazwan Mohamed Norli | 1. Department of Mechanical Engineering, Politeknik Banting Selangor, Jalan Sultan Abdul Samad, 42700 Banting, Selangor Malaysia, 2. School of Mechanical Engineering, College of Engineering, Universit |

| Ahmad Kamil Adib Sukimi | School of Mechanical Engineering, College of Engineering, Universiti Teknologi MARA, 40450 Shah Alam, Selangor Malaysia |

| Muhammad Hanif Ramlee | Department of Biomedical Engineering & Health Sciences, Faculty of Electrical Engineering, Universiti Teknologi Malaysia, 81310 Skudai, Johor Malaysia |

| Jamaluddin Mahmud | School of Mechanical Engineering, College of Engineering, Universiti Teknologi MARA, 40450 Shah Alam, Selangor Malaysia |

| Abdul Halim Abdullah | School of Mechanical Engineering, College of Engineering, Universiti Teknologi MARA, 40450 Shah Alam, Selangor Malaysia |

The transtibial Prosthetic Socket serves as the

primary connection between the residual limb of an amputee and the prosthesis.

The socket must provide a secure and stable base for the amputee to bear their

body weight and move around comfortably. Topological optimization is a process

that aims to improve the mechanical properties of the prosthetic socket. It

involves designing a structure that minimizes stress concentrations and

maximizes strength while using the least amount of material. The objective of

this study is to improve the parametric design of the transtibial socket

prosthesis through topology optimization and determine the stress performance

of 3D-printed transtibial sockets using static structural analysis. The method

used is Finite Element Analysis (FEA) simulations of forces onto the socket

during phases of walking on different topology-optimized socket designs and

using the same material, which is ABS. Furthermore, the results were analyzed

through static structural analysis using ANSYS software. The analysis revealed

that a reduction in the weight of the model correlates with an increase in

stress thus may contribute to material fatigue and reducing long term

performance.

FEA; Prosthetic; Static; Topology Optimization; Transtibial

A prosthetic leg socket allows patients who have had a

limb amputated below the knee to place their limb inside the socket and link it

to the prosthetic leg. It is known as a transtibial socket for a prosthetic

leg. Demet

et al. (2003), patients with lower limb amputations

reported a worse quality of life and greater problems integrating into society

than the general population. Lower limb prosthesis users have identified the

socket as the most important aspect of their overall happiness with their

prosthesis. Thus, the primary goal of this project is to ensure that consumers

are more comfortable and pleased when wearing their sockets. A study conducted

by Iridiastadi,

Vani, and Yamin (2020) also affirms that musculoskeletal

disorders influenced by abnormal working conditions can be alleviated by

providing practitioners with well-designed handling aids.

Topology

optimization and Finite Element Analysis (FEA) will be used to achieve the

major aims of this research. Topology optimization is a structural optimization

approach for predicting material and load distribution by specifying design

parameters. Kentli

(2020) Topology optimization provides the optimum material

distribution based on stated limitations and preserves zones to achieve

superior structural performance.

Figure

1 Typical transtibial prosthesis

The Finite Element Method (FEM) is a powerful tool for

analyzing the behavior structures of the prosthesis socket to find out the

contact pressure between computer-interfaced prostheses. Shankar et al.

(2020); Faustini et al. (2006) FEM were used to look at the

designs of compliant features to reduce pressure between the stump and socket.

Moreover, FEM plays a crucial role and provides significant benefits in the

study conducted by Irsyad et al. (2020). This is

because FEM allows the analysis of the mechanical integrity of various

materials, ensuring the strength of the hub in withstanding the equivalent

forces caused by accidental falls and the grip of surgeons.

Similarly, Portnoy et al. (2008) made

a patient-specific FE parametric biomechanical model of the residual limb that

predicts stresses transmitted through the muscle flap by the shin bones during

static and dynamic loading. The topology optimization technique is used to find

possible structure designs that reduce mass and improve socket performance.

Faustini

et al. (2006) used topology optimization to

find the best compliant features, which they then put into the geometry of the

socket. Finite element analysis can be used to generate ideas and provide an

overview of the design process, particularly for materials within their yield

strength. In this case, the method was applied to a prosthetic socket to

replicate how it moved when loaded at the top while leaving the bottom surface

unchanged. The consistency of the FEA was demonstrated by considering four

factors: the geometry, the mesh, the material properties, and the boundary

conditions. The results of the FEA provide valuable insights into the design

and customization of prosthetic sockets.

Integration of new technology can make a big difference

in how the socket is designed and analyzed, and 3D printing technology has

significantly impacted the production of transtibial sockets. Whulanza et al.

(2020) has different logical assumptions about this process,

only that it cannot produce millions of quantities in a shorter time. In spite

of that, 3D printing can create these sockets at a faster production time (but

low quantity), easier customization, lower costs, and improved performance.

Based on Walker

et al., (2020), the stump's complex shape and

the fact that it is different for each amputee make it hard to design

prosthesis sockets. The prosthetist chooses the best socket design based on the

condition of the patient's skin and where the missing limb is Peery, Ledoux, and Klute (2005).

The main way to make the patient feel better is to reduce the pressure between

the stump and socket and reduce the temperature surrounding the stump.

Hence, new designs are being constructed to reduce

pressure and the temperature surrounding the stump for the patient's comfort. Dakhil et al.

(2020) states that topology optimization is a design method that

aims to minimize the size of a structure while maintaining its strength.

Geometry reduction of the socket influences the stress distribution of the

socket, which ultimately improves performance and comfortability.

For the static analysis of the transtibial socket, it was

assumed that the mechanical properties of the liner, bones, and socket were

linear, elastic, isotropic, and homogeneous. According to Zachariah and Sanders (2000), the

strength and durability of prosthetic components are evaluated using the ISO

10328 test standard, which provides guidelines for static proof, ultimate

strength, and cycle testing as three distinct tests.

The

Ansys program, which enables the simulated test forces to be applied at a rate

of 100 N/s, is used to conduct all experiments. The maximum loading at various

points of the walking cycle is related to the test loading configurations (I

and II) mentioned in the standard. The maximum loading during the early stance

phase of walking is related to Configuration I, while the maximum loading

during the late stance phase is related to Configuration II. Neo, Lee, and Goh (2000) Figure

2 shows the model for the transtibial leg.

Figure 2 A model for transtibial leg

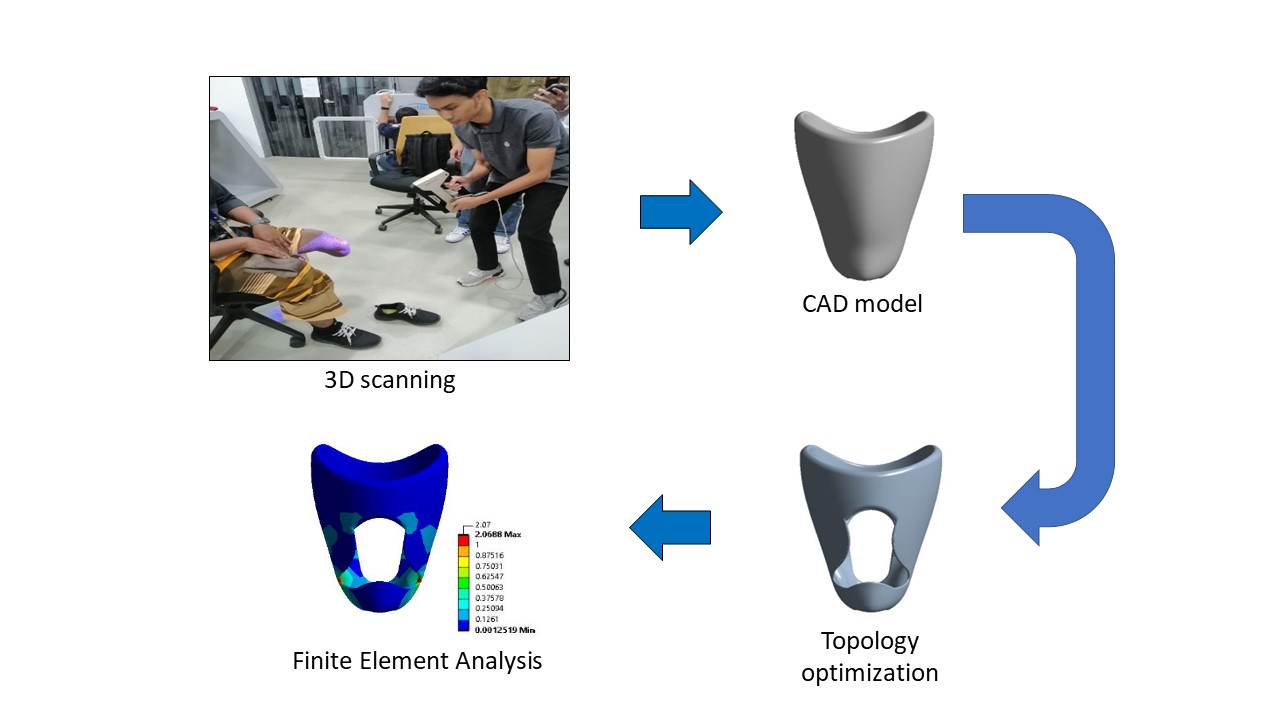

2.1. 3D Scanning

The patient’s limb was 3D

scanned using Sense3D Scanner, as shown in Figure 3, to get the geometric shape

of the limb to make sure the device is a perfect fit for the patient, thus

giving better ergonomic and patient-specific value. Then, 3D scanning was converted

into a 3D model, and Solidworks software was used to run a few analyses, such

as topology optimization and FEA.

Figure 3 3D

scanning process of patient's limb

2.2 Topology Optimization

The

topology design of the transtibial socket model was optimized by reducing the

weight, resulting in the creation of 5 different optimized sockets, as

illustrated in Figure 4.

Figure 4 Topology Optimized Designs

2.3 Analysis Method

The static structural analysis ignores inertia and

damping effects. The project analyzed 5 different model designs based on the

weight reduction achieved through the topology optimization of the transtibial

socket using the same material, which is ABS. The criteria considered for

analysis include stress analysis, safety factors, and weight ratio. Stress

analysis, safety factors and weight ratio are the criteria to be considered.

3.1. Static Structural Analysis

3.1.1. Weight

of the socket

From the topology optimization process of the transtibial socket, the

weight is reduced for each design. Thus, each design does not have the same

weight. The weight reduction of the transtibial socket range is between 10% and

21% for each design, as shown in Figure 5. Design 4 has the

highest weight percentage of reduction, which is 74.22%.

Figure 5 Weight percentage of the

socket after redesigning with topology process

3.1.2. Stress distribution on the socket

The strength of the socket is based on the

material selection and the design itself. The material used in this study is

plastic ABS. Figure 6 shows the front view of stress distribution happening at

the socket for each design.

Figure 6 The

front view of stress distribution in the socket at different designs (1) - (5)

for static structural analysis

Figure 7 The upper view of stress distribution in the socket at different designs (1) – (5) for static structural analysis

Table 1

Comparison of stress distribution in the socket at different designs (1) – (5)

|

Type of Design |

1 |

2 |

3

|

4 |

5

|

|

1250N |

0.1731 MPa |

0.5895 MPa |

1.4631 MPa |

2.0688 MPa |

0.5442 MPa |

According

to Table 1, the simulation shows that Design 4 has the highest stress value on

the socket with a maximum stress magnitude of 2.068 MPa, while Design 1 has the

lowest stress value, which is 0.1731 MPa.

Comparing the stress on the model with the weight reduction shows that as the

weight reduction of the model increases, the stress on the model also

increases.

3.1.3. Safety factor in the socket

As depicted in Figure 8, the safety factor

graph obtained from the simulation reveals that Design 1 has the highest safety

factor, reaching 62.7. On the other hand, Design 4 has the lowest safety

factor, measuring 12.2. This decrease in safety factor is attributed to the

significant weight removal in Design 4, causing a reduction in the model's

strength.

Figure 8

Safety Factor in the socket model at different designs (1) - (5) for static

structural analysis

In this study, the topology optimization for the

transtibial socket for a prosthetic leg was designed and analyzed using static

structural analysis. The socket is the material ABS. The analysis shows that

the socket is under more stress when its weight is reduced. Hence, weight

reduction might change the model's mass distribution and lead to higher stress

at particular spots due to the loss of the support that the removed material

provided. However, the observed stress patterns have the potential to influence

various aspects of the prosthetic leg's functionality, comfort, and durability.

The ultimate goal of this project is to successfully design a customized

transtibial socket prosthetic leg, thereby achieving the overall objectives.

This research

received support from Jabatan Pendidikan Politeknik & Kolej Komuniti

(JPPKK) through scholarship package in the year 2022. We express our gratitude

to the Ministry of Higher Education, Malaysia, and extend our thanks to our

colleagues from Politeknik Banting Selangor and UiTM Shah Alam for their

valuable advice and expertise in the research work.

Dakhil, N., Tarrade, T., Behr, M., Mo, F.,

Evin, M., Thefenne, L., Liu, T., Llari,

M., 2020. Influence of The Scale Reduction in Designing Sockets for

Trans-Tibial Amputees. Proceedings of the Institution of Mechanical

Engineers, Part H: Journal of Engineering in Medicine, Volume 234(8), pp.

761–768

Demet, K., Martinet, N., Guillemin, F.,

Paysant, J., Andre, J.M., 2003. Health Related Quality of Life and Related

Factors in 539 Persons with Amputation of Upper and Lower Limb. Disability and

Rehabilitation, Volume 25(9), pp. 480–486

Farah, S., Anderson, D. G., Langer, R., 2016.

Physical and Mechanical Properties of PLA, and Their Functions in Widespread

Applications — a Comprehensive Review. Advanced Drug Delivery Reviews,

Volume 107, pp. 367–392

Faustini, M.C., Neptune, R.R., Crawford,

R.H., Rogers, W.E., Bosker, G., 2006. An Experimental and Theoretical Framework

for Manufacturing Prosthetic Sockets for Transtibial Amputees. IEEE

Transactions on Neural Systems and Rehabilitation Engineering, Volume

14(3), pp. 304–310

Iridiastadi, H., Vani, T., Yamin, P.A.R., 2020. Biomechanical Evaluation of a Patient-Handling Technology Prototype. International

Journal of Technology, Volume 11(1), pp. 180–189

Irsyad, M., Nadhif, M.H., Rahyussalim, A.J.,

Assyarify, H., Utomo, M.S., 2020. Material Selection Techniques for Polymer

Hubs of Novel Spinal Stem Cell Introducers using Finite Element and Weighted

Property Method. International Journal of Technology, Volume 11(5), pp.

1056–1065

Kentli, A., 2020. Topology Optimization

Applications on Engineering Structures. Truss and Frames - Recent Advances

and New Perspectives, Volume 2020, pp. 1–23

Neo, L.D., Lee, P.V.S., Goh, J.C.H., 2000.

Principal Structural Testing of Trans-Tibial Prosthetic Assemblies: Specimen

Preparation. Prosthetics and Orthotics International, Volume 24(3), pp.

241–245

Peery, J.T., Ledoux, W.R., Klute, G.K., 2005.

Residual-Limb Skin Temperature in Transtibial Sockets. Journal of

Rehabilitation Research and Development, Volume 42(2), pp. 147–154

Portnoy, S., Yarnitzky, G., Yizhar, Z.,

Kristal, A., 2008. Real-Time Patient-Specific Finite Element Analysis of

Internal Stresses in The Soft Tissues of a Residual Limb: A New Tool for

Prosthetic Fitting. Journal of Biomechanics, Volume 41(1), pp. 1897–1909

Shankar, S., Nithyaprakash, R.,

Santhosh, B.R., Uddin, M.S., Pramanik, A., 2020. Finite Element Submodeling

Technique to Analyze the Contact Pressure and Wear of Hard Bearing Couples in

Hip Prosthesis. Computer Methods in Biomechanics and Biomedical Engineering,

Volume 23(8), pp. 422–431

Walker, N.R., Nickel, E.A., Santa-Ana, C.K.,

Cataldo, A.Y., Laine-Dyreson, M.P., Gravely, A.A., Hand, B.D., Hansen, A.H.,

2020. Prosthetic 3D Printing. Journal of Prosthetics and Orthotics,

Volume 32(2S), pp. 35–39

Whulanza, Y., Supriadi, S., Chalid, M., Kreshanti,

P., Agus, A.A., Napitupulu, P., Supriyanto, J.W., Rivai, E., Purnomo, A., 2020.

Setting Acceptance Criteria for a National Flocked Swab for Biological

Specimens during the COVID-19 Pandemic. International Journal of Technology,

Volume 11(5), pp. 888–899

Zachariah, S.G., Sanders, J.E., 2000. Finite

Element Estimates of Interface Stress in The Trans-Tibial Prosthesis Using Gap

Elements Are Different from Those Using Automated Contact. Journal of

Biomechanics, Volume 33(7), pp. 895–899