Anaerobic Digestion Potential in Traditional Boarding School

Corresponding email: cindy.priadi@eng.ui.ac.id

Published at : 07 Dec 2023

Volume : IJtech

Vol 14, No 7 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i7.6699

Bilqis, A.T., Abdillah, A., Jahroh, S., Abdullah, A., Dewi, F., Tjahjono, B., Rakhmani, I., Priadi, C.R., 2023. Anaerobic Digestion Potential in Traditional Boarding School. International Journal of Technology. Volume 14(7), pp. 1496-1505

| Adelia Tsaltsani Bilqis | Environmental Engineering Study Program, Department of Civil and Environmental Engineering, Universitas Indonesia, Depok, West Java 16424, Indonesia |

| Ayik Abdillah | Environmental Engineering Study Program, Department of Civil and Environmental Engineering, Universitas Indonesia, Depok, West Java 16424, Indonesia |

| Siti Jahroh | School of Business, IPB University, Bogor, West Java 16151, Indonesia |

| Asaduddin Abdullah | School of Business, IPB University, Bogor, West Java 16151, Indonesia |

| Febriantina Dewi | School of Business, IPB University, Bogor, West Java 16151, Indonesia |

| Benny Tjahjono | Centre for Business in Society, Coventry University, Coventry CV1 5FB, United Kingdom |

| Inaya Rakhmani | Department of Communication, Faculty of Social and Political Sciences, Universitas Indonesia, Depok, West Java 16424, Indonesia |

| Cindy Rianti Priadi | Environmental Engineering Study Program, Department of Civil and Environmental Engineering, Universitas Indonesia, Depok, West Java 16424, Indonesia |

There are approximately 36,600 religious boarding schools in

Indonesia accommodating a student population of 3.4 million. Traditional

religious boarding school is one of the most significant contributors to waste

generation after housing. This study is aimed to measure waste generation and the

potential to implement anaerobic digestion in traditional boarding schools. At

Al Hikam Boarding School, with a population of 265 residents, the average daily

waste generation was measured at 33.6 kg/day, with organic waste constituting

41.8%. Over three months, the study included the stages of seeding, acclimatisation,

and operation of anaerobic digestion using organic waste generated by the boarding

school and traditional buffet. With an input of 7.6 kg/day, the results showed

that organic waste used had a pH, total solid (TS), volatile solid (VS), chemical

oxygen demand (COD), and temperature of 6.1±0.38, 25±0.092%, 95±0.0054%TS,

453±188 g/L, and 29.5±1.12°C, respectively. The digester reported a volatile

solid destruction (VSD) and chemical oxygen demand (COD) reduction of 91±0.015%

and 89±0.081%, respectively. This produced biogas volume and methane yield of

805±219 L/day and 292±130 L.methane/kg.VS. So, anaerobic digestion with a Toren

Biogas reactor is the recommended technology to manage organic waste at

traditional boarding schools, with a potential reduction factor of 54%.

Anaerobic digestion; Biogas; Boarding school; Organic waste treatment

By the end of 2017, Indonesia had generated 65.8 million

metric tons of waste, of which 60% was dominated by organic waste (Ministry of

Environment and Forestry, 2020). Then, a landfill is

dominated by organic waste and the degradation of that waste causes methane gas production, potentially resulting in landfill fires that are harmful to humans and the environment (Amritha and Anilkumar, 2016). Management of organic waste

results in reduced financial expenditures and serves as a crucial measure to

mitigate adverse environmental impacts

The management of organic waste is best done at the source

to avoid waste transportation. Thus, it is strategic to target waste producers

with a high amount of organic waste. In Indonesia, there are 36,600 religious

boarding schools with 3.4 million students and 370,000 teachers (Ministry of Religious Affairs, 2022). Therefore, traditional boarding schools play an important

role in contributing to Indonesia's journey towards achieving 100% effective

waste management.

The

most highly recommended method for processing organic waste is anaerobic

digestion, which produces digestate rich in nutrients and could potentially be

used as fertilizer and biogas for cooking (Abdillah, 2017). Anaerobic digestion is waste-to-energy technology that adopts bacteria

to degrade organic content of solid waste into biogas

Al Hikam Boarding School, located in Depok, West Java, has at least 265

residents and still lacking the technology of organic waste processing and

management (Pramadita et al., 2021). Currently, school focuses on the management of

inorganic waste processing, with no corresponding efforts for organic waste

processing. Appropriate management is critical in reducing environmental

contamination and greenhouse gas emissions caused by disposal in landfills

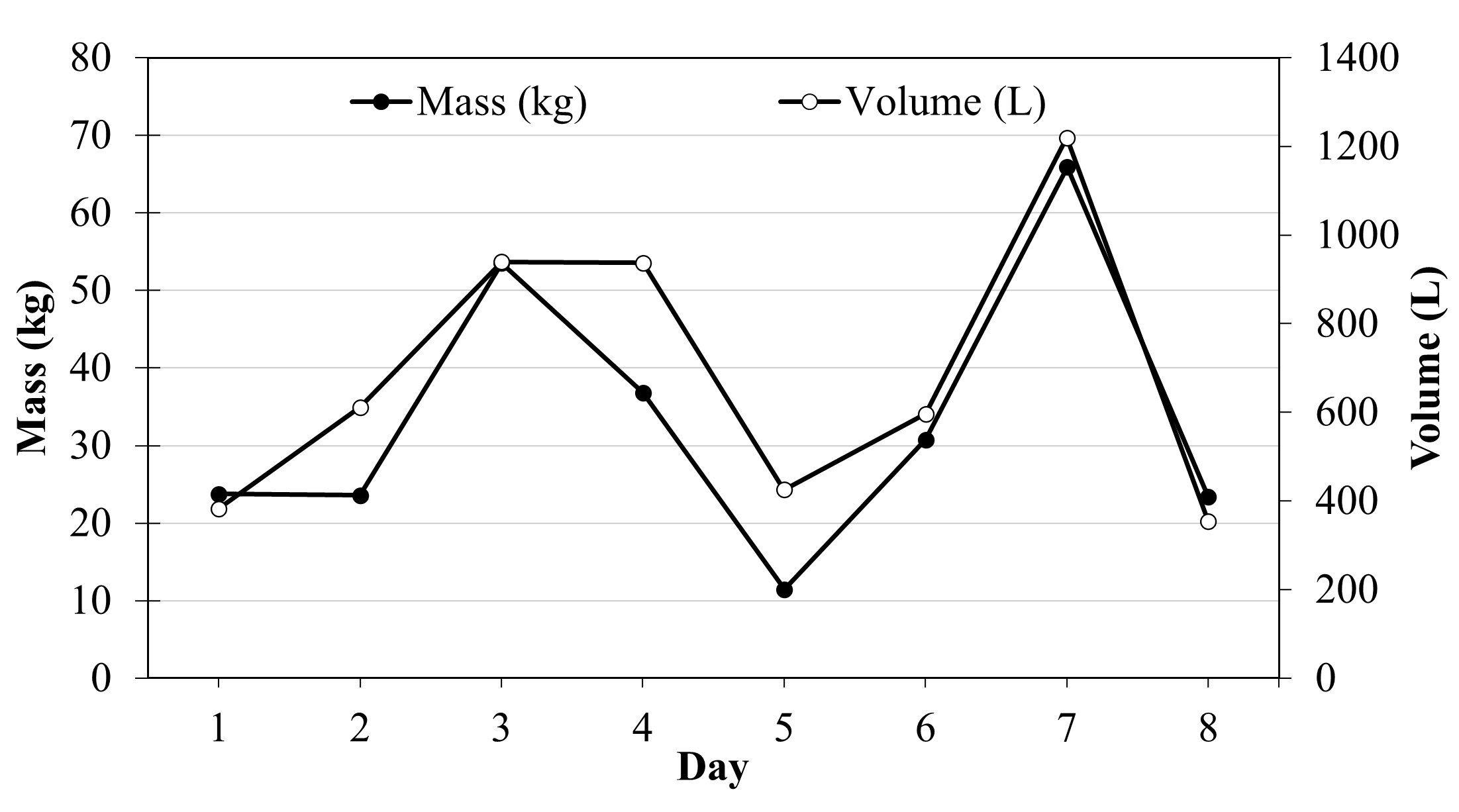

Sampling of solid waste was

carried out for 8 days by using load count analysis to calculate the loads

during a specific period. The procedure refers to SNI 19-3964-1994 concerning

Methods of Taking and Measuring Samples of The Generation and Composition of

Urban Waste. This study continued with organic waste processing through

anaerobic digestion using Toren Biogas,

also known as TORBI, is anaerobic digestion reactor produced by AIUEO Kreasi

Energi Co. Ltd. TORBI, as shown in

Figure 1, had design patent P00201910803 with a processing capacity of 1200 L

and was made of LLDPE (Linear Low-Density Polyethylene) (Cahyono, Priadi, and Abdillah-Ayik, 2023). This particular reactor shows

favorable characteristics for implementation and offers ease of use,

affordability, and portability

Figure 1 Design Patent of Toren

Biogas

To mitigate

the uncertainty related to the results acquired a triple-sample testing process

was implemented, including substrate and static conditions. Furthermore, the

data analysis was conducted using the IBM SPSS Statistics 22 software. The analysis

of solid waste was obtained through a descriptive method, followed by anaerobic digestion data using efficiency

values and correlation tests. Additionally, this attempt aims to derive

relevant conclusions.

The following is the process carried out at Toren Biogas:

Figure 2 Toren Biogas

Process

2.1. Seeding Process

The seeding process is a starter with cow dung and water in a ratio of 1:1 as substrates. In this study, a homogenous mixture was prepared by mixing 7 liters of cow dung and water in an immense bucket placed into the TORBI. The feeding procedure takes place for approximately three weeks on each working day, accompanied by periodic observations of gas production.

2.2.

Acclimatisation Process

The process of acclimatisation covers around five weeks and includes the use of organic waste derived from Al Hikam

Boarding School complemented with waste from traditional buffet, such as nasi

uduk and warteg. The total mass required refers to the amount of

organic waste generated, which is 7.6 kg each day. Subsequently, it is

important to raise the proportion of total mass waste to avoid shock loading

and promote optimal adaptation of microorganisms. In the initial week, the

quantity of newly generated waste constitutes 20% of the total mass. However,

this percentage incrementally increases by 20% to achieve a value of 100% by

the end of the fifth week. The substrate was crushed to a particle size of 20 mm as part of an effort

to improve the production of biogas and anaerobic digestion process based on (Silvestre, Bonmatí, and

Fernández 2015). This can occur due to the greater contact between

susbtrates and microbes, leading them to produces a higher methane yield (Arifan et al., 2022). The reactor is controlled by measuring pH, temperature,

TS, VS, and COD in TORBI effluent using standard methods. Meanwhile, biogas

volume is measured regularly using a flow meter and gas bags on-site.

2.3.

Operational Process

After completing the acclimatisation procedure, the operating process may

continue for approximately four weeks. The TORBI feeding process uses 7.6

kg/day of organic waste from Al Hikam and traditional buffet restaurants in a

ratio of 1:1.5. The substrate must be crushed and not

contain any waste that has potential to interfere with the degradation process,

such as corn weevils, chicken bones, beef bones, fruit seeds, banana peels, and

twigs or wood (Shodiq, 2020). The parameters of pH and temperature were measured

directly using a Hanna pH meter and a termometer every day. Total solids,

volatile solids, chemical oxygen demand, and ammonia were measured in the

Environmental Engineering Laboratory, Universitas Indonesia, while biogas

volume was obtained using a flow meter. That parameter was measured every two

days for four weeks. The sample of biogas was stored in a 1 L tedlar bag to

analyze biogas composition in the Chemical Engineering Laboratory, Universitas

Indonesia.

The factor reduction potential can be calculated according to the equation

(1).

3.1. Waste Generation and Composition

Based on

Figure 4, the composition is dominated by 41.8%, 20.5%, and 15.7% of organic,

plastic, and paper waste. The presence of organic waste shows potential for implementing eco-friendly waste management

such as anaerobic digestion. Meanwhile, the large amount of plastic waste shows

the importance of reducing plastic consumption and promoting responsible

disposal. The paper waste can be recycled to reduce landfill waste while

fostering environmental awareness within school community. The sustainable

practices for these categories can significantly minimize school's

environmental effects and promote a culture of responsibility among students

and staff.

3.2.

Analysis of Anaerobic Digestion Implementation

Examining the characteristics of the substrate before the feeding process is crucial. This is important since these characteristics have a significant influence on the subsequent operation of the reactor. The characteristics have a pH, temperature, TS, VS, and COD of 5.9±0.058, 30±0.15oC, 23±0.022%, 97±0.021%TS, and 357±38.4 g/L. Based on its characteristics, the substrate has an organic loading rate (OLR) value of 1.4 kg.VS/m3.day. After that, the acclimatisation process takes place on the 1st to the 35th days, while the operational process lasts on the 36th to the 58th days.

Figure 5 The Parameters Result During Acclimatisation and

Operational Process

Figure

5 shows that the pH

of the substrate and digestate remains relatively stable during the acclimatisation

process, with pH substrate concentration

ranging from 5.6-6 and 6.8-7.5. The acclimatisation process is complete when

the substrate mass has reached 100% and the pH has fluctuated by less than 10%

for three consecutive days. During the operating process, the pH levels of both

fluctuated. Furthermore, the pH concentration of the substrate and digestate

range from 5.4 to 6.7 and 8-8.3, with an average concentration of 6.1±0.38 and

7.6±0.53, respectively. The concentration of pH digestate is classified as a

phase in the process of methanogenesis

Based on the data in Figure 5, there are slight fluctuations in the

temperature and digestate of the substrate during the acclimatisation

process, which ranges from 29-31°C and 26°C- 29°C, respectively. The

concentrations of both the substrate and the digestate fluctuate during the

operational process, ranging between 27–32°C and 27–29°C. The temperature of

the digestate is lower than the substrate because of the growth and metabolic

processes of microbes (Rizal, Mahidin, and Ayyub, 2015). The acetogenesis and methanogenesis phases influence

digestate fluctuations in temperature during acclimatisation and the

operational process. The current study is in the mesophilic phase, which is

relatively stable due to the slower rate of methane production and the longer

detention time of 32 days.

Based on Figure 5, the TS concentrations of the substrate, digestate, and

reduction show fluctuations during the operational process. The

concentration of the substrate varies from 15%-47%, with an average of

25±0.092%. A high and low TS concentration means that the substrate

contains solids and water, respectively. The substrate has a water content

ranging from 53%-85%, with an average of 75±0.092%. There is an

associated rise in the rate of decomposition of organic waste when the water

content increases

Figure 5 shows that VS concentration

of the substrate shows a high level of stability within

the range of 94–96%TS, with an average of 95±0.0054%TS. The presence of organic

molecules in the solid material can explain the higher VS concentration (Sarwono, Subekti, Widiarti, 2018). The fluctuation, ranging from 56%-68%TS, with an average

concentration of 64±0.042%TS, is related to the impact of organic compound

decomposition. VSD concentrations are 88-92%TS, with an average of

91±0.015%TS. The presence of fluctuations is caused by a high

concentration of organic material in the substrate, which leads to an

accumulation of inhibitors, increased ammonia, and a decrease in temperature

due to bacterial activity during the hydrolysis process.

As shown in Figure 5, COD of the substrate and digestate is 357 g/L.COD and 1.3-2.4 g/L.COD. Based on the data obtained, the average percentage is 99±0.0013%. During the operational process, there is a decrease in COD substrate to digestate due to the decomposition of organic matter. In the operational process, the concentration of substrate and digestate fluctuates between 189-885 g/L and 3.8-89 g/L.COD, with an average of 453±188 g/L.COD and 45±34 g/L.COD. Therefore, a COD reduction of 73%-99% is realized and organic matter reduction greater than 50% leads to stable conditions (Akhiar et al., 2017).

As seen in Figure 6, the ammonia

concentration of the digestate increases initially before stabilizing. The

concentration ranges from 358-1315 mg/L.NH3, with an average of

1057±378 mg/L.NH3. Therefore, ammonia is below the specified range

of 1500-3000 mg/L.NH3 (Rajagopal, Massé, and Singh, 2013), providing an

acceptable nutrition source for microorganisms and preventing disturbance to

anaerobic digestion process.

Based on Figure 7, the volume of biogas

during the acclimatisation process shows a continuous increase. This can be

attributed to the adaptation of bacteria, with an average of 163-561

L.biogas/day. Subsequently, during the operating phase, there is an increase in

the volume of biogas, which tends to stabilize within the range of 496-975

L.biogas/day. This occurs because the methanogen bacteria reached the optimum

conditions for activity

Figure 8 (a) Correlation of Methane Yield and Volatile Solid Destruction; (b) Correlation

of Organic

Loading

Rate and Methane Yield

According to Figure 8a, there is a

correlation between the methane yield and VSD concentration using the ICM

SPSS Statistic 22 application. On May 20, 2023, a decrease in VSD and VS concentrations

of digestate occurred simultaneously.

Figure 5 shows the fluctuations of

the OLR, with a range of 0.9-2.8 kg.VS/m3days. Subsequently, a

reversal in the relationship between OLR and VSD was observed.

According to the literature

Based on the data presented in

Figure 8b, the highest increase in methane yield, reaching 197 L.CH4/kg.VS,

was on May 25, 2023. The decrease occurred when the OLR concentration was

1.3 kg.VS/m3.day. A negative correlation was also carried out

between OLR and methane yield using the ICM SPSS Statistic 22 application.

High-generation organic waste has the

potential to be used in the production of new products

In

conclusion, waste generated at Al Hikam Boarding School was measured to be 33.6

kg/day, which was equivalent to 0.127 kg/person/day. Furthermore, the quantity

of waste amounted to 683 liter/day or 2.58 liters/person/day. The composition of

organic, plastic, paper, residue, textiles, B3, leather and rubber, glass, and

metal waste was 41.8%, 20.5%, 15.7%, 12.7%, 4.906%, 1.91%, 0.937%, 0.799%,

and 0.769%, respectively. During the

operating procedure

of the anaerobic digestion, the typical substrate has a pH

of 6.1±0.38, TS of 25±0.092%, VS of 95±0.0054%TS, COD of 453±188 g/L, and

temperature of 29.5±1.12oC. Meanwhile, the concentration of

ammonia, VSD, and COD reduction was 1057±378 mg/L, 91±0.015%, and 89±0.081%.

The parameter data affected biogas volume and methane production, which had a

concentration of 805±218 L/day and 292±130 L.CH4/kg.VS. The

gas was composed of methane and carbon dioxide, with a concentration of

59±0.035% and 41±0.035%. Thus, anaerobic digestion with a TORBI rector had the potential to

reduce organic waste at boarding school by about 54%, with a communal setting

where fluctuations were complemented by waste from surrounding areas such as

restaurants. This method reduced

waste going to landfills and produced biogas, which might be used for cooking

regularly. Further study could

conduct controls on the type of substrate used to identify the optimal methane

yield value.

The author

expresses gratitude for the study

funding provided by The Indonesia Endowment Funds for Education (LPDP) through

the United Kingdom-Indonesia Consortium for Interdisciplinary Sciences (UKICIS)

Program Number 4345/E4/AL.04/2022. This collaboration comprises IPB University

and the Ministry of Education, Culture, Research and Technology, with

Universitas Indonesia, under the project number NKB-870/UN2.RST/HKP.05.00/2022. Furthermore, the authors are grateful to the Global

Challenges Research Fund (GCRF) Networking Grants scheme GCRFNGR3/1211 for

providing funding collaboration with Coventry University, as well as Al Hikam

Boarding School as partners for the pilot study and the laboratory of the

Environmental Engineering Study Program at Universitas Indonesia.

Abdillah, A., 2017. Nutrient Recovery Nitrogen

And Phosphorus From Digestate Using Microalgae Chlorella Vulgaris. Thesis,

Universitas Indonesia, Depok, Indonesia

Akhiar, A., Battimelli, A., Torrijos, M.,

Carrere, H., 2017. Comprehensive Characterization of the Liquid Fraction of

Digestates from Full-Scale Anaerobic Co-Digestion. Waste Management,

Volume 59, pp. 118–128

Amritha, P.K., Anilkumar, P.P., 2016.

Development of Landscaped Landfills Using Organic Waste for Sustainable Urban

Waste Management. Procedia Environmental Sciences, Volume 35, pp. 368–376

Arifan, F., Broto, R.T.D.W., Sumardiono, S.,

Sutaryo, Dewi, A.L., Yudanto, Y.A., Sapatra, E.F., 2022. Effect of Thermal

Pretreatment of Pineapple Peel Waste in Biogas Production using Response

Surface Methodology. International Journal of Technology, Volume 13(3),

pp. 619–632

Babaee, A., Shayegan, J., 2011. Effect of Organic

Loading Rates (OLR) on Production of Methane from Anaerobic Digestion of

Vegetables Waste. In: Proceedings of the World Renewable Energy

Congress – Sweden, pp. 411–417

Bartocci, P., Massoli, S., Zampilli, M., Liberti,

F., Yunjun, Y., Yang, Q., Yang, H., Zhou, H., Gul, E., Bidini, G., Fantozzi,

F., 2021. Substrate Characterization in the Anaerobic Digestion Process. Bioenergy

Research: Basic and Advanced Concepts, Volume 2021, pp. 307–342

Cahyono, B.B., Priadi, C.R., Abdillah-Ayik, 2023.

TORBI Plas Mass Production Research [WWW Document]. Available online at https://torbi.id/,

Accessed September 28, 2023

Dhanya, B.S., Mishra, A., Chandel, A.K., Verma,

M.L., 2020. Development of Sustainable Approaches for Converting the Organic

Waste to Bioenergy. Science of the Total Environment, Volume 723, p. 138109

Dong, X., Shao, L., Wang, Y., Kou, W., Cao, Y.,

Zhang, D., 2015. Biogas by Two-Stage Microbial Anaerobic and Semi-Continuous

Digestion of Chinese Cabbage Waste. Chinese Journal of Chemical Engineering,

Volume 23, pp. 847–852

Hapsari, K.L., Tharifa, F., Moersidik, S.S.,

Adityosulindro, S., Priadi, C.R., 2019. The Effect of Magnesium Sulfate

Addition on Volatile Solid Destruction and Chemical Oxygen Demand Reduction of

Food Waste Anaerobic Digestion. International Journal of Technology,

Volume 10(8), pp. 1602–1608

Hartono, D.M., Kristanto, G.A., Amin, S., 2015.

Potential Reduction of Solid Waste Generated from Traditional and Modern

Markets. International Journal of Technology, Volume 6(5), pp. 838–846

Ismaniari, 2020. Sustainability of

Implementation of Pre-fabricated Cylindrical Biogas Reactors for Household

Organic Waste Treatment in Individual and Communal Scale. Thesis, Graduate

Program, Universitas Indonesia

Khalid, A., Arshad, M., Anjum, M., Mahmood, T.,

Dawson, L., 2011. The Anaerobic Digestion of Solid Organic Waste. Waste

Management, Volume 31, pp. 1737–1744

Kharola, S., Ram, M., Goyal, N., Mangla, S.K., Nautiyal,

O.P., Rawat, A., Kazancoglu, Y., Pant, D., 2022. Barriers to Organic Waste

Management in a Circular Economy. Journal of Cleaner Production, Volume 362,

p. 132282

Kustiasih, T., Setyawati, L.M., Anggraini, F.,

Darwati, S., Aryenti, 2014. Faktor Penentu Emisi Gas Rumah Kaca dalam

Pengelolaan Sampah Perkotaan (Determinant Factor of Greenhouse Gas Emission In

Urban Waste Management). Jurnal Pemukiman, Volume 9(2), pp. 78–90

Ministry

of Environment and Forestry, 2020. National Plastic Waste Reduction Strategic

Actions for Indonesia. Ministry of Environment and Forestry, Republic of Indonesia

Ministry of Religious Affairs, 2022.

Religious Boarding School: Past, Present, and Future. Ministry of Religious

Affairs, Republic of

Indonesia

Pramadita, S., Aprillia, R., Mukhtar, W., 2021. Potensi

Daur Ulang Sampah Melalui Identifikasi Jenis Dan Karakteristik Sampah Di Panti

Asuhan Dan Pesantren Darul Khairat (Potential Recycling of Waste Through

Identification of the Type and Characteristics of the Waste at Darul Khairat

Boarding School). Jurnal Teknologi Lingkungan Lahan Basah, Volume 9(2),

pp. 82–89

Rajagopal, R., Massé, D.I., Singh, G., 2013. A

Critical Review on Inhibition of Anaerobic Digestion Process by Excess Ammonia.

Bioresource Technology, Volume 143, pp. 632–641

Rizal, T.A., Mahidin, Ayyub, M., 2015. Pengembangan

Anaerobic Digester Untuk Produksi Biogas Dari Limbah Cair Pabrik Kelapa Sawit (Development

of Anaerobic Digesters for the Production of Biogas From the Liquid Waste of

the Sawit Coconut Factory). Jurnal Ilmiah Jurutera, Volume 2(2), p. 575

Sarwono, E., Subekti, F., Widiarti, B.N., 2018. Pengaruh

Variasi Campuran Eceng Gondok (Eichhornia Crassipes) dan isi Rumen Sapi

Terhadap Produksi Biogas (Eichhornia Crassipes Mixture Variation Effect and

Cow Rumination Content on Biogas Production). Jurnal Teknologi

Lingkungan Universitas Mulawarman, Volume 2(1), p. 1574

Shodiq, J., 2020. Potensi Pengolahan Limbah Ikan

dan Sampah Organik dengan Anaerobic Digestion Skala Pilot (Potentials of

Fish Waste and Organic Waste Treatment with Pilot-Scale Anaerobic Digestion).

Thesis, Universitas Indonesia, Depok, Indonesia

Silvestre, G., Bonmatí, A., Fernández, B., 2015.

Optimisation of Sewage Sludge Anaerobic Digestion Through Co-Digestion with

OFMSW: Effect of Collection System and Particle Size. Waste Management,

Volume 43, pp. 137–143

Tanimu, M.I., Ghazi, T.I.M., Harun, M.R., Idris,

A., 2014. Effect of Feed Loading on Biogas Methane Production in Batch

Mesophilic Anaerobic Digesters Treating Food Waste. International Journal of

Chemical and Environmental Engineering, Volume 5(1), pp. 41–43

Wainaina, S., Awasthi, M.K., Sarsaiya, S., Chen, H., Singh, E., Kumar, A., Ravindran, B., Awasthi, S.K., Liu, T., Duan, Y., Kumar, S., Zhang, Z., Taherzadeh, M.J., 2020. Resource Recovery and Circular Economy from Organic Solid Waste using Aerobic and Anaerobic Digestion Technologies. Bioresource Technology, Volume 301, p. 122778

Windraswara, R., Prihastuti, D.A.B., 2017. Analisis Potensi Reduksi Sampah Rumah Tangga untuk Peningkatan Kualitas Kesehatan Lingkungan (Analysis of the Potential of Reducing Household Waste for Improving Environmental Health Quality). Unnes Journal of Public Health, Volume 6(2), p. 15360