Digital Image Correlation for the Determination of Mechanical Properties of Concrete with Modified Expanded Polystyrene

Corresponding email: eric.vincens@ec-lyon.fr

Published at : 05 Feb 2024

Volume : IJtech

Vol 15, No 2 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i2.6697

Sjah, J., Handika, N., Adnanta, N.K., Nurhakim, M.Y., Vincens, E., 2024. Digital Image Correlation for the Determination of Mechanical Properties of Concrete with Modified Expanded Polystyrene. International Journal of Technology. Volume 15(2), pp. 394-403

| Jessica Sjah | Department of Civil Engineering, Faculty of Engineering, Universitas Indonesia, Depok, 16424, Indonesia |

| Nuraziz Handika | Department of Civil Engineering, Faculty of Engineering, Universitas Indonesia, Depok, 16424, Indonesia |

| Naufal Karim Adnanta | Department of Civil Engineering, Faculty of Engineering, Universitas Indonesia, Depok, 16424, Indonesia |

| Mochamad Yanuar Nurhakim | Department of Civil Engineering, Faculty of Engineering, Universitas Indonesia, Depok, 16424, Indonesia |

| Eric Vincens | Université de Lyon, Ecole Centrale de Lyon, CNRS, ENTPE, LTDS, UMR5513, Écully, 69130, France |

Modified Expanded Polystyrene (MEPS) has emerged as a promising material obtained

by heating and shredding Expanded Polystyrene (EPS) to enhance its specific

gravity and strength. This study investigates the suitability of MEPS as a

partial replacement for coarse and fine aggregates in non-structural

lightweight concrete. The substitution levels of MEPS were set at 10%, 20%, and

25% of the total aggregate volume. Cylindrical concrete specimens (10 x 20 cm)

and concrete cubes (15 x 15 x 15 cm) were used for the experimentation.

Ultrasonic Pulse Velocity (UPV) and Digital Image Correlation (DIC) were

performed to evaluate the mechanical properties of the concrete under

compressive stress test. Through DIC, the approach to obtain the concrete's

properties, including compressive strength, stiffness, elastic modulus, and

poisson's ratio, were obtained. The results demonstrated that the concrete

mixture with 20% MEPS substitution exhibited the most favorable performance.

Overall, the use of MEPS as a replacement for aggregates in non-structural

lightweight concrete shows promise for optimizing the material's mechanical

properties. This study provides valuable insights into sustainable construction

practices and contributes to the ongoing research in utilizing innovative

materials for enhancing concrete performance.

Digital image correlation; Innovative material; Lightweight Concrete; Modified expanded polystyrene; Ultrasonic pulse velocity

The utilization of expanded polystyrene (EPS) in concrete mixtures has been investigated in various research studies. Research has shown that the inclusion of expanded polystyrene can reduce the density of concrete, making it lightweight and providing potential benefits in construction applications (Gamal et al., 2023; Purnomo, Baskoro, and Muslim, 2021; Kan and Demirboga, 2009). The thermal insulation properties of polystyrene concrete have also been investigated, indicating its potential to enhance energy efficiency in buildings (Chung, Elrahman, and Stephan, 2018).

Furthermore, studies have examined the mechanical properties and structural performance of polystyrene concrete to assess its suitability for different engineering applications. Research findings suggest that this type of concrete can exhibit favorable structural behavior and resistance to specific loading conditions (Kulkarni and Shete, 2022; Vinod, Surendra, and Shobha, 2022). Its lightweight nature also contributes to improving some advantages in civil engineering applications (Rishith, Kumar, and Kiran, 2021; Hussein, 2021; Sjah et al., 2018; Sulong, Mustapa, and Rashid, 2018).

The manufacturing process and mix design of

polystyrene concrete have been investigated to optimize its properties and

performance (Zhang, 2021). Researchers have

investigated different additives, mix proportions, and curing methods to

improve the strength, durability, and workability of the material (Shabbar, Al-Tameemi, and Alhassani, 2022; Ulhaq and Andayani, 2021; Mwero and Onchaga,

2020; Patidar et al., 2019; Xu et al., 2012).

The

use of Expanded Polystyrene (EPS) material in everyday life has increased EPS waste. Essentially, EPS waste is highly

resistant to decomposition and becomes a major issue in waste management. As a

form of environmental concern, concrete with a mixture of partial fine/coarse

aggregate EPS can be a viable and considerable answer to this issue. This

research aims to explore an innovation by examining the mechanical properties

of concrete with a mixture of partial fine/coarse aggregate with Modified

Expanded Polystyrene (MEPS). MEPS is a material resulting from the modification

of EPS (Kan and Demirboga, 2009). This

modification is carried out by heating the expanded polystyrene using an oven

at a specific temperature, which slightly alters the shape and characteristics

of the material compared to EPS, but the differences are not too significant.

The most notable difference lies in the volume and density of this material.

MEPS has a smaller volume than EPS, thereby increasing its density, which in

turn affects the strength of the concrete produced. It is indicated that the

density of MEPS concrete will increase while the volume of MEPS will decrease (Kan and Demirboga, 2009). By replacing a portion

of the fine/coarse aggregate with MEPS, the lightweight concrete manufacturing

standards can be met while gradually addressing the issue associated with EPS

waste.

2.1. Preparation and Material

Properties of Aggregates

Before casting the concrete, it is necessary to prepare and test the material properties of the aggregate. The types of aggregate used in this study were natural coarse aggregate, natural fine aggregate, and MEPS material as a partial substitute for natural coarse/fine aggregate.

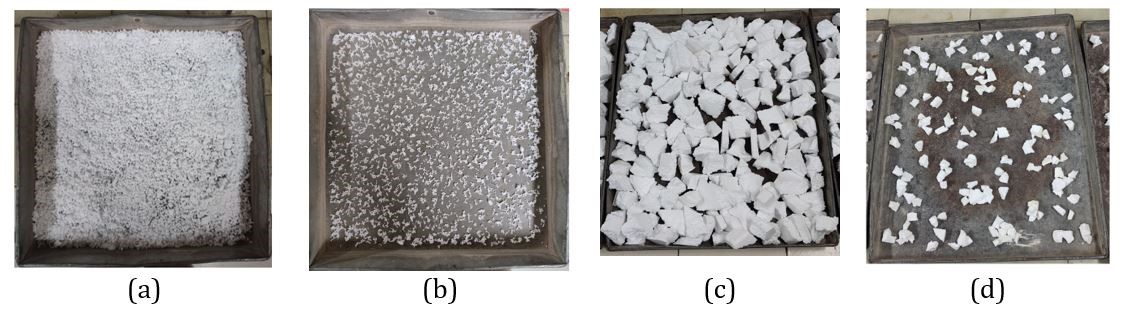

Figure 1 Transformation of EPS to MEPS material before and

after oven-dry for (a, b) fine aggregate (FA); (c,d) coarse aggregate (CA)

Preparation to obtain MEPS material needs to be

done to be used as a partial substitute for aggregate in concrete. Expanded

polystyrene (EPS) obtained from waste of electronic equipment packaging is

prepared. This EPS waste will then undergo treatment by being heated in an oven

at a temperature of 130°C for 15 minutes to become a new material called

Modified Expanded Polystyrene (MEPS). For fine aggregate composed of MEPS, the

first step is to grate the EPS to form granules of a size like fine aggregate

( 4.75 mm), then oven-dry them at a temperature of 130°C for 15 minutes. When

producing coarse aggregate with MEPS, the initial step involves cutting the EPS

into randomly sized pieces using a cutting tool or by hand. Subsequently, these

pieces are oven-dried at a temperature of 130°C for 15 minutes (Kan and Demirboga, 2009). The transformation of EPS material into MEPS

for fine and coarse aggregate is illustrated respectively in Figure 1.

Table 1

Material properties of natural fine aggregate, natural coarse aggregate, and

MEPS material as a partial substitute for fine and coarse aggregate

|

Material Properties |

Natural Fine Aggregate (Sand) |

MEPS as a partial substitute for Fine Aggregate (MEPS-FA) |

Natural Coarse Aggregate (Stone) |

MEPS as a partial substitute for Coarse Aggregate (MEPS-CA) |

|

Specific Gravity (SG) (g/cm3) |

2.63 |

0.24 |

2.37 |

0.24 |

|

Absorption (%) |

3.52 |

- |

8.6 |

- |

|

Bulk Density (Compacted) |

1.64 |

- |

1.362 |

- |

|

Size Max. Aggregate (inch) |

0.187 |

0.187 |

1 |

1 |

|

Fineness Modulus (fm) |

2.18 |

3.06 |

4.39 |

4.76 |

|

Abrasion (%) |

- |

- |

54.86 |

- |

|

Organic Content Test |

No.8 |

- |

- |

- |

The

condition of natural coarse and fine aggregates used at the time of casting the

concrete were in saturated surface-dry condition. The material properties of

natural coarse and fine aggregates can be seen in Table 1.

2.2. Mortar Mix

and Testing Result

The compressive strength of mortar with variations in the

proportion of using MEPS as a partial substitution of fine aggregate was

evaluated. Three cases are studied involving normal mortar, MEPS FA-25% mortar

(mortar with MEPS material as a

substitute for fine aggregate with 25% of the total weight of fine aggregate), and MEPS

FA-50% mortar (mortar with MEPS

material as a substitute for fine aggregate with 50% of the total weight of

fine aggregate).

The normal mortar mix

design was conducted following ASTM C109/C109M Standard (ASTM C109/C109M, 2020). For each case, 60 samples will be cast and

tested at ages 1, 3, 7, and 28 days.

Figure 2 shows the compressive strength and density results of normal mortar, MEPS FA-25% mortar, and MEPS FA-50% mortar. The higher the density of the mortar, the higher the compressive strength of the mortar tends to be. The use of MEPS material as a substitute for fine aggregate causes the density of the mortar to decrease, resulting in a lighter sample than normal mortar. The density of the mortar sample was reduced by 7% and 18% for case MEPS FA-25% and case MEPS FA-50%, respectively. The MEPS FA-25% mortar exhibits better compressive strength than MEPS FA-50%. Therefore, in this research, MEPS material from 0% to 25% will be utilized as a substitute for aggregate in concrete.

Figure 2 Compressive strength and density of “Normal Mortar”, “MEPS

FA-25% Mortar”, and “MEPS FA-50% Mortar”

2.3. Concrete

Mix Design

The concrete

mix design will be conducted using the ACI 211.1 Standard. The water-to-cement

ratio is 0.424, with a normal concrete density of 2400 kg/m3, and

the target slump for each composition is 7 - 8 cm. The specimens are 120

cylinders (diameter of 10 cm and height of 20 cm), which will be tested at the

ages of 7, 14, and 28 days, and 80 cubes (15 cm x 15 cm x 15 cm), which will be

tested at the ages of 7 and 28 days. A total of 5 samples will be made for each

day and each composition. The average will be taken from the results of testing

all these samples to ensure that the generated data is more representative.

The research

will investigate the effects of incorporating MEPS material at proportions of

10%, 20%, and 25%, serving as a substitute for both fine aggregate (FA) and

coarse aggregate (CA) in the concrete.

Table 2

Concrete mix design

|

Specimen |

Material weights per unit volume (kg/m3) | |||||

|

Water |

Cement |

Fine Aggregate (Sand) |

MEPS as a partial substitute for Fine Aggregate (FA) |

Coarse Aggregate (Stone) |

MEPS as a partial substitute for Coarse Aggregate (CA) | |

|

Normal |

192.8 |

454.7 |

596.8 |

- |

997.5 |

- |

|

FA-10% |

192.8 |

454.7 |

537.1 |

5.5 |

997.5 |

- |

|

FA-20% |

192.8 |

454.7 |

477.4 |

11.1 |

997.5 |

- |

|

FA-25% |

192.8 |

454.7 |

447.6 |

13.8 |

997.5 |

- |

|

CA-10% |

192.8 |

454.7 |

596.8 |

- |

897.8 |

10.3 |

|

CA-20% |

192.8 |

454.7 |

596.8 |

- |

798.0 |

20.5 |

|

CA-25% |

192.8 |

454.7 |

596.8 |

- |

748.1 |

25.7 |

2.4. Digital

Image Correlation, Ultrasonic Pulse Velocity, and Compressive Test Set-Up

DIC is a

method that can be used for non-contact optical analysis of concrete. It

involves capturing digital images of the surface of the test object to analyze

the deformation of that plane through the related images (Ernawan et al., 2023; Deltanto, Handika, and

Sentosa, 2021; Ghani et al., 2016; Pan and Li, 2011). Digital Image

Correlation (DIC) testing is performed using a camera with a setting of 3 fps

and in black and white. Before conducting DIC, the test object is painted with

white paint and then sprayed with black points to create a speckle pattern that

can be read by the GOM Correlate application. The image capturing is performed

before the compressive strength testing begins, capturing the failure pattern.

Ultrasonic Pulse Velocity (UPV) testing is conducted using

the UPV Pundit Lab+ instrument, following the ASTM C597 standard (ASTM C597, 2016). Before the UPV testing, the

instrument needs to be calibrated according to the desired settings. Then, the

test object is coated with grease on each side to be tested, which acts as a

medium for transmitting ultrasonic waves through the specimen (Zarate et al., 2022).

Compressive strength testing is performed following the ASTM C39/C39M standard (ASTM C39/C39M, 2014). For cylindrical test specimens, capping of the specimens is processed using gypsum to ensure a flat surface and a loading direction parallel to the axis of the cylinder.

3.1. Compressive

Strength and Density

The results of concrete compressive strength and bulk density for cube and cylinder specimens are shown respectively in Figure 3(a) and Figure 3(b). In this figure, the average compressive strength results of cylindrical concrete specimens at ages 7, 14, and 28 days, as well as cubic concrete specimens at ages 7 and 28 days, can be observed. The use of MEPS as a substitute for fine aggregate and coarse aggregate shows better results than normal concrete in the variation of 20% composition. The substitution of 20% MEPS for fine aggregate increases compressive strength by 14%, while the substitution of 20% MEPS for coarse aggregate shows an increase in compressive strength of 5.6% compared to normal concrete. These results indicate that the optimal composition of MEPS material as a substitute for both fine and coarse aggregate is 20%, regardless of the shape of the tested specimens (cube or cylinder). The obtained bulk density decreases as the amount of MEPS increases. This is due to the lightweight nature of the MEPS material, which reduces the bulk density of the concrete.

Figure 3 Compressive strength and density of using

MEPS material as a substitute of fine (FA) and coarse aggregate (CA) in

concrete for (a) cube and (b) cylinder specimens

3.2. Correlation of Compressive Strength and

Ultrasonic Pulse Velocity

Ultrasonic pulse velocity (UPV) testing is

used to determine the density of concrete based on the results of the

ultrasonic wave propagation velocity within the concrete. The results of the

UPV test will be compared with the compressive strength test results to

determine the relationship between them. The correlation between compressive

strength and wave propagation velocity for cube and cylinder specimens can be

seen respectively in Figure 4(a) and Figure 4(b).

Figure 4 Compressive strength and UPV of using MEPS

material as a substitute for fine (FA) and coarse (CA) aggregate in concrete

for (a) cube and (b) cylinder specimens

3.3. Digital Image Correlation (DIC)

DIC testing is conducted

using the GOM Correlate Pro application to obtain results, such as

displacement, stiffness, elastic modulus, and Poisson's ratio for each sample.

3.3.1. Load - displacement

The relationship between load and displacement is obtained through DIC (Digital Image Correlation) testing, as shown in Figure 5 and Figure 6. In this figure, the magnitude of deformation of the test specimen can be observed for each applied load captured by the camera at a speed of 3 fps. This image can be used to identify the vertical and horizontal displacement directions of the test specimen. The deformation results can be influenced by factors such as the strength of the test specimen, the placement of the test specimen in the compression testing machine, and the speckle pattern applied prior to testing.

Figure 5 Load – u displacement (horizontal displacement) response of using 20% MEPS material as a substitute for fine aggregate (FA) and coarse aggregate (CA) in concrete

Figure 6 Load – v displacement (vertical

displacement) response of using 20% MEPS material as a substitute for fine

aggregate (FA) and coarse aggregate (CA) in concrete

3.3.2. Stiffness, Poisson’s ratio, and modulus of

elasticity

The displacement data obtained can be processed into mechanical

properties data of concrete, including stiffness, elastic modulus, and

Poisson's ratio. It's important to note that these values are considered

approximate as they are derived through digital image correlation processing.

These results are then used for analysis for each variation of concrete using

MEPS (Modified Expanded Polystyrene) mixtures.

The magnitude of stiffness using MEPS as a mixture in concrete shows

better results compared to normal concrete. It indicates that concrete using

MEPS has a higher level of stiffness, as evidenced by smaller vertical

deformations compared to normal concrete for each applied load.

The Poisson's ratio values obtained for each variation still meet the

criteria of normal concrete Poisson's ratio, which is 0.15 - 0.2. However,

Poisson's ratio value for the FA-25% composition does not yet meet the existing

standards, indicating that the 25% composition has a less optimal mixture

proportion.

The magnitude of elastic modulus obtained through the DIC approach is

significantly different from the theoretical elastic modulus values. This may

be due to factors during the DIC imaging process. The elastic modulus values

produced by concrete using MEPS are better than those of normal concrete. Based

on the results shown in Table 4, the conclusion is that concrete with MEPS

mixtures has better mechanical properties than normal concrete, especially in

the 20% mixture, which has the most optimal mechanical properties.

Table 4 Stiffness, Poisson’s Ratio, and Modulus of Elasticity

|

Specimen |

Average Stiffness (kN/mm) |

Average Poisson’s Ratio |

Average Elastic Modulus (MPa) |

|

Normal |

1784.1 |

0.18 |

7666.4 |

|

FA-10% |

2763.7 |

0.16 |

12283.1 |

|

FA-20% |

2751.2 |

0.19 |

12227.6 |

|

FA-25% |

2058.0 |

0.36 |

9146.3 |

|

CA-10% |

2132.9 |

0.17 |

9570.4 |

|

CA-20% |

3595.4 |

0.18 |

16569.0 |

|

CA-25% |

1345.5 |

0.16 |

10709.4 |

3.3.3. Failure pattern

The failure pattern is related to the displacement values obtained. The higher the displacement value, the greater the likelihood of failure occurring. The failure patterns of each sample can be clearly observed using the GOM Correlate application, and the failure patterns are then analyzed. The top failure patterns from each variation can be seen in Figure 7. Each failure pattern is compared to the failure pattern provided by BS-EN-12390-2019, and the MEPS-FA10%, MEPS-FA10%, and MEPS-FA10% patterns fall into the "satisfactory" category.

Figure 7 Failure pattern of specimens

The substitution of MEPS-FA results in a reduction in both

compressive strength and bulk density of the mortar. By introducing MEPS-FA and

MEPS-CA at a 20% content in concrete effectively enhances its compressive

strength. However, it is important to note that the use of 20% MEPS-FA/CA

substituted concrete can be deemed suitable for non-structural applications;

although it does not reduce the bulk density, it does not qualify as

lightweight concrete. Conversely, the application of 25% MEPS-FA/CA substituted

concrete meets the criteria for lightweight concrete, but its mechanical

properties are inferior to those of normal concrete. The stiffness magnitude,

when MEPS is incorporated into the concrete mixture, demonstrates superior

results compared to conventional concrete. Moreover, the Poisson's ratio values

obtained for most variations still conform to the specified criteria for normal

concrete (0.15 - 0.20). Additionally, the elastic modulus values produced by

concrete utilizing MEPS surpass those of normal concrete. Lastly, the failure

patterns observed, specifically for MEPS-FA10%, MEPS-CA10%, and MEPS-FA10%,

align with the "satisfactory" category as per the standards outlined

in BS-EN-12390-2019. The use of MEPS as an aggregate substitute in concrete can

be considered a good alternative because it has mechanical properties that are

relatively better than concrete without MEPS. The utilization of MEPS as an

aggregate substitute meets the criteria for non-structural lightweight concrete

with a minimum compressive strength value of 17.24 MPa, but it does not meet

the criteria for the density of non-structural lightweight concrete. So, for

further research it is necessary to investigate further to increase the amount

of MEPS as a substitute for aggregate so that it can meet the criteria for

non-structural lightweight concrete.

This research is funded by

the Directorate of Research and Development, Universitas Indonesia, under Hibah

PUTI Q2 2023 (Grant No. NKB-819/UN2.RST/HKP.05.00/2023).

American Society for Testing and

Material (ASTM) C109/C109M, 2020. Standard Test Method for

Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube

Specimens). ASTM, United States of America

American Society for Testing and

Material (ASTM) C39/C39M, 2021. Standard Test Method for

Compressive Strength of Cylindrical Concrete Specimens. ASTM, United States of

America

American Society for Testing and

Material (ASTM) C597, 2016. Standard Test Method for

Pulse Velocity Through Concrete. ASTM, United States of America

Chung, S.-Y., Elrahman, M.A.,

Stephan, D., 2018. Effects of Expanded Polystyrene (EPS) Sizes and Arrangements

on The Properties of Lightweight Concrete. Materials and Structures, Volume

51, pp. 1–11

Deltanto,

A.D., Handika, N., Sentosa, B.O.B., 2021. Response

of Load-Displacement on Cubical Sample of Oil-Palm Shell with Fly ash Concrete

Using Digital Image Correlation System. In: AIP Conference Proceedings, Volume

2376(1)

Ernawan, E., Sjah, J., Handika, N.,

Astutiningsih, S., Vincens, E., 2023. Mechanical Properties of Concrete

Containing Ferronickel Slag as Fine Aggregate Substitute Using Digital Image

Correlation Analysis. Buildings, Volume 13(6), p. 1436

Gamal, S.E.,

Al-Jardani, Y., Meddah, M.S., Abu-Sohel, K., Al-Saidy, A., 2023. Mechanical

And Thermal Properties of Lightweight Concrete with Recycled Expanded

Polystyrene Beads. European Journal of Environmental and Civil Engineering,

Volume 28(1), pp. 80–94

Ghani, A.F.A., Ali, M.B., Malingam,

S.D., Mahmud, J., 2016. Digital Image Correlation (DIC) Technique in Measuring

Strain Using Opensource Platform Ncorr. Journal of Advanced Research in

Applied Mechanics, Volume 26(1), pp. 10–21

Hussein, W.A., 2021. Production of

Lightweight Concrete by Using Polystyrene (Cork) Waste. Journal of Physics:

Conference Series, Volume 1973(1), p. 012128

Kan, A., Demirboga, R., 2009. A New

Technique of Processing for Waste-Expanded Polystyrene Foams as Aggregates. Journal

of Materials Processing Technology, Volume 209(6), pp. 2994–3000

Kulkarni,

P.B., Shete, G.N., 2022. Experimental Study on Properties of

Concrete by using Expanded Polystyrene Beads (EPS) as a Partial Replacement of

Coarse Aggregate. International Research Journal of Engineering and

Technology (IRJET), Volume 9(1), pp. 188–192

Mwero, J. Onchaga, V., 2020. Experimental Study on

Behavior of Lightweight Concrete with Partial Replacement of Coarse Aggregates

with Expanded Polystyrene. International Journal of Scientific and Research

Publications, Volume 10(2), pp. 351–362

Pan, B., Li, K., 2011. A Fast Digital

Image Correlation Method for Deformation Measurement. Optics and Lasers in

Engineering, Volume 49(7), pp. 841–847

Patidar, H., Singi, M., Bhawsar, A.,

2019. Effect of Expanded polystyrene (EPS) on Strength Parameters of Concrete

as a Partial Replacement of Coarse Aggregates. International Research

Journal of Engineering and Technology (IRJET), Volume 6(6), pp. 3779–3783

Purnomo, H.,

Baskoro, H., Muslim, F., 2021. Stress and Strain

Behavior of Confined Lightweight Concrete using Sand Coated Polypropylene

Coarse Aggregate. International Journal of Technology, Volume 12(6), pp.

1261–1272

Rishith, P., Kumar, V.R., Kiran, K.

S., 2021. An Experimental Study on Engineering Properties of Different Type of

Light Weight Concrete. International Journal of Engineering Research and

Applications, Volume 11(9), pp. 59–62

Shabbar, R., Al-Tameemi, A.A.,

Alhassani, A.M.J., 2022. The Effect of Expanded Polystyrene Beads (EPS) On the

Physical and Mechanical Properties of Aerated Concrete. Open Engineering, Volume

12(1), pp. 424–430

Sjah, J.,

Chandra, J., Rastandi, J.I., Arijoeni, E., 2018. The

Effect of Usage of Crushed Polypropylene Plastic Waste in Mechanical Properties

of Concrete. International Journal of Civil Engineering and Technology

(IJCIET), Volume 9(7), pp. 1495–1505

Sulong, N.H.R., Mustapa, S.A.S.,

Rashid, M.K.A., 2019. Application of Expanded Polystyrene (EPS) in Buildings

and Constructions: A Review. Journal of Applied Polymer Science, Volume

136(20), p. 47529

Ulhaq, N.D., Andayani, R., 2021.

Normal Concrete Mix Design based on the Isoresponse of Slump as a Function of

Specific Surface Area of Aggregate and Cement Paste-Aggregate Ratio. International

Journal of Technology, Volume 12(3), pp. 495–505

Vinod, B.R., Surendra, H.J., Shobha,

R., 2022. Lightweight Concrete Blocks Produced Using Expanded Polystyrene and

Foaming Agent. Materials Today: Proceedings, Volume 52(3), pp. 1666–1670

Xu, Y., Jiang,

L., Xu, J., Li, Y., 2012. Mechanical Properties of Expanded

Polystyrene Lightweight Aggregate Concrete and Brick. Construction and

Building Materials, Volume 27(1), pp. 32–38

Zárate, D.M., Cárdenas, F., Forero,

E.F., Peña, F.O., 2022. Strength of Concrete through Ultrasonic Pulse Velocity

and Uniaxial Compressive Strength. International Journal of Technology,

Volume 13(1), pp. 103–114

Zhang, D., 2021. Linkedin - Pentane,

Hexane and Heptane Manufacturer. Available online at

https://www.linkedin.com/pulse/manufacturing-processes-expandable-polystyrene-eps-david-zhang, Accessed on April 03, 2023