Development of Magnesium Diboride Superconducting Wires through Hot Working with Different Initial Filling Density

Corresponding email: ahyuwono@eng.ui.ac.id

Published at : 07 Dec 2023

Volume : IJtech

Vol 14, No 7 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i7.6695

Herbirowo, S., Yuwono, A.H., Sofyan, N., Imaduddin, A., Pramono, A.W., Supriyadi, S., Mohamed, J.J., 2023. Development of Magnesium Diboride Superconducting Wires through Hot Working with Different Initial Filling Density. International Journal of Technology. Volume 14(7), pp. 1570-1577

| Satrio Herbirowo | 1. Department of Metallurgical and Materials Engineering, Faculty of Engineering, Universitas Indonesia, Depok 16424, West Java, Indonesia, 2. Research Center for Advanced Materials, National Research |

| Akhmad Herman Yuwono | 1. Department of Metallurgical and Materials Engineering, Faculty of Engineering, Universitas Indonesia, Depok 16424, West Java, Indonesia, 2.Advanced Materials Research Center (AMRC), Faculty of Engi |

| Nofrijon Sofyan | 1. Department of Metallurgical and Materials Engineering, Faculty of Engineering, Universitas Indonesia, Depok 16424, West Java, Indonesia, 2. Advanced Materials Research Center (AMRC), Faculty of Eng |

| Agung Imaduddin | Research Center for Advanced Materials, National Research and Innovation Agency (BRIN) Building 440, PUSPIPTEK, South Tangerang 15314, Banten, Indonesia |

| Andika Widya Pramono | Research Center for Advanced Materials, National Research and Innovation Agency (BRIN) Building 440, PUSPIPTEK, South Tangerang 15314, Banten, Indonesia |

| Sugeng Supriyadi | Department of Mechanical Engineering, Faculty of Engineering, Universitas Indonesia, Depok 16424, West Java, Indonesia |

| Julie Juliewatty Mohamed | Faculty of Bioengineering and Technology, Universiti Malaysia Kelantan, 17700 Jeli, Kelantan, Malaysia |

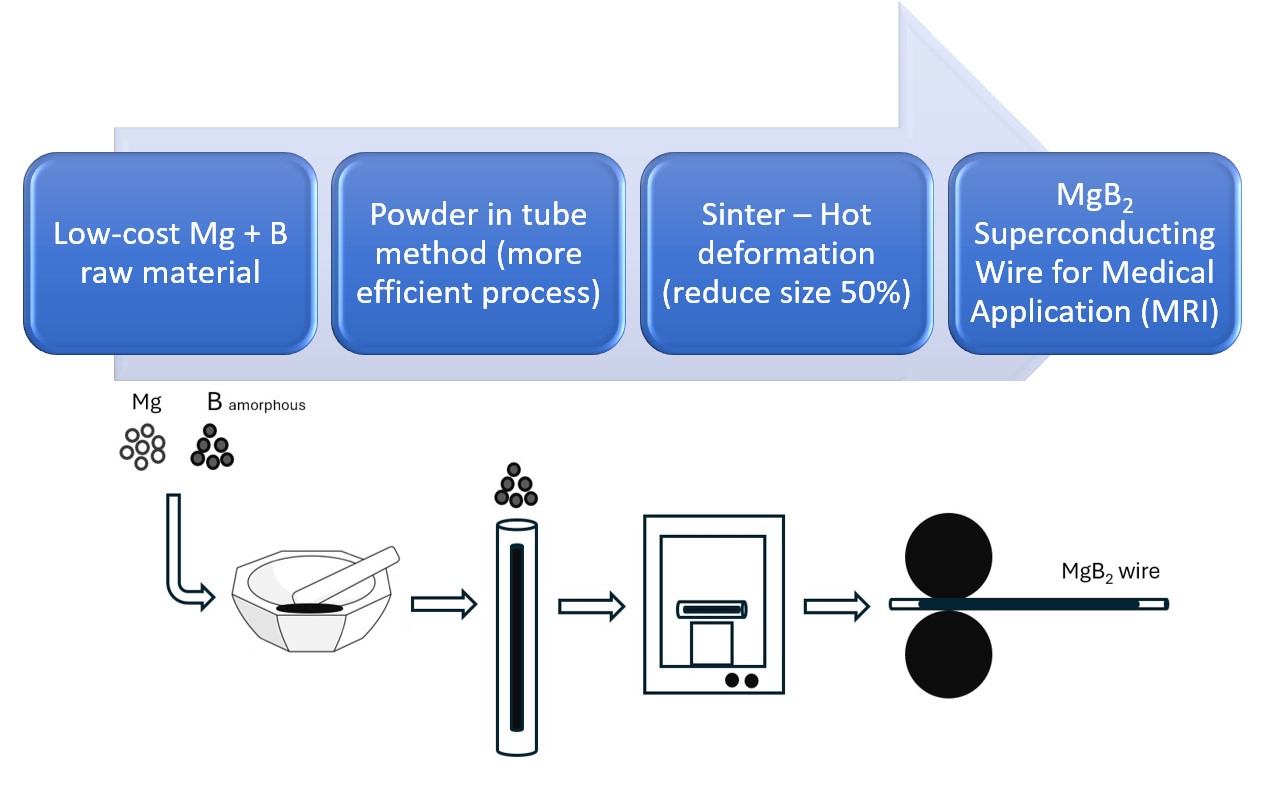

This study aimed to investigate the use of the hot

working in a sealed tube method for the production of Magnesium Diboride (MgB2)

wires from a powder state. The wires were synthesized using different initial

filling densities of 60%, 80%, and 100%. The Magnesium and Boron powder was

ground using agate mortar into a stoichiometric mixture by weight of Mg:B=1:2

and then packed into a stainless steel (SUS316L) tube. Subsequently, the pack

was sintered for two hours at 800°C in an air atmosphere and continuously

rolled to form a wire. XRD and SEM analyses were then conducted to observe the

phase development of the sample produced. The diffraction pattern and

microstructure observation results showed that MgB2 phase was

successfully created using economically advantageous raw materials of

crystalline Mg and amorphous B with 60% filling density. The size of the

crystallites and superconducting phase was shown to experience a significant

increase. The R-T cryogenic magnet assessed the sample of critical temperature,

and MgB2 produced using full amorphous boron had a transition

temperature of 39 K.

Critical temperature; Filling density; Hot working; MgB2 Superconductors; Wire

Magnesium diboride, MgB2, is a novel high critical

temperature superconductor with a critical temperature of 39 K, initially

introduced in the early twenty-first century (Nagamatsu et al., 2001). The versatility of MgB2 also extends to its production in various

forms and shapes, including bulk (Arvapalli et al., 2021; Zhang et al., 2020; Zheng et al., 2019),

thin films, tapes, and wires (Balog et al., 2018;

Grivel, 2018b; Herbirowo

et

al., 2018; Kovác et al., 2011; Vinod et al., 2009). Consequently, this material has

found promising applications in various electronic devices due to its excellent

electrical contact between grains and cost-effectiveness. Several studies have

shown that its superconductivity has a

The

powder-in-tube (PIT) technique was used to create MgB2 monofilament

wire (Lubis et al., 2018; Glowacki et al.,

2001). The feedstocks used included magnesium powder (Sigma Aldrich, 98%

purity) and amorphous low-cost boron powder (Luoyang China, 95% purity).

Furthermore, the SUS316L tube with an outer diameter and inner diameter of 6

and 4 mm, respectively were used as a container for MgB2 powder with

a ratio Mg:B = 1:2. The powders were then mixed and ground in an agate mortar

for 30 minutes in an environment of air. The SUS316L stainless steel rod (4 mm

in diameter) was used to seal the stainless-steel tube container after it had

been filled with the mixture. The SUS316L tubes in wire product manufacturing

offered the advantage of enhanced corrosion resistance and durability, ensuring

a longer lifespan and reduced maintenance requirements for the final product (Widyianto, Baskoro and Kiswanto, 2022; Anwar et al.,

2021). The coarse-grained SUS 304 had a higher surface roughness ratio

compared to the coarse-grained SUS 316. The fine-grained SUS 304 and the

fine-grained SUS 316 had comparable inhomogeneous grain strengths (Abdul et al., 2021). Hot rolling was used

to create 3 mm square rods, introducing a novel method that enabled the

formation of the desired rod geometry but also effectively mitigated strain

hardening, thereby streamlining the overall manufacturing process. Hot working

in superconducting wire manufacturing was crucial for achieving densification,

consolidating the powder, refining the grain structure, improving mechanical

properties, and shaping the wire into the desired form. A wire specimen was

sintered for one hour at 1073 K in a muffle furnace. The hot rolling process in

this study showed that the wire that was still hot from the furnace was taken

out directly to be rolled by the rolling machine. X-ray diffraction (Smartlab

Rigaku) was used to determine the phase of materials. The Field Emission Scanning

Electron Microscope - EDX (JEOL JIB 4610F) was used to examine the specimen's

morphology, porosity, and elemental composition. The four-point probes method

and Oxford Instrument Teslatron PT's cryogenic magnet apparatus were used to

measure temperature dependence resistivity. Furthermore, the device was used to

measure resistivity at temperatures between 8 and 200 K for the samples.

X-ray diffraction was used to identify MgB2 wire that had been sintered at 800°C and then hot rolled. The wire was cut transversely to obtain MgB2 from inside the wire for XRD measurement. Figure 1 depicted the metallography preparation of the SUS316L tube wire, followed by the diffraction pattern of MgB2 powder. The pattern showed that MgB2 phase was one of the main phases, which increased from 98.2% to 98.5% and contained other elements, with a small quantity of Fe impurities. This proved that the SUS316L sheath was in contact with the diffraction process. According to Varghese et al., unreacted Fe and SS in MBFe and MBSS provided a greater volume percentage of MgB2 core, superior current density characteristics, and flux pinning behavior. This showed that Fe and SS were better sheath materials for the manufacture of MgB2 wire and tape (Varghese et al., 2007).

Figure

1 The

diffraction pattern and difference plot of MgB2 wire with 100% and

60% initial filling density

The largest current density was obtained when filling density was increased from 50% to 60% of the theoretical mass density of Mg+B in a previous study (Akdogan et al., 2015). However, the filling mass density had a significant impact on the temperature of production. Based on these results, the ideal filling density for powder was less than 100%. To prevent the porosity or size reduction of MgB2 wire, MgB2 formation problem must be addressed during sintering.

Figure 2 showed the W-H plot of MgB2 superconducting wire with various variations of powder filling, namely 100% and 60%. Analysis of the Williamson-Hall method for this computational analysis gave an increase in crystallite size from 85.6 nm to 159.9 nm, with a slight decrease in the amount of crystallite strain. This showed that slightly higher oxide formation tended to increase the crystallinity of the wire towards the ceramic material (Herbirowo et al., 2023). MgB2 wire specimen for morphological analysis is presented in Figures 3 and 4. Furthermore, the results showed that the porosity decreased from 6.3% to 5.4%, as shown in Figure 4. Based on Figure 3, it was easy to detect the location of the SUS316L tube and MgB2 phase boundaries. The results showed that the SUS316L did not react with Mg and B precursors. The cross-section line scan with EDX shown in Figure 3 also showed the presence of oxide in the material. Compared to XRD results, which did not show any oxide phase, it was estimated that the oxygen element in the EDS results was due to the oxidation process occurring on the surface of MgB2 sample.

Figure 3 EDX line scan on cross-sectional MgB2 wire of 60% filling density with a magnification of 20 times

Figure 4 The microstructure

of the SUS316L/MgB2 wire sintered at 1073K for 1 hour through hot

rolling with (a) 100% (b) 80%, and (c) 60% filling density under a

magnification of 5.000 times on the left (Secondary Image) and right (porosity

analysis) sides

Table 1 The objective of MgB2

synthesis was to create a material with a microstructure, phase, and composition

with the highest levels of superconductivity. The electrical resistivity's

temperature dependency was one of the most important properties to be assessed.

Furthermore, all synthesized MgB2-based samples had their

resistivity evaluated using a cryogenic magnet setup and the four-point probe

(FPP) method. The electrical resistivity of the SUS316L/MgB2

monofilament wire was shown as a function of temperature in Figure 5. The

results showed that the resistance value of the SUS316L/MgB2 wire

sample with 60% filling density was initially 2.00x10-4 ohm at 200 K

and decreased continuously until 8 K to 1.50x10-4 ohm, before

dropping at Tconset of 39K.

Figure 5 Resistivity measurement (left) and normalized resistivity (right) of the SUS316L/MgB2 wire specimen with different initial filling densities without an applied magnetic field

In

conclusion, MgB2 wires were fabricated successfully, leveraging the

economic benefits of using raw materials from crystalline Mg and amorphous B,

with a 60% initial filling density. Furthermore, the size of the crystallites

and superconducting phase greatly increased in this study. The R-T cryogenic

magnet assessed the specimen of critical temperature, and the results showed

that MgB2 specimen created using crystalline magnesium and fully

amorphous boron had a transition temperature of 39 K.

The

authors are grateful for the financial support from Universitas Indonesia

offered by the Research Grant of International Publication Indexed for Final

Project Student 2022 (PUTI Pascasarjana 2022) with contract number:

NKB-301/UN2.RST/HKP.05.000/2022. The authors are also grateful to the Research

Center for Advanced Materials BRIN (ELSA-BRIN), which provided characterization

for the study facilities.

Akdogan, M., Yeti?, H.,

Gajda, D., Karabota, F., Ülgen, A.T., Demirtürk, E., Belenli, I., 2015. Effect of the Initial

Filling Density

on the Critical Current of In-situ

Fe/MgB2 Wires. Journal of Alloys and Compounds, Volume 649, pp.

1007–1010

Anwar, M.S., Melinia,

R.K., Pradisti, M.G., Siradj, E.S., 2021. Effect

of Prior Austenite Grain Size on the Annealing Twin Density and Hardness in

Austenitic Stainless Steel. International Journal of Technology, Volume 12(6), pp. 1149–1160

Arvapalli, S.S., Miryala,

M., Sunsanee, P., Jirsa, M., Murakami,

M., 2021. Superconducting

Properties of Sintered

Bulk MgB2 Prepared from Hexane-mediated

High-energy-ultra-Sonicated Boron. Materials Science and Engineering B:

Solid-State Materials for Advanced Technology, Volume 265, p. 115030

Abdul, A., Yang, M., Shimizu, T., Furushima, T., 2021. Effect of Grain Misorientation and

Martensitic Transformation on Surface Roughening Behavior in Thin Austenitic

Stainless Steel Foils. International

Journal of Technology, 12(6), pp. 1161–1167

Balog, M., Rosova, A.,

Szundiova, B., Orovcik, L., Krizik, P., Svec, P., Kulich, M., Kopera, L.,

Kovac, P., Husek, I., Ibrahim, A.M.H., 2018. HITEMAL-an

Outer Sheath

Material for MgB2 Superconductor Wires:

The Effect of Annealing at 595–655 °C on the Microstructure and Properties. Materials and Design, Volume 157, pp. 12–23

Flukiger, R., Hossain,

M.S.A., Senatore, C., 2009. Strong

Enhancement of Jc and Birr Vin Binary

in Situ MgB2 Wires After

Cold High

Pressure Densification. Superconductor Science and Technology, Volume 22(8), p. 085002

Gajda, D., Zaleski, A.J.,

Morawski, A., Ma?ecka, M., Akdo, M., 2021. Influence

of Amorphous Boron Grain Size, High Isostatic Pressure, Annealing Temperature,

and Filling Density of Unreacted Material on Structure, Critical Parameters,

n-Value, and Engineering Critical Current Density in MgB2 Wires. Materials, Volume 14(13), p. 3600

Glowacki, B.A., Majoros,

M., Vickers, M., Evetts, J.E., Shi, Y., 2001. Superconductivity

of Powder-in-tube MgB2 Wires. Superconductor Science and Technology, Volume 14(4), p. 193

Grivel, J.C., 2018b. Influence

of Iridium Doping

in MgB2 Superconducting Wires. Physica C: Superconductivity and its Applications, Volume 547, pp.

7–15

Herbirowo, S., Hendrik,

Sebleku, P., Sergio, Imaduddin, A., Sofyan, N., Yuwono,

A.H., 2018. Effect of SiC and Sintering Temperature

Variations on the Characteristic of Fe-sheathed MgB2 Superconductor Wires. Materials Science Forum, Volume 929, pp. 27–32

Herbirowo, S., Yuwono,

A.H., Sofyan, N., Tinambunan, D., Nugraha, H., Imaduddin,

A., 2023. Fabrication

and Characterization of MgB2/SS

316L Superconducting Wire with Amorphous

Boron Prepared

by Sintering and Cold

Rolling. Materials Science for Energy Technologies, Volume 6, pp. 409–416

Ková?, P., Hušek, I.,

Pachla, W., Kulczyk, M., Melišek, T., Dvorák,

T., 2011. As-deformed

Filament’s Density

and Transport Currents of MgB2/Ti/Glidcop Wire. Journal of Alloys and Compounds, Volume 509(35), pp. 8783–8787

Ková?, P., Hušek, I.,

Pérez, N., Rosová, A., Berek, D., Gelušiaková, B., Kopera, L., Melišek, T., Nielsch, K., 2020. Structure and Properties

of Barrier-free MgB2 Composite Wires

Made by Internal

Magnesium Diffusion

Process. Journal of Alloys and Compounds, Volume 829, p.

154543

Lubis, H., Imaduddin, A.,

Sebleku, P., Herbirowo, S., Hendrik, Marlina, H., Marlianto, E., Alkindi, C., Sitorus, Z., 2018. The Influence of MgO Addition on the

Fabricating BPSCCO Superconducting Monofilament Wires using Ag-sheated and

Stainless Steel 316 Tubes Prepared by PIT Method. In: Journal

of Physics: Conference Series, Presentasi

Database Institute of Physics (IOP) Publishing

Nagamatsu,

J., Nakagawa, N., Muranaka, T., Zenitani, Y., Akimitsu, J., 2001. Superconductivity

at 39 K in Magnesium Diboride. Nature, Volume 410(6824), pp. 63–64

Varghese,

N., Vinod, K., Abhilash Kumar, R.G., Syamaprasad, U., Sundaresan, A., 2007. Influence

of Reactivity of Sheath Materials with Mg/B on Superconducting Properties of

MgB2. Journal of Applied Physics, Volume 102(4)

Vinod, K.,

Varghese, N., Rahul, S., Syamaprasad, U., 2009. Preparation of in Situ MgB2/Fe

Superconducting Tapes with Highly Densified Core by Hot Pressing of Electrically

Self-Heated PIT Wires. Materials Science and Engineering B: Solid-State

Materials for Advanced Technology, Volume 164(2), pp. 131–134

Widyianto,

A., Baskoro, A.S., Kiswanto, G., 2022. Investigation on Weld Characteristic,

Welding Position, Microstructure, and Mechanical Properties in Orbital Pulse

Current Gas Tungsten Arc Welding of AISI 304L Stainless Steel Pipe. International

Journal of Technology, Volume 13(3), pp. 473–48

Zhang, D.,

Sumption, M.D., Collings, E.W., Thong, C.J., Rindfleisch, M.A., 2020. Enhancement

of Bc2 and Birr in Bulk MgB2 Superconductors with SnO2

Additions. Physica C: Superconductivity and its Applications, Volume 578,

p. 1353749

Zheng, L.,

Zhang, W., Wang, Q., Zhang, H., Yu, Z., Cheng, C., Zhang, Y., Lei, M., Zhao, Y.,

2019. Superconducting Properties of NaCl Doped MgB2 Bulks Fabricated

by Hot Pressed Sintering. Journal of Alloys and Compounds, Volume 803,

pp. 742–747