Effect of Multi-walled Carbon Nanotube and Polyethylene Glycol Addition in Nanofluid Quench Medium for Steel Heat Treatment Application

Corresponding email: wahyuaji.np@gmail.com

Published at : 05 Feb 2024

Volume : IJtech

Vol 15, No 2 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i2.6690

Putra, W.N., Ariati, M., Suharno, B., Noviyanto, A., Riko, I.M., 2024. Effect of Multi-walled Carbon Nanotube and Polyethylene Glycol Addition in Nanofluid Quench Medium for Steel Heat Treatment Application. International Journal of Technology. Volume 15(2), pp. 364-372

| Wahyuaji Narottama Putra | Department of Metallurgical & Materials Engineering, Faculty of Engineering, Universitas Indonesia, Kampus Baru UI, Depok, 16424, Indonesia |

| Myrna Ariati | Department of Metallurgical & Materials Engineering, Faculty of Engineering, Universitas Indonesia, Kampus Baru UI, Depok, 16424, Indonesia |

| Bambang Suharno | Department of Metallurgical & Materials Engineering, Faculty of Engineering, Universitas Indonesia, Kampus Baru UI, Depok, 16424, Indonesia |

| Alfian Noviyanto | 1. Nano Center Indonesia, Jl. Puspiptek, South Tangerang, Banten, 15314, Indonesia, 2. Department of Mechanical Engineering, Mercu Buana University, Kebun Jeruk, Jakarta, 11650, Indonesia |

| I Made Riko | Institute of Materials Research and Engineering, A*Star Singapore, 2 Fusionopolis Way, 138634, Singapore |

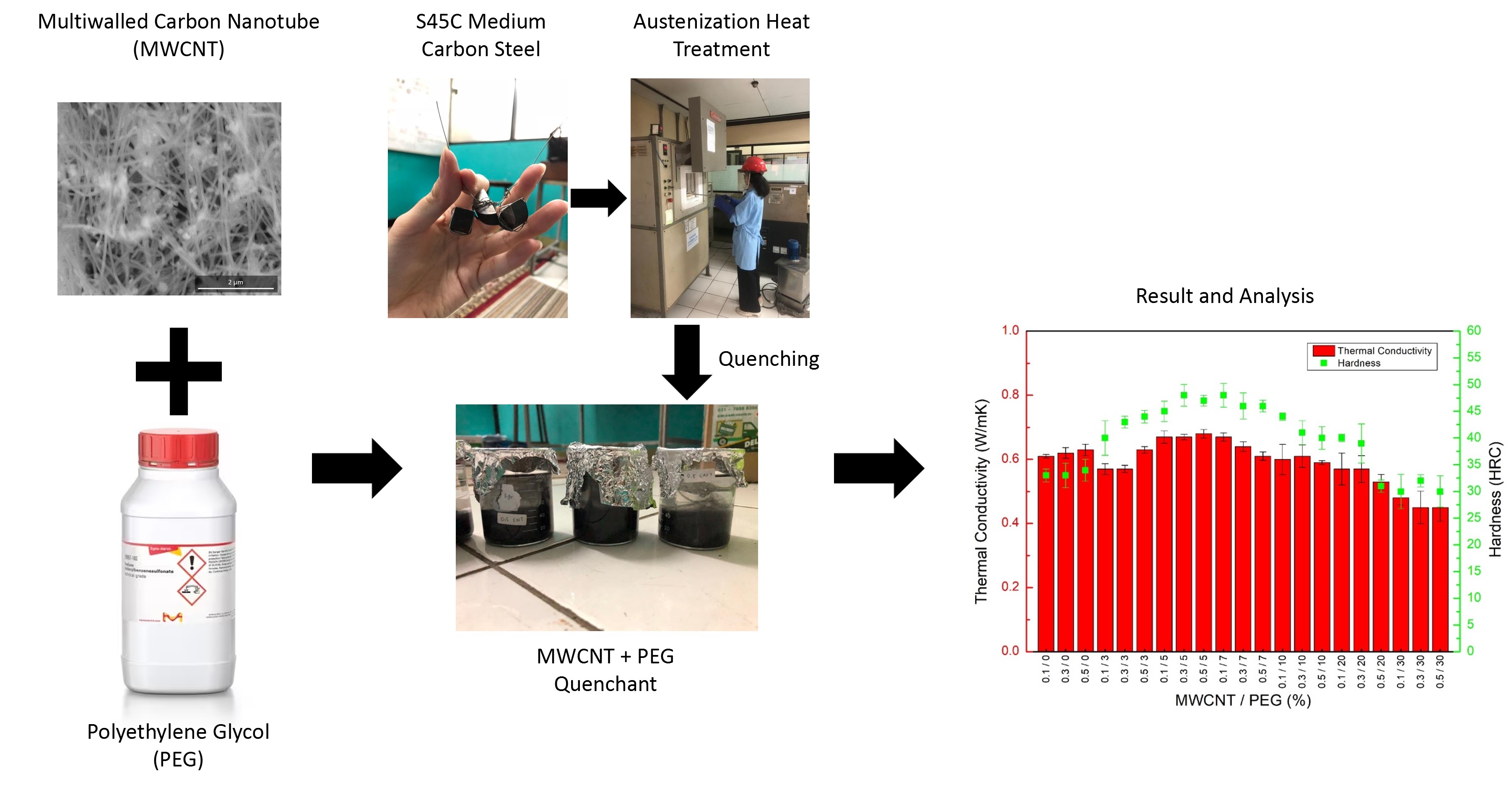

In the steel heat treatment industry, quenching is a critical stage for

enhancing the characteristics of steel. However, the lack of adherence to

appropriate procedures, especially in quenchant selection, can lead to cracks

or distortion. Quenchant selection is based on the required cooling rate for

the specific steel being quenched. Cooling rate of the quenchant is primarily

determined by the thermal conductivity of the fluid. This conductivity can be

modified by dispersing stabilized solid particles, typically in the nano-scale

range, thus forming a nanofluid. It is important to note that a higher

conductivity will increase the heat transfer characteristic and vice versa,

hence, cooling rate can be controlled by adjusting the amount of the dispersed

particle. In this study, the dispersed particle and surfactant used was

multi-walled carbon nanotube (MWCNT) and polyethylene glycol (PEG),

respectively. The concentrations of the dispersed particle were 0.1, 0.3, and

0.5 weight%. Furthermore, the surfactant was added at 3 – 30% on each particle

variation. The results showed that the highest thermal conductivity of 0.68

W/mK was achieved at 0.5% MWCNT and 5% PEG. This translated into better steel

properties, as it led to a hardness of 48 in Hardness Rockwell C-scale (HRC)

compared with the water-quenching technique. A higher percentage of PEG

surfactant decreases the thermal conductivity of the quenching medium and steel

hardness. This decrease was attributed to the high viscosity of the medium. In

conclusion, adjusting the particle and surfactant concentration allows for the

optimal quenching medium, offering enhanced steel properties.

Heat Treatment, MWCNT, Nanofluid, PEG, Quench Medium, S45C Carbon Steel

Nanofluid is a fluid containing nano-sized particles suspended in a base

fluid. These nanoparticles serve to improve thermal conductivity. It is

important to note that solid particles generally have higher conductivity

compared to any fluid (Ali and Salam, 2020).

The extensive surface area in nanoparticles contributes to even higher

conductivity. Therefore, nanofluid is commonly used in heat transfer-intensive

processes, such as coolant systems (Septiadi et

al., 2020), or quenching mediums in heat treatment (Radhiyah and Nurziela, 2020; Yahya et al., 2018; Babu, Arularasan, and

Ramkumar, 2017).

Several types of

solid particles can be added to nanofluid, including metals, metal oxides such

as CuO, TiO2, and Al2O3, as well as

carbon-based particle (Arularasan and Babu, 2021;

Ramadhani et al., 2019; Xia et

al., 2014). Carbon-based particle, specifically advanced types such

as MWCNTs, has garnered increased attention due to the significantly higher

thermal conductivity (Chen, Zeng, and Yuan, 2017).

Therefore, a small addition of this particle has the potential to substantially

increase the thermal conductivity of nanofluid (Hamidi

and Putra, 2023).

In the base fluid,

nanoparticles were dispersed, but a challenge, namely agglomeration, arises

with the particle dispersion (Ilyas, Pendyala, and

Marneni, 2014). Fine particles are prone to easy agglomeration, leading

to inhomogeneous nanofluid. This problem also impacted the stability of

nanoparticles, as they tend to settle at the bottom of nanofluid container (Ilyas, Pendyala, and Marneni, 2014). To overcome

the challenge, a surfactant was added to improve the dispersion inside the

fluid (Jehhef and Siba, 2019; Adiwibowo, Ibadurrohman,

and Slamet, 2018). Several types of these surfactants were categorized

as anionic, cationic, non-ionic, and zwitterionic. The classification was based

on the charge type of the molecule. Surfactants modify the surface of

nanoparticles by decreasing the surface tension, thereby enhancing stability

and dispersion, leading to higher thermal conductivity (Qadariyah

et al., 2022; Asadi et al., 2017; Paramashivaiah

and Rajashekhar, 2016; Kusrini et al., 2019).

Nanofluid

application is primarily applied in heat transfer fluid due to the superior

thermal conductivity. A specific application of the heat transfer fluid is in

the quenching medium during the heat treatment of steel (Agboola et al., 2020; Kresnodrianto et al., 2018; Ikubanni

et al., 2017). Improving steel properties, particularly hardness,

can be achieved by quenching it from the austenitizing temperature,

transforming the microstructure from Austenite to the Martensite phase. The

cooling rate plays a crucial role in the transformation, with a slower rate

resulting in a phase other than Martensite.

Rapid cooling

leads to cracks and distortion in the steel, necessitating the need for

appropriate quench medium with better cooling rate (Fredj

et al., 2017). The use of nanofluid offers a distinct advantage

as cooling rate can be adjusted based on the quantity of nanoparticles added to

the base fluid. This adjustability makes the quenchant highly versatile in the

heat treatment industry.

This study aimed

to provide a more comprehensive experimental analysis of the effect of

combining MWCNT and PEG in nanofluid, which is to be used specifically as a

quenchant in a steel heat treatment process. The difference in the thermal

conductivity of the quenchant was compared directly to the hardness of the

quenched steel. A direct relationship between the thermal conductivity and

cooling rate could be used to design a better quenchant. In summary, a

nanofluid with an adjustable cooling rate may provide an appropriate solution

in a thermal-sensitive heat treatment process to prevent defects.

MWCNT used in this study was a laboratory grade

purchased from Sigma Aldrich. According to the datasheet, MWCNT particle had a

diameter ranging from 50 – 90 nm, with an average of 65 nm. To explore deeper

into the particle characteristics, a Scanning Electron Microscope (SEM),

specifically FEI Inspect F50 with integrated Energy Dispersive Spectroscopy

(EDS) from EDAX, was applied for observation. Nanotube was used to synthesize a

nanofluid with distilled water as the base fluid. Finally, the particle

concentration was varied at 0.1, 0.3, and 0.5 % w/v.

To

improve the dispersion of MWCNT in the base fluid, Polyethylene Glycol (PEG)

surfactant was used as a stabilizer. PEG, purchased from Sigma Aldrich as a

liquid with an average molecular weight of 200, was added at concentrations

ranging from 3 – 30 % v/v for each MWCNT percentage variation. To study

nanofluid characteristics, zeta potential and thermal conductivity were

conducted. Zeta potential was performed using the Horiba SZ-100 series machine

to observe the stability of the particle in the fluid. Meanwhile, KD2 Pro

Thermal Properties Analyzer was adopted to examine the thermal conductivity

based on the transient heat transfer principle.

The

synthesized nanofluid was used as a quench medium in the steel heat treatment

process to enhance the characteristic, particularly hardness. A medium carbon

steel S45C was used as the sample for the heat treatment. The chemical

composition was verified using Optical Emission Spectroscopy (OES) with the

Foundry-Master Xpert equipment. The dimension of the steel is shown in Figure

1a. This sample was austenized at 900°C for 60 minutes to achieve a complete

Austenite phase. However, to prevent cracking or distortion due to thermal

shock, preheating at 540°C was conducted (Mochtar, Putra, and Abram, 2023). The complete thermal treatment

cycle is presented in Figure 1b. After austenitization, the steel was quenched

in nanofluid to obtain a Martensite phase. Microstructure observation and

hardness test were performed to confirm the phase transformation in the sample.

In this study, the microstructure was observed using Olympus

Inverted Metallurgical Microscope BX41M-LED. The steel sample was prepared

beforehand by etching in 2% Nital solution. The etchant duration was varied

from 3 – 10 seconds. For hardness measurement, Rockwell and Vickers hardness

tests were performed with the application of Qualirock Digital Hardness Tester

and Micromet 5100 series micro-indentation tester, respectively.

Figure 1 (a) Steel sample

dimension, (b) Thermal cycle for steel heat treatment

3.1. Preliminary

Observation on the Multiwalled Carbon Nanotube and S45C Steel Sample

MWCNT was examined using SEM to observe the

morphology. Figure 2 presents the electron microscope imaging of MWCNT

particle, showing a length of more than 1 .

Figure 2 Electron microscope image of Multiwalled Carbon Nanotube

The sample

used for quenching was S45C medium carbon steel. Furthermore, the chemical composition was verified

using OES and the result is presented in Table 1.

Table 1 S45C chemical composition by OES

|

Element |

Weight % |

|

Fe |

98.2 |

|

C |

0.42 |

|

Si |

0.26 |

|

Mn |

0.68 |

|

P |

0.008 |

|

S |

0.006 |

Based on the result, the steel sample

conformed to the S45C standard (Otai, 2015)

3.2. Multiwalled

Carbon Nanotube Stability of Nanofluid in Various Surfactant Concentrations

Zeta potential was used to assess the

stability of MWCNT inside nanofluid. The measurement specifically targeted the

concentration of 0.5% MWCNT, with the addition of 3, 7, 10, and 30% of

surfactant. Table 2 shows the result of the measurement.

Table 2 Zeta potential measurement of nanofluid

|

MWCNT (%) |

PEG (%) |

Zeta Potential (mV) |

|

0.5 |

3 |

-37.2 |

|

7 |

-25.5 | |

|

10 |

-23.4 | |

|

30 |

-23.2 |

The result showed that the

introduction of additional PEG enhanced stability by increasing zeta potential

to -37.2 mV. Nanofluid with a zeta potential of more than ± 30 mV was

considered to the moderately stable (Ghadimi, Saidur,

and Metselaar, 2011). On the other hand, less than ± 30 mV implied

suboptimal stability, potentially leading to sedimentation. The augmentation of

PEG contributes to stability improvement by modifying the surface tension on

the particle. During absorption, the particle will have lower surface tension

and create a layer to avoid agglomeration with similar particles. Therefore,

the addition of 3% PEG yielded the most favorable zeta potential in this

investigation. A decrease in stability was observed with higher PEG

concentration, attributable to the formation of micelles from the bulk

surfactant (Zhang et al., 2021; Paramashivaiah and Rajashekhar, 2016). The formation of micelle reduces the ability to

modify the surface tension of the particle, resulting in lower stability.

An examination of the effect of additional MWCNT and surfactant on thermal conductivity was also conducted. Figure 3a shows the measurement result on all nanofluid variables. The inclusion of MWCNT increased the thermal conductivity of the quenchant, even without surfactant. Increasing the percentage of nanotube and PEG could enhance conductivity. The highest thermal conductivity of 0.68 W/mK was obtained after 0.5% MWCNT and 5% PEG were added. For comparison, distilled water had a conductivity of 0.59 W/mK, which was improved by approximately 15%. The results suggested that the optimum surfactant concentration was 5%.

Figure 3 (a) Thermal conductivity measurement result,

(b) Steel hardness measurement result

The thermal conductivity

decreased at a higher percentage of PEG surfactant. The poorest conductivity

was observed after the addition of 30% PEG, yielding a value of 0.45 W/mK, even

lower than distilled water. This decline could be attributed to the formation

of surfactant micelles, as explained previously. Higher surfactant

concentration may compromise stability and create agglomeration of MWCNT. This

results in an inhomogeneous nanofluid and reduces the effective transfer of

heat.

3.4.

Improvement of S45C Steel Hardness after Quenching Process in Various

MWCNT-based Nanofluid Quenchant

Nanofluid was used as a

medium to quench austenized S45C medium carbon steel. After quenching, the

sample hardness was measured and presented in Figure 3b. The hardness value

trend was similar to the thermal conductivity. The variable with the highest

thermal conductivity (0.5% MWCNT and 5% PEG) also had the highest hardness at

48 Rockwell hardness C scale (HRC). For comparison, S45C steel sample had a

value of 12 HRC before any heat treatment process, then escalated to 43 HRC

after being quenched with distilled water. Therefore, the increase in hardness achieved

through nanofluid was up to 11% compared to distilled water quenching. S45C

steel sample after being treated with nanofluid was nearly identical to the

expensive high alloy tool steel SKD 61 (Kosasih, Priadi,

and Suliyanti, 2023).

The same trend was followed

for the sample with higher surfactant concentrations. Hardness decreased quite

significantly after the addition of 20% and 30% surfactant. The decrease has a

strong relation with the lower thermal conductivity. In heat treatment, a high

cooling rate was needed for the transformation from the Austenite to the

Martensite phase. Therefore, a quench medium with high thermal conductivity was

essential to obtain a high cooling rate and vice versa (Aziz

and Zaharudin, 2020). Based on the result, it was concluded that higher

thermal conductivity could provide a faster cooling rate, resulting in higher

steel hardness.

3.5. Microstructure

Evolution of S45C Steel after Quenching Process

Microstructure

observation was conducted to support the steel hardness result. Figure 4a and 4b shows the microstructure before and

after heat

treatment, respectively.

Figure 4 Microstructure of S45C (a) before heat

treatment, (b) after quenched in distilled water.

In Figure 4b, distinguishing between Bainite and Martensite

phases in microstructure after quenching proved challenging. A Vickers Hardness was used to

discriminate between the two phases, based on their hardness, as shown in Table

3. Microhardness result suggested that the brighter area was the Martensite

phase, while the darker

area was the Bainite phase. This interpretation was in line with a

similar microstructure

reported by

Nishimoto (Nishimoto et

al., 2022).

Table 3 Vickers microhardness results in

quenched microstructure

|

Area |

Vickers Hardness Number (HV) |

|

Brighter phase |

743 ± 15 |

|

Darker phase |

563 ± 17 |

For comparison, the microstructure of the

steel with the lowest and highest hardness after quenched in nanofluid are

presented in Figure 5a and 5b, respectively. Figure 5a showed that the

microstructure was dominated by Ferrite and pearlite phases, with some

Martensite phases in certain areas. Due to the presence of Ferrite phase,

hardness was low. Meanwhile, Figure 5b showed only Martensite and Bainite

phases, contributing to significantly higher steel hardness. Comparing Figure 4b

(quenched in distilled water) and 5b (quenched in nanofluid), it was observed

that the amount of Martensite was slightly higher in 5b, hence, hardness was

also higher.

Figure 5 Microstructure of S45C quenched in nanofluid

with (a) 0.5% MWCNT and 30% PEG, (b) 0.3% MWCNT and 5% PEG

In conclusion, the integration of MWCNT as nanoparticle and PEG

surfactant improved the performance of quenching medium by enhancing thermal

conductivity. The superior thermal conductivity of nanoparticles contributed to

enhanced nanofluid conductivity. The results showed that in the absence of a

surfactant, the inclusion of MWCNT alone elevated water conductivity to 0.63

W/mK. Significantly, the introduction of 5% PEG concentration led to further

refinement, thereby increasing the value to 0.68 W/mK. This refinement resulted

from the improved dispersion and stabilization of MWCNT particles facilitated

by PEG. Zeta potential analysis showed that the addition of 3% surfactant led

to an increase, reaching -37.2 mV. This showed a moderate level of nanofluid

stability. The pursuit of higher thermal conductivity translated into a faster

cooling rate and increased steel hardness. Experimental results substantiated

this notion, as steel sample subjected to quenching in nanofluid with high

conductivity showed hardness level of 48 HRC. The excessive addition of

surfactant adversely affected thermal conductivity and steel hardness

post-quenching. At higher concentrations, micelle formation occurred,

diminishing the efficacy of modifying surface tension and leading to particle

agglomeration. Consequently, thermal conductivity was reduced to 0.45 W/mK, and

steel hardness decreased to a minimum of 30 HRC due to a slower cooling rate.

This study explored the development of an adaptable cooling rate quenchant

based on nanofluid, offering a potential solution for steel heat treatment

industry, particularly for products sensitive to thermal variations. The determination

of an optimal ratio between particle and surfactant concentration was a

critical factor in achieving the desired objectives.

The authors are grateful to Mr. Eddie Susanto and Ms.

Edela Uswah Dien-Muhammad for the significant assistance provided on the

technical aspect of this study.

Adiwibowo, M.T., Ibadurrohman, M., Slamet, S.,

2018. Synthesis of Zno Nanoparticles and their Nanofluid Stability in the

Presence of a Palm Oil-Based Primary Alkyl Sulphate Surfactant for Detergent

Application. International Journal of

Technology, Volume 9(2), pp. 307–316

Agboola, O.O., Ikubanni, P.P., Adeleke, A.A.,

Adediran, A.A., Adesina, O.S., Aliyu, S.J., Olabamiji, T.S., 2020. Optimization

of Heat Treatment Parameters of Medium Carbon Steel Quenched in Different Media

using Taguchi Method and Grey Relational Analysis. Heliyon, Volume 6(7)

Ali, A.R.I., Salam, B., 2020. A Review on Nanofluid:

Preparation, Stability, Thermophysical Properties, Heat Transfer Characteristics

and Application. SN Applied Sciences, Volume 2(10), p. 1636

Arularasan, R., Babu, K., 2021. Thermally Annealed

Biochar Assisted Nanofluid as Quenchant on the Mechanical and Microstructure Properties

of AISI-1020 Heat-treated steel—a Cleaner Production Approach. Biomass

Conversion and Biorefinery, pp. 1–10

Asadi, A., Asadi, M., Siahmargoi, M., Asadi, T.,

Gholami Andarati, M., 2017. The effect of surfactant and sonication time on the

stability and thermal conductivity of water-based nanofluid containing Mg(OH)2

nanoparticles: An experimental investigation. International Journal of Heat

and Mass Transfer, Volume 108, pp. 191–198

Aziz, R.A., Zaharudin, R., 2020. Thermal

Conductivity and Stability Studies of Cooking and Waste Cooking Oil as a Based

Fluid of TiO2 Nanofluid for Carbon Steel Quenching Process. Journal

of Advanced Research in Fluid Mechanics and Thermal Sciences, Volume 78, pp.

22–33

Babu, K., Arularasan, R., Ramkumar, S.S., 2017.

Quenching Performance of AISI 1010 in CNT Nanofluids. Materials Today:

Proceedings, Volume 4, pp. 11044–11049

Chen, S., Zeng, X., Yuan, Q., 2017. Effect of Carbon

Nanotube Concentration on Cooling Behaviors of Oil-based Nanofluids During the Immersion

Quenching. Journal of Shanghai Jiaotong University (Science), Volume 22,

pp. 395–401

Fredj, E.B., Nanesa, H.G., Shahriari, D., Morin,

J.-B., Jahazi, M., 2017. Effect of Cooling Rate on Phase Transformation and Microstructure

Evolution in a Large Size Forged Ingot of Medium Carbon Low Alloy Steel. In:

TMS 2017 146th Annual Meeting and Exhibition Supplemental

Proceedings, pp. 413–423

Ghadimi, A., Saidur, R., Metselaar, H.S.C., 2011.

A Review of Nanofluid Stability Properties and Characterization in Stationary Conditions.

International Journal of Heat and Mass Transfer, Volume 54 (17-18), pp. 4051–4068

Hamidi, R.R., Putra, W.N., 2023. Effect of Polyethylene

Glycol Addition as Surfactant on Thermal Conductivity of Carbon Nanotube Based Nanofluids.

In: AIP Conference Proceedings, Volume 2538(1), p. 030001

Ikubanni, P.P., Adediran, A.A., Adeleke, A.A.,

Ajao, K.R., Agboola, O.O., 2017. Mechanical Properties Improvement Evaluation

of Medium Carbon Steels Quenched in Different Media. International Journal

of Engineering Research in Africa, Volume 32, pp. 1–10

Ilyas, S.U., Pendyala, R., Marneni, N., 2014.

Preparation, Sedimentation, and Agglomeration of Nanofluids. Chemical

Engineering & Technology, Volume 37(12), pp. 2011–2021

Jehhef, K.A., Siba, M.A.A.A., 2019. Effect of

Surfactant Addition on the Nanofluids Properties: A Review. Acta Mechanica

Malaysia, Volume 2(2), pp. 01–19

Kosasih, R., Priadi, D., Suliyanti, M.M., 2023.

Coating Material Development by Pulsed Laser Deposition for JIS SKD61 Steel

Insert Pins Used in Aluminum Casting Industry. International Journal of

Technology, Volume 14(4), pp. 833–842

Kresnodrianto, Harjanto, S., Putra, W.N.,

Ramahdita, G., Yahya, S.S., Mahiswara, E.P., 2018. Characterization of Water-based

Nanofluid for Quench Medium. In: IOP Conference Series: Materials

Science and Engineering, Volume 348(1), p. 012009

Kusrini, E., Putra, N., Siswahyu, A., Tristatini,

D., Prihandini, W.W., Alhamid, M.I., Yulizar, Y., Usman, A., 2019. Effects of

Sequence Preparation of Titanium Dioxide–Water Nanofluid using

Cetyltrimethylammonium Bromide Surfactant and TiO2 Nanoparticles for

Enhancement of Thermal Conductivity. International Journal of Technology, Volume

10(7), pp. 1453–1464

Mochtar, M.A., Putra, W.N., Abram, M., 2023.

Effect of Tempering Temperature and Subzero Treatment on Microstructures, Retained

Austenite, and Hardness of AISI D2 Tool Steel. Materials Research Express,

Volume 10(5), p. 056511

Nishimoto, M., Muto, I., Doi, T., Kawano, K.,

Sugawara, Y., 2022. Effect of Quenching in Aqueous Polyvinylpyrrolidone Solutions

on the Microstructure and Pitting Corrosion Resistance of AISI 1045 Carbon Steel.

Materials and Corrosion, Volume 74(5), pp. 724–733

Otai, 2015. JIS G4051 S45C Steel For Machine

Structural Use. Available Online at: https://www.astmsteel.com/product/jis-s45c-steel-machine-structural/,

Accessed on August 01, 2023

Paramashivaiah, B.M., Rajashekhar, C.R., 2016.

Studies on the Effect of Various Surfactants on Stable Dispersion of Graphene Nanoparticles

in Simarouba Biodiesel. In: IOP Conference Series: Materials Science and

Engineering, Volume 149(1), p. 012083

Qadariyah, L., Sahila, S., Sirait, C., Purba,

C.P.E., Bhuana, D.S., Mahfud, M., 2022. Surfactant Production of Methyl Ester

Sulfonate from Virgin Coconut Oil using Aluminum Oxide with Microwave

Assistance. International Journal of Technology, Volume 13(2), pp. 378–388

Radhiyah, A.A., Nurziela, K., 2020. Effect of TiO2

Nanofluid and Hybrid TiO2 Nanofluid on Mechanical Properties of

Steels for Automotive Applications. In: Journal of Physics: Conference

Series, Volume 1529(5), p. 052036

Ramadhani, C.A., Putra, W.N., Rakhman, D.,

Oktavio, L., Harjanto, S., 2019. A Comparative Study on Commercial Grade and

Laboratory Grade of TiO2 particle in Nanofluid for Quench Medium in

Rapid Quenching Process. In: IOP Conference Series: Materials Science

and Engineering, Volume 622(1), p. 012017

Septiadi, W.N., Prasetia, K.W.T., Murti, M.R.,

Sukadana, I.G.K., Rahman, F., Putra, G.J.P., Marianti, K.M., 2020. Investigated

on Thermal Design of a Computer Cooling System with the Effective Length of a

Cascade Heat Pipe. International Journal of Technology, Volume 11(7),

pp. 1388–1396

Xia, G., Jiang, H., Liu, R., Zhai, Y., 2014.

Effects of Surfactant on the Stability and Thermal Conductivity of Al2O3/de-ionized

Water Nanofluids. International Journal of Thermal Sciences, Volume 84, pp.

118–124

Yahya, S.S., Harjanto, S., Putra, W.N., Ramahdita, G., 2018. Characterization and Observation of Water-Based Nanofluids Quench Medium With Carbon Particle Content Variation. In: AIP Conference Proceedings, Volume 1964,(1) pp. 1–10

Zhang, J., Ge, D., Wang, X., Wang, W., Cui, D., Yuan, G., Wang, K., Zhang, W., 2021. Influence of Surfactant and Weak-Alkali Concentrations on the Stability of O/W Emulsion in an Alkali-Surfactant–Polymer Compound System. American Chemical Society (ACS) Omega, Volume 6(7), pp. 5001–5008