Reverse Logistics Network Design for Plastic Waste Management in Jakarta: Robust Optimization Method

Corresponding email: romadhani.ardi@ui.ac.id

Published at : 07 Dec 2023

Volume : IJtech

Vol 14, No 7 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i7.6681

Ardi, R., Nurkamila, S., Citraningrum, D.L., Zahari, T.N., 2023. Reverse Logistics Network Design for Plastic Waste Management in Jakarta: Robust Optimization Method. International Journal of Technology. Volume 14(7), pp. 1560-1569

| Romadhani Ardi | Department of Industrial Engineering, Faculty of Engineering, Universitas Indonesia, Kampus Baru UI, Depok 16424, Indonesia |

| Syifa Nurkamila | Department of Industrial Engineering, Faculty of Engineering, Universitas Indonesia, Kampus Baru UI, Depok 16424, Indonesia |

| Dyas Latiefah Citraningrum | Department of Industrial Engineering, Faculty of Engineering, Universitas Indonesia, Kampus Baru UI, Depok 16424, Indonesia |

| Teuku Naraski Zahari | Energy Economics Research Group, Graduate School of Energy Science, Kyoto University, Yoshida-Honmachi, Sakyo-Ku, Kyoto, 606-8501, Japan |

Indonesia

experiences

a consistent annual escalation in plastic production, primarily

attributed to the

high demands from numerous industries. As a result of this escalated production rate, more significant quantities of plastic waste

continue to be produced each year. In

this regard, it is essential to comprehend that uncontrolled plastic waste generates harmful

substances for humans and the environment. A reverse logistics network was introduced and

developed to decrease the damaging effects of this waste on the environment. The

Indonesian plastic waste reverse logistics system encountered some

uncertainties due to limited data availability, showing significant

fluctuations. To address these uncertainties, this study proposed a

robust optimization model for the

management of plastic waste within the reverse logistics system in Jakarta. The

results showed that the model could accurately identify optimal facility

locations and determine the exact quantity to transport between facilities

while considering social, economic, and environmental factors. The results also

showed that the proposed model minimized cost by 332 million USD, reduced gas emissions to

626 million m3 (ca. 1.2 billion kgCO2), and maximized

labor by 611 thousand people.

Network design; Plastic waste management; Reverse Logistics; Robust optimization

The absence of comprehensive and accurate

data on reverse logistics requires the consideration of uncertain variables or

parameters when making decisions regarding the networks (Rahimi

and Ghezavati, 2018). To address these uncertainties,

it was recommended that the reverse logistics network incorporate a robust

design (Pishvaee,

Rabbani and Torabi, 2011). Uncertainty conditions have

prevailed in different regions, particularly in Jakarta, a city generating

approximately eight thousand tons of plastic waste daily (Kristanto,

Jansen and Koven, 2020). Following this, the Ministry of

Environment and Forestry in Indonesia has stated that the availability and

accuracy of data for plastic waste in Jakarta are currently sporadic and vary (Ministry

of Environment and Forestry, 2020).

Previous studies on reverse logistics

network design have utilized mathematical models for multi-product design

primarily. These studies were observed to utilize specific parameters and

single objective functions (Sadrnia,

Langarudi, and Sani, 2020; Paydar and Olfati, 2018; Kilic, Cebeci, and Ayhan,

2015). Therefore, this study aims to

develop a reverse logistics network design model for plastic waste management

in Jakarta using a robust optimization method. The model has several

objectives, including minimizing costs, reducing carbon emissions, and creating

employment opportunities while optimizing the network. It is essential to

acknowledge that this study expands a previous work comprising a mixed-integer

programming model for designing a reverse logistics network dedicated to

plastic waste management in urban settings (Nurkamila

and Ardi, 2022). Our current study utilizes a

robust optimization approach, and its results could serve as the foundation to

provide essential insights to aid the government in decision-making.

Literature Review

2.1. Plastic Waste Management in Indonesia

Plastic waste management refers to the systematic handling, collection, disposal, recycling, and overall regulation of plastic materials to minimize environmental impact, promote sustainability, and mitigate the adverse effects of plastic pollution. This definition aligns with what was posited in the Government Regulation of Indonesia Number 81 of 2012 on the Management of Household and Household-like Wastes. Here, it was established that the handling of all waste, including plastic, comprises a series of processes, namely sorting, collection, transportation, processing, and ultimate waste disposal. Accordingly, these processes were executed at designated facilities such as temporary dumping places (TPS), final landfills (TPA), Waste Banks, Hoarders, and Recyclers.

Figure 1 Reverse

logistics network of plastic waste management in Indonesia

Initiating the

reverse logistics network for plastic waste in Indonesia comprised the transfer

of plastic waste to designated facilities, including Waste Banks or temporary

dumping places, informally known as "TPS" in Indonesia. This process

extends from the point of origin to the recycling phase at the Recycler. Figure

1 shows a schematic representation of the reverse logistics network for plastic

waste in Indonesia

(Ministry

of Environment and Forestry, 2020).

2.2. Reverse Logistics Network Design of

Plastic Waste

The importance of the circular economy and

sustainability underscore the significance of reverse logistics for plastic

waste (Valenzuela

et al., 2021). A reverse logistics network

design comprises strategic decisions concerning waste management facilities,

allocation, and product movement, including opening or closing facilities.

Many previous works developed plastic waste

reverse logistics analysis using mathematical models, particularly emphasizing

the use of mixed-integer linear programming (Demirel, Demirel and Gökçen, 2016).

Accordingly, some studies have utilized robust optimization models (Xu et al., 2021). Some of

the objective functions of these models have considered the environmental (Trochu, Chaabane and

Ouhimmou, 2020; Bing et al., 2015), economic (Galvez et al., 2015), and social

(Pedram et al., 2017) impact. In

this regard, the objective function, incorporating environmental considerations,

was oriented towards minimizing emissions and mitigating production processes

that harm the environment within the logistics network (Safdar et al., 2020). A specific

environmental consideration in a previous study was the reduction of the costs

of carbon dioxide emission associated with the processing and transportation of

plastic waste products within the networks (Bing, Bloemhof-Ruwaard and van der Vorst, 2014).

Moreover,

the objective function, incorporating economic considerations, is concerned

with assessing the impact of various cost components on the profitability or

lack thereof of the network (Safdar et al., 2020). An

economic consideration aimed to minimize the fixed costs associated with

facility construction, processing costs at hoarder centers and all reprocessing

facilities, manufacturing and material costs, shortage costs, and

transportation costs. The study aimed to decrease the entire cost of a

closed-loop supply chain (Pourjavad and Mayorga, 2018). Finally,

the objective function incorporating social aspects focused on how to enhance

social responsibility (Pedram et al., 2017)

It is essential

to acknowledge that only a few studies have considered the collective impact of

the triple bottom line, namely economic, environmental, and social (Safdar et al., 2020). Most

studies considered either only the economic aspect (Roudbari, Ghomi, and Sajadieh, 2021;

Xu et al., 2017; Kilic, Cebeci, and Ayhan, 2015) or economic

and environmental aspects (Yu and Solvang, 2016; Xiao et al.,

2019). In

addition, several models have also considered uncertainty (Roudbari, Ghomi, and Sajadieh, 2021;

Sadrnia, Langarudi and Sani, 2020; Xu

et al., 2017).

This study is an extension of an initial work (Nurkamila and Ardi, 2022) where the objective was only to minimize cost. The current study introduces three objective functions: minimizing costs, reducing gas emissions, and maximizing job creation. Under this, the study commenced with data collection through a literature review on reverse logistics network design and reverse logistics network applied for managing plastic waste in Jakarta. The methodology is shown in Figure 2.

Figure 2 Methodology

3.1. Mixed Integer Linear

Programming

Linear programming is an

optimization method that addresses problems with objective functions,

constraints, and decision variables in linear functions (Safdar

et al., 2020). It is the most widely used method

for improving supply chain management in the context of the agri-food

supply chain (Deepradit,

Ongkunaruk and Pisuchpen, 2020). Furthermore, it could solve routing and planning ocean transportation

(Soegiharto

et al., 2022). Previous works have

adopted linear

programming to optimize the plastic waste management network with

specific consideration

of costs (Castro-Amoedo

et al., 2021).

3.2. Robust Optimization

Robust Optimization is a method for handling data uncertainty, which is presumed to be encapsulated within a designated uncertainty set (Gorissen, Yanikoglu and den Hertog, 2015). This method could function reliably even under unfavorable circumstances, offering the best alternative in the worst-case situation (Ben-Tal, Ghaoui, and Nemirovski, 2009). The general linear programming model is shown by equation (1) as follows:

where

Assume that the box uncertainty set where

contains each uncertain parameter. By removing

the uncertainty from problems, robust optimization creates a single

deterministic problem known as a robust counterpart. As a result, the following

definition, as shown in equation (3) applies to a robust counterpart for an

uncertain linear programming problem:

3.3. Nominal Model for Jakarta

Plastic Waste Management Reverse Logistics Network

The design of the plastic waste reverse logistics network in Jakarta was prototyped using a mathematical model. Before creating the mathematical model, this study proposed a conceptual model that could represent real systems. Following this, the conceptual model for reverse logistics network design for managing plastic waste in Jakarta is shown in Figure 3. This model consists of several assumptions including c Clients, w Waste Banks, s TPSs, h Hoarders, r Recyclers, and a TPAs.

Figure 3 The conceptual model of Jakarta

plastic waste management reverse logistics

The model of the reverse logistics network introduced

in previous

studies (Roudbari, Ghomi, and Sajadieh, 2021; Safdar et al., 2020; Xu et

al., 2017) served as the basis for the nominal model proposed

in this study. Sets,

parameters, and decision variables are shown from Table 1 to Table 3.

Table 1 Definition of the model sets

Table 2 Definition of the model parameters

Table 3 Decision variables of the model

The nominal model aims to minimize facility costs, reduce carbon emissions from transportation, and maximize job creation. Its economic, environmental, and social objectives are to reduce costs (equation 4), minimize emissions (equation 5), and maximize work generation (equation 6) respectively.

Transshipment constraints are formulated in equations (7) through (12), while the constraints in (equation 13) through (19) comprised limitations on capacity. Finally, the constraints in equation (18) and equation (19) are for defining the decision variables as binary & continuous.

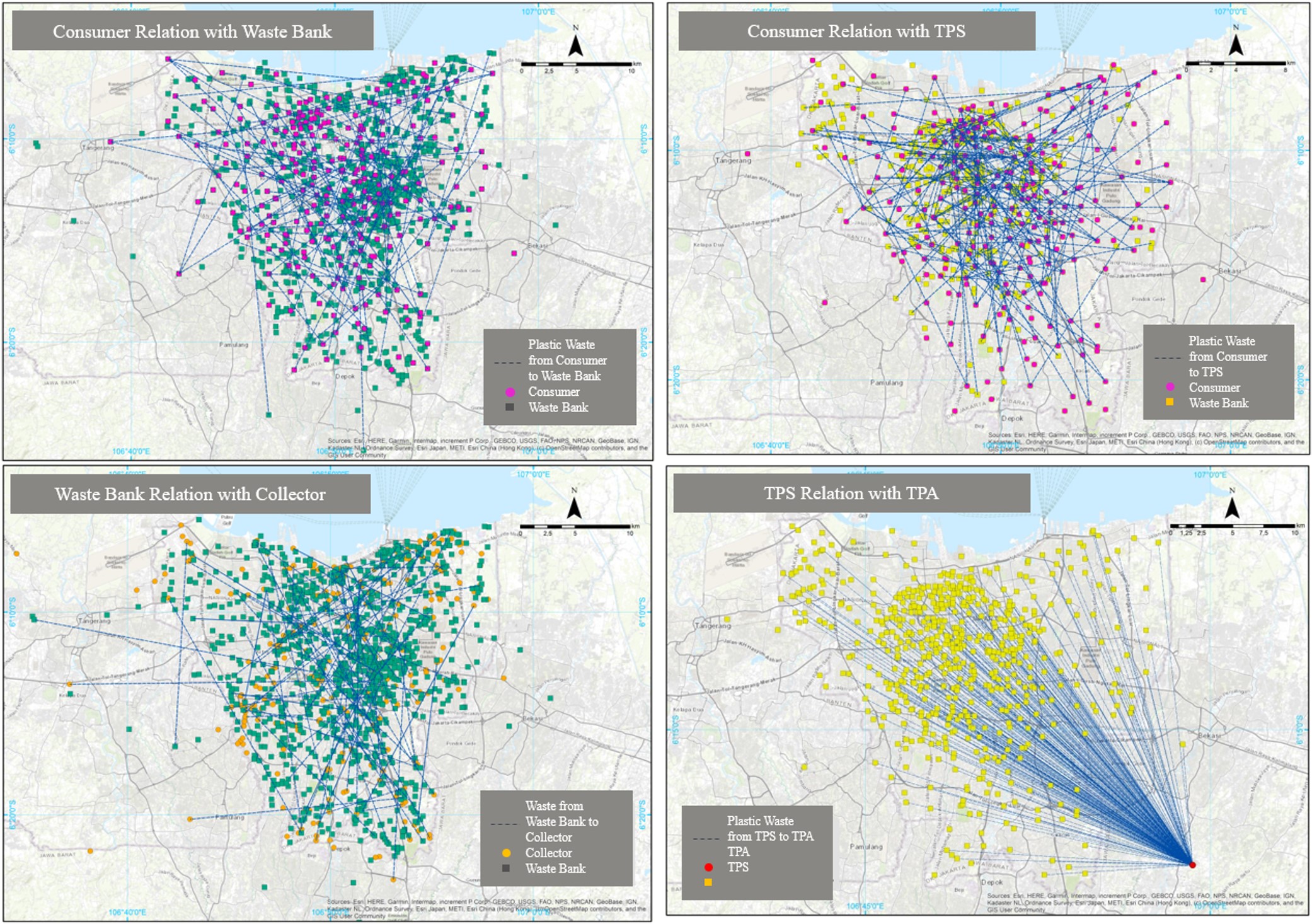

4.1. Application of the Model

This

study adopted a robust optimization model in a case study on plastic waste

management in Jakarta, Indonesia, focusing on a specific set of plastic waste.

The Jakarta reverse logistics network for plastic waste management comprises

260 Clients, 1262 Waste Banks, 1262 TPS, one TPA, 784 Hoarders, and 19

Recyclers.

This study proposed a robust optimization model designed specifically

for Jakarta's reverse logistics network, addressing the effective management of

plastic waste. The model incorporated the process of clients transferring waste

to Waste Banks and TPS, which subsequently experienced recycling at Hoarder or

disposal at TPA. Regarding tackling data uncertainty, the model considers

economic, environmental, and social aspects. It also aided the determination of

optimal locations and transportation routes for plastic waste in Jakarta. This

study showed that the availability of several new facilities, including 125

Waste Banks, 154 TPS, and 275 Hoarders, along with two Recyclers, was essential

to optimize plastic waste management. Following this, the considered

uncertainty in this model was confined to the parameter of the quantity of

returned plastic from consumers, which was assumed to reside within a box of

uncertainties. Hence, future studies might explore additional uncertainty issues,

such as facility capacity and plastic waste quality.

This

study was supported by Universitas Indonesia through Hibah Publikasi Terindeks

Internasional (PUTI) Q2 Grant 2022, grant number

NKB-711/UN2.RST/HKP.05.00/2022.

Aviso, K.B., Baquillas, J.C., Chiu,

A.S.F., Jiang, P., Fan, Y.Van, Varbanov, P.S., Klemes, J.J., Tan, R.R., 2023. Optimizing Plastics Recycling Networks. Cleaner Engineering and

Technology, 14, p. 100632

Ben-Tal, A., Ghaoui, L. El., Nemirovski,

A., 2009. Robust Optimization. Princeton University

Benson, N.U., Bassey, D.E., Palanisami, T., 2021. COVID

Pollution: Impact of COVID-19 Pandemic on Global Plastic

Waste Footprint. Heliyon, Volume

7(2), p. e06343

Bing, X., Bloemhof-Ruwaard, J., Chaabane, A., Van Der Vorst,

J., 2015. Global Reverse Supply Chain Redesign for Household Plastic Waste

Under the Emission Trading Scheme. Journal of Cleaner

Production, Volume 103(2015), pp. 28–39

Bing, X., Bloemhof-Ruwaard, J.M., van der Vorst,

J.G.A.J., 2014. Sustainable Reverse Logistics Network Design for Household

Plastic Waste. Flexible Services and Manufacturing Journal, Volume 26, pp.119–142

Castro-Amoedo, R., Dahmen, A., Barbosa-Povoa, A., Marechal, F.,

2021. Network Design Optimization of Waste Management Systems:

The Case of Plastics. Computer Aided Chemical

Engineering, Volume 50, pp. 185–190

Deepradit, S., Ongkunaruk, P., Pisuchpen, R., 2020.

Tactical Procurement Planning under Uncertainty in Aromatic Coconut

Manufacturing. International Journal of Technology, 11(4), pp. 698–709

Demirel, E., Demirel, N., Gökçen, H., 2016. A Mixed

Integer Linear Programming Model to Optimize Reverse Logistics

Activities of End-Of-Life Vehicles in Turkey. Journal of

Cleaner Production, 112(part 3), pp.2101–2113

Gabriel, D.S., Anindityo, A.W., 2017.

Development of Stakeholder Roles in Supporting Material Value

Conservation of Plastic Packaging Using Brain-Writing And

Interpretive Process. International Journal of Technology, Volume 8(7), pp. 1361–1370

Galvez, D., Rakotondranaivo, A., Morel, L., Camargo, M., Fick, M., 2015.

Reverse Logistics Network Design for a Biogas Plant: An Approach Based on MILP

Optimization and Analytical Hierarchical Process (AHP). Journal of

Manufacturing Systems, Volume 37, pp. 616–623

Gorissen, B.L., Yanikoglu, I., den Hertog, D., 2015. A

Practical Guide to Robust Optimization. Omega (United Kingdom),

Volume 53, pp. 124–137

Govindan, K., Paam, P., Abtahi, A.R., 2016. A Fuzzy

Multi-Objective Optimization Model for Sustainable Reverse

Logistics Network Design. Ecological Indicators, Volume 67, pp. 753–768

Kamaruddin, H., Maskun, Patittinggi, F., Assidiq, H.,

Bachril, S.N., Mukarramah, N.H. Al., 2022. Legal Aspect of

PlasticWaste Management in Indonesia and Malaysia: Addressing Marine Plastic

Debris. Sustainability (Switzerland), Volume 14(12),

p. 6985

Khoo, K.S., Ho, L.Y., Lim, H.R., Leong, H.Y., W, C.K., 2021.

Plastic Waste Associated With The COVID-19 Pandemic: Crisis or Opportunity? Journal

of Hazardous Materials, Volume 417, p.

126108

Kilic, H.S., Cebeci, U., Ayhan, M.B., 2015. Reverse

Logistics System Design for the Waste of Electrical and Electronic

Equipment (WEEE) in Turkey. Resources, Conservation, and Recycling, Volume 95, pp.120–132

Kristanto, G.A., Jansen, A., Koven, W., 2020. The Potential of Landfill Mining in Two Inactive

Zones of the Bantar Gebang Landfill in Jakarta, Indonesia. International

Journal of Technology, Volume 11(7), pp. 1430–1441

Liang, Y., Tan, Q., Song, Q., Li, J., 2021. An Analysis of

the Plastic Waste Trade and Management in Asia. Waste Management, Volume 119, pp. 242–253

Ministry of Environment and Forestry, 2020. National

Plastic Waste Reduction Strategic Actions for Indonesia

Nurkamila, S., Ardi, R., 2022. A

Mixed-Integer Robust Programming Model for Reverse Logistics Network Design of

Plastic Waste Management in Indonesia. In: the International Conference

on Industrial Engineering and Operations Management Nsukka, Nigeria.

pp.1507–1516.

Paydar, M.M., Olfati, M., 2018. Designing

and Solving a Reverse Logistics Network for Polyethylene

Terephthalare Bottles. Journal of Cleaner Production, Volume 195, pp. 605–617

Pedram, A., Pedram, P., Yusoff, N. Bin, Sorooshian, S.,

2017. Development of Closed–Loop Supply Chain Network in Terms Of

Corporate Social Responsibility. PLOS ONE, Volume 12(4), p.

e0174951

Pishvaee, M.S., Rabbani, M., Torabi, S.A., 2011. Robust

Optimization Approach to Closed-Loop Supply Chain Network Design Under

Uncertainty. Applied Mathematical Modelling, Volume 35(2), pp. 637–649

Pourjavad, E., Mayorga, R.V., 2018. An

Optimization Model for Network Design of a Closed-Loop Supply Chain:

A Study for a Glass Manufacturing Industry. International Journal of

Management Science and Engineering Management, Volume 14(3), pp. 169–179

Rahimi, M., Ghezavati, V., 2018. Sustainable

Multi-Period Reverse Logistics Network Design and Planning Under

Uncertainty Utilizing Conditional Value at Risk (Cvar) for Recycling

Construction and Demolition Waste. Journal of Cleaner

Production, Volume 172, pp. 1567–1581

Roudbari, E.S., Ghomi, S.F.M.T., Sajadieh,

M.S., 2021. Reverse Logistics Network Design For Product Reuse,

Remanufacturing, Recycling and Refurbishing Under Uncertainty. Journal of

Manufacturing Systems, Volume 60, pp. 473–486

Sadrnia, A., Langarudi, N.R., Sani,

A.P., 2020. Logistics Network Design to Reuse Second-Hand Household Appliances for

Charities. Journal of Cleaner Production, Volume 244, p. 118717

Safdar, N., Khalid, R., Ahmed, W., Imran, M., 2020.

Reverse Logistics Network Design for E-Waste Management Under the Triple Bottom

Line Approach. Journal of Cleaner Production, Volume 272, p.

122662

Soegiharto, S., Zagloel, T.Y.M., Sunaryo, Komarudin, 2022.

Inventory Ship Routing and Cargo Stowage Planning on Chemical Tankers. International

Journal of Technology, Volume 13(2), pp. 240–253

Stallkamp, C., Steins, J., Ruck, M., Volk, R., Schultmann, F.,

2022. Designing a Recycling Network for the Circular Economy of Plastics with

Different Multi-Criteria Optimization Approaches. Sustainability

(Switzerland), Volume 14(17), p. 10913

Trochu, J., Chaabane, A., Ouhimmou, M., 2020. A

Carbon-Constrained Stochastic Model for Eco-Efficient Reverse

Logistics Network Design Under Environmental Regulations in the CRD Industry.

Journal of Cleaner Production, Volume 245, p. 118818

Valenzuela, J., Alfaro, M., Fuertes, G., Vargas, M., Saez-Navarrete,

C., 2021. Reverse Logistics Models for the Collection of Plastic Waste:

A Literature Review. Waste Management and Research,

Volume 39(9), pp. 1116–1134

Xiao, Z., Sun, J., Shu, W., Wang, T., 2019.

Location-Allocation Problem of Reverse Logistics for End-Of-Life

Vehicles Based on the Measurement of Carbon Emissions. Computers

& Industrial Engineering, Volume 127, pp. 169–181

Xu, X., Elomri, A., Liu, W., Liu, H.,

Li, M., 2021. Robust Global Reverse Logistics Network Redesign for High-Grade

Plastic Waste Recycling. Waste Management, Volume 134, pp. 251–262

Yu, H., Solvang, W.D., 2016. A General Reverse Logistics

Network Design Model For Product Reuse and Recycling with

Environmental Considerations. The International Journal of Advanced

Manufacturing Technology, Volume 87, pp. 2693–2711