Performance of In-Situ Stirring Batch Reactor Transesterification of Nannochloropsis sp Microalgae into Biodiesel

Corresponding email: yustiawulandari_che@itats.ac.id

Published at : 10 Jul 2024

Volume : IJtech

Vol 15, No 4 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i4.6678

Mirzayanti, Y.W., Marlinda, L., Irawan, H., Al Muttaqii, M., Ma'sum, Z., Asri, N.P., Chern, J.-M., 2024. Performance of In-Situ Stirring Batch Reactor Transesterification of Nannochloropsis sp Microalgae into Biodiesel. International Journal of Technology. Volume 15(4), pp. 859-869

| Yustia Wulandari Mirzayanti | Department of Chemical Engineering, Faculty of Technology Industrial, Institut Teknologi Adhi Tama Surabaya, Surabaya 60117, Indonesia |

| Lenny Marlinda | Department of Industrial Chemistry, University of Jambi, Jambi 36361, Indonesia |

| Hery Irawan | Department of Mechanical Engineering, Faculty of Technology Industrial, Institut Teknologi Adhi Tama Surabaya, Surabaya 60117, Indonesia |

| Muhammad Al Muttaqii | Research Center for Chemistry, Badan Riset dan Inovasi Nasional, South Tangerang 15314, Indonesia |

| Zuhdi Ma'sum | Department of Chemical Engineering, University of Tribhuwana Tungga Dewi, Malang 65144, Indonesia |

| Nyoman Puspa Asri | Department of Food Technology, University of Ciputra, Surabaya, 60219, Indonesia |

| Jia-Ming Chern | Department of Chemical Engineering and Biotechnology, Tatung University, Taipei, 10491, Taiwan |

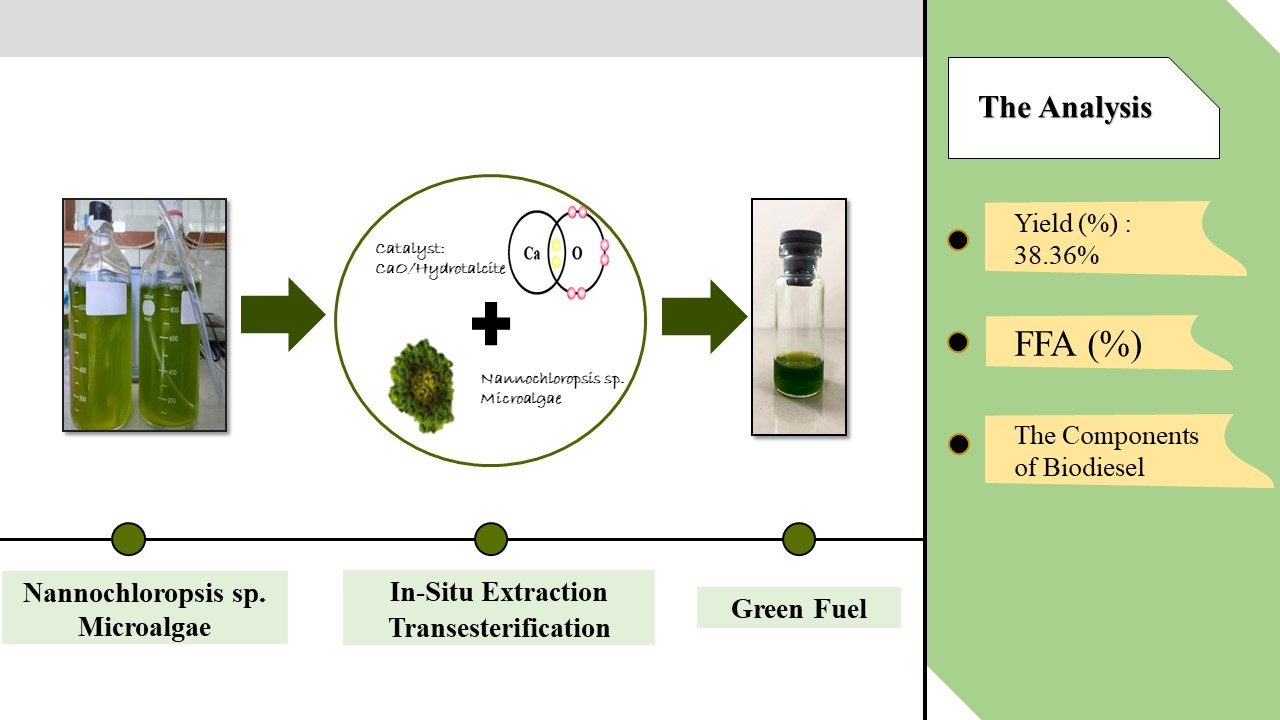

In-situ

stirring batch reactor transesterification is a widely used method for the

conversion

of various biomass into biodiesel,

particularly Nannochloropsis sp

microalgae. Therefore,

this study aims to investigate the effect of CaO/Hydrotalcite catalyst loading

ratio and stirring rate on in situ stirring batch reactor

transesterification of Nannochloropsis sp microalgae to produce

biodiesel. In-situ transesterification was carried out using stirring

with a four-blade paddle (50 w), while CaO/Hydrotalcite catalyst preparation

was performed using incipient wetness impregnation. Nannochloropsis sp

microalgae were then converted into biodiesel with varying loading ratio of

catalyst (1:1, 3:1, and 5:1 %wt/wt) and stirring speed of agitation (50, 100,150, 200, and 250 rpm) for 4 hours

(60oC). Subsequently, biodiesel obtained from the process was

analyzed using gas chromatography (GC). The results showed that the surface

area of CaO/Hydrotalcite was 45.756 m2/g. The conversion yields of Nannochloropsis

sp microalgae to biodiesel with CaO/Hydrotalcite reached 38.36% with an

agitation rate of 250 rpm. Based on the fatty acids analyzed using GC methods,

the products predominantly contained olefine (61.49%) and gasoline (38.51%).

Biodiesel; CaO/Hydrotalcite; In-Situ transesterification; Nannochloropsis sp.

Renewable energy, such

as biofuels, is a valuable alternative to fossil fuels due to its beneficial

properties. In addition, biofuels

are classified into generations based on the raw materials used during their

synthesis, including edible and non-edible oils, biomass, lignocellulose, and

residues (Lomeu et al., 2023;

According to previous studies, biodiesel is predominantly produced using transesterification

method, which comprises mixing lipid (triglyceride) and alcohol, with catalysts being used to facilitate the

synthesis of ester and glycerol. High free fatty acids (FFA) cannot be directly

tranesterified using an alkaline catalyst, which gives low yield and low

quality of biodiesel

Several studies have explored the conventional conversion of Nannochloropsis

sp. microalgae to biodiesel using extraction with solvents, followed by

transesterification process (

Heterogeneous catalyst are gaining more interest because its

have advantages over homogeneous catalysts (Aisyah et al., 2023; Rahma and Hidayat, 2023; Cercado,

Ballesteros, and Capareda, 2018). Based on previous studies, calcium oxide (CaO)

is a base heterogeneous catalyst with good potential for chemical reaction,

particularly transesterification reaction

The novelty in this current

study lies in the use of a metal catalyst (CaO/Hydrotalcite) to convert Nannochloropsis

sp microalgae into biodiesel using in-situ transesterification method as

well as exploring the effectiveness of the agitation rate parameters on reactor

batch in-situ transesterification. CaO is an alkali metal oxide with various

advantages, while hydrotalcite is a heterogeneous catalyst that can accelerate

transesterification reaction. The investigation primarily focuses on the

performance of the combination of CaO metal and hydrotalcite as catalyst. Reactor's design was in-situ

stirred batch reactor with a unique design comprising a four-blade paddle. Catalyst

used was an alkali metal, which comprised the combination of CaO/Hydrotalcite

heterogeneous catalyst and methanol as a solvent and a reactant in in-situ

transesterification process, with n-hexane serving as a co-solvent. Therefore, this study aims to determine the

effect of CaO/Hydrotalcite loading ratio and stirring rate in converting Nannochloropsis

sp. microalgae.

This section described the principal materials

and the methodologies used in the experimental procedures.

2.1. Material, Equipment, and Apparatus

Nannnochloropsis sp

microalgae were obtained from the Brackish Water Aquaculture Fisheries at

Jepara, Central Java, Indonesia. Meanwhile, calcium carbonate, methanol,

n-hexane (Merck & Co, 99%), and hydrotalcite synthetic (Sigma Aldrich, 99%)

were purchased from an Indonesian supplier. The major equipment was in-situ

stirred batch reactor (material: stainless steel type 304), vertical

cylindrical shape equipped with a stirrer. The top and bottom covers were

flange-shaped, with a total tank volume of 20 liters and a stirrer of 50 w

(four-blade paddle) (Figure 1a). Figure 1b illustrated a stirred tank batch

reactor with dimensions of outside diameter (do) = 7.48 in; cylinder

height (Ls) = 7.48 in; cylinder thickness (ts) = 3/16 in;

and leg support (l) = 20 in (Scale 1:1). The heating circulation

had a maximum speed of 500 rpm, a maximum temperature of 250oC, and

H of 20.5 in (scale = 1:1).

2.2.

Synthesis and Characterization of

CaO/Hydrotalcite

The incipient wetness impregnation method was

used for the synthesis of the CaO/Hydrotalcite catalyst, which was placed in an

oven for 12 hours at 100oC. The calcium carbonate (CaCO3)

was calcined into CaO for 3 hours at 900oC and then weighed with

loading ratio of CaO to hydrotalcite (1:1, 3:1, and 5:1 wt/wt). Subsequently,

CaO was dissolved in distilled water, and the solution was sprayed onto

hydrotalcite slowly and evenly until it seeped into hydrotalcite pores at room

temperature. The sample was dried at 100oC for 12 h and treated in

the furnace at 900oC for 3 hours. The final product was

CaO/Hydrotalcite catalyst powder, which was characterized using X-ray

diffraction (XRD), X-ray Fluorescence (XRF), and Brunaur Emmett and Teller (BET) to investigate the surface area. The characterization techniques

of XRD investigations were performed using instruments possessing Cu K-Alpha

source, 40 kV and 30 mA generator settings, and no beam monochromator.

Figure 1 a) In Situ stirred batch

reactor transesterification, b) stirred tank batch reactor, and c) heat

circulation

2.3.

In-Situ Transesterification Reaction

The experimental setup consisted of in-situ stirred batch reactor, as

shown in Figure 1. The weighed amount of Nannochloropsis sp microalgae

biomass was mixed with CaO/Hydrotalcite catalyst (10%wt of microalgae) and

methanol. The mixture obtained was then blended for 4 hours at 60oC

with varying agitation rates of 50, 100, 150, 200, and 250 rpm. After the

reaction had occurred, it was cooled to separate biodiesel from glycerol and

suspended solids. Subsequently, the filtered residue was washed

using 30 mL of a mixture of methanol-n-hexane (1:1 v/v) to obtain fatty acids

methyl ester (FAME). The filtrate was separated by adding n-hexane with a 1:1

(v/v) ratio, shaken, and allowed to stand until 2 layers formed for 30 minutes.

The bottom layer was then removed from the separating, and n-hexane was added

with a 1:1 (v/v) ratio. The solution was shaken and allowed to stand until 2

layers formed for 8 hours. The top layer was washed to remove any catalyst and

glycerol in the mixture. The product obtained was distilled (70oC)

to separate FAME and solvent. Gas Chromatography-Mass Spectrometry

(GC-MS) was used to analyze biodiesel for detected fatty acids in higher yields

in all variables. The peak area from GC-MS data could be read by the

normalization method based on the peak area per percentage of identified

components used to measure the GC-MS results. All hydrocarbon components were

identified using Wiley275 and NIST02 mass spectral data libraries. Hydrocarbon

components with a probability equal to or above 80% were considered in line

with previous studies (Marlinda

et al., 2022; Mirzayanti et al., 2020b). This current study optimized the process variables for the highest

yield, namely the effectivity of the speed

of stirring conversion to crude biodiesel and loading of CaO/Hydrotalcite

catalyst by microalgae, density, acid number, and %FFA. The limitation

of this report was that it solely focused on the effect of the CaO and

hydrotalcite loading ratio and stirring speed on yield and FFA. The best yield

obtained was subjected to GC-MS testing to determine the content of hydrocarbon

compounds produced.

2.4. Analysis of Crude Biodiesel

Analysis and determination of the %yield of crude biodiesel was calculated with the formulations presented below (Equation 1)

where

MB is the mass

of crude biodiesel (g); and MA is microalgae (g) mass. Compound analysis

biodiesel components (ASTM D4007) were analyzed using GC-MS.

3.1. Characteristics of

Nannochloropsis sp Microalgae

Characteristics

of lipid of liquid Nannochloropsis sp microalgae biomass are presented in Table 1.

The results showed that the highest fatty acids content in Nannochloropsis sp microalgae was oxygenated compounds

(51.80%), followed by carboxylic acid (46.61%). In addition, oxygenated compounds were hydrocarbons containing at least 1 oxygen

atom as a part of their chemical structure, and are commonly referred to as

fuels. The 4 general classes of hydrocarbons included

alkanes, alkenes, alkynes, and arenes. Carboxylic acid, in organic

chemistry, is an organic acid containing a carboxyl group (C(=O)OH) attached to

an R-group. This compound was characterized by its carbon (C) atom being bonded to an

oxygen (O) atom by a double bond as well as to a hydroxyl group (?OH) by a

single bond. Based on Table 1, Nannochloropsis sp microalgae could be

used as raw materials for biodiesel.

Table 1

Fatty acid content in Nannochloropsis sp microalgae

|

No |

Component |

%area |

|

1 |

Alkenes/olefins |

1.59 |

|

2 |

Oxygenated compounds |

51.80 |

|

3 |

Carboxylic acid |

46.61 |

The

total lipid content of microalgae biomass largely depended on the specific

cultivation technology. Microalgae culture condition, nutrients, and light intensity could be

optimized to increase the oil content, leading to enhanced biodiesel

production. In addition, the growth rate of this organism and maximum biomass

production depended on their culture systems (light, temperature, pH, salinity,

consumption of O2, CO2, nutrients, and toxic chemicals) (Medipally et al., 2015). According to previous

studies, nutrients for microalgae growth included nitrogen (N) and/or

phosphorus (P) (Kazemifard et al.,

2019). Nannochloropsis sp microalgae could serve as biodiesel due to

the abundance of its oleic acid content (73.40%) among the remainder of the

MUFA composition (Kanagesan

et al., 2020). The

specific growth rate of Nannochloropsis

sp microalgae strains generally ranged from 0.11 to 0.21 per day, with

total lipid content of 37-60% of dry weight (DW) (Ma et al., 2016).

3.2. Catalyst Characterization

Figure

2 showed a series of XRD diffractions of CaO/Hydrotalcite. The initial

incipient wetness impregnation at 900oC in 3 hours predominantly

contained CaO and MgO with few amounts of Al2O3. In

addition, the XRD pattern of CaO/Hydrotalcite catalyst had related curves in terms of

uniformity. The peaks obtained were compared with the Joint Committee on Powder

Diffraction Standards (JCPDS) file. From Figure 3, the principal components of

CaO/Hydrotalcite catalyst

included CaO, Ca2Al, and MgO. Diffraction 2? from JCPDS for

using CaO was 32.2o, 37.3o, and 53.8o.

Therefore, the pattern in Figure 2 showed the intensified and narrow peaks at 2 =

17.88o, 28.47o, 33.92o, 42.88o,

47.07o, and 50.60o, as reported in a previous study (Mohamad

et al., 2018). Catalyst characterization

also used XRF analysis to determine the chemical compositions. The elemental

chemical compositions of catalyst in this study are presented in Table 2.

According to the XRF, the CaO content of the various ratio of CaO with hydrotalcite

(1:1, 3:1, and 5:1 %wt/wt) increased gradually. The highest amount of CaO was

obtained at ratio of 5:1 %wt/wt (84.13 %m/m), as shown in Table 2. The results

suggested that the decomposition of carbonates was achieved at 900oC

for approximately 3 hr. In a previous study, the majority of variation ratio

catalyst above 50% were CaO species (Amusan et al., 2019). The total content of MgO and Al2O3

was below 50% because hydrotalcite was decomposed into metal oxides when

calcined at 900oC

for 3 hours (Amusan et al., 2019; Mohamad et al., 2018).

The surface area of CaO/Hydrotalcite particles synthesized to catalyst (obtained by calcination at 900oC for 3 h) from BET and BJH was 45.756 m2/g. Furthermore, the surface area of the obtained catalyst showed good activity for converting Nannochloropsis sp oil into biodiesel. This result was consistent with a previous study, which distributed CaO or K2CO3 in various support materials (Manurung et al., 2023; Zhang et al., 2019). Navajas et al. (2018) also reported the best results for hydrotalcite activity as a heterogeneous methanolysis catalyst. These outcomes were attributed to the high basicity properties of the solid that was subjected to the rehydration process after calcination with a surface area of 12 and 66 m2/g. Apart from the strong basic sites, the presence of interlayer hydroxide anions at the accessible crystal edges enhanced catalyst's activity. However, hydrotalcite synthesized using a variety of processes had a surface area of 131-153 m2/g at pH 10 and 150oC (Navajas et al., 2018). This result was better than previous studies, which obtained an average value of 34.6 m2/g (Anr et al., 2017). The CaO/Hydrotalcite area was more significant compared to a previous study at 4.34 m2/g (Win and Khine, 2017).

Figure 2 XRD diffractogram of CaO/Hydrotalcite calcined at

900oC for 3 h (5:1 %wt/wt)

Table 2 XRF

analysis of CaO/Hydrotalcite at 900oC for 3 hours

|

No |

Component |

%Massa (m/m) | ||

|

1:1 |

3:1 |

5:1 | ||

|

1 |

CaO |

55.05 |

66.80 |

84.13 |

|

2 |

MgO |

32.33 |

24.08 |

11.76 |

|

3 |

Al2O3 |

12.35 |

8.90 |

4.00 |

|

4 |

SiO2 |

0.17 |

0.11 |

0.02 |

|

5 |

Na2O |

0.08 |

0.10 |

0.08 |

|

6 |

Fe2O3 |

0.01 |

0.01 |

0.00 |

|

7 |

SO3 |

0.01 |

0.01 |

0.01 |

3.3. Catalytic Performance for

Biodiesel Production

In-situ

stirring batch reactor transesterification reaction was performed using

CaO/Hydrotalcite, and the reaction conditions were investigated by varying the

different parameters. The effect of stirring speed and CaO loading on

transesterification was also studied in the reaction.

3.3.1. Effect

of stirring rate and CaO loading on %yield crude biodiesel

Figure

3a presents stirring speed of the different CaO/Hydrotalcite ratio of

CaO/Hydrotalcite catalyst. In addition, the highest yield of crude biodiesel at

250rpm was obtained with a 1:1 wt/wt ratio of catalyst (38.36%). A high mixing

must be used during in situ transesterification to obtain high FAME and

yield (Salam, Velasquez-Orta, and Harvey, 2016). The results showed that the yield increased with an increase in mixing

speed. The process showed that the mixing speed at 250 rpm was 38.36%. Figure 3 also showed the presence of an anomaly in the decrease of

%yield crude biodiesel of CaO/Hydrotalcite catalyst (1:1 %wt/wt; 150 rpm and

3:1 %wt/wt; 100 and 200 rpm). Loading ratio of CaO/Hydrotalcite catalyst at 1:1

produced the highest yield. This was due to the best metal composition in the

1:1 %wt/wt composition. When catalyst loading ratio was increased (5:1 %wt/wt),

the results showed a decrease in

%yields, as reported in previous studies (Koech, Kumar, and Siagi, 2020). The outcome observed was caused by interaction

with other molecules/compounds, leading to increased by-products. The high

catalyst concentration led to a corrosive nature, which hindered

transesterification reaction.

Figure 3 Effect of stirring speed (a) on %yield crude biodiesel based on

the effect of CaO/Hydrotalcite loading ratio (b) on FFA crude biodiesel based

on the effect of CaO/Hydrotalcite loading ratio

3.3.2. Effect of stirring rate and CaO loading on %FFA crude

biodiesel

Figure 3b

showed that the lowest FFA in loading ratio CaO/Hydrotalcite of 1:1 %wt/wt (250

rpm) was 1.39%. In addition, the higher stirring speed, the higher the level of

decrease in %FFA. The results also showed that stirring rate had a significant

effect on the FFA of crude biodiesel, where the higher stirring rate, the

smaller the FFA observed. The acid number obtained affected the quality of

biodiesel, and the higher the acid number in biodiesel, the lower its quality.

This parameter could also affect the shelf life and the level of corrosiveness

of the engine. The results showed that high acid numbers created deposits in the fuel

system and reduced the quality of fuel system components.

3.4. Properties of

Nannochloropsis sp Microalgae Biodiesel

Table 3 presented the physicochemical characteristics of Nannochloropsis sp microalgae biodiesel. The properties showed that Nannochloropsis sp microalgae could be used as biodiesel raw material. According to a previous study, biodiesel obtained from this species had a density quality of 0.839 g/m3 (Koech, Kumar, and Siagi, 2020; Salam, Velasquez-Orta, and Harvey, 2016). The results in Table 3 confirmed the good characteristics of Nannochloropsis sp microalgae for conversion into biodiesel.

Table 3 Physicochemical properties Characteristics of Nannochloropsis

sp Microalgae

Biodiesel

|

No |

Properties |

Test method |

Standard |

Values of algae Biodiesel |

|

1 |

Density (g/cm3) |

SNI 7182:2015 |

0.850 – 0.890 |

0.869 |

|

2 |

Acid value (KOH/g) |

ASTM D 664 |

max. 0.5 |

0.315 |

|

3 |

Free Fatty Acid value |

- |

max. 2 |

1.39 |

Based on the results of data

processing of GC-MS, Nannochloropsis

sp microalgae biodiesel using CaO/Hydrotalcite consisted of

toluene (61.49%area) and Octane (38.51%), as shown in Table 4. Toluene was a

hydrocarbon compound belonging to the olefin/alkenes group with a closed chain/aromatic

type. Several studies had shown that it had the molecular formula of C6H5CH3

and was a derivative of benzene compounds, namely methylbenzene. Meanwhile,

octane was a hydrocarbon compound with an open/aliphatic chain type in the

Alkane group. According to previous reports, it had the molecular formula of C8H18

was a compound belonging to the alkane group. Petroleum fractions were

classified based on the amount of carbon in the hydrocarbon bond chain where C4-C12

was included in gasoline, C10-C16 was kerosene, and C12-C22

was categorized as biodiesel. Olefins contained in biofuels were C7

hydrocarbons, and constituents were hydrocarbons with the number of carbon

chains C8 included in one of the gasoline, which had a range of

carbon numbers C4-C12 (Salam, Velasquez-Orta, and Harvey, 2016).

Transesterification process in the presence of CaO occurred through various steps. Protons (H+) were extracted from CH3OH at the CaO base site to form CH3O-. In triglyceride compounds, the carbon atom of the carbonyl functional group was attacked by CH3O- to produce the alkoxy carbonyl compound, which was rearranged into FAME (the desired product) and the diglyceride anion. Subsequently, the diglyceride anion attacked the calcium hydroxide cation to form diglyceride and CaO, leading to the recovery of catalyst. Based on the results and previous studies, CaO/Hydrotalcite catalyst was a solution to obtain catalyst system that combined the characteristics of a bimodal pore distribution and micropores. In addition, it provided basic sites and high surface density along with the presence of a suitable macro or mesopore network responsible for triglyceride transport. This allowed rapid access to the active site from the bulk reaction medium and removal of products (glycerol and FAME) from catalyst (Nisar et al., 2021). The reaction mechanism comprising the use of CaO is presented in Figure 4.

Figure 4 A chemical reaction

mechanism involving CaO

Table 4 Nannochloropsis sp microalgae biodiesel compounds using GC-MS analysis

|

No |

Compounds |

Retention Time |

%area |

|

1 |

Toluene |

2.876 |

61.49 |

|

2 |

Octane |

3.181 |

38.51 |

In conclusion, Nannochloropsis

sp microalgae was subjected to in situ extraction-transesterification with

methanol (solvent) and n-hexane (co-solvent) using CaO/Hydrotalcite catalyst.

The highest yield obtained was 38.36%, with an FFA content of 1.39% (250 rpm;

acid number 7.63 mg NaOH/g sample, and density 0.908 g/cm3). The

GC-MS analysis showed the presence of toluene-like olefin (61.49%) and

octane-like gasoline (38.51%)s group, showing the effectiveness of CaO/Hydrotalcite

catalyst in converting Nannochloropsis sp microalgae to biodiesel using in

situ stirring batch reactor transesterification.

The authors are grateful to the Ministry of Education, Culture, Research, and Technology for supporting

this study in the Regular Fundamental Research Project. The number of contract

was 183/E5/PG.02.00.PL/2023; 074/SP2H/PT/LL7/2023.

Aisyah, A.N., Ni’maturrohmah, D., Putra, R.,

Ichsan, S., Kadja, G.T.M., Lestari, W.W., 2023. Nickel Supported on MIL-96(Al)

as an Efficient Catalyst for Biodiesel and Green Diesel Production from Crude

Palm Oil. International Journal of Technology, Volume 14(2), pp. 276–289

Amusan,

O.O., Louis, H., Hamzat, A.T., Oyebanji, O.F., Alagbe, A.T., Magu, T.O., 2019.

Asian Journal of Nanoscience and Materials Synthesis and Characterization of

CaO Catalyst Obtained from Achatina Achatina and Its Application in Biodiesel

Production. Asian Journal of Nanoscience and Materials, Volume 2, pp. 271–277

Asri, N.P., Saraswati, R., Hindarso, H.,

Suprapto, Mirzayanti, Y.W., Yogaswara, R.R., 2021. Study of Catalyst Support

Utilization on Zno-Based Solid Catalyst to Its Activity at Transesterification of

Kesambi (Schleichera oleosa) Oil. IOP Conference Series: Materials Science

and Engineering, Volume 1034(1), p. 012059

Budianto, A., Pambudi, W.S., Sumari, S., Yulianto,

A., 2018. PID Control Design for Biofuel Furnace Using Arduino. Telkomnika

(Telecommunication Computing Electronics and Control), Volume 16(6), pp. 3016–3023

Cercado,

A.P.I., Ballesteros, F.C., Capareda, S.C., 2018.

Biodiesel From Three Microalgae Transesterification Processes Using Different

Homogenous Catalysts. International Journal of Technology, Volume 9(4), pp.

645–651

Culaba,

A.B., Ubando, A.T., Ching, P.M.L., Chen, W.H., Chang, J.S., 2020. Biofuel from

Microalgae: Sustainable Pathways. Sustainability, Volume 12(19), pp. 1–19

El-Sheekh,

M.M., 2021. Biodiesel from Microalgae: Advantages and Future Prospective. Egyptian

Journal of Botany, Volume 61(3), pp. 669–671

Ghedini, E., Taghavi,

S., Menegazzo, F., Signoretto, M., 2021. A

Review on The Efficient Catalysts for Algae Transesterification to Biodiesel. Sustainability,

Volume 13(18), p. 10479

Kanagesan,

K., Palanisamy, K.M., Maniam, G.P., Hasbi, M., Rahim, A., Govindan, N., 2020.

Biodiesel Production by Microalgae Nannochloropsis sp. Grown in Palm Oil Mill

Effluent. Maejo International Journal of Energy and Enviromental

Communication, Volume 2(3), pp. 21–26

Kazemifard,

S., Nayebzadeh, H., Saghatoleslami, N., Safakish, E., 2019. Application of

Magnetic Alumina-Ferric Oxide Nanocatalyst Supported by KOH for in-situ

Transesterification of Microalgae Cultivated in Wastewater Medium. Biomass

and Bioenergy, Volume 129, p. 105338

Koech, A.K.,

Kumar, A., Siagi, Z.O., 2020. In Situ Transesterification of Spirulina

Microalgae to Produce Biodiesel Using Microwave Irradiation. Journal of

Energy, Volume 2020, pp. 1–10

Larida,

A.Q., Bañaga, J.B., 2021. Extraction and Characterization of Algal Oil from

Lake Sebu, South Cotabato: A Potential Source of Biodiesel. Journal of

Science and Science Education, Volume 5(1), pp. 12–25

Lomeu, A.A.,

Mendonça, H.V.de, Mendes, M.F., 2023. Microalgae As Raw Material for Biodiesel

Production: Perspectives and Challenges of The Third Generation Chain. Engenharia

Agrícola, Volume 2023, p. 43

Ma, X.N.,

Chen, T.P., Yang, B., Liu, J., Chen, F., 2016. Lipid production from

Nannochloropsis. Marine Drugs, Volume 14(4). p. 61

Makareviciene, V., Sendzikiene, E., 2022.

Application of Microalgae Biomass for Biodiesel Fuel Production. Energies,

Volume 15(11), p. 4178

Manurung,

R., Parinduri, S.Z.D.M., Hasibuan, R., Tarigan, B.H., Siregar, A.G.A., 2023.

Synthesis of Nano-CaO Catalyst with SiO2 Matrix Based on Palm Shell ash

as Catalyst Support for One Cycle Developed in The Palm Biodiesel Process. Case

Studies in Chemical and Environmental Engineering, Volume 7, p. 100345

Marlinda,

L., Prajitno, D.H., Roesyadi, A., Gunardi, I., Mirzayanti, Y.W., Al-Muttaqii,

M., Budianto, A., 2022. Biofuel From

Hydrocracking of Cerbera Mangas Oil Over Ni-Zn/HZSM-5 Catalyst. Ecletica

Quimica, Volume 47(1), pp. 17–39

Medipally,

S.R., Yusoff, F.M., Banerjee, S., Shariff, M., 2015. Microalgae as Sustainable

Renewable Energy Feedstock for Biofuel Production. BioMed Research

International, Volume 2015, p. 519513

Mirzayanti, Y.W., Alisa, A., Sari, D., 2020a. Biodiesel Production from Rice Bran using a

Two-Stage In-Situ Method Using Sulfuric Acid and CaO/Hydrotalcite Catalysts. Jurnal

Rekayasa Mesin, Volume 11(3), pp. 375–382

Mirzayanti,

Y.W., Kurniawansyah, F., Prajitno, D.H., Roesyadi, A., 2020b. Selectivity of

Zinc-Molybdenum Catalyst to Produce Gasoil Via Catalytic Hydrocracking of

Kapook Seed Oil (Ceiba Pentandra). Journal of Physics: Conference Series,

Volume 1442, p. 012055

Mohamad, M.,

Ngadi, N., Wong, S., Yahya, N.Y., Inuwa, I.M., Lani, N.S., 2018. Synthesis and

Characterization of CaO-TiO2 for Transesterification of Vegetable Palm Oil. International

Journal of Engineering, Transactions B: Applications, Volume 31(8), pp. 1326–1333

Navajas, A.,

Campo, I., Moral, A., Echave, J., Sanz, O., Montes, M., Odriozola, J.A.,

Arzamendi, G., Gandía, L.M., 2018. Outstanding Performance of Rehydrated Mg-Al

Hydrotalcites as Heterogeneous Methanolysis Catalysts for The Synthesis of

Biodiesel. Fuel, Volume 211, pp. 173–181

Nisar, S.,

Hanif, M. A., Rashid, U., Hanif, A., Akhtar, M.N., Ngamcharussrivichai, C., 2021).

Trends in Widely Used Catalysts for Fatty Acid Methyl Esters (Fame) Production:

A Review. Catalysts, Volume 11(9), p. 1085

Purkan, P.,

Safa, A., Abdulloh, A., Baktir, A., Arissirajudin, R., Hermansyah, H., Kim,

S.W., 2021. In-Situ Biodiesel Synthesis from Microalgae Nannochloropsis Oculata

Using Nio Nanocatalyst. Rasayan Journal of Chemistry, Volume 14(3), pp. 2097–2103

Rahma, F.N., Hidayat, A., 2023. Biodiesel

Production from Free Fatty Acid using ZrO2/Bagasse Fly Ash Catalyst. International

Journal of Technology, Volume 14(1), pp. 206–218

Salam, K.A., Velasquez-Orta, S.B., Harvey, A.P., 2016. A Sustainable Integrated in Situ

Transesterification of Microalgae for Biodiesel Production and Associated

Co-products- A Review. Renewable and Sustainable Energy Reviews, Volume

65, pp. 1179–1198

Salam, K.A., Velasquez-Orta, S.B., Harvey, A.P., 2016. Surfactant-Assisted Direct

Biodiesel Production from Wet Nannochloropsis Occulata by in Situ

Transesterification/Reactive Extraction. Biofuel Research Journal, Volume

3(1), pp. 366–371

Sardi, B., Ningrum, R.F., Ardiansyah, V.A.,

Qadariyah, L., Mahfud, M., 2022. Production of Liquid Biofuels from Microalgae

Chlorella sp. via Catalytic Slow Pyrolysis. International Journal of

Technology, Volume 13(1), pp. 147–156

Shirazi, Y., Viamajala, S., Varanasi, S.,

2020. In situ and Ex situ Catalytic Pyrolysis of Microalgae and Integration with

Pyrolytic Fractionation. Frontiers in Chemistry, Volume 8

Tabatabaei, M., Aghbashlo, M., Dehhaghi, M.,

Panahi, H.K.S., Mollahosseini, A., Hosseini, M., Soufiyan, M.M., 2019. Reactor

Technologies for Biodiesel Production and Processing: A Review. Progress in

Energy and Combustion Science, Volume 74, pp. 239–303

Wahyono, Y., Hadiyanto, Budihardjo, M.A.,

Hariyono, Y., Baihaqi, R.A., 2022. Multifeedstock Biodiesel Production from a

Blend of Five Oils through Transesterification with Variation of Moles Ratio of

Oil: Methanol. International Journal of Technology, Volume 13(3), pp. 606–618

Win, T.T.,

Khine, M.M., 2017. Synthesis and Characterization of CaO and KF Doped CaO

(KF/CaO) Derived from Chicken Eggshell Waste as Heterogeneous Catalyst in

Biodiesel Production. Technology, and Sciences (ASRJETS) American Scientific

Research Journal for Engineering, Volume 38(2), pp. 134–151

Wood, D.A., 2021.

Microalgae to Biodiesel - Review of Recent Progress. Bioresource Technology

Reports, Volume 14, p. 10065

Zhang, C.Y.,

Shao, W.L., Zhou, W.X., Liu, Y., Han, Y.Y., Zheng, Y., Liu, Y.J., 2019.

Biodiesel Production by Esterification Reaction on K+ Modified

MgAl-Hydrotalcite Catalysts. Catalysts, Volume 9(9), p. 742

Zul, N.A., Ganesan, S., Hamidon, T.S., Oh, W.-Da,

Hussin, M.H., 2021. A Review on The Utilization of Calcium Oxide as a Base

Catalyst in Biodiesel Production. Journal of Environmental Chemical

Engineering, Volume 9(4), p. 105741