Effect of Coagulation Bath Composition on Cellulose-Based Polymer Electrolyte Fabricated via Non-Solvent-Induced Phase Separation Method

Corresponding email: adam.febriyanto04@ui.ac.id

Published at : 07 Dec 2023

Volume : IJtech

Vol 14, No 7 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i7.6677

Ratri, C.R., Aguta, T.B., Arundati, A.H., Rohib., Chalid, M., Astutiningsih, S., Nugraha, A.F., 2023. Effect of Coagulation Bath Composition on Cellulose-Based Polymer Electrolyte Fabricated via Non-Solvent-Induced Phase Separation Method. International Journal of Technology. Volume 14(7), pp. 1605-1614

| Christin Rina Ratri | 1. Green Polymer Technology Laboratory, Department of Metallurgical and Materials Engineering, Faculty of Engineering, Universitas Indonesia, Depok, Jawa Barat, 16424, Indonesia, 2. Research Center fo |

| Tegar Budi Aguta | Green Polymer Technology Laboratory, Department of Metallurgical and Materials Engineering, Faculty of Engineering, Universitas Indonesia, Depok, Jawa Barat, 16424, Indonesia |

| Annisaa Hayya Arundati | Graduate Institute of Ferrous and Energy Materials Technology, Pohang University of Science and Technology, Pohang 37673, Republic of Korea |

| Rohib Rohib | Institut De Recherches Sur La Catalyse Et L'environnement De Lyon, Umr 5256, Cnrs Avenue Albert Einstein, 69626, Lyon, France |

| Mochamad Chalid | Green Polymer Technology Laboratory, Department of Metallurgical and Materials Engineering, Faculty of Engineering, Universitas Indonesia, Depok, Jawa Barat, 16424, Indonesia |

| Sotya Astutiningsih | Green Polymer Technology Laboratory, Department of Metallurgical and Materials Engineering, Faculty of Engineering, Universitas Indonesia, Depok, Jawa Barat, 16424, Indonesia |

| Adam Febriyanto Nugraha | Green Polymer Technology Laboratory, Department of Metallurgical and Materials Engineering, Faculty of Engineering, Universitas Indonesia, Depok, Jawa Barat, 16424, Indonesia |

Cellulose acetate (CA) membrane was developed through

a non-solvent-induced phase separation (NIPS) technique to replace the

commercial petroleum-based Celgard separator membrane in Li-ion battery (LIB).

The morphology of a membrane can have a substantial impact on both its

mechanical and electrochemical properties, which are influenced by the

solvent-nonsolvent interaction. Therefore, this study examined the effect of

solvent fraction in an acetone-water system on the membrane morphology. CA

dissolved in acetone was cast on a glass plate and immersed in the coagulation

bath with varying acetone-water ratios. The resulting free-standing membrane

was analyzed subsequently and showed increased porosity, hydrophilicity, and

electrolyte uptake with higher acetone ratios in the coagulation bath. It was

also found that a more porous membrane contributes to a lower tensile strength,

including, 6.8 MPa, 5.5 MPa, 4.6 MPa, and 2.6 MPa for the coagulation baths

containing 0%, 25%, 50%, and 75% acetone, respectively. These results showed

that the mechanical properties of CA membranes are higher than those of

commercial Celgard membranes (1.42 MPa). LIB separator performance was measured

using electrochemical impedance spectroscopy (EIS). CA membrane fabricated with

50% acetone content in the coagulation bath possessed the highest ionic

conductivity, 4.79×10-4 S/cm, which is higher than the ionic

conductivity of the Celgard membrane (9.41×10-7 S/cm). Considering

their superior mechanical properties and electrical performance, CA membranes

could potentially substitute Celgard as a more sustainable alternative for LIB

separators.

Cellulose acetate; Coagulation bath; LIB separator; NIPS

The increasing demand for mobile devices and electric or hybrid vehicles has led to the widespread use of lithium-ion batteries (LIBs). Their popularity is attributed to outstanding energy density, substantial specific capacity, relatively low self-discharge rate, durability, and lightweight design (Tabani, Maghsoudi, and Fathollahi Zonouz, 2021). The important role of LIBs separators includes preventing short circuits between the electrodes and second, to absorb and optimize lithium-ion conductivity by absorbing and retaining electrolytes (Yang et al., 2022).

Polyolefin

separators, such as polyethylene (PE) and polypropylene (PP) membranes, are widely used due to their suitably sized pores, excellent mechanical

strength, and chemical stability (Setiaji et al., 2022; Razalli et al., 2015). However,

their primary disadvantage is insufficient liquid electrolyte capacity and the

inability to absorb high-dielectric-constant electrolytes on their hydrophobic

surfaces (Xu et al.,

2017).

To address these challenges, biodegradable

battery separators, made from renewable natural-resource-based polymers, are

being developed as a sustainable, non-toxic, and biodegradable alternative to

petroleum-based membranes. Among these

solutions, cellulose acetate (CA) is a promising host

polymer for LIBs separators (Febriasari et al., 2021). Subsequently,

CA polymers, characterized by carbonyl and hydroxyl groups, exhibit a strong

affinity for electrolytes and superior compatibility with electrodes. CA's

versatility extends to film formation and efficient electrical insulation,

rendering it well-suited for use as a matrix in LIBs (Li et al., 2017).

Polymeric

membranes can be produced in various ways including

nonsolvent-induced phase separation (NIPS), thermally induced phase separation

(TIPS), melt extrusion, electrospinning, and track etching (Rochardjo et al., 2021). The easy

processing and high reliability of NIPS membranes make them attractive choices.

As a widely used method for fabricating membranes made from polymers, NIPS has

several advantages over other methods. Subsequently,

with

NIPS, this approach facilitates fine control and generates small, evenly

distributed micropores (Choi, Ingole, and Park, 2022). Furthermore, this method

is superior to alternative methods, such as dry spinning and hot drawing, in

terms of achieving appropriate tensile strength, biaxial strength, and puncture

resistance (Kahrs and

Schwellenbach, 2020; Li et al., 2017). In

the NIPS process, the polymer and solvent are homogeneously dissolved, poured

onto a glass plate, and submerged in a nonsolvent bath (Li et al., 2008). After

phase separation and removal of residual

solvent, the nonsolvent must have a high affinity for the solvent but not for

the polymer (Wang et al.,

2019).

Previous NIPS studies used

various approaches to fabricate porous membranes, such as changing the

composition of the coagulation bath (Thankamony et al., 2018). The

properties and morphology of membranes are significantly influenced by the bath

composition during immersion in the coagulation bath (Pagliero et al., 2020). The porous

membrane structure was affected by the solvent fraction in the coagulation bath

(Asghar et al. 2018). The results

showed that increasing the solvent concentration in the coagulation bath

increased membrane crystallinity (Jung et al., 2016).

This

study specifically focuses on the preparation of CA membranes

using the NIPS method. There is a gap in study

addressing the contribution of solvent fractions in acetone-water systems to

the effectiveness of CA-based membranes as LIB separators. In the NIPS

method, the solvent amount in the coagulation bath plays a crucial

role in the demixing process, influencing pore formation and potentially

affecting the electrochemical performance of the membrane. Using a

facile approach, a porous CA membrane with superior ionic conductivity was successfully produced for use as a lithium-ion battery separator.

To prepare the separators through NIPS, CA (Mn =

30,000) was dissolved in acetone until homogeneous. The

dissolution process occurred at room temperature, using a vial and a magnetic

stirrer

(IKA C-MAG HS 7) to maintain constant stirring. After achieving homogeneity, the solution was set aside for a period to

eliminate any gas bubbles and was subsequently placed on a glass plate

at room temperature.

A 15-minute evaporation process was used

to partially evaporate the polymer solution. Subsequently, the glass plate was

placed in a room-temperature water coagulation bath for 15 min and the membrane

was peeled off slowly. Three variations of porous membranes were prepared, each

based on the solvent fraction used in the coagulation bath, as shown in Table 1. The membrane was dried on

sandwich-like filter paper using a vacuum desiccator for further analysis. An overview

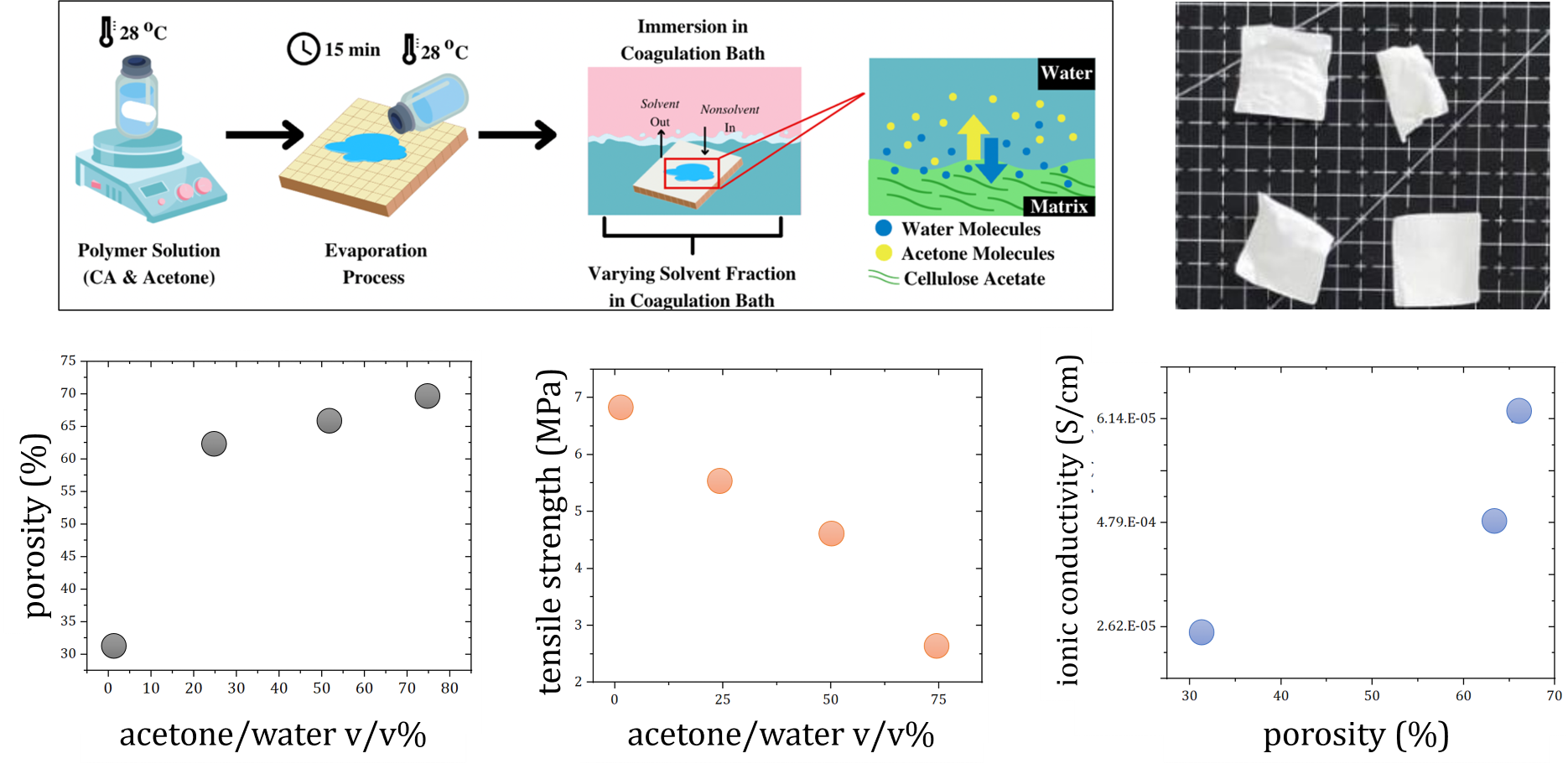

of the NIPS procedure is shown in Figure 1.

Table 1 Sample

specification for the membrane fabrication

|

Sample code |

Water/acetone (v/v) |

|

A0W100 |

100/0 |

|

A25W75 |

75/25 |

|

A50W50 |

50/50 |

|

A75W25 |

25/75 |

Figure 1 Overview

process of the NIPS method

2.2. Cellulose Acetate

Membrane Characterization

Fourier

transform infrared (FTIR, Thermo Scientific iS-10 Spectra) spectroscopy was

used to evaluate the functional groups of CA membrane at

4000–400 cm-1 absorbance under ambient conditions.

To evaluate thermal stability, changes in membrane dimensions were

calculated.

Approximately 2 cm diameter pieces were cut from the samples. After a 2-hour

storage at 90°C, the membrane was examined for heat-induced shrinkage caused by

heat. Based on Equation (1), the shrinkage was calculated (Liang et al., 2018):

where So is the membrane surface

area before heating and S is the membrane surface area after heating.

The contact

angle was determined using the sessile

drop method, using wet agents such as water, ethylene glycol, and

an electrolyte (0.67 M LiClO4). Using a desiccator vacuum overnight,

residual humidity was removed from the membrane before the wettability test.

After dropping the electrolyte solution for 3 and 30 s, the contact angles were

measured.

To measure separator porosity (P), a gravimetric method based on n-butanol absorption was used. Each sample measured approximately 2 cm in diameter. Equation (2) was used to calculate the porosity of the separator (Cui et al., 2017).

where P is the separator porosity, the mass

of the separator at the start is Mi; the mass after an hour of

n-butanol soaking is Mn, the density of n-butanol is (0.81 g/cm3), the separator surface area is s, and its thickness is

d.

The surface and

cross-section of the separator were observed using a

scanning electron microscope (SEM, Hitachi SU3500, Tokyo, Japan) with an

acceleration voltage of 10 kV. After analyzing the surface images, the ImageJ

software was used to determine the pore sizes.

The tensile

properties of the membranes were determined using a universal testing machine

(UTM, Shimadzu AGS-X Series 5 kN) in accordance with ASTM D1708.

The test was conducted under ambient conditions at a

speed of 0.25 mm/min.

A gravimetric measurement of membrane electrolyte uptake was conducted by weighing the membranes before and after soaking in 0.67 M LiClO4 for 2 h. Electrolyte uptake was measured following Equation (3).

where W1 shows the separator

weight before and W2 shows the weight after electrolyte soaking. The

mean and standard deviation were calculated from three measurements.

Electrochemical

impedance spectroscopy (EIS, Metrohm Autolab, Potentiostat Mode) was performed

at frequencies ranging from 1 Hz to 1 MHz to quantify the membrane ionic

conductivity between the stainless-steel electrodes. Cell assembly started with

the membranes being soaked in 0.67 M LiClO4 electrolyte solution for

two hours before assembly. Coin cells (CR2032) were assembled using a separator

and blocking electrodes. Equation (4) was used to calculate the ionic

conductivity, (Luiso

et al., 2021).

where t is the membrane thickness, Rb is the bulk resistance, and A is the contact area between the separator and electrodes.

The

coagulation process plays a crucial role in the formation of hollow membranes,

influenced by both thermodynamics and kinetics. Membrane

morphology is impacted by factors such as polymer-solvent interactions,

solution viscosity, and solvent diffusivity. Typically, water serves as the most common nonsolvent. The addition

of a solvent can delay instant demixing by lowering polymer concentration and

decreasing nonsolvent activity. This delay in liquid-liquid demixing is the

predominant effect, as this method is used to produce dense membranes (Cui et al., 2017).

The

identification of functional groups in CA membrane was based on FTIR spectra,

analyzing the location and intensity of spectral peaks. In Figure 2, the FTIR spectrum of CA

membrane shows two characteristic peaks at wavelengths of 1730 and 1220

cm-1, corresponding to the C=O and C–O–C functional groups,

respectively (Ramesh, Shanti, and Morris, 2013).

The stretching vibration of hydroxyl group O-H was denoted by the peak at 3497

cm-1, and methyl group C-H stretching at 2945 cm-1 (Sudiarti et al., 2017), confirming the formation of true CA. Figure 2

shows the FT-IR spectra of CA in the powder and membrane forms.

Figure 2 FT-IR spectra of

cellulose acetate powder and membrane form

Porosity is a crucial factor

for separators because it impedes the penetration of active components and

prevents dendritic Li penetration (Ngamaroonchote

and Chotsuwan 2016). The membrane obtained using the NIPS process

exhibited a more porous structure compared to the solution casting method. This

is showed by the SEM results shown in Figure 3.

Figure 3 SEM micrograph of (top row) surface and (bottom row) cross-sectional

morphology of (a) Celgard and cellulose acetate membrane obtained with (b) NIPS

and (c) solution casting

The observation in Figure 4 shows that an increase in acetone content in the coagulation bath leads to higher porosity in CA separator. This effect is attributed to the higher acetone concentration reducing the solubility difference between the solvent and nonsolvent. This reduction promotes demixing during the coagulation process, ultimately yielding a membrane with increased porosity.

Figure 4 Influence of solvent fraction on porosity of the membrane

In LIB, specifically those

with high power and energy, dimensional stability is crucial for separators.

The separator should not shrink or wrinkle significantly when the temperature increases

and it should minimize the thermal shrinkage during drying. As shown in Figure

5, the Thermal Shrinkage Ratio (TSR) for each composition of the coagulation

bath was less than 5%. This satisfies the dimensional stability requirements of

battery separator applications.

Figure

5 Influence of (a) solvent fraction and (b)

porosity to thermal shrinkage ratio

Membrane hydrophilicity plays

a significant role in interfacial interactions and can be modified by adjusting

the phase-inversion process conditions. Valuable information is obtained by

measuring the contact angle between the wetting agent and the membrane surface (Song, Birbach, and Hinestroza, 2012). The results

are shown in Figure 6. Increasing hydrophilicity was also observed with higher

acetone composition in the coagulation bath, and this is attributed to the

increasing miscibility, which accelerates the precipitation process and

promotes pore formation (Silva, Belmonte-Reche and

Amorim, 2021).

Figure 6 Influence of (a) solvent

fraction and (b) porosity to the membrane wettability

Figure 7 shows the influence of the solvent

fraction and porosity on the membrane tensile strength. These results show that

the tensile strength of CA membrane decreased with increasing acetone content

in the coagulation bath. This is in accordance with the literature, as an

increase in the composition of acetone causes an increase in porosity, and

negatively affects the tensile strength of the membrane (Kartha and Mallik, 2020; Zhao et al., 2008). The tensile strength of the

Celgard membrane was measured at 1.42 MPa. All the fabricated CA separator membranes had a tensile strength that

exceeded that of a conventional Celgard separator membrane.

Figure 7 Influence of (a) solvent

fraction and (b) porosity to the tensile strength

Figure

8

Influence of (a) solvent fraction and (b) porosity to the electrolyte uptake

As shown in

Figure 8, a higher acetone ratio in the coagulation bath resulted in a higher

electrolyte uptake. This is caused by higher absorption of the electrolyte in

the membrane. It is important to note that electrolyte uptake increases

linearly, while the porosity increases logarithmically (Shi et al., 2015). An excellent ionic conductivity is required for

the separator because it controls ions passing between the positive and

negative terminals (Arrieta, Barrera, and Mendoza,

2022). Subsequently, EIS measurements were performed by applying a

frequency within a certain range, resulting in real and imaginary impedances

presented in the Nyquist plot (Figure 9). The calculated ionic conductivities

are listed in Table 2.

Figure

9

(a) Nyquist plot of cellulose acetate membranes and (b) influence of porosity

on ionic conductivity

Table

2

Ionic conductivities () of

cellulose acetate and conventional Celgard membrane

The ionic conductivity

calculation shows that a higher acetone composition in CA-based membrane leads

to higher ionic conductivity compared to using water only as a non-solvent.

Additionally, the results of all CA-based solid polymer electrolyte membranes show

better performance than that of Celgard.

In conclusion, CA separator membrane was

successfully fabricated using the NIPS method with acetone as the solvent and

water as the nonsolvent. Higher acetone composition

in the coagulation bath facilitated faster phase

separation, potentially leading

to larger

pores, higher electrolyte absorption, lower tensile

strength, and lower thermal shrinkage. Increased

acetone content also correlated with higher ionic conductivity. The contact

angle between CA membrane and water and ethylene glycol decreased with

increasing acetone content in the coagulation bath. The wetting ability of the

membrane electrolyte increased because of increased membrane porosity. CA-based

membranes have shown better mechanical and

electrical properties than commercial Celgard membranes. The tensile strength

of the pure CA membrane was 6.8 MPa while that of Celgard was 1.42 MPa. The

ionic conductivity of the CA membrane with 50% acetone content was 4.79×10-4

S/cm while that of Celgard was 9.41×10-7 S/cm. These results showed

that CA has potential as a viable alternative to replace polyolefin separators.

The

authors express

profound gratitude to

the Integrated Laboratory of Advanced Materials Characterization, National

Research and Innovation Agency of Indonesia (BRIN), and the Material Research

Center, Universitas Indonesia, for the laboratory and materials

characterization facility. Special appreciation to the Indonesia Endowment Fund for Education (LPDP) for providing

financial support in the PhD program (awardee number 202112210108100).

Arrieta,

A., Barrera, I., Mendoza, J., 2022. Impedantiometric Behavior of Solid

Biopolymer Electrolyte Elaborated from Cassava Starch Synthesized in Different

pH. International Journal of Technology, Volume 13(4), pp. 912–920

Asghar,

M.R., Zhang, Y., Wu, A., Yan, X., Shen, S., Ke, C., Zhang, J., 2018.

Preparation of Microporous Cellulose/Poly (Vinylidene

Fluoride-Hexafluoropropylene) Membrane for Lithium Ion Batteries by Phase

Inversion Method. Journal of Power Sources, Volume 379, pp. 197–205

Choi,

O., Ingole, P.G., Park, C.H., 2022. Precision-Aiming Tuning of Membranes

Prepared by NIPS And Its Performance Enhancement. Journal of Cleaner

Production, Volume 365, p. 132858

Cui, J.,

Liu, J., He, C., Li, J., Wu, X., 2017. Composite of Polyvinylidene

Fluoride–Cellulose Acetate with Al(OH)3 as a Separator For

High-Performance Lithium Ion Battery. Journal of Membrane Science,

Volume 541, pp. 661–667

Febriasari,

A., Suhartini, M., Yunus, A.L., Rahmawati, R., Sudirman, S., Hotimah, B., Hermana,

R.F., Kartohardjono, S., Fahira, A. and Permatasari, I.P., 2021. Gamma

Irradiation of Cellulose Acetate-Polyethylene Glycol 400 Composite Membrane and

Its Performance Test for Gas Separation. International Journal of Technology,

Volume 12(6), pp. 1198–1206

Jung,

J.T., Kim, J.F., Wang, H.H., Di-Nicolo, E., Drioli, E., Lee, Y.M., 2016.

Understanding The Non-Solvent Induced Phase Separation (NIPS) Effect During the

Fabrication of Microporous PVDF Membranes via Thermally Induced Phase

Separation (TIPS). Journal of Membrane Science, Volume 514, pp. 250–263

Kahrs,

C., Schwellenbach, J., 2020. Membrane Formation via Non-Solvent Induced Phase

Separation using Sustainable Solvents: A Comparative Study. Polymer,

Volume 186, p. 122071

Kartha, T.R., Mallik, B.S., 2020. Revisiting LiClO4 as an Electrolyte for Li-ion

Battery: Effect of Aggregation Behavior on Ion-Pairing Dynamics and

Conductance. Journal of Molecular Liquids, Volume 302, p. 112536

Li, L.,

Yu, M., Jia, C., Liu, J., Lv, Y., Liu, Y., Zhou, Y., Liu, C., Shao, Z., 2017.

Cellulosic Biomass-Reinforced Polyvinylidene Fluoride Separators with Enhanced

Dielectric Properties and Thermal Tolerance. ACS Applied Materials and

Interfaces, Volume 9(24), pp. 20885–20894

Li,

Z.H., Zhang, H.P., Zhang, P., Li, G.C., Wu, Y.P., Zhou, X.D., 2008. Effects of

the Porous Structure on Conductivity of Nanocomposite Polymer Electrolyte for

Lithium Ion Batteries. Journal of Membrane Science, Volume 322(2), pp.

416–422

Liang,

S., Yan, W., Wu, X., Zhang, Y., Zhu, Y., Wang, H., Wu, Y., 2018. Gel Polymer

Electrolytes for Lithium Ion Batteries: Fabrication, Characterization and

Performance. Solid State Ionics, Volume 318, pp. 2–18

Luiso,

S., Williams, A.H., Petrecca, M.J., Roh, S., Velev, O.D. Fedkiw, P.S., 2021.

Poly(Vinylidene Difluoride) Soft Dendritic Colloids as Li-Ion Battery

Separators. Journal of The Electrochemical Society, Volume 168(2), p.

020517

Ngamaroonchote,

A., Chotsuwan, C., 2016. Performance and Reliability of Cellulose Acetate-Based

Gel Electrolyte for Electrochromic Devices. Journal of Applied

Electrochemistry, Volume 46(5), pp. 575–582

Pagliero,

M., Bottino, A., Comite, A., Costa, C., 2020. Novel Hydrophobic PVDF Membranes

Prepared by Nonsolvent Induced Phase Separation for Membrane Distillation. Journal

of Membrane Science, Volume 596, p. 117575

Ramesh,

S., Shanti, R., Morris, E., 2013. Characterization of Conducting Cellulose

Acetate Based Polymer Electrolytes Doped With “Green” Ionic Mixture. Carbohydrate

Polymers, Volume 91(1), pp. 14–21

Razalli,

S.M.M., Saaid, S.I.Y.S.M., Ali, A.M.M., Hassan, O.H., Yahya, M.Z.A., 2015.

Cellulose Acetate-Lithium Bis (Trifluoromethanesulfonyl) Imide Solid Polymer

Electrolyte: ATR-FTIR And Ionic Conductivity Behavior. Functional Materials

Letters, Volume 8(3), p. 1540017

Rochardjo,

H.S.B., Fatkhurrohman, Kusumaatmaja, A., Yudhanto, F., 2021. Fabrication of

Nanofiltration Membrane based on Polyvinyl Alcohol Nanofibers Reinforced with

Cellulose Nanocrystal using Electrospinning Techniques. International

Journal of Technology, Volume 12(2), pp. 329–338

Setiaji,

D.A., Chalid, M., Abuzairi, T., Efroza, M., Nugraha, A.F., 2022. Effect of Cold

Plasma Treatment on Physical Properties of Multilayer Plastics for Polymer

Asphalt Applications. Piston: Journal of Technical Engineering, Volume

6(1), pp. 1–14

Shi, J.,

Xia, Y., Yuan, Z., Hu, H., Li, X., Zhang, H., Liu, Z., 2015. Porous Membrane

with High Curvature, Three-Dimensional Heat-Resistance Skeleton: A New and

Practical Separator Candidate for High Safety Lithium Ion Battery. Scientific

Reports, Volume 5(1), pp. 1–9

Silva,

M.A., Belmonte-Reche, E., Amorim, M.T.P.De., 2021. Morphology and Water Flux of

Produced Cellulose Acetate Membranes Reinforced by The Design of Experiments

(DOE). Carbohydrate Polymers, Volume 254, p. 117407

Song,

J., Birbach, N.L., Hinestroza, J.P., 2012. Deposition of Silver Nanoparticles

on Cellulosic Fibers via Stabilization of Carboxymethyl Groups. Cellulose,

Volume 19(2), pp. 411–424

Sudiarti,

T., Wahyuningrum, D., Bundjali, B., Arcana, I.M., 2017. Mechanical Strength and

Ionic Conductivity of Polymer Electrolyte Membranes Prepared from Cellulose

Acetate-Lithium Perchlorate. In: IOP Conference Series: Materials

Science and Engineering, Volume 223(1), p. 012052

Tabani,

Z., Maghsoudi, H., Fathollahi-Zonouz, A., 2021. High Electrochemical Stability

of Polyvinylidene Fluoride (PVDF) Porous Membranes Using Phase Inversion

Methods For Lithium-Ion Batteries. Journal of Solid State Electrochemistry,

Volume 25(2), pp. 651–657

Thankamony,

R.L., Li, X., Fan, X., Sheng, G., Wang, X., Sun, S., Zhang, X., Lai, Z., 2018.

Preparation of Highly Porous Polymer Membranes with Hierarchical Porous

Structures via Spinodal Decomposition of Mixed Solvents with UCST Phase

Behavior. ACS Applied Materials and Interfaces, Volume 10(50), pp.

44041–44049

Wang,

H.H., Jung, J.T., Kim, J.F., Kim, S., Drioli, E., Lee, Y.M., 2019. A Novel

Green Solvent Alternative for Polymeric Membrane Preparation via

Nonsolvent-Induced Phase Separation (NIPS). Journal of Membrane Science,

Volume 574, pp. 44–54

Xu, R.,

Huang, X., Lin, X., Cao, J., Yang, J., Lei, C., 2017. The Functional Aqueous

Slurry Coated Separator Using Polyvinylidene Fluoride Powder Particles for

Lithium-Ion Batteries. Journal of Electroanalytical Chemistry, Volume

786, pp. 77–85

Yang, B., Yang, Y., Xu, X., Ke, Y., Pan, Y., Su, L., Wang, Y., Wang, S., Qian, J., Xia, R., Fu, E., 2022. Hierarchical Microstructure and Performance Of PVDF/PMMA/SiO2lithium Battery Separator Fabricated by Thermally-Induced Phase Separation (TIPS). Journal of Materials Science, Volume 57(24), pp. 11274–11288

Zhao, H., Jiang, C., He, X., Ren, J., Wan, C., 2008. Preparation of Micro-Porous Membrane Electrodes and Their Application in Preparing Anodes of Rechargeable Lithium Batteries. Journal of Membrane Science, Volume 310(1–2), pp. 1–6