Effectiveness Analysis of Insulation and Roof Covering Material in Office Flat Roof

Corresponding email: rossyarmyn@eng.ui.ac.id

Published at : 07 Dec 2023

Volume : IJtech

Vol 14, No 7 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i7.6665

Machfudiyanto, R.A., Riantini, L.S., Rachmawati, T.S.N., Rarasati, A.D., Rachman, M.D.A., 2023. Effectiveness Analysis of Insulation and Roof Covering Material in Office Flat Roof. International Journal of Technology. Volume 14(7), pp. 1487-1495

| Rossy Armyn Machfudiyanto | Department of Civil and Environmental Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok 16424, Indonesia |

| Leni Sagita Riantini | Department of Civil and Environmental Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok 16424, Indonesia |

| Titi Sari Nurul Rachmawati | Department of Architectural Engineering, Kyung Hee University, Yongin-si 17104, Korea |

| Ayomi Dita Rarasati | Department of Civil and Environmental Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok 16424, Indonesia |

| Mochamad Daffa Alfiansyah Rachman | Department of Civil and Environmental Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok 16424, Indonesia |

Wasteful consumption of electricity in

high-rise building in Indonesia is the primary trigger for the increase in

carbon emissions. Predominantly, the excessive use of electrical appliances and

air conditioning systems is the principal factor contributing to the use of

energy within these structures. To effectively address this issue, the

importance lies in adopting suitable building envelope material. Therefore,

this study aimed to analyze the effectiveness of different insulation types and

roof covering in improving the energy-saving performance of office building.

There were six proposed renovation for the flat roof of building, consisting of

two approaches, namely (1) the incorporation of insulation and (2) the

replacement of roof covering layers. Scenarios A1, A2, and A3 have incorporated

100 mm of polyurethane (PU) foam, polyisocyanurate (PI) foam, and fiberglass

batt into the design. Meanwhile, Scenarios B1, B2, and B3 opted for ceramic

material, Ethylene Propylene Diene Terpolymer (EPDM) membrane, and grass vegetation

as roofing material for the existing roof. The results showed that the addition

of insulation to roof through Insight 360 and the replacement of roof covering

layers produced an energy reduction of 19.5% to 20.2% and 19.5% and 23.5%,

respectively. The implementation of green roof in scenario B3 was selected as

the most promising renovation option, achieving a remarkable 23.5% reduction in

energy consumption.

Covering Layers; Energy Usage; Flat Roof; Insulation Layers

High-rise

building in Indonesia is contributing to an increase in carbon gas emissions.

The increase in carbon gas emissions is caused by the extensive operations of

conventional power plants, required to meet the high electricity demands of building.

Among the various types of high-rise building, office is object with the

highest energy consumption. In 2020, Energy Use Intensity (EUI) of 213.27

kWh/m2/year was produced (B2TKE-BPPT, 2020).

The major factor behind the electricity demand is the excessive use of air

conditioning to maintain indoor thermal comfort, regardless of the weather (Hakim et al., 2021). Therefore, providing

warm and cool rooms during rainy and dry seasons can reduce excessive reliance

on air conditioning and energy use.

The presence of a fit building envelope can prevent rapid heat

transfer, effectively regulating indoor thermal comfort. Building envelope

includes the outermost layer of architectural elements, namely

walls, roof, basement, doors, windows, and other external element that

withstands the surrounding environment (Bachrun, Ming, and Cinthya, 2019). Roof is one of the most essential envelope

components for maintaining the quality of indoor thermal comfort and reducing

the energy consumption of building. The study by (Feng et al., 2020) showed that the installation of insulation material on roof

reduced energy consumption by up to 78%. Furthermore, (Ibrahim et al., 2018) proved that a roof design with

ventilation effectively mitigated overheating. Building designers commonly use

various roof insulation material, including polyurethane (PU) foam,

polyisocyanurate (PI) foam, and fiberglass batts. Even with the comparable attributes,

PU foam is distinguished by its low thermal conductivity and density (Gama, Ferreira, and Timmons, 2018), while PI shows reduced thermal conductivity

under low-temperature conditions (Makaveckas,

Bliudzius, and Burlingis, 2021). Meanwhile, fiberglass batts are good in insulation performance

due to the higher R-value.

The type of

covering material used for roof affects its ability to absorb or reflect heat.

The study by (Algarni, Almutairi, and Alqahtani, 2022) showed that green roof with

shallow-rooted grass lowered energy usage by 3.6% in six months (Shaharuddin, Khalil, and Saleh, 2019). Apart from the use of green roof, ceramic tiles and Ethylene

Propylene Diene Terpolymer (EPDM) membranes can also serve as roofing material.

(Sedaghat et al., 2023) showed that these tiles were capable of reflecting solar radiation

by up to 50%, resulting in energy savings for building. EPDM membranes also

show commendable reflective qualities, particularly when white in color.

Therefore, the incorporation of suitable insulation material and roof covering

can help anticipate an increase in electricity consumption due to rapid heat

transfer.

Insulating

and using covering material must be adapted to the geometric shape of an office

building. In this context, flat roof represents the most prevalent geometric

configuration found in office building, satisfying the functional requirements

of HVAC system components. Prior study substantiated the effectiveness of using

insulation and covering material on flat roof. The comparison between roof

insulation usage and the addition of covering layers has not been addressed.

Therefore, this study aims to analyze the effectiveness of different insulation

types and roof covering in improving the energy-saving performance of office

building. Building designers should be assisted in selecting the most effective

flat roof renovation options to minimize energy usage.

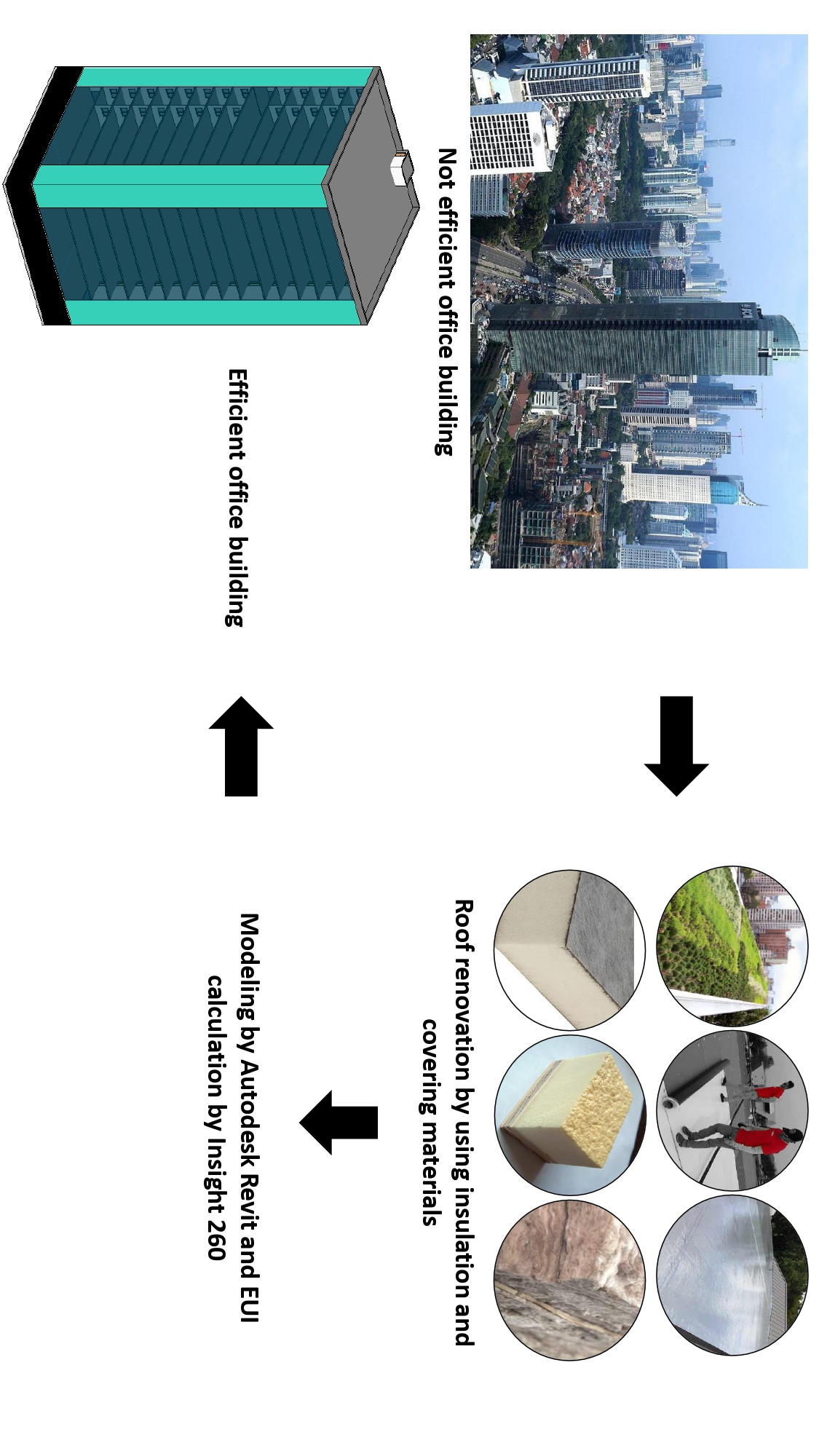

In this section, a description of the study process is provided

and the flow of each stage is shown in Figure 1. This study used

a design model in which the dimensions and location of the selected design were

determined based on the latest government data on building energy consumption

Figure 1 Study methods workflow

Table 1 Summary of material types

and thickness for initial design

|

Envelope

Component |

Material

selection |

Thickness |

|

Basement

Exterior Wall |

Concrete,

Cast-in-place |

150 mm |

|

Sand/cement

screed |

20 mm | |

|

Exterior

Insulation |

100 mm | |

|

Plaster |

12.5 mm | |

|

Façade Wall |

Concrete,

Precast |

100 mm |

|

Sand/cement

screed |

20 mm | |

|

Rigid

insulation |

50 mm | |

|

Gypsum

wallboard |

12 mm | |

|

Plaster |

12.5 mm | |

|

Curtain Wall |

Aluminium

frame |

50 mm |

|

|

Triple

glazing Low-e glass |

30 mm |

Table 1 Summary of material and

thickness for initial design [Cont.]

|

Envelope Component |

Material

selection |

Thickness |

|

Floors |

Concrete,

Cast-in-place |

100 mm |

|

Sand/cement

screed |

20 mm | |

|

Plaster |

12 mm | |

|

Carpet tile |

10 mm | |

|

Ceiling |

Metal stud

layer |

45 mm |

|

Rigid

insulation |

50 mm | |

|

Gypsum

wallboard |

12 mm | |

|

Roof |

Concrete, Cast-in-place |

150 mm |

|

Sand/cement

screed |

50 mm | |

|

Vapor

retarder |

membrane | |

|

Roofing felt |

4 mm |

The initial

building design was created using Autodesk Revit and default settings. The

default settings are inherently consistent with ASHRAE standards, obviating the

necessity for system adjustments, as explained in Table 2. Following the

completion of the initial building design, the initial EUI analysis was

conducted using Insight 360. The energy analysis used an equation created based

on the DOE 2.2 engine program, where the initial EUI calculations were compared

to the six renovation scenarios.

Table 2 Summary of space type distribution for each

room

|

Room name |

Space type |

Criteria |

|

Lobby |

Lobby -

Office |

6 Am to 11 PM

operating schedule |

|

Heating set

point: 21.11oC | ||

|

Cooling set

point: 23.89oC | ||

|

Lighting

load: 13.99 W/m2 | ||

|

Power load:

5.81 W/m2 | ||

|

Canteen;

Meeting room |

Office

Enclosed; Dining Area |

6 Am to 11 PM

operating schedule |

|

Heating set

point: 21.11oC | ||

|

Cooling set

point: 23.89oC | ||

|

Lighting

load: 10 W/m2 | ||

|

Power load:

5.81 W/m2 | ||

|

Praying room |

Religious

Building |

Retail

lighting operating schedule |

|

Heating set

point: 21.11oC | ||

|

Cooling set

point: 23.89oC | ||

|

Lighting

load: 13.99 W/m2 | ||

|

Power load:

5.81 W/m2 | ||

|

Working area |

Office - Open

plan |

6 Am to 11 PM

operating schedule |

|

Heating set

point: 21.11oC | ||

|

Cooling set

point: 23.89oC | ||

|

Lighting

load: 11.84 W/m2 | ||

|

Power load:

16.15 W/m2 | ||

|

Toilet |

Dressing/Locker/Fitting

room |

6 Am to 11 PM

operating schedule |

|

Heating set

point: 21.11oC | ||

|

Cooling set

point: 23.89oC | ||

|

Lighting

load: 6.03 W/m2 | ||

|

Power load:

5.81 W/m2 |

The two categories of renovation implemented in this study are 1) the incorporation of 100 mm-thick roof insulation and 2) the

adoption of novel roofing material. The first type of renovation introduced PU

foam, PI foam, and fiberglass batt materials onto roof, denoted as Scenarios

A1, A2, and A3, respectively. The selection of these three materials was

informed by the existence of prior studies discussing the characteristics, as

shown in the Introduction section. Furthermore, the second renovation category

comprised the use of glossy ceramic, EPDM membrane, and vegetation layers,

identified as Scenarios B1, B2, and B3. The vegetation layer included a

waterproof to prevent seepage into the concrete, soil serving as a growth

medium, and a layer of grass and rocks as the topmost cover. These three

roofing materials were selected for the capacity to create a cool roof environment by reflecting or

absorbing sunlight, which cools the space beneath. Finally, the most preferable renovation scenario for diminishing EUI

value is shown in the conclusion.

This section shows the outcomes derived from the calculations conducted through Insight 360. Subsequently, a comprehensive discussion will be provided, delving into the comparative analysis among the various scenarios. Building design model is shown in Figure 2, where the colors do not influence the energy analysis results. In Figure 2, the basement and roof floors are black and gray, respectively.

Figure 2 Building design model using Autodesk Revit:

basement (black) and roof (gray)

Energy analysis conducted using Insight 360

showed that the initial EUI value for the designed building was 272 kWh/m2/year.

According to the government data

Table 3 EUI calculation results for each

renovation scenario

|

Scenario id |

Criteria |

Initial EUI

value (kWh/m2/year) |

Final EUI

value (kWh/m2/year) |

% Reduction |

|

A1 |

Insulating PU

foam |

272 |

219 |

19.49 |

|

A2 |

Insulating PI

foam |

272 |

217 |

20.22 |

|

A3 |

Insulating

fiberglass batt |

272 |

217 |

20.22 |

|

B1 |

Using glossy

ceramic |

272 |

219 |

19.49 |

|

B2 |

Using EPDM membrane |

272 |

218 |

19.85 |

|

B3 |

Implementing

green roof |

272 |

208 |

23.53 |

Previous

studies showed that EUI calculation was influenced by the heat transfer

capability of building envelope material. The capability can be measured using

thermal coefficient commonly referred to as U-value (W/m2. K). Based

on the basic formula, U-value is affected by thermal conductivity () and

material thickness. Table 4 presents

values of each material used in

Scenarios A and B, with the corresponding U-value and roof thicknesses after

the renovation. Roof thickness in Scenario A remains consistent using the same

insulation thickness, specifically 100 mm. Meanwhile, Scenario B shows

variations in roof thickness due to adjustments made to accommodate the

dimensions of each type of roof covering.

Table 4 Summary of U-value for each material used

|

Thickness (mm) |

U-value (W/m2.K) | |

|

PU foam |

0.032 |

204 |

0.2955 |

|

PI foam |

0.02 |

204 |

0.1902 |

|

Fiberglass |

0.019 |

204 |

0.1811 |

|

Glossy ceramic |

0.84 |

238 |

3.748 |

|

EPDM membrane |

0.138 |

278 |

1.6202 |

|

Green roof |

- |

251 |

0.4694 |

As

presented in Table 4, Scenario A reported lower U-value compared to Scenario B.

U-value increases with higher , even though Scenario A had the same roof

thickness. The results were consistent with the theory that an increase in

U-value was directly proportional to

but inversely related to material

thickness. Despite a lower

value and thicker layer compared to green roof,

the calculation showed that green roof U-value was lower than EPDM membrane.

This contradicts existing theories, suggesting the presence of other factors

influencing U-value of material.

The drainage and substrate layers act as heat

absorbers while simultaneously providing a cooling effect on roof area of

building. This phenomenon occurs because the substrate and drainage layers

consist of organic material with high emissivity values, facilitating an

extremely efficient heat transfer circulation. According to (Yildirim, Ozburak, and Ozden, 2023) and (Wang , Huang, and Li, 2021), green roof

possesses the capability to provide a cooling effect on building roof through

effective heat transfer circulation. A reduction in U-value becomes possible

through this mechanism and green roof was intentionally designed with densely

packed grass vegetation. This was conducted to ensure that incoming heat could

be effectively absorbed by the high grass density, reducing heat convection

into building. The observation is consistent with

The examination of the relationship between U-value and EUI shows interesting trends. Scenario A, comprising A1, A2, and A3, shows that smaller U-value corresponds to lower EUI value, particularly evident with fiberglass batts. However, Scenarios B1 and B2 reports EUI value that can match or be lower than A1, despite having U-value five times higher. This contradicts the results of (Carvalho et al., 2021), where smaller U-value leads to lower EUI value. This phenomenon is attributed to the low emissivity values of glossy ceramic and EPDM membranes in B1 and B2, which effectively block excessive solar heat radiation, showing a reflective effect. This study also explores the influence of thermal conductivity and thickness on EUI, as presented in Figure 3. A linear relationship was observed between higher thermal conductivity and larger EUI value, as well as a negative correlation with thickness. However, the very low R2 value is due to the lack of data samples, resulting in a non-normal distribution. The need for additional data samples becomes apparent to ensure and strengthen the statistical validity of the results. However, the trendline shows a relationship consistent with the results in this study.

Figure 3 The trendline of thermal conductivity and

thickness with EUI value

The

results complement previous studies on energy assessment in

building roof renovation, as shown in Table 5 with five previous examples. The

study by (Borras et

al., 2022) reported the

installation of three types of building roof renovation including 2 green roofs

in 6 different climate zones in Spain. Therefore, a more comprehensive change

in building envelope led to a higher reduction in EUI. According to (He

et al., 2020), cool roof was

more effective in reducing a building's EUI due to the excellent reflectivity

compared to green roof. However, (Jovanovic

, Zivkovic, and Stevanovic, 2018) stated the advantages of

green roof in improving indoor and outdoor building quality by generating

additional oxygen and absorbing air pollutants. (Cai et al., 2019) also provided evidence that

green roof was effective in reducing EUI and room temperature.

Table 5 Five examples of previous study outcomes

|

No |

Previous

study title |

Study outcomes |

|

1 |

Contribution

of green roof to energy savings in building renovation (Borras

et al., 2022) |

Among the

three types of roof renovation, showed a decrease in energy consumption by 9%

to 13% |

|

2 |

Thermal and

energy performance of green roof and cool roof: A comparison study in

Shanghai area (He et al., 2020) |

Cool roof was

superior in reducing room temperature, resulted in more significant

electricity savings compared to green roof |

|

3 |

Inverted roof

insulation kits and their durability (Francke and Gerylo, 2018) |

The decrease

in the quality of insulation material was caused by freeze-thaw cycles. |

|

4 |

The impact of

building envelope with the green living system on the built environment (Jovanovic , Zivkovic, and Stevanovic, 2018) |

The

utilization of green roof and vertical gardens on facades reduced air

pollutant levels by up to 11 g/m2/year, eliminated air bacteria,

and contributed to building energy savings. |

|

5 |

Reduction in

Carbon Dioxide Emission and Energy Savings Obtained by Using Green Roof (Cai et al., 2019) |

The use of

green roof reduced energy consumption by up to 11.53 kWh/m2/year

while effectively preserving heat. |

From

Table 5, this study complements information regarding building energy analysis

concerning the addition of insulation and replacement of covering layers in

building roof renovation in a single discourse. This study also developed six

different scenarios including three types of insulation material and covering

layers. The energy calculation results showed that the use of green roof in

Scenario B3 obtained the highest percentage reduction in EUI. Meanwhile, the

addition of insulation in Scenarios A1-A3 did not have a significant impact on

reducing EUI despite the better heat transfer capability. Furthermore, the study conducted by (Francke and Gerylo, 2018) reported the limitations of insulation

material quality in response to environmental temperature changes. Based on EUI

calculation, the use of green roof is selected as the best solution for

application in office building roof in Jakarta.

In conclusion, the optimization of flat roof

was reported to prevent excessive building energy consumption. The

implementation of several envelope renovation showed that the addition of

insulation or alterations to roof covering effectively reduced EUI value. The

additional insulation layer restricted the solar heat radiation rate due to

extremely low conductivity, acting as a heat-absorbing material. Covering

material had a cooling effect on roof area. Through Insight 360 analysis, six

scenarios were investigated, resulting in energy consumption reductions ranging

from 19.49% to 20.22% for scenarios A1–A3. Similarly, Scenarios B1, B2, and B3

reduced energy consumption by approximately 19.49%, 19.5%, and 23.53%,

respectively. The final energy analysis and previous results showed that green

roof system in Scenario B3 yielded the most significant energy savings.

However, this study necessitated the incorporation of additional data regarding

insulation thickness and the varieties of covering material. This inclusion

aimed to enhance the data distribution efficacy, obtaining more accurate

results.

This study was funded by the Directorate of

Research and Development, Universitas Indonesia, under Hibah PUTI Q2 (Grant No.

NKB-821/UN2.RST/HKP.05.00/2023).

Algarni, S.,

Almutairi, K., Alqahtani, T., 2022. Investigating the Performance of Energy

Management in Office Buildings by Using a Suitable Green

Roof Design to Reduce the Building's Energy

Consumption. Sustainable Energy Technologies and Assessments, Volume

54(102825), pp. 1–8

Arabi, R., 2018. Assessment of Vegetation Cooling Effect

Through the Application of Green Roofs in Tropical

Campus Environment. Environmental Science. Available online at:

http://psasir.upm.edu.my/id/eprint/76306, Accessed on September 19, 2023

B2TKE-BPPT, 2020. Benchmarking Specific Energy Consumption in Commercial Building,

Serpong: Indonesian Government. Available online at: https://simebtke.esdm.go.id/sinergi/assets/content/20210527150029_Laporan_Akhir_SEC-130120.pdf,

Accessed on July 2, 2023

Bachrun, A.S., Ming, T.Z., Cinthya, A., 2019. Building Envelope

Component to Control Thermal Indoor Environment in Sustainable

Building: A Review. Sinergi, Volume 23(2), pp. 79–98

Berawi, M.A., Sari, M., Salsabila, A.A., Susantono, B.,

Woodhead, R., 2022. Utilizing Building Information Modelling in the Tax

Assessment Process of Apartments Buildings. International Journal

of Technology, Volume 13(7), pp. 1515–1526

Borras, J.G., Lerma, C., Mas, A., Vercher, J., Gil, E., 2022.

Contribution of Green Roofs to Energy Savings in Building Renovations.

Energy for Sustainable Development, Volume 71, pp. 212–221

Cai, L., Feng, X-P., Yu, J-Y., Xiang, Q-C., Chen, R., 2019. Reduction

in Carbon Dioxide Emission and Energy Savings Obtained by Using Green Roof.

Aerosol and Air Quality Research, Volume 19, pp. 2432–2445

Carvalho, J.P., Almeida, M., Braganca, L., Mateus, R., 2021.

BIM-based Energy Analysis and Sustainability

Assessment-Application to Portuguese Buildings. Buildings, Volume

11(246), pp. 1–25

Feng, H., Liyanage, D.R., Karunathilake, H., Sadiq, R., Hewage, K., 2020. BIM-based

life Cycle Environmental Performance Assessment of Single-Family Houses:

Renovation and Reconstruction Strategies for Aging Building Stock in

British Columbia. Journal of Cleaner Production, Volume 250(119543), pp.

1–17

Fitriani, H., Rifki, M., Foralisa, M., Muhtarom, A., 2022.

Investigation of Energy Saving Using Building Information Modeling for Building

Energy Performance In Office Building. Civil Engineering and Architecture,

Volume 10(4), pp. 1280–1292

Francke, B., Gerylo, R., 2018. Inverted Roof Insulation Kits

And Their Durability. Warsaw, MATEC Web of Conference. Available online at:

https://doi.org/10.1051/matecconf/201816308005, Accessed on September 6, 2023

Gama, N.V., Ferreira, A., Timmons, A.B., 2018. Polyurethane

Foams: Past, Present, and Future. Materials, Volume 11(10), pp. 1–35

Hakim, F.N., Muhamadinah, Y., Atthaillah, ., Mangkuto, R.A.,

Sudarsono, A.S., 2021. Building Envelope Design Optimization of a Hypothetical

Classroom Considering Energy Consumption, Daylighting, and Thermal

Comfort: Case Study In Lhokseumawe, Indonesia. International Journal of

Technology, Volume 12(6), pp. 1217–1227

He, Y., Yu, H., Ozaki , A., Dong, N., 2020. Thermal and

Energy Performance of Green Roof and Cool Roof: A Comparison

Study in Shanghai Area. Journal of Cleaner Production,

Volume 267(122205), pp. 1–15

Ibrahim, S.H., Roslan, Q., Affandi, R., Razali, A.W., Samat,

Y.S., Nawi, M.N.M., 2018. Study on the Optimum Roof Type with 30° Roof Angle to

Enhance Natural Ventilation and Air Circulation of a Passive Design. International

Journal of Technology, Volume 9(8), pp. 1692–1701

Jovanovic , D., Zivkovic, P., Stevanovic, Z., 2018. The Impact

of the Building Envelope with the Green Living System on

the Built Environment. Thermal Science, Volume 22, pp. 1033–1045

Makaveckas, T., Bliudzius, R., Burlingis, A., 2021.

Determination of the Impact of Environmental Temperature

on the Thermal Conductivity of Polyisocyanurate (PIR)

Foam Products. Journal of Building Engineering, Volume 41(102447), pp.

1–14

Sedaghat, A., Salem, H., Hussam, W.K., Mahdizadeh, A., Al-Khiami, M.I., Malayer, M.A., Soleimani, S.M., Sabati, M., Narayanan, R., Rasul, M., Khan,

M.M.K., 2023. Exploring Energy-Efficient Building Solution in Hot Regions: A

Study on Bio-Phase Change Material and Cool Roof

Coatings. Journal of Building Engineering, Volume 76(107258), pp. 1–22

Shaharuddin, S., Khalil, N., Saleh, A. A., 2019. Review of Significant

Maintenance Criteria for Tropical Green Roofs in Malaysia. International

Journal of Technology, Volume 10(1), pp. 69–80

Wang , L., Huang, M., Li, D., 2021. Strong Influence of Covective Heat

Transfer Efficiency on the Cooling Benefits of Green Roof

Irrigation. Environmental Research Letters, Volume 16(084062), pp. 1–13

Yildirim, S., Ozburak, C., Ozden, O., 2023. Green Roofs,

Vegetation Types, Impact on the Thermal Effectiveness: An Experimental Study in

Cyprus. Sustainability, Volume 15(2807), pp. 1–19