Cyclic Strain Rate Dependent Low-Cycle Fatigue Behavior of Alloy 617

Correction for this article:

Corrigendum to: Cyclic Strain Rate Dependent Low-Cycle Fatigue Behavior of Alloy 617Published at: 20 Feb 2026

Published at : 07 Dec 2023

Volume : IJtech

Vol 14, No 7 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i7.6658

Dewa, R.T., Aulia, A., Kim, S.-J, Akbar, R., 2023. Cyclic Strain Rate Dependent Low-Cycle Fatigue Behavior of Alloy 617. International Journal of Technology. Volume 14(7), pp. 1419-1427

| Rando Tungga Dewa | Department of Mechanical Engineering, Republic of Indonesia Defense University, IPSC Area Sentul, Bogor, West Java 16810, Indonesia |

| Aditia Aulia | Department of Mechanical Engineering, Republic of Indonesia Defense University, IPSC Area Sentul, Bogor, West Java 16810, Indonesia |

| Seon-Jin Kim | Department of Mechanical Design Engineering, Pukyong National University, Busan 48547, Republic of Korea |

| Raja Akbar | Department of Mechanical Design Engineering, Pukyong National University, Busan 48547, Republic of Korea |

Alloy

617 is identified as a potential material for defense applications,

particularly in military air platforms. Therefore, this study aims to examine

the impact of strain rate on Alloy 617 properties during low-cycle fatigue

(LCF) at room temperature (RT). LCF life properties and damage mechanism of

alloy 617 are examined across a strain rate range of (5x10-4 ~ 10-2

s-1) in a fully-reversed controlled total strain range of 1.2%. Slow

strain rate test (SSRT) is found to be a cost-effective method for assessing

the material capability to respond to environmental interference. This study

shows that LCF life of Alloy 617 is strongly influenced by the time-dependent

mechanism, in terms of SSRT. The relationship between total strain, plastic

strain, and time to failure with strain rates are established and expressed

using the power law function to describe the fatigue life. Fractured specimens

undergo metallography examination using an electron microscope, and

fractography is discussed to differentiate the impact of SSRT on the physical

damage characteristics under LCF loadings. LCF resistance of Alloy 617 is found

to be time-dependent. Based on the results, it is recommended that the factor

of safety must be considered in the designing phase to evaluate the fatigue

life.

Alloy 617; Fatigue life; Fractography; Low-cycle fatigue; Slow strain rate test

In the

strategy framework, advanced materials are identified as an important

technology for driving innovation in defense. These materials represent a

domain where the nation has globally competitive research and development

capabilities for industrial strength as stated in the Indonesian National

Strategy. The development of the new superalloy to be implemented for extreme

conditions has attracted researchers and defense industries, specifically

military air platforms. Among the emerging materials is Alloy 617, a solid

solution-strengthened alloy composed of chromium, cobalt, and molybdenum, with

added aluminum. This alloy is engineered to deliver a balance of heightened

strength and stability at elevated temperatures. Additionally, it provides good

properties for components of power generating plants, gas turbines, and high

temperature superior required applications. Alloy is now being widely used for

high-temperature applications (Dewa et al.,

2018a; Dewa et al., 2018b; Dewa et al.,

2016; Ekaputra et al., 2016; Redy et al., 2010).

In the high-temperature environment,

resistance to low-cycle fatigue (LCF) and creep-fatigue (CF) interaction is an

important requirement for the successful design due to the complex

interactions between metals, high temperature, and air. LCF loadings are

expected to result from thermally induced strain cycles and fluctuations during

operations. Time-dependent mechanisms, influenced by environmental factors,

have the potential to affect fatigue life synergistically or independently.

Therefore, accurate prediction of LCF in extreme temperature conditions relies

on characterizing a rate-controlling damage process that shapes cyclic

deformation. This involves considering the appropriate combination of

experimental stress/strain, temperature, strain rate, environment, and the

prior metallurgical condition of the material (Sofyan

et al., 2010; Redy et al., 2010). The effect of these

time-dependent processes may reduce an alloy cyclic life resistance by orders

of magnitude as compared to the room temperature (RT) behavior. Therefore, in

this study, the phenomenon is initially tested on the laboratory scale to

examine the damage mechanism, which is closely dependent on strain rate and the

structures.

The literature on the slow strain rate

deformation of alloy 617 is still rare, specifically at the initial RT setup.

Recent studies show that the behavior observed in slow strain rate tests (SSRT)

on stainless steel and structural steel is closely in line with the responses

under creep conditions (Calmunger et al.,

2013; Luo et al., 2013; Luo et

al., 2013). Numerous studies have been conducted to modify and

improve the relationship to cover materials model through conventional or

adapted methods (Ekaputra et al., 2020;

Suastika et al., 2019; Chou et al.,

2016; Alie, 2016; Chen, Sun, and Chan, 2014; Nakai and

Yokoyama, 2012). However, SSRT is found to be

promising as a low-cost methodology for the evaluation of materials capability

to respond to such environmental interference. The variance of strain rates in

the order of magnitudes can be used in LCF test at RT. Understanding the

variations in fractography appearance and applying accurate life prediction

methods under these conditions provides crucial information for the ongoing

rapid assessment of elevated temperature test behavior, specifically for Alloy

617.

The primary objective of this study is

to determine the influence of individual and interactive time-dependent

processes by performing SSRT under LCF loadings for Alloy 617 at RT.

Furthermore, this finding focuses on the fatigue life interpolation methods,

comparing their predictions to determine the suitability of the power-law

relationship. The influence of change in strain rates on the damage mechanisms

is also investigated. The aim is to establish a comprehensive understanding of

LCF mechanism and draw conclusions related to the time-dependent damage.

The

composition (wt.%) of the commercial-grade Alloys used in this study is shown

in Table 1. The as-received microstructure of the alloy 617 is shown in Figure

1, showcasing a fully austenitic face-centered cubic (FCC) structure known for

maintaining superior mechanical properties at high temperatures (Dewa et al., 2018a). Figure 2 shows the monotonic

stress-strain behavior of Alloy 617, with FCC matrix, mainly consisting of

nickel, cobalt, iron, chromium, and molybdenum. For microstructural analysis,

the as-received sample was cross-sectioned and etched to reveal the grain

structure. The sample was sequentially etched in solutions of hydrochloric

acid, ethanol, and copper II chloride for at least 10-20 seconds. However, the

microstructure appearance in Alloy 617 is well-uniformed equiaxed grains. The

number of grains per unit was measured according to ASTM E112 to determine the

average grain size. The small grain size ranges from 10 to 30and the large

grain size is approximately 40–100

in diameter.

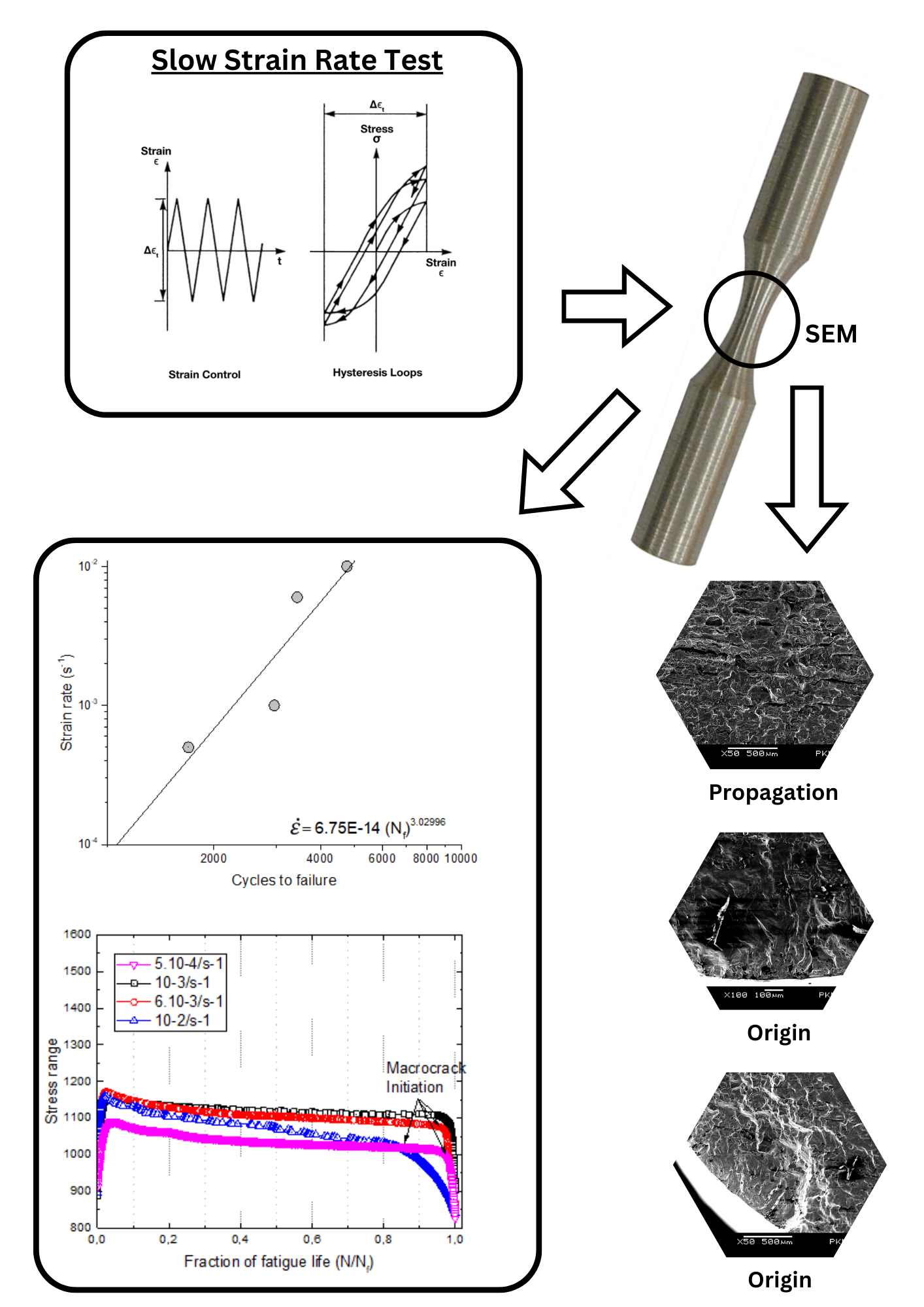

For LCF tests, polished cylindrical specimens with a 6.0 mm

diameter in the reduced section and a gauge length of 12.5 mm were used. The specimen

design adhered to certain standards to prevent

premature buckling or deformation under the highest tension stress anticipated

during LCF test. Fully-reversed LCF tests were performed in ambient air at RT

with different strain rates, i.e. 5x10-4, 10-3,

6x10-3, and 10-2 s-1, respectively, under 1.2%

total strain range. A high-precision extensometer was attached to the specimen

to record and collect the real-time data of the stress-strain response.

Triangular waveforms were used for all LCF tests, with measurements of

displacement, load, and strain signals taken for each cycle, comprising 200

data points. The test was concluded upon specimen separation or fracture,

essential for a comprehensive examination of the complete fracture surface.

However, the fatigue life criterion is defined according to the 25% reduction

in stress range after the macrocrack is initiated. Finally, a metallography

examination was carried out using Olympus GX51 Metallurgical Microscope and

JEOL JSM Scanning Electron Microscope.

Table 1 Chemical composition of Alloy 617 (wt.%)

|

Ni |

Cr |

Co |

Mo |

Al |

C |

Fe |

Ti |

Si |

Mn |

Cu |

P |

S |

B |

|

53.11 |

22.2 |

12.3 |

9.5 |

1.06 |

0.08 |

0.949 |

0.4 |

0.084 |

0.029 |

0.027 |

0.003 |

<0.002 |

<0.002 |

Figure 1 The as-received microstructure of Alloy 617

Figure 2

Monotonic stress-strain

curve of Alloy 617

3.1. LCF life

analysis

Figure 3 shows the influence of strain rate on LCF life indicating a decrease in fatigue life with lower strain rates. The linear

relationship between fatigue life and strain rate can be drawn in the

logarithmic function as shown in the Figure. The equation (1) used to describe

the relationship is as follows:

(1)

Where

Figure 3 The function of LCF life with the variation of strain

rates for Alloy 617

To provide a better understanding of the

damage parameter, fatigue life function is then plotted in Figure 4, with

plastic strain and time to failure spent until fracture. This relationship is

described in the following equation (2):

(2)

Where is strain rate, M and n are constants describing

the regression fit (intercept and slope), respectively. The plastic strain

values were derived from the mid-life of cycles to failure. It was assumed that the mid-life is best considered as

the stabilized cycle for LCF testing at RT condition. According to Figure 4a,

the lower strain rate test had a higher plastic strain. Furthermore, for LCF

test with the influence of a time-dependent factor, the time to failure

compared to that in terms of cycles to failure must be considered and can be

shown in the following equation (3):

(3)

Where tr is time to failure in terms of

hour, X and y are constants describing the regression fit

(intercept and slope), respectively. In Figure 4b, the time to

failure with strain rates is plotted in a logarithmic function. Despite

lower cycles to failure at lower strain rates, the time to failure exhibits a

higher level. The

equation generated from the time-to-failure function with strain rates for

fitting interpolation is also provided in the Figure. The

results show that the time-dependent crack mechanism is the dominant fatigue

mechanism for Alloy 617 (Sah,

Park, and Kim, 2023). The power law function seems to

be well-fitted to the experimental data in terms of the linearity agreement,

showing that the predicted life coincides well with the measured LCF life. This

suggests that the time-dependent

deformation can take place gradually with a slow strain rate fatigue (Luo et al., 2013). In the verification process, the prediction

techniques are confirmed with the predicted life derived by back-substituting

experimental data into equations (Eq. 1 and 3). The estimated error accuracies

are 12.6% and 13.7%, respectively. The results fall within a factor of 1.0 for

conversion, affirming the observed linearity as shown in Figures. 3-4.

Figure

4 The

plot of diagrams: (a) Plastic strain versus strain rates, and (b) Time to

failure with strain rates function

3.2. Influence of strain rate

on LCF properties

Cyclic stress response behaviors at different strain rates of

Alloy 617 are shown in Figure 5. In Figure 5a, all materials show a similar

trend with the initial hardening phase, followed by cyclic softening and rapid

drop of stress or failure. This is typical cyclic stress response behavior of

superalloy under LCF loading at RT. Based on the result, a significantly lower

strain rate test condition decreases the strength of the material, which can be

seen in the lower stress range response (pink dot line). Furthermore, Figure 5b

shows cyclic stress responses in order of normalized cycle. The materials show

a short initial hardening of about 5% of the fatigue life. The initial

hardening occurred due to the increasing dislocation density of fatigue slips

in material reconciliation. The increase in the number of cycles leads to an

augmentation in dislocation movement. When the rate of dislocation

multiplication equals the rate of dislocation annihilation, cyclic stress

becomes stabilized (Ekaputra et al., 2016). Accordingly, the

material shows significant cyclic softening gradually (almost for the entire

life) until the initiation of macrocrack where the stress suddenly dropped.

Cyclic softening phase of this material may be due to the annihilation of

dislocations that exceed the dislocation multiplication, therefore, cyclic

stress is decreased. Subsequently, at lower strain rates,

there is a decrease in dislocation mobility, consequently leading to a reduced

stress range (Sah, Hwang, and Kim, 2021). From the Figure, it can also be

observed that the macrocrack initiation for the specimen with the fastest

strain rate occurred earlier. Cyclic crack propagation is much higher for a

high strain rate specimen.

To quantify the degree of cyclic softening during LCF, the

softening ratio is defined as the ratio between the peak stress after initial

hardening (Smax) and the

stress at the sudden drop point (Sc).

Figure 6 shows the degree of softening phase at different strain rates. It can

be seen from the Figure that the trend of degree of softening increases

generally with an increase in strain rate. The impact of cyclic softening phase

is more pronounced at higher strain rates. This is attributed to the higher

number of cycles to failure and accumulated plastic deformation compared to

specimens tested at lower strain rates. This result is in line with the earlier

discovery that at higher strain rates, there is an increase in dislocation

mobility, leading to a heightened stress response, and vice versa (Nakai and

Yokoyama, 2012).

Figure 5 (a) Cyclic stress response behavior at different strain rates of Alloy 617, and (b) Normalised cycle of cyclic stress response curves

Figure

6 Degree

of softening ratio at different strain rates of Alloy 617

3.3. Fractography examination

Figure 7 shows typical fractography SEM micrographs (with

zoomed images on each zone) for LCF specimens tested at a high strain rate.

Figure 7c shows a typical fatigue fracture consisting of the initiation zone

(pointed by the black arrows), Figure 7b shows the crack propagation area, and

Figure 7a shows the final fracture zone in the dashed line. In the crack

initiation zone, the fracture surface shows cleavage-like facets. The crack

propagation predominantly shows a flat surface characterized by dense

striations and a limited number of secondary cracks. The sharp features on the

surface, indicative of substantial tension during fracture, contribute only a

small portion to the final fracture zone. However, the failure modes generally

show a transgranular crack in nature with cleavage-like facets for typical

fatigue loadings at RT. This type of crack shows that fatigue failure occurred

due to the slips at the surface. No indications of premature failure or defect

failure are noticed during the examination. Furthermore, Figure 8 shows SEM

micrographs (with zoomed images on each zone) for LCF specimens tested at a low

strain rate. For low strain rate specimens, however, the crack propagation can

be characterized into two stages (separated by a yellow line). The first stage

in Figure 8c shows a typical transgranular fracture with a bigger step of

striations, and it is related to the lower cycle. Subsequently, the second

stage in Figure 8b shows the domination of secondary cracks. It is hypothesized

that the occurrence of secondary cracks precedes the arrival of the main crack

tip. These secondary cracks can be originated from typical cavities/voids. At

the final fracture zone, intergranular dimple fracture is even more obvious.

The failure mode shows an intergranular fracture mechanism with creep (Sah, Hwang, and Kim, 2021). Therefore, it can be shown

that the intergranular crack-fatigue interaction can be promoted at a very low

strain rate LCF loading even at RT, as the deformation of grain boundary

sliding is more prevalent at this condition and results in lower cycles to

failure. Therefore, a lower fatigue life at a very low strain rate can be

expected from this mechanism during fatigue. The findings shows that a longer

tensile loading rate per cycle is needed for the type of experiment which

increases this cavities-driven crack interaction. The results are substantiated

under lower strain rate conditions, where the strength is reduced, accompanied

by higher ductility and a slower softening rate. Consequently, the dislocation

mobility is constrained in comparison to specimens tested at high strain rates (Sah, Hwang, and Kim, 2021; Redy

et al., 2010). Additionally, valuable observations obtained from the continuous rapid

assessment of the environmental test behavior for the studied material, given

the significant connection to time-dependent behavior, are crucial for further

understanding.

Figure 7 SEM micrographs of fracture surface specimen tested at 10-2 s-1, showing typical: (a) Failure zone features, (b) Crack propagation, and (c) Crack initiation

Figure

8 SEM

micrographs of fracture surface specimen tested at 5x10-4 s-1,

showing typical: (a) Failure zone features, (b) Second stage of crack

propagation, (c) First stage of crack propagation, and (d) Crack initiation

In conclusion, LCF resistance of Alloy 617 was found

to be time-dependent over a range of 5x10-4 ~ 10-2 s-1

strain rates. All materials showed a similar trend with an initial hardening

phase, followed by cyclic softening and a rapid drop of stress or failure.

However, it was observed at a lower strain rate that the

specimen had a lower stress range compared to other specimens and the macrocrack initiation for specimen with the fastest strain rate

occurred earlier. The influence of strain rates on fatigue life was evidenced

through fractography images. At the lowest strain rate, the specimen fractured

with additional failure mode in an intergranular manner. The domination of

secondary cracks was obvious at the surface, possibly originating from cavities

or voids. A typical mixed intergranular dimple fracture for the very low strain

rate specimen similarly indicated the interaction of cavities-driven cracking

mechanism during fatigue loading at RT, attributing to the lower LCF life. It

was recommended that the factor of safety should be considered in the designing

phase to evaluate the fatigue life. The fatigue life variation could be

extremely broad at millions of cycles, specifically out of time-dependent

damage towards catastrophic failure.

The

authors express gratitude and acknowledge the mutual collaboration between universities.

The dissemination of this study was funded by the Republic of Indonesia Defense

University and the research was carried out at Pukyong National University.

Alie, M.Z.M., 2016. The Effect of Symmetrical and

Asymmetrical Configuration Shapes on Buckling and Fatigue Strength Analysis of

Fixed Offshore Platforms. International Journal of Technology.

Volume 7(6), pp. 1107-1116

Calmunger, M., Chai, G.C.,

Johansson, S., Moverare, J., 2013. Damage and Fracture Behaviours in Aged

Austenitic Materials During High-Temperature Slow Strain Rate Testing. Key

Engineering Materials, Volume 592–593, pp. 590–593

Chen, Y., Sun, W., Chan,

T.-M., 2014. Cyclic Stress-Strain Behavior of Structural Steel with Yield Strength Up To 460 N/mm2. Frontiers of

Structural and Civil Engineering, Volume 8(2), pp. 178–186

Chou, L.H., Chiou, Y.C.,

Wu, C.C., Huang, Y.J., 2016. Predictions of the Stress-Strain Curve and Fatigue

Life for AISI 316 Stainless

Steel in Cyclic Straining. Journal of Marine Science and Technology,

Volume 24(3), pp. 426-433

Dewa, R.T., Kim, S.-J.,

Kim, W.-G., Kim, E.-S., 2016. Understanding low cycle

fatigue behavior of alloy 617 base metal and weldments at 900 °C. Metals,

Volume 6(8), p. 178

Dewa, R.T., Park, J.-H.,

Kim, S.-J., Lee, S.-G., 2018a. High-temperature creep-fatigue behavior of alloy

617. Metals, Volume 8, p. 103

Dewa, R.T., Kim, S.-J., Kim,

W.-G., Kim, E.-S., 2018b. Evaluation of the low

cycle fatigue failure properties for GTAW weldments of alloy 617 at 950 °C. Engineering

Failure Analysis, Volume 90, pp. 202–214

Ekaputra, I.M.W, Dewa, R.T.,

Haryadi, G.D., Kim, S.J., 2020. Fatigue Strength Analysis

of S34MNV Steel by Accelerated Staircase

Test. Open Engineering, Volume 10(1),

pp. 394–400

Ekaputra, I.M.W., Kim,

W.-G., Park, J.-Y., Kim, S.-J., Kim, E.-S., 2016. Influence of Dynamic Strain

Aging on Tensile Deformation Behavior of

Alloy 617. Nuclear Engineering and Technology, Volume 48, pp. 1387–1395

Sah, I.J., Park, J.H.,

Kim, E.S., 2023. Fatigue Life Curves of Alloy 617 In the Temperature Range of

800–950 °C. Nuclear Engineering and Technology, Volume 55(2), pp. 546–554

Sah, I.J., Hwang, J.B., Kim,

E.S., 2021. Creep Behavior of Diffusion-Welded Alloy 617. Nuclear

Engineering and Technology, Volume 329,

pp. 142–146

Luo, Y., Huang, C., Tian,

R., Wang, Q., 2013. Effects of Strain Rate on Low Cycle Fatigue Behaviors of High-Strength Structural Steel. Journal of Iron and Steel Research

International, Volume 20(7),

pp. 50–56

Luo, Y., Huang, C., Guo,

Y., Wang, Q., 2012. Energy-Based Prediction of Low Cycle Fatigue Life of

High-Strength Structural Steel. Journal of Iron and Steel Research

International, Volume 19(10), pp. 47–53

Nakai, K., Yokoyama, T.,

2012. High Strain-Rate Compressive Properties and Constitutive Modeling of Selected Polymers. Journal of Solid Mechanics and Materials

Engineering, Volume 6(6), pp. 731–741

Redy, G.V.P., Harini, P.,

Sandhaya, R., Rao, K.B., Paretkar, R.K., 2010. On dual-slope linear cyclic hardening

of Hastelloy X. Materials Science and Engineering A, Volume 527, pp. 3848–3851

Sofyan, B.T., Berndt, C.C., Stefano, M., Pardede,

H.J., 2010. WC-Co Coatings for High-Temperature Rocket Nozzle Applications: An

Applications Note. International Journal of Technology. Volume

1(1), pp. 48–56

Suastika, K., Sahlan, S.,

Nugroho, W.H., Zubaydi, A., Misbah, M.N., Murdjito, M., 2019. Fatigue Life

Assessment of Waste Steel Reused as

Tsunami Buoy Keel Structures: A Case Study. International Journal of Technology,

Volume 10(4), pp. 700–709