Development of Optical Fiber Sensor for Water Salinity Detection

Corresponding email: punitha@unikl.edu.my

Published at : 31 Oct 2023

Volume : IJtech

Vol 14, No 6 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i6.6650

Nor, M.S.M., Khan, A.A., Mohamad, S., Thirunavakkarasu, P., 2023. Development of Optical Fiber Sensor for Water Salinity Detection. International Journal of Technology. Volume 14(6), pp. 1247-1255

| Muhammad Safwan Mohammed Nor | Communication Technology Section, British Malaysia Institute, Universiti Kuala Lumpur, 53100 Gombak, Malaysia |

| Abdul Ali Khan | Communication Technology Section, British Malaysia Institute, Universiti Kuala Lumpur, 53100 Gombak, Malaysia |

| Suraya Mohamad | Communication Technology Section, British Malaysia Institute, Universiti Kuala Lumpur, 53100 Gombak, Malaysia |

| Punithavathi Thirunavakkarasu | Communication Technology Section, British Malaysia Institute, Universiti Kuala Lumpur, 53100 Gombak, Malaysia |

This project addresses the lack of a real-time, low-cost sensor to detect salt levels in water. The authors aim to develop an optical fiber sensor for water salinity detection. The sensor employs the principles of absorption spectroscopy using a broadband light source and spectrometer to detect changes in the optical spectrum of the sensor in the presence of varying concentrations of sodium chloride ions. A D-shaped sensor is fabricated by modifying the circular structure of a plastic optical fiber. Functionalized carbon nanotubes are drop casted over the D-shaped sensing region. Both uncoated and CNT-coated POF sensors are exposed to different concentrations of sodium chloride in water, and the spectral response is recorded. The results show that the sensors exhibited a strong correlation in their intensity response towards varying concentrations of sodium chloride salt ranging from 0 to 25%. The uncoated sensor had a sensitivity of 31A.U./% salt, and the CNT-coated Sensor had a sensitivity of 114 A.U/% salt. The functionalized CNT layer increased the sensitivity of the POF sensor by approximately 4 times. The outcome of this research provides a cost-effective and reliable method for water salinity detection in industrial and environmental applications.

Carbon Nanotubes (CNT); D-shape optical fiber; Optical fiber sensor; Sodium chloride ions, Sensitivity; Water salinity detection

Water salinity plays a crucial role in numerous fields, including

environmental monitoring, industrial processes, and agriculture. Precise and

continuous measurement of water salinity is essential for effective water

resource management and ensuring optimal conditions for various applications.

However, conventional sensors are affected by electromagnetic interference,

radio frequency interference, and real-time monitoring may also poses potential

risks, such as short circuits when used in an aqueous environment (Arrieta, Barrera and Mendoza, 2023; Abuzairi

et al. 2022; Hardi and Rahman 2020).

To address these constraints, the development of an optical fiber sensor (OFS) for water salinity sensing has emerged as a promising solution. This sensor employs absorption spectroscopy principles and integrates a D-shaped optical fiber sensing zone to detect changes in optical parameters when exposed to dissolved salts. Moreover, the coating of the OFS with carbon nanotubes (CNT) has shown remarkable potential in enhancing sensitivity and improving detection capabilities.

Optical

fiber sensors utilize the interaction between light and the analyte in the

surrounding environment to sense alterations in the surrounding refractive

index (SRI). The versatility of optical fiber sensors enables various sensing

mechanisms such as (absorption-based, reflection-based, evanescent wave, and

surface plasmon resonance (SPR)) sensors (Liu and

Peng, 2021).

Absorption-based sensors rely on the principle that the absorption spectrum of

water changes with salinity. The salinity level can be determined by measuring

the intensity of light transmitted through an optical fiber immersed in the

water sample.

Refractive

index [RI] sensors, on the other hand, exploit the refractive index variations

caused by changes in water salinity (Tan et al.,

2014). Thus making it viable by

measuring the intensity or phase of light reflected or transmitted through the

fiber. Evanescent wave sensors make use of the electromagnetic field extending

beyond the fiber core. When the fiber is exposed to a water sample, the RI of

the evanescent field changes due to salinity variations, leading to alterations

in the transmitted or reflected light. SPR sensors utilize the excitation of

surface plasmons on a thin metal film deposited on the fiber surface.

The interaction between plasmons and the salinity of a water

sample leads to changes in RI, which enables the measurement of water salinity

levels. When designing optical fiber sensors for this purpose, researchers must

consider several key factors. Among these, the choice of fiber is of utmost

importance. In this study, plastic optical fibers were selected due to their

robustness, large core size, and flexibility. Additionally, the selection of

materials for the sensor probe, including coatings or sensing layers, plays a

vital role in enhancing sensitivity and stability.

Sensor geometry and configuration have a significant impact on the

sensor's performance. Various modifications, such as tapered fibers,

long-period gratings, or microstructured fibers, can be used to increase the

interaction between the fiber and the surrounding medium, leading to increased

sensitivity

Great

progress has been made in the field of optical fiber sensors for water salinity

measurement (Flores, Janeiro, and Viegas, 2019).

Researchers have concentrated on the development of novel sensing

configurations, enhancing sensitivity and selectivity, and incorporating

optical fiber sensors with other technologies for multi-parameter measurements,

such as using nanomaterial coatings on the fiber surface to increase

sensitivity and enable selective detection of specific ions in saline water.

However, fiber sensors have several limitations, such as low mechanical

strength, especially in glass fibers, complex modification processes, and low

selectivity without a sensitive film.

Researchers

have also explored the combination of optical fiber sensors with microfluidics,

allowing real-time monitoring of water salinity. This integration offers

benefits such as smaller sample volume requirements, rapid response times, and

the capability to analyze multiple samples simultaneously. CNTs are now popular

as an efficient material for chemical sensing detection due to their

distinctive structural and optical properties, such as strong tensile

characteristics, extremely lightweight, and chemical and thermal stability (Khalaf et al.,2017; Pokhrel et al., 2017). These special characteristics have gained

substantial interest in using CNTs in research areas involving emerging

nanomaterials and their applications. Optical spectroscopy techniques measure

the changes in the RI of the CNTs caused by salt adsorption or desorption

processes. Furthermore, functionalization is

a chemical process that introduces specific functional groups onto the

sidewalls of CNTs. These functional groups can be created using specific

molecules or coatings, and they can enhance the selectivity of CNT-based

sensors towards particular salts, thereby improving the sensor's performance (Norizan et al., 2020).

Overall,

carbon nanotubes provide a promising platform for salt detection, offering high

sensitivity, rapid response times, and the potential for integration into

miniaturized and portable sensing devices. Further research is being conducted

to optimize the sensing performance, selectivity, and stability of CNT-based

salt sensors for a broad range of applications, including environmental

monitoring, agriculture, and healthcare. In this research, we propose a novel

salinity sensor using a D-shaped polymer optical fiber with a carbon nanotube sensing

layer. By optimizing the sensor's sensitivity, accuracy, and real-time

monitoring capabilities, it holds the potential to offer a more efficient and

cost-effective alternative to traditional methods such as microstrip moisture

sensor

In this research, MWCNTs 95%, sodium chloride 99%, nitric acid 65%, and sulfuric acid 95% were purchased from Sigma-Aldrich, and a 1000-micron diameter plastic optical fiber (POF) core and cladding made of (poly methyl methacrylate and fluorine resin) purchased from Mouser Electronics (Malaysia) was used to design a D shaped sensor. The POF was then placed in a v groove to secure it, and a fine file was used to polish the fiber down to the required size, as shown in Figure 1 (a). The POF sensing zone was fabricated to be 1 cm in length. After polishing, the cladding of the POF over the sensing region was totally removed. The side view and cross-section diagrams of the D-shaped POF are depicted in Figure 1(b and c) separately, and the resultant D-shaped sensor is depicted in Figure 1(d).

Figure 1 POF in V

groove for side polishing process a) Aerial view; b) Side view; c) Cross section view d) D-shaped sensor

To functionalize CNTs, acid treatment was employed using commonly

used acids such as nitric acid sulfuric acid

or a mixture of both

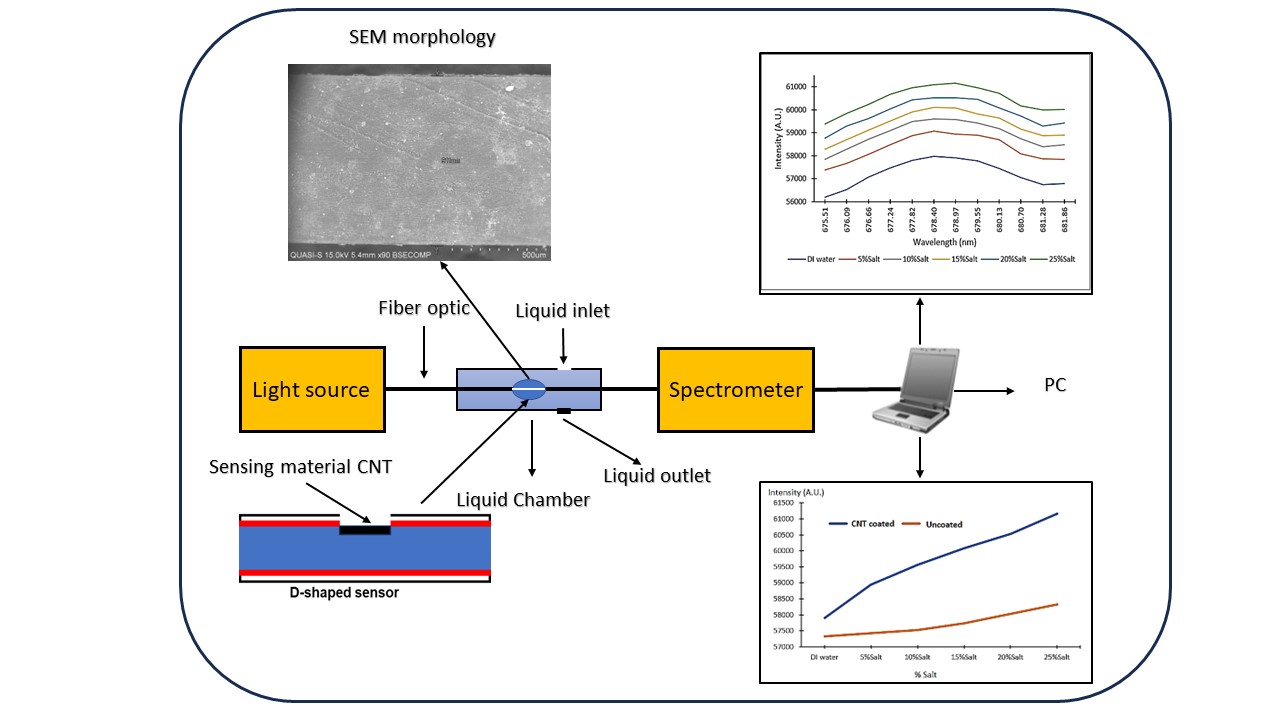

Figure 2 shows the sensing setup for this research. The sensing region of the POF sensor was positioned in a liquid chamber. The POF was connected to a broadband light source at one end and a spectrometer at the other end.

The AvaLight-HAL-S-MINI Tungsten-Halogen Light

Source has a spectral range of (400-2000 nm) and the spectrometer (AvaSpec-ULS2048CL)

has a range of (400-1100) nm. The

resulting data was analyzed using dedicated software on a PC. The sensitivity

of the sensor was evaluated by measuring the response to salt solutions of

varying concentrations ranging from (0-25)%. The measurements were taken after

20 sec for each concentration repeated for both the uncoated fiber and the

CNT-coated fiber. The collected data was further analyzed, compared, and

calculated to determine the sensitivity of the sensor.

The described material and method provide a systematic approach for the fabrication, functionalization, characterization, sensing, optimization, and analysis of the optical fiber sensor, with functionalized carbon nanotubes (CNTs) playing an important part in enhancing the sensor's performance for water salinity detection.

Figure 3 SEM image of CNT on POF with 90x magnification

Figure 4 SEM image of CNT on POF with 30000x magnification

Table 1 EDX analysis of CNT

|

Element |

Weight% |

Atomic% |

|

C K |

97.04 |

97.9 |

|

O K |

2.45 |

1.90 |

|

S K |

0.51 |

0.20 |

|

Totals |

100 |

100 |

Figure 5 XRD analysis of CNT

Figures 6 and 7 present the intensity results of the uncoated and CNT-coated POF sensor towards different concentrations of salt, respectively. The observed trend reveals that as the salt concentration increases, the intensity spectrum exhibits a corresponding increase. This phenomenon can be attributed to the variations in the RI of the surrounding medium as the salt concentration is increased. When the CNT-coated POF sensor is deployed, it can be clearly observed that the changes in intensity are more noticeable for each concentration of salt. Due to the high surface-to-volume ratio of nanotubes, it allows more salt molecules to interact. As the salt concentration increases, the salt molecules bind with the CNTs, causing greater changes to the CNT’s effective RI.

Figure 6 Spectral response of uncoated POF sensor towards salt solutions

Figure 7 Spectral response of CNT-coated POF sensor towards salt solutions

Figure 8 compares the performance of the uncoated and CNT-coated POF sensor. The results clearly demonstrate the superior performance of the

CNT-coated fiber in terms of intensity change when exposed to different salt

concentrations.

The

results indicate that the CNT-coated fiber demonstrates a significantly larger

intensity change compared to the uncoated fiber. This enhanced response is

attributed to the functionalization of CNTs, which leads to an improved

selectivity towards specific salts. The chemical composition of the

functionalized CNTs enables a binding interaction between the salt ions and the

CNTs, resulting in a greater difference in the effective RI between the sensor

surface and the surrounding medium.

The sensitivity of the uncoated and CNT-coated sensors is quantified using equation 4 (Arasu et al. 2016) and summarized in Table 2. It is noteworthy that the CNT-coated sensor exhibits approximately four times higher sensitivity compared to the uncoated sensor. This increased sensitivity is attributed to the unique properties of the functionalized CNTs, which enhance the sensing capability of the fiber. The functionalized CNTs facilitate a more precise and selective detection of salt concentrations by inducing significant variations to the effective RI of the sensor surface.

Figure 8 Comparison

of the intensity shift of the uncoated and CNT coated sensor

Table 2 Sensitivity Comparison

|

Type of

fiber |

Sensitivity

(AU/%salt) |

|

Uncoated

fiber |

31 AU/%salt |

|

Coated CNT

fiber |

114 AU/%salt |

Overall, the results

demonstrate the effectiveness of the CNT-coated fiber sensor in detecting and

quantifying salt concentrations. The uncoated sensor had a sensitivity of

31A.U./% salt, and the CNT-coated Sensor had a sensitivity of 114 A.U/% salt.

The functionalization of the CNTs enhances the sensor's (selectivity and

sensitivity) making it a favorable choice for a range of potential applications

requiring accurate and reliable water salinity detection.

In

conclusion, the development of a D-shaped fiber sensor for water salinity

detection has proven to be successful. The use of CNT coating through the

drop-casting method has significantly enhanced the sensitivity of the sensor,

achieving up to 4 times the sensitivity of the uncoated sensor. The CNT-coated

fiber sensor’s superior sensing capabilities have been established, providing a

better sensing mechanism for water salinity detection. This research opens up

possibilities for further exploration and improvement in the area of optical

fiber sensing. Future work in this area may be focused towards the sensing

layer. More research can be done towards determining the optimum thickness of

the sensing layer that would produce the highest sensitivity. Varying the

sensing layer with other sensitive materials such as graphene, Zinc Oxode,

conductive ploymers as well as nanocomposite layers could be another direction

for further work in this area. This would broaden the variety of materials for

sensor coating and potentially uncovering novel sensing mechanisms. The successful development of the CNT-coated fiber sensor and the

demonstrated improvements in sensitivity hold great promise for various

applications requiring water salinity detection. Industries such as

environmental monitoring, industrial processes, and agriculture can benefit

from the cost-effective, reliable, and real-time monitoring capabilities

offered by this optical fiber sensor. The simplicity and robustness of this

sensor make it easy to deploy in various environmental conditions. The findings of this research contribute to

the advancement of sensor technology and provide a foundation for future

studies in the field of water salinity detection and related applications.

This work was

supported by the Malaysian Ministry of Higher Education (MOHE) through the

Fundamental Research Grant Scheme (FRGS/1/2020/TK0/UNIKL/02/15).

Abuzairi, T., Sumantri,

N.I., Putri, N.A., Andarini, M.V., Lampung, E.J., Sitinjak, D., 2022.

Development of the Sterilization Box for Medical Equipment with an Ozone Gas

Leak Sensor Feature. International Journal of Technology, Volume 13, pp. 1672–1680

Arasu, P.T., Noor, A.S.M.,

Shabaneh, A.A., Yaacob, M.H., Lim, H.N., Mahdi, M.A., 2016. Fiber Bragg grating

assisted surface plasmon resonance sensor with graphene oxide sensing layer. Optics

Communications, Volume 380, pp. 260–266

Arrieta, A., Barrera, I.,

Mendoza, J., 2023. Application of a Polypyrrole Sensor Array Integrated into a

Smart Electronic Tongue for the Discrimination of Milk Adulterated with Sucrose.

International Journal of Technology, Volume 14, pp. 90–99

Deng, X., Shen, Y., Liu, B., Song, Z., He, X.,

Zhang, Q., Ling, D., Liu, D., Wei, D., 2022. Terahertz Metamaterial Sensor for

Sensitive Detection of Citrate Salt Solutions. Biosensors, Volume 12, p.

408

Flores, R., Janeiro, R.,

Viegas, J., 2019. Optical Fibre Fabry-Pérot Interferometer Based on Inline

Microcavities For Salinity and Temperature Sensing. Scientific Reports, Volume 9(1), p. 9556

Hardi, G.W., Rahman, S.F.,

2020. Amperometric Detection of Dopamine based on a Graphene Oxide/PEDOT:PSS

Composite Electrode. International Journal of Technology, Volume 11, pp. 974–983

Jain, S., 2022. Early Detection of Salt and Sugar

by Microstrip Moisture Sensor Based on Direct Transmission Method. Wireless

Pers Communications, Volume 122, pp. 593–601

Khan, A.A.,

Thirunavakkarasu, P.M., Saidin, N.B., Khalaf, A.L., Roslan, F.S., Haider, M.L.,

2022. Characterization of Plain and Zno Coated D-Shaped Plastic Optical Fiber

Sensor Of Different Diameters. In: 8th International Conference on

Engineering and Emerging Technologies, ICEET 2022

Khalaf, A.L., Arasu, P.T., Lim, H.N., Paiman, S., Yusof, N.A., Mahdi, M.A., Yaacob, M.H., 2017. Modified Plastic

Optical Fiber with CNT and Graphene Oxide Nanostructured Coatings for Ethanol Liquid Sensing. Optics

Express, Volume 25(5), pp. 5509-5520

Liu, Y., Peng, W., 2021. Fiber-Optic

Surface Plasmon Resonance Sensors and Biochemical Applications: A Review. Journal of

Lightwave Technology, Volume 39(12), pp. 3781–3791

Norizan, M.N., Moklis,

M.H., Demon, S.Z.N., Halim, N.A., Samsuri, A., Mohamad, I.S., Abdullah, N., 2020. Carbon Nanotubes:

Functionalisation and Their Application in Chemical Sensors. RSC Advances, Volume 10(71), pp. 43704–43732

Pokhrel, L.R., Ettore, N.,

Jacobs, Z.L., Zarr, A., Weir, M.H., Scheuerman, P.R., Kanel, S.R., Dubey, B., 2017. Novel Carbon

Nanotube (CNT)-Based Ultrasensitive Sensors for Trace Mercury (II) Detection in Water: A Review.

Science of the Total Environment, Volume 574, pp. 1379–1388

Tan, Y.C., Ji, W.B., Mamidala, V., Chow, K.K., Tjin, S.C., 2014. Carbon-Nanotube-Deposited Long Period Fiber Grating for Continuous Refractive Index Sensor Applications. Sensors and Actuators B: Chemical, Volume 196, pp. 260–264