Transforming Agricultural Supply Chain Challenges into Operational Strategies: Insights from an Agri-Machinery Company

Published at : 10 Jul 2024

Volume : IJtech

Vol 15, No 4 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i4.6635

Karasu, T., Zulkarnain, Leviakangas, P., 2024. Transforming Agricultural Supply Chain Challenges into Operational Strategies: Insights from an Agri-Machinery Company. International Journal of Technology. Volume 15(4), pp. 1071-1087

| Taha Karasu | Department of Civil Engineering, Faculty of Technology, University of Oulu, P.O. Box 8000, FI-90014, Finland |

| Zulkarnain | Department of Industrial Engineering, Faculty of Engineering, Universitas Indonesia, Kampus Baru UI, Depok 16424, Indonesia |

| Pekka Leviakangas | Department of Civil Engineering, Faculty of Technology, University of Oulu, P.O. Box 8000, FI-90014, Finland |

The paper proposes a process to translate systemic grand challenges of

agricultural supply chain into company specific operationalization actions. The

objectives of this study are to elucidate the requisite stages of the process,

delineate the specific aspects addressed by each step, and present potential

methodologies employed throughout the process. The approach adopted in this

paper is inherently constructive, employing a mixed methodology that integrates

various methods and tools. Furthermore, 90 challenges of agricultural supply

chain are delineated and structured around 6 themes. The strength of evidence

of the challenges is then analyzed with a model that takes into account the

number and types of references in which the challenges are mentioned and found,

respectively. The study identified 21 challenges as “evident” and proceeded to

the next step for quality function deployment. Finally, operationalization

actions, including cooperating with other stakeholders of the supply chain,

regulators, and farmers were determined to tackle critical first mile

challenges for the case company. The paper makes a distinctive contribution by

presenting a comprehensive framework for translating systemic agricultural

supply chain challenges into actionable steps, uniquely addressing the

intersection of intricate challenges and sustainability imperatives. This novel

approach does not only advance the understanding of operationalization but also

underscores the vital role of sustainability in navigating the complexities of

modern agricultural supply chains.

Agriculture; First mile; Supply Chain; Sustainability; Quality function deployment

Climate change, biodiversity loss, deforestation,

agricultural land degradation, and declining soil quality due to compaction are

significant challenges to major production systems (Hussain et al., 2023; Karasu, Hussain, and Leviäkangas, 2023a;

FAO, 2017). These challenges

affect various stages of the agricultural supply chain (ASC), with

inefficiencies leading to the global loss of one-third of agricultural produce,

mainly at the first and last mile stages

Despite the pivotal influence of first mile activities on subsequent ASC stages, research into agricultural logistics predominantly concentrates on the last mile ASC (Karasu, Hussain, and Leviäkangas, 2023a; Lingjuan, Linhong, and Menghan, 2018). Therefore, this study, aims to determine the challenges encountered in the first mile of ASC. Dasgupta, Kanchan, and Kundu (2019) defined first mile as “essentially the leg of fulfillment cycle where products are picked up from sellers and are connected to the sortation centers to facilitate the further downstream connections to deliver the product on time to the customers.” The challenges are vast and mostly responded in an incremental manner, i.e., solving only one or few problems at a time instead of one-time systemic, or radical innovations.

The corporate sector played a crucial role in

addressing these challenges, aiming to ensure that products and services

contributed positively to the solution rather than worsening the issues

The European Union (EU) acknowledged the significant

role of the corporate sector in transitioning to a green economy, as proven by the

Green Deal initiative

The translation of the challenges into actionable

steps remained unclear due to competitive pressures which focused on meeting customer

requirements rather than addressing broader challenges. Several existing labeling

and certification systems, such as International Organization for

Standardization (ISO) standards, namely ISO 14025, ISO 1406, and ISO 14027,

often lack transparency. These systems

often assess a limited scope of parameters, raising concerns among

organizations, including the

Translating enormous challenges into

operationalization actions (OAs) poses a complex task

In recent agricultural logistics research,

technology adoption and sustainability have gained significant attention

This study addressed the following

research questions.

RQ1.

What are the first mile challenges identified in previous research and

references focusing on the agricultural supply chain, and how can these

challenges be categorized into clusters?

RQ2. How can the evidence level of first

mile challenges be evaluated, and what challenges are particularly evident?

RQ3. Which of the first mile challenges

relate the most to the selected use case, i.e., agri-machinery case company?

RQ4. How can the first mile challenges be

operationalized?

To address RQ1, this study identified and

clustered first-mile ASC challenges from existing literature, as discussed in Subsection

3.1. For RQ2, a method to rank and prioritize the evidence of challenges

was developed, as stated in Subsection 3.2. To address RQ3,

semi-structured interviews and surveys were conducted with a company specialized

in agri-machinery. The insights gathered from these interactions informed the

development of the QFD framework in Subsection 3.3. Finally, the QFD

framework was implemented in an agri-machinery company to explore RQ4, as

stated in the same subsection. This systematic process enabled the

formulation of concrete plans for agri-machinery companies to reduce first-mile

challenges effectively.

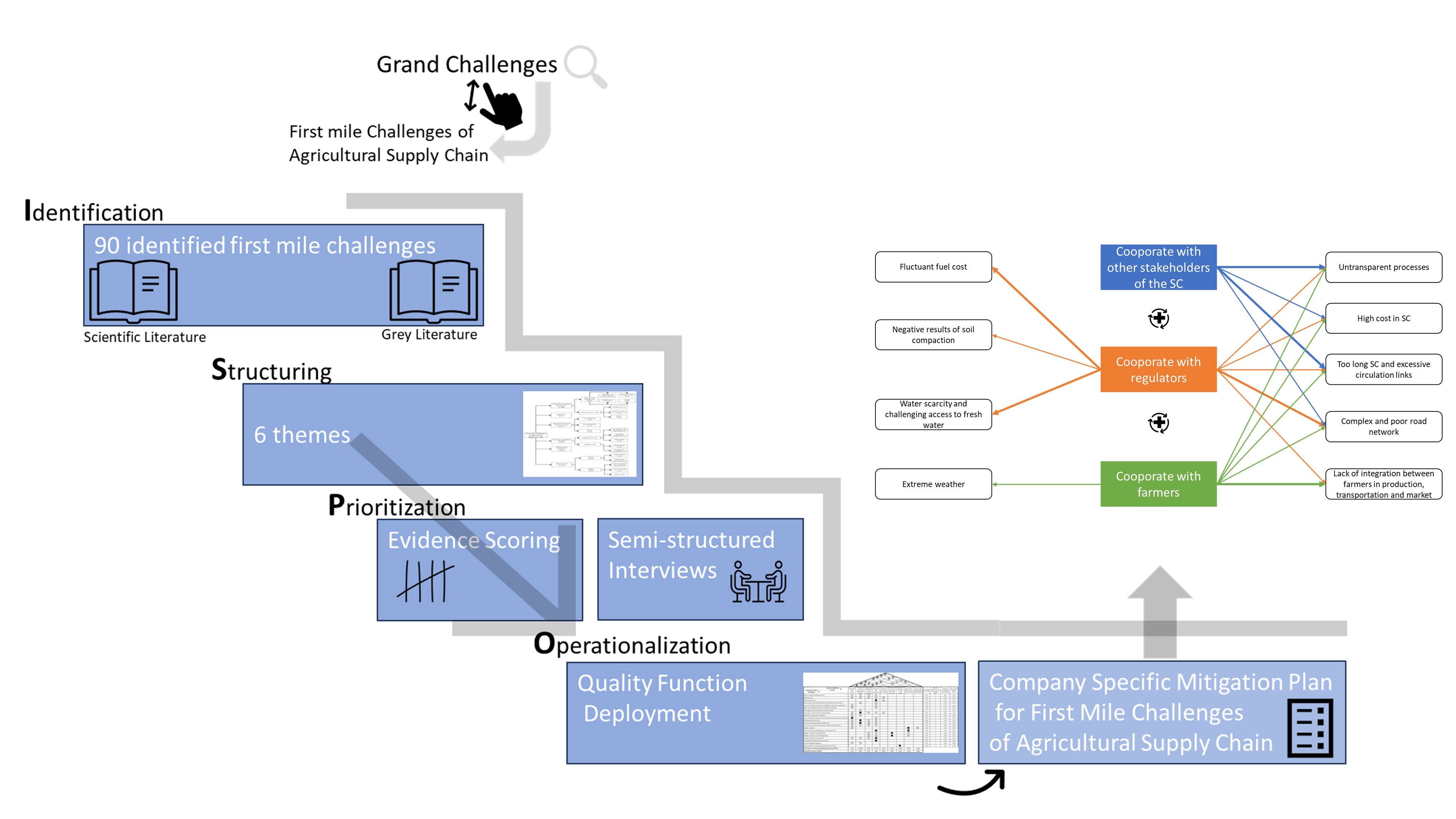

The proposed construct described

four significant steps, namely Identification (I), Structuring (S),

Prioritization, and weighing (P), including Operationalization (O),

collectively referred to as ISPO in separate sections of the research, as shown

in Figure 1. ISPO aimed to address challenges systematically using methods and

tools described in subsequent subsections. It acts as a stair-like research

process, refining systemic challenges into structured solutions and operational

actions, starting upstream rather than following traditional models

Figure

1

Overview

of the research process for transforming agricultural supply chain challenges

into operational strategies

2.1. Identification and Structuring of

Challenges (I and S)

The scientific literature

review protocol (Sauer and Seuring, 2023), supplemented by an analysis of grey literature was used to identify the

challenges. The main search terms were formulated for scanning the selected

database, Scopus. However, due to the limited use of the term first mile

logistics in preliminary research, the search focused on identifying challenges

associated with the first mile stage of ASC through the following string. The search

was limited to the last decade, ensuring the identification of up-to-date

challenges using Scopus, which was scanned by applying the following search

string.

TITLE ( (

"challenge" OR "problem" ) AND ( "supply chain"

OR "logistic" ) AND ( "agri* " ) ) AND ( PUBYEAR > 2011

AND PUBYEAR < 2023 ). Forty grey literature resources, comprising

international and national reports, were added to the 46 references screened in

Scopus. Based on the inclusion and exclusion criteria, the 86 resources was

reduced to 66 references obtained from both scientific (29) and grey literature

(37). The literature review of selected references resulted in the

identification of 90 overlapping but distinct first mile challenges of ASC.

These 90 challenges were initially grouped into 30 concepts and subsequently

clustered around 6 distinct themes. In addition, a detailed literature review

is presented in Subsection 3.1.

2.2. Prioritization and Weighing of Challenges

(P)

The need to distinguish

between evident and recessive challenges became apparent. The data obtained was

analyzed, and references were ranked based on a six-level evidence scale, which

ranged from 1 to 6

1. In how many references was the first mile challenge identified?

2. What are the evidence values of references that identified the first

mile challenge?

The following formula was used to calculate the evidence score of each challenge. In Equation 1, BEV denotes the base evidence value, representing the value of the most evident reference where a challenge is found.

where ES is the evidence

score, BEV is the base evidence value, and EV is the evidence value of other

references that a challenge is identified from (if any).

For example, assuming a challenge appeared in four references with evidence values of 2, 3, 4, and 4, then the BEV would be 2. Meanwhile, EV refers to the evidence values of other references where the challenge was identified, namely 3, 4, and 4. Equation 2 was used to calculate the evidence score of challenge X.

Subsection 3.2 further describes the analysis of evidence power for

first-mile challenges. Subsequently, the ES of the challenges is explored in

the QFD framework. The first mile challenges are ranked according to the

prioritized importance for the case company.

2.3. Operationalization of challenges (O)

Quality function deployment

(QFD) was developed as a practical tool to improve product and service quality by

focusing on customer needs and demands (Onar et al., 2016). Even though this method was

first introduced conceptually by

QFD is a practical tool that

converts consumer demands into quality characteristics, initially focused on

the context of product development

3.1. Identification and

Structuring of First Mile Challenges

Ninety first mile challenges

were identified from 66 references with varying levels of evidence. Even though

the clusters were naturally interrelated, there was enough data to categorize

each challenge distinctly. The identified clusters were economics, business,

finance, regulations, natural environment, phenomena, supply

chain management, logistics, skill set, workforce, and infrastructure

as shown in Figure 2.

The ever-increasing cost of

fuel, often caused by turbulent international politics, negatively affects

first mile actors

The agricultural industry is inherently

connected to nature, therefore, it is directly affected by changes in climate,

soil, and biodiversity (Isbister, Blackwell, and Riethmuller, 2013). Climate change and extreme

weather act as catalysts for other challenges

Regulations are intended to promote

the process development of ASC, although it often hinder the use of innovative

tools and managerial practices due to bureaucratic barriers in licensing and

registration

The efficiency of SC and the

logistics of agricultural produce is highly dependent on the location (Patidar and Agrawal, 2020). As globalization leads to

lengthier SC, efficiency becomes increasingly relevant

The Internet of Things and

blockchain are two examples of modern technologies that enhance process tracking

and support machinery and equipment management at the first-mile stage. However,

the adoption of such technologies is limited, particularly in developing

regions

Figure 2 Hierarchical clusters of

first mile challenges for agricultural logistics

Despite being a labor-intensive industry, agriculture holds immense

potential for technological advancement and automation to reduce repetitive tasks

and aid in process monitoring. However, the industry is in high need of skilled

and comprehensive professionals (Tang, Liu, and Chen, 2013). The training of stakeholders,

particularly at the first mile, is a fundamental need to equip these

individuals with the required skills for modern agricultural practices

3.2. Evidence

Power Analysis

The identified challenges were

grouped into three classes based on the evidence power. These categories are as follows

· - The evident challenges (n = 21) the evidence scores of

first mile challenges in this class were less than the value of 2.72 (M-(s/2))

and identified in at least two references, as shown in Figure 3. M: Median, s:

standard deviation

· - Median evidence challenges (n = 18) the evidence

scores of first mile challenges in this class were higher than the value of

2.72 and lower than the value of 3.88 (M+(s/2)) and were identified at least in

two references.

· - Recessive challenges (n = 51) This class has two types

of challenges. The first group included the first mile challenges with evidence

scores higher than 3.88. Meanwhile, the second group comprised challenges

identified from only one source, regardless of the evidence score.

The higher the first mile

challenges located on the diagram, the more evident the issues. The most prominent

challenge identified is too long SC and excessive circulation links. Heavy

wastage throughout the SC, extreme weather and complex and poor

road network were other identified first mile challenges from the

literature. The challenges from the regulation cluster were not classified as evident,

therefore, it was not shown in Figure 3. The only challenge classified as

evident in the skill set and workforce was aging workforce shortage

and performance of labor.

The evident challenges were presented to managers in the case company

through semi-structured interviews. For further analysis in the QFD framework,

the challenges were ranked with respect to four options, namely Crucial,

essential, not necessary, and no information. However, out of 21 evident

first mile challenges, four were identified as crucial from respective

perspectives, too long SC and excessive circulation links, high costs

in SC, fluctuant fuel costs, and nontransparent processes, as

shown in Figure 3. Additionally, seven evident first mile challenges were

identified as necessary from diverse perspectives, as shown in Figure 3.

Figure 3 Evident first mile

challenges

3.3. Demonstration

of QFD

QFD was usually applied through the House of Quality, a matrix-style chart that correlates Whats with Hows, consisting of six submatrices, as shown in Figure 4.

Figure 4 Design of house of

quality. Customer requirements (1), technical specifications (2), planning

matrix (3), interrelationship matrix (4), technical correlation matrix (5), and

technical priorities (6)

In the case of this study,

zone 1 represented evident first mile challenges, which are classified based on

respective ES, while the ES of each challenge was found in zone 3. Zone 2 consisted of

operationalization actions (OAs) aimed at reducing identified challenges. Some

identified actions were at a high level, requiring cooperation with regulatory

bodies and stakeholders, while others were related to product features.

Prospective actions were determined through workshops and meetings with a focus

working group.

In zone 3, the planning matrix

is comprised of the ES of challenges and value for importance (VFI) specific to

the case company. Furthermore, the ES model is described in Section 2.

VFI were identified through surveys and semi-structured interviews with the

case company, using a 4-level likert scale. The evident challenges were ranked as

not significant (-1), no information (0), important (3),

and crucial (5). To accurately reflect the ratings, first mile challenges

considered as not important were assigned a value of -1 on the likert scale.

Similarly, no information was assigned a neutral value quantified as 0.

The weighted prioritization

score (WPS) was located in the far-right column of zone 3 and can be developed

in varied ways depending on decision-making needs

The WPS model was developed for challenge ?, using Equation 3.

For example, the WPS for the challenge of too

long SC and excessive circulation links was calculated as follows Equation 4.

Zone

4 served as the core of the house of quality, depicting the quantified relationship

level between OAs and evident first mile challenges. The zone connects OAs with

the first mile challenges, while the respective quantified relationship levels

and symbols are shown in Table 1. The values for relationship levels were used

in zone 6 - OAs priority assessment.

Figure 5 Demonstration of House of Quality

Table 1 Relationship levels and symbols

Zone 5 showed

the mutual and reverse relationships between prospective OAs, which were

depicted by (+) and (-), respectively. This zone enabled decision makers to

understand how the implementation of an action affected others. In particular, it

allows decision makers to discern how closely ranked actions relate to each other.

Assuming an action facilitates the implementation of others (more +), then the

decision maker can prioritize it over the other.

In zone 6, the

priority of OAs was assessed by determining the relationship matrix values and

the WPS. This included summing the products of WPS for each first mile challenge

and the corresponding value in the relationship matrix for each OAs connected in

the same pathway

Where RL is the relationship level between a particular challenge and operationalization action. For example, to calculate the priority score for Decrease the cost of the vehicle:

4. Discussion

This study

sheds light on first mile challenges of ASC and their transformation into

actionable operations through an agri-machinery case. The transformation of

these overarching challenges into operationalization actions that guide further

innovative solutions were illustrated through exploration. Furthermore,

a practical application with prospective tools was demonstrated, with the

introduction of a comprehensive four-step process known as ISPO

(identification, structuring, prioritization, and operationalization).

Initially, 90 first mile ASC challenges, clustered around six themes as shown

in Figure 2, were identified, but after evidence power analysis, the number

reduced to 21. Figure 3 showed that the case company identified 11 of these as

important or crucial. Using QFD, nine challenges were prioritized with normalized

WPS exceeding 0.5. Finally, cooperating with other stakeholders of the SC,

including regulators and farmers, was considered critical in effectively

addressing prioritized first mile challenges, as shown in Figures 5 and 6.

Technological advancement and

sustainability are prominent themes in research on the agricultural supply

chain (ASC). However, significant attention has been paid to the overall supply

chain or downstream aspects rather than the upstream segment

Thicker arrows in the figure reflect a strong relationship, while

thinner arrows reflect a moderate relationship. With the help of the QFD

framework, organizations can strategically divert efforts to more effective

areas in line with prioritized solution demands

The

operationalization action plan included cooperating with regulators,

other stakeholders of the SC, and farmers as a result of the proposed

framework for the agri-machinery case company. The action of cooperating

with regulators was reported to be the most critical. The first mile

challenges with higher WPS were strategically positioned, requiring cooperation

with and support from regulatory bodies. For example, addressing challenges

related to complex and poor road network, fluctuating fuel costs

and water scarcity, as well as challenging access to fresh water

strongly depended on cooperation with these regulatory bodies

Figure 6

Critical operationalization actions and first mile challenges

The negative impacts of soil compaction are unique to the first

mile stage of SC, as opposed to several other challenges that tend to affect

other stages. Meanwhile, since the soil can easily be compacted by agriculture

machinery and equipment during logistics operations around the field

This study investigates the primary challenges faced by ASC and their

translation into actionable operations using a case study involving

agricultural machinery. It illustrates the transformation of these challenges into

practical steps through the ISPO framework: Identification, Structuring,

Prioritization, and Operationalization. In this

context, the study significance focused on the instrumental value, drawing from

constructive methodologies. The present investigation inevitably had a number

of limitations. Firstly, the Scopus search was limited to titles, potentially

excluding relevant references discussing first mile challenges solely within

the text. Secondly, grey literature searches were limited to available online

reports, possibly overlooking significant offline resources. Additionally, some

references were excluded due to limited discussion of target concepts.

Exclusion decisions included multiple research projects to ensure objectivity.

Finally, the developed method required testing across diverse ASC stakeholders,

as it was only applied in one agri-machinery use case. The proposed process

represented a construct awaiting validation through subsequent research and

practical implementation. Further research needs to be conducted, concentrating

on applying the same method to different ASC stakeholders.

The authors are grateful to Docent Professor David

Edwards for his significant support and insights in this research. The authors are

also grateful to the LEVITOI partners for funding this research through the

Business Finland (Grant ID 3509/31/2021).

Abdullahi, H.O.,

Mohamud, I.H., Gele, A.O.M., Kafi, A., 2024. The Role of Technology in

Transforming Agricultural Supply Chain Management: Systematic Literature

Review. Journal of Logistics, Informatics and Service Science, Volume 11(1),

pp. 239–251

Akao, Y., 1990.

Quality Function Deployment: Integrating Customer Requirements into Product

Design. G.H Mazur (trans). Cambridge: Productivity Press

Asian

Development Bank, 2016. Improving Logistics for Perishable Agricultural Products

in the People’s Republic of China. Available online at:

https://rksi.adb.org/wp-content/uploads/2021/01/2016-Report-improving-logistics-agriculture.pdf,

Access ed on September 1, 2023

Awan, S., Ahmed,

S., Ullah, F., Nawaz, A., Khan, A., Uddin, M.I., Alharbi, A., Alosaimi, W., Alyami,

H., 2021. IoT with BlockChain: A Futuristic Approach in Agriculture and Food

Supply Chain. Wireless Communications and Mobile Computing, Hindawi Limited,

Volume 2021, pp. 1–14

Bannor, R.K., Kyire,

S.K.C., 2021. A Review on Understanding Blockchain Technology in Global Supply

Chains: Opportunities and Challenges for Agribusinesses. Indian Journal of

Economics and Development, Volume 17(4), pp. 917–927

Benner, M.,

Geerts, R.F.R., Linnemann, A.R., Jongen, W.M.F., Folstar, P., Cnossen, H.J.,

2003. A Chain Information Model For Structured Knowledge Management: Towards

Effective and Efficient Food Product Improvement. Trends in Food Science and

Technology, Volume 14(11), pp.

469–477

Cagliano, R., Worley, C.G., Caniato, F.F.A., 2016. The Challenge of

Sustainable Innovation in Agri-Food Supply Chains. Organizing for

Sustainable Effectiveness, Volume 5, pp. 1–30

Cuéllar, A.D., Webber,

M.E., 2010. Wasted food, wasted energy: The embedded energy in food waste in

the United States. Environmental Science and Technology, American

Chemical Society, Volume 44(16), pp. 6464–6469

Dasgupta, S., Kanchan, S., Kundu, T., 2019. Creating a KPI

Tree for Monitoring and Controlling Key Business Objectives of First Mile

Logistics Services. In: Proceedings of the International Conference on

Industrial Engineering and Operations Management, IEOM Society International,

Bangkok, pp. 716–727

DEFRA, 2015.

Cross Compliance in England: Soil Protection Standards. Available online at: https://www.gov.uk/government/publications/cross-compliance-guidance-for-2015,

Accessed on September 1, 2023

Despoudi, S.,

2021. Challenges in Reducing Food Losses at Producers’ Level: The Case of Greek

Agricultural Supply Chain Producers. Industrial Marketing Management,

Volume 93, pp. 520–532

Dzebo, A.,

Janetschek, H., Brandi, C., Iacobuta, G., 2019. Connections between the Paris

Agreement and the 2030 Agenda The Case for Policy Coherence, Stockholm.

Available online at: https://www.sei.org/wp-content/uploads/2019/08/connections-between-the-paris-agreement-and-the-2030-agenda.pdf,

Accessed on September 1, 2023

European Commission,

2023. Communication from the Commission to the European Parliament, The

European Council, The Council, The European Economic and Social Committee and

The Committee of the Regions. A Green Deal Industrial Plan for the Net-Zero

Age. Brussels, 1.2.2023. COM(2023) 62 final. Available online at: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52023DC0062,

Accessed September 1, 2023

European

Consumer Organisation, 2022. Joint Open Letter on Concerns Over PEF Methodology

for Agri-Food Products. Available online at

https://eeb.org/wp-content/uploads/2022/03/Joint-letter-on-concerns-over-PEF-methodology-for-agri-food-products.-MAR-2022..pdf,

Accessed on September 1, 2023

European

Environment Agency, 2019. Communication from the Commission to the European

Parliament, The European Council, The Council, The European Economic and Social

Committee and The Committee of the Regions. The European Green Deal.

COM/2019/640 final”, SG, Brussels. Available online at: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52020SC0209&rid=3,

Accessed on September 1, 2023

European

Parliament, 2017. State of Play of Farmland Concentration in the EU: How to

Facilitate the Access to Land for Farmers. Available online at: https://www.europarl.europa.eu/doceo/document/A-8-2017-0119_EN.html,

Access ed on September 1, 2023

European Union,

2021. Regulation (EU) 2021/1119 of the European Parliament and of the Council

of 30 June 2021 Establishing The Framework For Achieving Climate Neutrality And

Amending Regulations (EC) No 401/2009 and (EU) 2018/1999. European Climate Law.

Available online at: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32021R1119#:~:text=This%20Regulation%20sets%20out%20a,Article%207%20of%20the%20Paris,

Accessed on September 1, 2023

Fargnoli, M.,

Costantino, F., Di-Gravio, G., Tronci, M., 2018. Product Service-Systems Implementation:

A Customized Framework to Enhance Sustainability and Customer Satisfaction. Journal

of Cleaner Production, Elsevier Ltd, Volume 188, pp. 387–401

Food and

Agriculture Organization (FAO), 2017. The Future of Food and Agriculture and

Challenges. Available online at: https://www.fao.org/3/i6583e/i6583e.pdf,

Accessed September 1 2023.

Gardas, B.B.,

Raut, R.D., Cheikhrouhou, N., Narkhede, B.E., 2019. A Hybrid Decision Support

System For Analyzing Challenges Of The Agricultural Supply Chain. Sustainable

Production and Consumption, Volume 18, pp. 19–32

Heryani, H., Legowo, A.C., Yanti, N.R., Marimin, Raharja, S.,

Machfud, Djatna, T., Martini, S., Baidawi, T., Afrianto, I., 2022. Institutional

Development in the Supply Chain System of Oil Palm Agroindustry in South

Kalimantan. International Journal of Technology, Volume 13(3), pp.

643–654

Hussain, S., Ahonen, V., Karasu, T., Leviäkangas, P., 2023. Sustainability

of Smart Rural Mobility and Tourism: A Key Performance Indicators-Based

Approach. Technology in Society, Volume 74, p. 102287

Isbister, B.,

Blackwell, P., Riethmuller, G., 2013. Controlled Traffic Farming Technical

Manual. Available online at:

https://www.nacc.com.au/wp-content/uploads/2015/05/NACC_Controlled_Traffic_Farming_Technical_Manual.pdf,

Accessed September 1, 2023

Jianying, F.,

Bianyu, Y., Xin, L., Dong, T., Weisong, M., 2021. Evaluation on Risks of

Sustainable Supply Chain Based on Optimized BP Neural Networks in Fresh Grape

Industry. Computers and Electronics in Agriculture, Volume 183, p. 105988

Karasu, T., Hussain, S., Leviäkangas, P., 2023a. First Mile

Challenges for Agricultural Logistics”, in Clausen, U. and Dellbrügge, M.

(Eds.), Advances in Resilient and Sustainable Transport, Springer, Cham,

Dortmund, pp. 60–74

Karasu, T., Hussain, S., Tuomela, A., Pekkala, V., Leviäkangas, P., 2023b.

Challenges for First-Mile Logistics in Primary Production, Oulu. Available

online at: http://urn.fi/urn:isbn:9789526234403, Accessed on September 1, 2023

Khoirunisa, R., Mushfiroh, A., Gamal, A., 2023. The Identification of

Challenges in Innovation Ecosystem of West Java, Indonesia Using a Systematic

Literature Review. International Journal of Technology, Volume 14(7),

pp. 1408–1418

Lingjuan, T.,

Linhong, L., Menghan, L., 2018. Optimization of the Front-end Logistics Routes

of Agricultural Products Based on Network Platform. International Journal

for Engineering Modelling, University of Split, Volume 31(4), pp. 1–14

Majluf-Manzur,

Á.M., González-Ramirez, R.G., Velasco-Paredes, R.A., Villalobos, J.R., 2021. An

Operational Planning Model to Support First Mile Logistics for Small

Fresh-Produce Growers. In Communications in Computer and Information Science,

Springer Science and Business Media Deutschland GmbH, Volume 1408, pp. 205–219

Mikhailov, L., Didehkhani, H., Sadi-Nezhad, S., 2011. Weighted

Prioritization Models In The Fuzzy Analytic Hierarchy Process. International

Journal of Information Technology and Decision Making, Volume 10(4), pp.

681–694

Naseer, M.A.U.R.,

Ashfaq, M., Hassan, S., Abbas, A., Razzaq, A., Mehdi, M., Ariyawardana, A.,

Anwar, M., 2019. Critical Issues at the Upstream Level in Sustainable Supply

Chain Management of Agri-Food Industries: Evidence from Pakistan’s Citrus

Industry. Sustainability, Volume 11 No. 5, p. 1326

Obour, P.B.,

Schjønning, P., Peng, Y., Munkholm, L.J., 2017. Subsoil Compaction Assessed By

Visual Evaluation and Laboratory Methods. Soil and Tillage Research, Volume

173, pp. 4–14

OECD, 2011. OECD

Sustainable Manufacturing Toolkit – Seven Steps to Environmental Excellence.

Available online at https://www.oecd.org/innovation /green/toolkit/48704993.pdf,

Accessed on March 15, 2023

OECD-FAO, 2016.

OECD FAO Guidance for Responsible Agricultural Supply Chains. OECD and Food and

Agriculture Organization

Onar, S.C.,

Oztaysi, B., Kahraman, C., Yanik, S., Senvar, O., 2016. A Literature Survey On

Metaheuristics in Production Systems. In Metaheuristics

for Production Systems, Operations

Research/ Computer Science Interfaces Series, Springer New York LLC, Volume 60,

pp. 1–24

Parfitt, J.,

Brockhaus, A., Croker, T., 2021. Driven to Waste: The Global Impact of Food

Loss and Waste on Farms. Available online at https://www.worldwildlife.org/publications/driven-to-waste-the-global-impact-of-food-loss-and-waste-on-farms,

Accessed on September 1, 2023

Patidar, R., Agrawal,

S., 2020. A Mathematical Model Formulation to Design a Traditional Indian

Agri-Fresh Food Supply Chain: A Case Study Problem. Benchmarking: An

International Journal, Volume 27(8), pp. 2341–2363

Patidar, R.,

Venkatesh, B., Pratap, S., Daultani, Y., 2018. A Sustainable Vehicle Routing

Problem for Indian Agri-Food Supply Chain Network Design, in Senanayake C,

Maheshwaran S., Perera K., Navarathna R. and Manipura A. (Eds.), In: 2018

International Conference on Production and Operations Management Society, IEEE,

Peradeniya, pp. 1–5

Porter, S.D., Reay,

D.S., 2016. Addressing Food Supply Chain and Consumption Inefficiencies:

Potential for Climate Change Mitigation. Regional Development and Change,

Volume 16(8), pp. 2279–2290

Puglieri, F.N.,

Ometto, A.R., Salvador, R., Barros, M.V., Piekarski, C.M., Rodrigues, I.M., Netto,

O.D., 2020. An Environmental and Operational Analysis of Quality Function

Deployment-Based Methods. Sustainability, Volume 12(8), p. 3486

Raut, R.D.,

Gardas, B.B., Narkhede, B.E., Jha, M.K., 2019. Analysing the Challenges In

Sustainable Agricultural Supply Chain System in India. International Journal

of Business Excellence, Volume 18(3), pp. 336–359

Reis, L.P.,

Fernandes, J.M., Silva, S.E., Pereira, A.D.S., 2022. Application of Quality

Function Deployment as an Integrative Method to Knowledge Management

Implementation. Journal of Information and Knowledge Management, Volume

21(2), p. 2250022

Sadati, A.K.,

Nayedar, M., Zartash, L., Falakodin, Z., 2021. Challenges for Food Security and

Safety: A Qualitative Study in an Agriculture Supply Chain Company in Iran. Agriculture

and Food Security, Volume 10(1), pp. 1–7

Sauer, P.C., Seuring,

S., 2023. How to Conduct Systematic Literature Reviews in Management Research:

A Guide in 6 Steps and 14 Decisions. In Review of Managerial Science,

Volume 17(5), pp. 1899–1933

Schjønning, P.,

Lamandé, M., Munkholm, L.J., Lyngvig, H.S., Nielsen, J.A., 2016. Soil

Precompression Stress, Penetration Resistance and Crop Yields in Relation to

Differently-Trafficked, Temperate-Region Sandy Loam Soils. Soil and Tillage

Research, Volume 163, pp. 298–308

Schjønning, P.,

Lamandé, M., Thorsøe, M.H., Frelih-Larsen, A., 2018. Policy Brief Subsoil

Compaction-A Threat to Sustainable Food Production and Soil Ecosystem Services.

Available online at: https://www.ecologic.eu/sites/default/files/publication

/2018/2730_recare_subsoil-compaction_web.pdf, Accessed on September 1, 2023

Schjønning, P.,

van den Akker, J.J.H., Keller, T., Greve, M.H., Lamandé, M., Simojoki, A.,

Stettler, M., Arvidsson, J., Breuning-Madsen, H., 2015.

Driver-Pressure-State-Impact-Response (DPSIR) Analysis and Risk Assessment for

Soil Compaction—A European Perspective. Advances in Agronomy, Volume

133, pp. 183–237

Sharma, A.K., Mehta, I.C., Sharma, J.R., 2010. Analysing

Programming Tools for the Development of Quality Function Deployment Software.

International Journal of Information and Decision Sciences, Volume 2(2),

pp. 132–146

Shen, X.X., Tan,

K.C., Xie, M., 2000. Benchmarking in QFD for Quality Improvement. Benchmarking:

An International Journal, Volume 7(4), pp. 282–291

Soto-Silva,

W.E., González-Araya, M.C., Oliva-Fernández, M.A., Plà-Aragonés, L.M., 2017.

Optimizing Fresh Food Logistics for Processing: Application For a Large Chilean

Apple Supply Chain. Computers and Electronics in Agriculture, Volume

136, pp. 42–57

Stichler, J.F.,

2010. Weighing the Evidence. Health Environments Research and Design

Journal, Volume 3(4), pp. 3–7

Tang, J., Liu,

K., Chen, Q., 2013. Study on Cold Chain Logistics of Vehicle Routing Problem for

Agricultural Products. In: Proceedings of 2013 IEEE International

Conference on Service Operations and Logistics, and Informatics, pp. 317–322

Verworn, B., Herstatt,

C., 2002. The Innovation Process: An Introduction To Process Models. Available

Online at https://www.econstor.eu/bitstream/10419/55466/1 /506450392.pdf,

Accessed on September 1, 2023

Wicaksono, T., Illés,

C.B., 2022. From Resilience to Satisfaction: Defining Supply Chain Solutions for

Agri-Food SMEs Through Quality Approach. PLoS ONE, Volume 17(2), p. 0263393

World Bank,

2019. Enabling the Business of Agriculture 2019. Available Online at: https://openknowledge.worldbank.org/server/api/core/bitstreams/9cd7105f-e1c2

-52ee-ad27-a63d983a2d2f/content, Accessed on September 1, 2023

World Economic

Forum, 2023. The Future of Industrial Strategies: Five Grand Challenges for

Resilient Manufacturing. Available Online at: https://www3.weforum.org/docs/ WEF_The_Future_of_Industrial_Strategies_2023.pdf,

Accessed on September 1 2023.

Yadav, S., Garg,

D., Luthra, S., 2020. Analysing Challenges for Internet of Things Adoption in

Agriculture Supply Chain Management. International Journal of Industrial and

Systems Engineering, Volume 36(1), pp. 73–97

Yazdani, M.,

Gonzalez, E.D.R.S., Chatterjee, P., 2019. A Multi-Criteria Decision-Making

Framework for Agriculture Supply Chain Risk Management Under a Circular Economy

Context. Management Decision, Volume

59(8), pp. 1801–1826

Zarei, M.,

Fakhrzad, M.B., Paghaleh, M.J., 2011. Food Supply Chain Leanness Using a

Developed QFD Model. Journal of Food Engineering, Volume 102(1), pp.

25–33

Zhang, Z., Liao,

H., Chang, J., Al-barakati, A., 2019. Green-Building-Material Supplier

Selection with A Rough-Set-Enhanced Quality-Function Deployment.

Sustainability, Volume 11(24), p. 7153

Ziemnowicz, C.,

2013. Joseph A. Schumpeter and Innovation. Encyclopedia of Creativity, Invention,

Innovation and Entrepreneurship. In Encyclopedia of

Creativity, Invention, Innovation and Entrepreneurship, pp. 1171–1176

Zulkarnain,

Machfud, Marimin, Darmawati, E., Sugiarto, 2023. Design of Graphic Concept

Model for Specialty Coffee Packaging Labels. International Journal of

Technology, Volume 14(3), pp.

606–617