Design Optimization of a Point Absorber and Hydraulic Power Take-Off Unit for Wave Energy Converter

Corresponding email: yanuar@eng.ui.ac.id

Published at : 18 Sep 2024

Volume : IJtech

Vol 15, No 5 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i5.6617

Waskito, K.T., Siahaan, J.A.C., Chuzain, M.A.N., Yanuar, Pal, S., 2024. Design Optimization of a Point Absorber and Hydraulic Power Take-Off Unit for Wave Energy Converter. International Journal of Technology. Volume 15(5), pp. 1524-1538

| Kurniawan T. Waskito | 1. Department of Mechanical Engineering, Universitas Indonesia, 16424, Depok, Indonesia. 2. Tropical Renewable Energy Center (TREC), Faculty of Engineering, Universitas Indonesia, 16424, Depok, Indon |

| Juan A.C. Siahaan | Department of Mechanical Engineering, Universitas Indonesia, 16424, Depok, Indonesia |

| Muhamad A.N. Chuzain | Department of Mechanical Engineering, Universitas Indonesia, 16424, Depok, Indonesia |

| Yanuar | Department of Mechanical Engineering, Universitas Indonesia, 16424, Depok, Indonesia |

| Sumit Pal | TU Delft Wind Energy Institute (DUWIND), Kluyverweg 1, 2629 HS Delft, The Netherland |

In recent times, the point absorber Wave Energy

Converter (WEC) has gained popularity due to its practicality. Investigating

the parameters of the Hydraulic Power Take-Off (HPTO) in the WEC, including

hose diameter and check valve variations, is crucial. This study analyzes

optimization using the Sequential Quadratic Programming (SQP) method in

MATLAB/SimScape, leading to a more comprehensive understanding of the

interactions among HPTO components, such as hydraulic cylinders, check valves,

hoses, accumulators, motors, and generators. Key system performance indicators,

including pressure drop, flow rate, and power output, were assessed in both

single and two-point absorber HPTO configurations. The optimization process

yielded a maximum hydraulic power output of 7.33 kW, a mechanical power output

of 6.41 kW, and an electrical power output of 5.4 kW using a 2-inch hose

diameter. Additionally, utilizing a two-point absorber model enhanced power

generation capacity by 47.4%, reaching 9.45 kW. The findings highlight the

significant pressure drop at the check valve, with the 2-inch hose model

experiencing a drop of 31.874 bar. These results demonstrate that optimizing

HPTO parameters can significantly improve the efficiency of converting wave

energy into electricity, providing valuable design recommendations for WEC

technology.

Design optimization; Hydraulic power take-off; Hose diameter; Sequential quadratic programming; Wave energy converter

Many

contemporary power plants predominantly rely on conventional energy sources.

However, a notable drawback associated with this approach is the considerable

emissions generated, which inflict detrimental effects on the environment. Consequently, there exists a progressive

trend towards adopting renewable energy sources that manifest a markedly

diminished ecological footprint

The

literature review highlights the significance of a robust Power-Take Off (PTO)

system in efficiently converting ocean wave energy into electrical power

Furthermore,

the review emphasizes the importance of evaluating the performance of valves

and hoses, pivotal components in the HPTO setup, to understand fluid flow

dynamics and pressure distribution within the system. However, it does not

explicitly compare the performance or effectiveness of different types of

valves and hoses, which could be a potential avenue in this research.

The

necessity for a more efficient and economical approach to optimize HPTO systems

for maximum power generation needs to be investigated. To advance WEC with

HPTO, the stability and energy absorption mechanisms of the HPTO system need

refinement. The optimal design of the kinematics of the floating arm cylinder

plays a pivotal role in the HPTO system. It plays a pivotal role in achieving

optimal power generation. Therefore, it is essential to accurately estimate

each component, as mentioned in the study by

In

this study, we employ the Sequential Quadratic Programming (SQP) numerical

optimization method to estimate parameter values for each component of the

Hydraulic Power Take-Off (HPTO) system, specifically focusing on the check

valve and hose. Unlike traditional experimental methods, SQP offers advantages

such as handling nonlinear relationships, constrained optimization, smooth and

continuous functions, iterative refinement, handling multiple design variables,

global convergence, and incorporation of sensitivity analysis. By leveraging

SQP, the study aims to identify parameter combinations that maximize power

output and consider existing constraints effectively and economically. This

systematic approach represents a novel method for optimizing HPTO systems in

WECs, thereby addressing the research gap and contributing to the advancement

of wave energy conversion technologies.

This section describes the methods for

modeling the floating absorbers and HPTO. It begins by modeling the WEC with

the HPTO unit, providing a mechanical overview of the WEC. Next, it describes

the mathematical formulation of the HPTO and the parameter optimization process

using Sequential Quadratic Programming.

2.1. Modeling the WEC with HPTO Unit: An Overview

The evaluation and presentation of the

HPTO is initiated by outlining its layout and key components. This includes a

description of the HPTO's main features and overall operation. The HPTO with

Double Acting Cylinder (DAC) was selected based on its component efficiency and

power generation capabilities. In this system, the floating absorber is

connected to a fixed body to capture the kinetic energy of ocean waves

effectively. The HPTO

system is coupled with floating absorbers to convert mechanical energy into

usable electrical power. Figure 2 displays the floating absorber system with a Hydraulic Power

Take-Off unit. This

unit comprises a Hydraulic Motor (HM), Check Valve (CV), High-Pressure

Accumulator (HPA), Low-Pressure Accumulator (LPA), and a generator (G). In this

design, the floating absorber's arm experiences reciprocating motion in

response to pitch and heave motions caused by ocean waves at certain

frequencies. This arm motion actuates the cylinder mechanism, generating

pressure in each chamber. This pressure drives hydraulic fluid into the HPA via

hydraulic hoses and check valves (CV1 and CV3). The pressurized fluid is then

directed to the HM. Any excess pressure from the hydraulic motor is stored in

the LPA, subsequently re-entering the flowline input of the double-acting

cylinder through CV2 and CV4.

Figure 1 Design and Modeling

of the WEC, Single-Point WEC System, Adepted fron

2.2. Mechanical overview of the WEC

The

geometry of the floaters can be represented as a combination of a sphere and an

upper truncated cone. These floaters are primarily constructed with glass-fiber

material and include a ballast chamber that can be filled through a hole

located at the bottom. This chamber retains water during power generation. The

ballast serves two main purposes: reducing the absorber's natural frequency and

adjusting the draft of the floater as required. Additionally, the PTO cylinders

serve as a mechanism for elevating the floaters during storm protection.

The

oscillating motion of the floater arm generates a moment, as depicted in Figure 3. The arm

position is described by the angle which is defined to be zero when the floater is horizontal. Positive

rotation is defined as the floater moving upwards. The angular velocity of the

arm is denoted

The PTO cylinder force is denoted

The length

is the cylinder stroke at which

the arm angle

is zero. The distance

is the cylinder’s moment arm for

applying torque to the float arm and is dependent on the angle

The relation of the cylinder stroke and arm angle may be expressed in

Equations (1-3),

The cylinder’s moment arm may be expressed as:

2.3. Mathematical formulation of the HPTO model

In the HPTO unit, many parameters are

considered, such as chamber piston area piston friction

the pressure of the hydraulic chamber

piston acceleration

Mass of the piston, rod, and oil

and gravitational acceleration

All equations are written

in Equation (6-8).

The piston chamber experiences constantly

changing pressure due to the upward and downward motion. By using equations (9)

and (10), it is possible to obtain dynamic values of pressure in the piston

chamber by considering the effective bulk modulus in/out volumetric flow

and velocity on piston

The chamber area is obtained from Equations (11) and (12).

are the piston and rod diameters.

The

fluid flow rectifier uses four check valves in each cylinder. In equation (13), is the flow through the check valve.

are the pressure on the in and out section of the

valve.

is the discharge coefficient.

is the area of the valve.

is the density of fluid, oil.

High-pressure

accumulators (HPA) and Low-Pressure accumulators (LPA) are essential components

in maintaining pressure stability in the PTO system. Equation (14-17) is used

to find the pressure and volume values of the accumulator. are the pressure and

pre-charge pressure in the HPA and LPA.

are the initial and the instantaneous volume

of gas in the HPA and LPA, and ? is the adiabatic index accumulators.

Volumetric flow in HPA and LPA can be calculated by

equations (18) and (19):

Equation

(20) below is used to obtain volumetric flow through the hydraulic motor. are displacement, speed, and volumetric flow

losses of the HM. The torque in the HM

can

also be determined by Equation (21), where

is the difference in pressure in HM.

Hoses

play a crucial role in connecting different components in hydraulic systems.

They facilitate the smooth flow of hydraulic fluid, which helps to convert

fluid energy into mechanical energy. This process ultimately leads to the

generation of electrical power. During simulations conducted in Simulink, hoses

are represented as hydraulic resistive tubes, accounting for the hydraulic

channel's resistance. Additionally, these hoses tend to experience pressure

losses, that is subsequently simulated within Simulink using the Darcy equation

as in the following Equations (22-24):

P is Pressure loss along the pipe due to friction, q is flowrate

through the pipe. Re is a Reynold Number, and are Reynold number at laminar and turbulent flow. Ks is the

shape factor that characterizes the pipe cross-section.

are friction factors at laminar and turbulent flow.

are area, diameter, and length of pipe

hydraulic. r is Height of the roughness on the pipe internal surface

and, v is fluid kinematic viscosity.

2.4. Parameter Optimization of HPTO using Sequential

Quadratic Programming

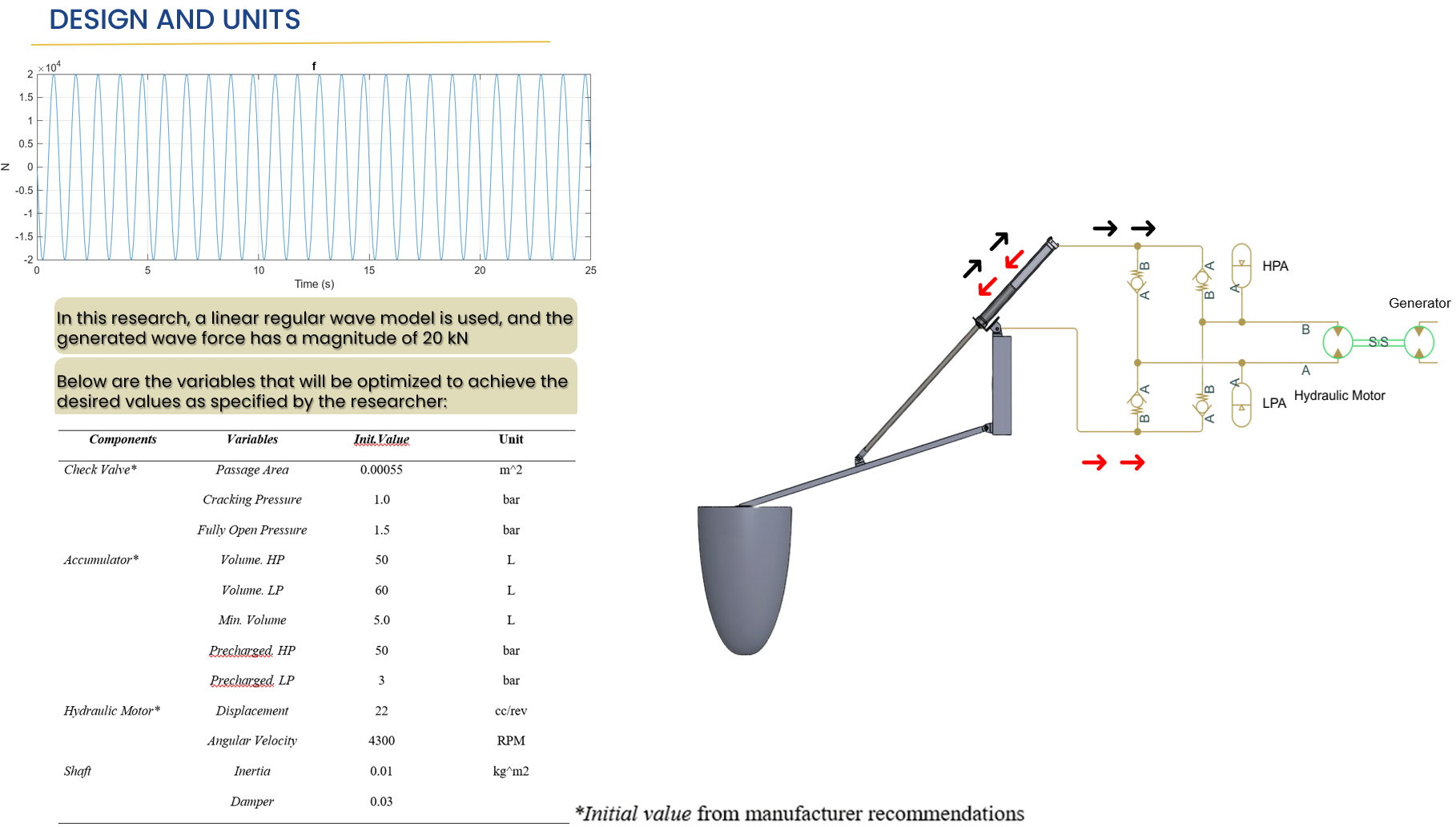

Figure 3 shows the flow chart of HPTO

optimization process. The initial value for finding the optimal parameters in

the check valve, accumulator, hose, and hydraulic motor is determined by the

predetermined sizing of the hydraulic cylinders and configurations of the

components.

The

Hydraulic Power Take-Off (HPTO) design phase encompasses the establishment of

layout, schematics, and configurations. This design process is executed using

MATLAB/Simscape and Simulink software. An approach based on available

manufacturer specifications is employed to determine initial component

parameters, as outlined in Table 1. Simulations are conducted on the design of

a single absorber to assess its performance, with simulation results compared

against desired performance outputs. This iterative process involves random

component selection until suitable outputs and parameters are

approximatedSubsequently, these parameters are processed using the Sequential

Quadratic Programming (SQP) algorithm through the Response Optimizer feature in

order to optimize the HPTO design. This optimization aims to determine the most

suitable parameter configurations obtained from Equation (25) is the gradient of the Lagrangian

function,

is the gradient of the objective

function

is the sum of all equality constraints,

is the sum of all inequality constraints. In

this study, the wave model employed is that of a regular wave with a force

amplitude of 20 kN and a wave frequency of 6.28 rad/s, as shown in Figure 4.

This wave frequency represents a wavelength of 1.56 m, and with an absorber

diameter of 0.2 m, it corresponds to

which is around resonance frequency.

Figure 3 Flow chart of the HPTO optimization process

Figure 4 Regular sine wave force input at the hydraulic cylinder 20kN

The Response Optimizer in MATLAB software enables users to determine design parameters based on the system's response to the desired objectives. To achieve this, specific values need to be defined. This optimization aims to ensure that the motor speed does not exceed 4300 RPM or 460 rad/s. Figure 5 illustrates the angular motor speed amplitude in rad/s before optimization.

Figure 5 Angular motor speed before optimization

Table 1 comprises variables to be optimized to achieve desired

values, referencing initial values provided by the manufacturer. Optimization is conducted for the design of

a single-point absorber with a schematic as depicted in Figure 6. In this

study, our focus lies in enhancing the generated power by analyzing the

appropriate valve utilization in conjunction with hose variations of sizes 1

inch, 1.5 inches, and 2 inches. Additionally, the inlet diameter of the check

valve is adjusted according to the hose size employed.

|

Components |

Variables |

Unit |

Initial Value* |

|

Hydraulic Cylinder |

Piston

Area |

m2 |

0.0031 |

|

|

Piston

Stroke |

m |

1 |

|

Check Valve |

Passage Area |

m2 |

0.0055 |

|

|

Cracking

Pressure |

bar |

1 |

|

|

Fully Open

Pressure |

bar |

2 |

|

Accumulator |

Volume,

HPA |

L |

50 |

|

|

Volume, HPA Min. Volume |

L L |

60 5 |

|

|

Precharged Pressure, HPA Precharged Pressure, LPA |

bar bar |

50 3 |

|

Hydraulic Motor |

Displacement

|

cc/rev |

22 |

|

|

Angular

Velocity |

RPM |

4300 |

|

Shaft |

Inertia Damper |

Kg/m2 Kg/m2 |

0.01 0.03 |

*Initial value obtained from the component

specification provided by the manufacturer

Figure 6 Schematic of the Single-Point

Absorber Model in Simulink illustrates the configuration of a single-point

absorber Wave Energy Converter (WEC) integrated with a Hydraulic Power Take-Off

(HPTO) system

The optimization

results yield recommended values for the predefined variables, with their

respective values presented in Table 2. These values are obtained after the

convergence of the optimization process, and they are subsequently used as

input values in each Simulink block. The system is then run to assess its

performance.

Table 2 Parameter of the HPTO model after optimization

|

Components |

Variables |

Unit |

Init. Value* |

Aft. Opt. (1”) |

Aft. Opt. (1.5”) |

Aft. Opt. (2”) |

|

Hyd. Cylinder |

Piston

Area |

m2 |

0.0031 |

0.0031 |

0.0031 |

0.0031 |

|

|

Piston

Stroke |

m |

1 |

1 |

1 |

1 |

|

Check Valve |

Passage Area |

m2 |

0.0055 |

0.0055 |

0.0077 |

0.01 |

|

|

Cracking

Pressure |

bar |

5 |

1.008925 |

1.162006 |

1.008783 |

|

|

Max

Opening Pressure |

bar |

2 |

2.0000136 |

1.202739 |

10.17489 |

|

Accumulator |

Volume,

HPA |

L |

50 |

45.62843 |

50.10132 |

45.59691 |

|

|

Volume, HPA Min. Volume |

L L |

60 5 |

45.62843 5 |

50.10132 5 |

45.59691 5 |

|

|

Precharged Pressure, HPA Precharged Pressure, LPA |

bar bar |

50 3 |

39.53618 3 |

38.25947 3 |

39.25947 3 |

|

Hyd. Motor |

Displacement

|

cc/rev |

22 |

25 |

25 |

25 |

|

Shaft |

Inertia Damper |

Kg/m2 Kg/m2 |

0.01 0.03 |

0.0108 0.033 |

0.01 0.031 |

0.01 0.033 |

Figure 7 Schematic of the Two-Point Absorber Model in Simulink presents a two-point absorber WEC system designed for enhanced energy capture. The model highlights the dual absorber configuration and its integration with the HPTO.

3.1. Cylinder Kinematics of a Single Floating Absorber

The following are the results of the

calculations for the arm angle, with the cylinder stroke,

as shown in Figure 8(a), and the moment arm

as shown in Figure 8(b), based on variations in the hydraulic cylinder

ratio with the arm length,

In Figure 8(a), the arm angle is formed

between 0° to 30° for a ratio of 0.84, and between -10° to 30° for a ratio o f

1. This limitation in the arm angle is due to the cylinder stroke limit, which

was designed to be 3.2 meters. From the graph in Figure 8(a), it is evident

that as the hydraulic cylinder ratio to

decreases, the stroke length of

the cylinder increases. This indicates that a longer arm length, bc

In

Figure 8(b), a smaller hydraulic cylinder ratio with the arm length, bc

Figure 8 The

Relationship Between the Arm Angle, and (a) the Cylinder Stroke,

and (b) the Moment Arm, da

3.2.

Performance of HPTO

The

double-acting cylinder initiates fluid flow from chamber A (high pressure) and

chamber B (low pressure), which is directed through hoses 1 and 2,

respectively. Subsequently, the high-pressure fluid encounters a barrier at CV1

before being flowed towards CV2. The flow emerging from CV2 proceeds through

hose 3, the HPA, hose 4, and eventually reaches the hydraulic motor. The fluid

discharged by the motor subsequently finds its way back to the cylinder by

means of the LPA.

Table

3 provides a comprehensive overview of the pressure drop and volumetric flow

rate across varying hose diameters. Notably, as the hose diameter increases,

there is a discernible decrease in pressure drop and a corresponding increase

in volumetric flow rate. Consequently, the angular velocity and torque are most

pronounced for the 2-inch diameter configuration. It's worth highlighting that

the primary source of substantial pressure drop occurs within the check valve,

whereas the dominant flow rate manifests within the HPA.

Table 3 Summary of flow parameter data on the

cylinder, hose, HPA, and motor.

|

Models |

Pressure at cylinder (port B) (bar) |

Pressure

at hyd. motor (bar) |

Total

pressure drops (bar) |

Volumetric flow rate at hose 2 (m3/s) |

Volumetric flow rate at hyd. motor(m3/s) |

Angular velocity (rad/s) |

Torque (Nm) |

|

1 in |

69.113 |

36.33 |

32.783 |

0.008675 |

0.002175 |

443 |

13.29 |

|

1.5 in |

69.15 |

37.06 |

32.09 |

0.009052 |

0.00225 |

456 |

13.68 |

|

2 in |

69.124 |

37.06 |

32.064 |

0.009128 |

0.00288 |

460 |

13.7 |

The results presented in Figure 9 and

Table 4 provide valuable insights into the performance of different

configurations of Hydraulic Power Take-Off (HPTO) systems in wave energy

conversion. In alignment

with the details outlined in Table 3, the focus on fluid dynamic parameters,

particularly angular velocity and torque, highlights their influence on

hydraulic motor performance, directly impacting the overall efficiency of power

generation.

Firstly,

it is noteworthy that the hydraulic motor power reaches its maximum when using

a 2-inch hose diameter. This indicates that the diameter of the hose plays a

crucial role in achieving optimal power output. This suggests that the diameter

of the hose plays a crucial role in optimizing power output. A larger hose

diameter likely allows for greater fluid flow, resulting in higher angular

velocity and torque, leading to increased power generation. This finding

underscores the importance of carefully selecting and optimizing the dimensions

of components within the HPTO system to maximize efficiency.

Figure 9 Torque,

angular velocity, and power output at the hydraulic motor for different hose

diameters

Additionally, Table 4

provides insight into the electrical power output derived from the generator

for each configuration. By comparing the power output of multi-point absorbers

with that of two-point absorbers, we can assess the potential for increased power

generation. The inclusion of multi-point absorber configurations demonstrates

the possibility of achieving higher power output through more complex absorber

designs that can capture energy from multiple points along the wave's motion.

Table 4 Power output data on

the motor and generator at different diameters

Compared to previous studies and other methods of energy conversion, this

current study focuses on an in-depth analysis of fluid dynamic parameters and

how they directly affect the performance of hydraulic motors. By optimizing

hose diameter and absorber configurations, the study enhances power generation

efficiency, thus contributing to advancements in wave energy conversion

technology. The inclusion of multi-point absorber configurations further

underscores the study's innovation, demonstrating the potential for increased

power output through more complex absorber designs.

However, the current approach may have limitations, such as potential constraints in scalability or adaptability to diverse marine environments. Future research directions could focus on addressing these limitations by exploring alternative materials for HPTO components or optimizing designs for varying wave conditions. Additionally, investigating the integration of complementary energy conversion methodologies, such as combining wave energy conversion with tidal or wind energy, could offer further enhancements in efficiency and overall performance.

In

conclusion, examining the cylinder kinematics of the WEC, a longer arm length,

denoted as "bc," leads to an amplified cylinder stroke, "xc,"

and an extended moment arm. The optimal configuration for hose diameter and

check valve passage area, yielding the highest power output, is achieved with a

2-inch hose diameter and a passage area of 0.01 m². This configuration yields a

hydraulic power output of 7.33 kW, a mechanical power output of 6.41 kW, and an

electrical power output of 5.4 kW. By employing a two-point absorber model, the

power generation capacity of the 2-inch model is enhanced by 47.4%, reaching

9.45 kW. Notably, the most significant pressure drop occurs at the check valve,

particularly in the 2-inch hose model, with a drop of 31.874 bar. Among the

models considered, the 1-inch hose model exhibits the highest pressure drop,

reaching 32.783 bar, signifying the difference between initial and final

pressures entering the motor. Volumetric flow rate experiences significant

fluctuations in the accumulator, as hydraulic fluid is filled and discharged

prior to reaching the motor. The most substantial volumetric flow rate is

achieved with the 2-inch hose model, owing to its larger hose volume, thereby

resulting in a greater volumetric flow rate.

This

work is supported by HIBAH PDUPT 2022 (091/E5/PG.02.00.PT/2022).

ANSYS, 2014. Aqwa Theory Manual Third-Party Software. Available online at

http://www.ansys.com, Accessed on February 25, 2023

Antolín-Urbaneja, J.C., Cortes, A., Cabanes,

I., Estensoro, P., Lasa, J., Marcos, M., 2015. Modeling Innovative Power

Take-Off Based on Double-Acting Hydraulic Cylinders Array for Wave Energy

Conversion. Energies, Volume 8(3), pp. 2230–2267

Ariefianto, R.M., Hadiwidodo, Y.S.,

Rahmawati, S., 2022. Experimental Study of a Wave Energy Converter Using a

Unidirectional Cascaded Gear System in a Short-Wave Period. International

Journal of Technology, Volume 13(2), pp. 321–331

Bosserelle, C., Reddy,

S., Kruger, J., 2016. Waves and Coasts in The Pacific Cost Analysis of

Wave Energy in The Pacific. Fiji: Pacific Community (SPC)

Cho, K.-P., Jeong,

S.-H., Sari, D.P., 2011. Harvesting Wind Energy from Aerodynamic Design for

Building Integrated Wind Turbines. International Journal of Technology,

Volume 3, pp. 189–198

Do, H.T., Dang, T.D., Ahn, K.K., 2018. A

Multi-Point-Absorber Wave-Energy Converter for The Stabilization of Output

Power. Ocean Engineering, Volume 161, pp. 337–349

Drew, B., Plummer, A.R., Sahinkaya, M.N.,

2009. A Review of Wave Energy Converter Technology. In: Proceedings of

The Institution of Mechanical Engineers, Part A: Journal of Power and

Energy, Volume 223(8), pp. 887–902

Gaspar, J.F., Calvario, M., Kamarlouei, M., Soares, C.G., 2018. Design

Tradeoffs of an Oil-Hydraulic Power Take-Off for Wave Energy Converters.

Renewable Energy, Volume 129, pp. 245–259

Hansen, A.H., Pedersen, H.C., 2016. Optimal Configuration of a Discrete

Fluid Power Force System Utilised in the PTO for WECs. Ocean Engineering,

Volume 117, pp. 88–98

Hansen, R.H., 2013. Design and Control of

the PowerTake-Off System for a Wave Energy Converter with Multiple Absorbers.

Department of Energy Technology, Aalborg University

Hansen,

R.H., Kramer, M.M., Vidal, E., 2013.

Discrete Displacement Hydraulic Power Take-Off System for The Wavestar Wave

Energy Converter. Energies, Volume 6(8), pp. 4001–4044

Jahangir, M.H., Alimohamadi,

R., Montazeri, M., 2023. Performance Comparison of Pelamis, Wavestar,

Langley, Oscillating Water Column and Aqua Buoy Wave Energy Converters

Supplying Islands Energy Demands. Energy Reports, Volume 9, pp.

5111–5124

Jusoh, M.A., Ibrahim, M.Z., Daud, M.Z.,

Albani, A., Yusop, Z.M., 2019. Hydraulic Power Take-Off Concepts for Wave

Energy Conversion System: A Review. Energies, Volume 12(23), p. 4510

Jusoh, M.A., Ibrahim, M.Z., Daud, M.Z.,

Yusop, Z.M., Albani, A., 2021. An Estimation of Hydraulic Power Take-Off Unit

Parameters for Wave Energy Converter Device Using Non-Evolutionary NLPQL and

Evolutionary GA Approaches. Energies, Volume 14(1), p. 79

Jusoh, M.A., Yusop, Z.M., Albani, A., Daud,

M.Z., Ibrahim, M.Z., 2022. An Improved Hydraulic Power Take-Off Unit Based on

Dual Fluid Energy Storage for Reducing the Power Fluctuation Problem in the

Wave Energy Conversion System. Journal of Marine Science and Engineering, Volume

10(8), p. 1160

Kusuma, A., 2018. Ocean Energy Overview: Feasibility Study of Ocean

Energy Ocean Energy Overview: Feasibility Study of Ocean Energy Implementation

in Indonesia Implementation In Indonesia. Dissertation, World Maritime

University

Langer, J., Quist, J., Blok, K., 2021. Review of Renewable Energy

Potentials in Indonesia and Their Contribution to a 100% Renewable Electricity

System. Energies, Volume14(21), p. 7033

Li, C., Zhang, D., Zhang, W., Liu, X., Tan,

M., Si, Y., Qian, P., 2022. A Constant-Pressure Hydraulic PTO System for a Wave

Energy Converter Based on a Hydraulic Transformer and Multi-Chamber Cylinder. Energies,

Volume 15(1), p. 241

Lin, Y., Bao, J., Liu, H., Li, W., Tu, L.,

Zhang, D., 2015. Review of Hydraulic Transmission Technologies for Wave Power

Generation. Renewable and Sustainable Energy Reviews, Volume 50, pp. 194–203

Marquis,

L., Kramer, M., Frigaard, P., 2010. First Power Production Figures From The Wave Star Roshage Wave Energy Converter. In: Proceedings of the 3rd International

Conference on Ocean Energy, Volume 68, pp. 1–5

Newman, J.N., 1986. Distributions of Sources

and Normal Dipoles Over a Quadrilateral Panel. Journal of Engineering

Mathematics, Volume 20(2), pp. 113–126

Pecher, A., 2017. Handbook of Ocean Wave Energy. Volume 7. Springer

International Publishing

Penalba, M., Cortajarena, J.A., Ringwood, J.V.,

2017. Validating a Wave-To-Wire Model for a Wave Energy Converter-Part II: The

Electrical System. Energies, Volume 10(7), p. 977

Penalba, M., Ringwood, J.V., 2016. A Review

of Wave-To-Wire Models for Wave Energy Converters. Energies, Volume

9(7), p. 506

Penalba, M., Sell, N.P., Hillis, A.J., Ringwood, J.V., 2017. Validating A

Wave-To-Wire Model For A Wave Energy Converter-Part I: The Hydraulic

Transmission System. Energies, Volume 10(7), p. 977

Prasetyo, F.A., Kurniawan, M.A., Komariyah, S., 2018. Indonesian Seastate

Condition and Its Wave Scatter Map. In: Proceeding of Marine Safety and

Maritime Installation (MSMI 2018), pp. 68–79

Purwanto, P., Sugianto, D. N., Zainuri, M., Permatasari, G., Atmodjo, W.,

Rochaddi, B., Ismanto, A., Wetchayont, P., Wirasatriya, A., 2021. Seasonal

Variability of Waves Within the Indonesian Seas and Its Relation With the

Monsoon Wind. Indonesian Journal of Marine Sciences/Ilmu Kelautan,

Volume 26(3), pp. 189–196

Rizal, A.M., Ningsih, N.S., 2022. Description

and Variation of Ocean Wave Energy in Indonesian Seas and Adjacent Waters. Ocean

Engineering, Volume 251, p.111086

Sofyan, N., Ridhova, A., Yuwono, A.H.,

Udhiarto, A., 2017. Fabrication of Solar Cells with TiO2

Nanoparticles Sensitized Using Natural Dye Extracted from Mangosteen Pericarps.

International Journal of Technology, Volume 8(7), pp. 1229–1238

Sotoodeh, K., 2022. Using Double-acting Hydraulic Actuators for Weight

Reduction in the Offshore Industry. Journal of Marine Science and

Application, Volume 21(2), pp. 159–169

Veerabhadrappa, K., Suhas, B.G., Mangrulkar, C.K., Kumar, R.S.,

Mudakappanavar, V.S., Seetharamu, K.N., 2022. Power Generation Using Ocean

Waves: A Review. Global Transitions Proceedings, Volume 3(2), pp.

359–370

Wahyudie, A., Susilo, T.B., Alaryani, F., Nandar, C.S.A., Jama, M.A.,

Daher, A., Shareef, H., 2020. Wave Power Assessment in the Middle Part of the

Southern Coast of Java Island. Energies, Volume 13(10), p. 2633

Wang, L., Isberg, J., Tedeschi, E., 2018. Review Of Control Strategies For Wave Energy Conversion Systems And Their Validation: The Wave-To-Wire Approach. Renewable and Sustainable Energy Reviews, Volume 81, pp. 366–379

Waskito, K.T., Geraldi, A., Ichi, A.C.,

Yanuar, Rahardjo, G.P., Al Ghifari, I., 2024. Design of Hydraulic Power

Take-Off Systems Unit Parameters for Multi-Point Absorbers Wave Energy

Converter. Energy Reports, Volume 11, pp. 115–127