Design, Manufacture and Control of a Multi-layer Piezoelectric Actuator

Corresponding email: indrawanto@itb.ac.id

Published at : 10 Jul 2024

Volume : IJtech

Vol 15, No 4 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i4.6605

Indrawanto, Saputro, I.A.A., Virdyawan, V., Tjahjowidodo, T., 2024. Design, Manufacture and Control of a Multi-layer Piezoelectric Actuator. International Journal of Technology. Volume 15(4), pp. 1118-1132

| Indrawanto | Production Engineering Research Group, Faculty of Mechanical and Aerospace Engineering, Institut Teknologi Bandung, Jl. Ganesa 10, Bandung 40132, Indonesia |

| Indra Agung Ariwi Saputro | Mechanical Engineering Study Program, Faculty of Mechanical and Aerospace Engineering, Institut Teknologi Bandung, Jl. Ganesa 10, Bandung 40132, Indonesia |

| Vani Virdyawan | Production Engineering Research Group, Faculty of Mechanical and Aerospace Engineering, Institut Teknologi Bandung, Jl. Ganesa 10, Bandung 40132, Indonesia |

| Tegoeh Tjahjowidodo | KU Leuven, Department of Mechanical Engineering, Jan Pieter de Nayerlaan 5, 2860 Sint-Katelijne-Waver, Belgium |

A piezoelectric-based

micro motion actuator is typically

used in micro-scale

movement technologies, with the actuator developed to

deliver very

small movements and high resolution for motion within several micrometer

ranges. However, a significant challenge from the strong, nonlinear hysteresis

arises affects the piezoelectric materials joining input voltage to output

movement, which deteriorates the accuracy of the actuator and causes

instability in a closed-loop system. To obtain high precision, accuracy and

reduced nonlinear effects, piezoelectric actuators must be controlled with

hysteresis compensation. Therefore, this research developed a

piezoelectric-based microactuator system with a control scheme based on PID

(proportional-integral-derivative) combined with the inverse hysteresis model

implemented to compensate for the actuator's hysteresis. Furthermore, a

Modified Prandtl-Ishlinskii (MPI) model was used to capture the hysteresis phenomenon, where its

parameters were obtained through a system identification process. The inverse

model of the hysteresis was then used to

generate

feedforward signals in the control system. The results showed that the control

scheme is able to provide an accurate motion due to the

decrease in hysteresis compensation signals from 4.87 to 0.97

. The closed

loop control system consisting of the PID control and hysteresis compensation

further improved the accuracy of the piezoelectric actuator and reduced the

error down to 0.41

.

Hysteresis; Micro motion actuators; Modified Prandtl-Ishlinskii model; PID control; Piezoelectric

A

micro motion actuator is a device capable of generating microscale movements at

an accuracy of 0.001 mm, even extending to nanometres. This technology is

widely applied in tools that require movement with exceptionally high precision

and accuracy, such as micro robots

Currently,

the types of actuators used to achieve precise and accurate movements

incorporate active or smart materials such as piezoelectric

Several mechanisms have been developed to

enable both planar and rotary motions using piezoelectric actuator.

In some applications, a direct piezo

actuation is required, and a typical example is a micro-macro manipulator such

as the one designed for in-vitro intracytoplasmic sperm injection

This paper focused on a detailed design of

a direct piezoelectric-based actuator system, with a feedback controller and

model-based feedforward compensation to counteract the hysteresis phenomenon.

The validation test results of the piezoelectric actuator, and the control law

were presented through numerical simulations and experimental trials. In

conclusion, it examined the main advantages of the developed actuator, with

focus on the internally equipped position sensor, which significantly enhanced

the performance.

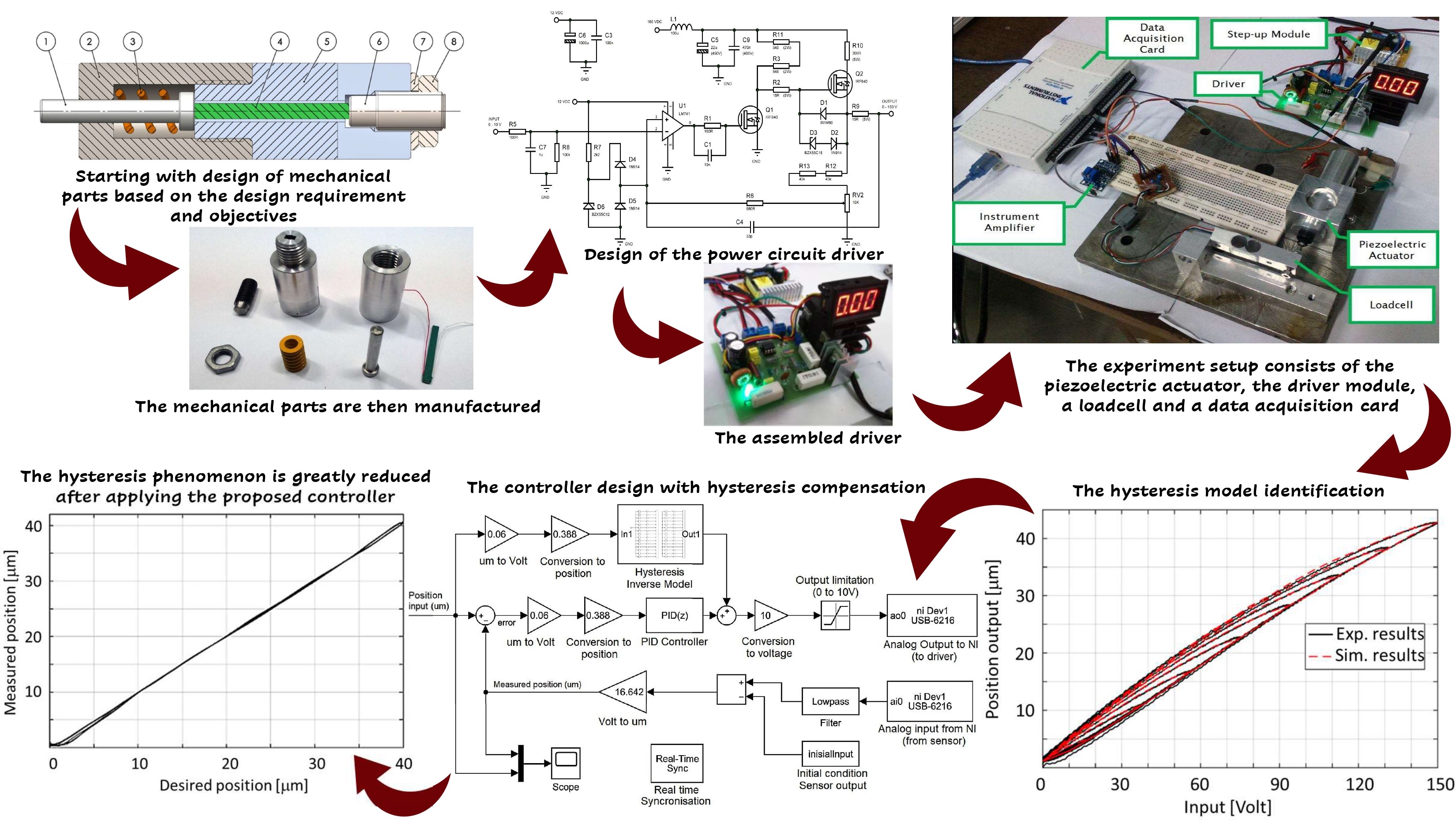

Figure 1 Phases in the development of the

piezoelectric-based actuator system

The

second phase focused on the manufacturing of the mechanical and electronical

components, as well as designing the structure of the position control system,

which integrated feedback and feedforward control strategies, using the

hysteresis model examined in the first phase.

The

third phase also known as the identification phase focused on distinguishing

the dynamic parameters of the mechanical system, and hysteresis model,

including testing the electronic circuit. The results obtained were then used

to adjust and optimize the parameters of the feedback and feedforward control

gains.

The

fourth phase centered on testing the performance of the developed system, by

using a reciprocating trajectory to investigate the effectiveness of the

control system. In addition, this phase was completed by proving the

satisfactory performance of the developed piezoelectric actuator system.

Hysteresis modelling was carried out to capture the characteristic behaviors of piezoelectric systems. In addition, through mathematical modeling, hysteresis can be accurately represented, enabling the development of compensatory strategies to reduce the effect. In this context, three hysteresis models, namely the Bouc-Wen, Prandtl-Ishlinskii (P-I) and Modified Prandtl-Ishlinskii(MPI), was discussed in the following sub-sections.

2.1. Bouc-Wen Model

where y(t) is the output of the piezoelectric actuator displacement, m, b and k are mass, damping, and spring constant, respectively. In addition, u is the input voltage, d is the ratio of the linear force constant to the input voltage, and h is the force with hysteresis. The values of and n are shape factors tuned for the hysteresis model. One advantage of the Bouc-Wen model is that it uses only a few parameters however, the traditional one is only suitable for symmetrical hysteresis forms (Ha et al, 2006; Wang and Zhu, 2011).

1.2. Prandtl-Ishlinskii (P-I) Model

Figure 2 Illustration of backlash, (a) backlash operator with weight/slope, (b) physical example of backlash in mechanical systems, (c) Simulink®

where is the input,

is the output of the hysteresis model,

is the threshold value or the width of the backlash, and

P-I model, proven to effectively capture hysteresis behavior, lacks the capability to distinguish the direction of motion, as stated in Equation 3. However, it is only effective for modeling symmetrical non-local memory hysteresis.

2.3. Modified Prandtl-Ishlinskii (MPI) Model

Figure 3 Dead zone with threshold: (a) negative {d<0}, (b) without dead zone {d=0}, and (c) positive {d>0}, (d) the MPI (Modified Prandtl-Ishilinskii) model is composed of combination of several backlash and dead zone operators

where

The proposed modification of the P-I model effectively captures the asymmetric hysteresis phenomenon. This improvement required additional parameters, potentially leading to a longer computational process. The use of a more elemental model increases the number of parameters to be optimized. Therefore, the trade-off between the model complexity and effectiveness needs to be carefully considered.

Actuator Design

The research developed a multilayer piezoelectric actuator, with the constituent components shown in Figure 4(a). Additionally, Figure 4(b) presents the manufactured parts, while Figure 5 illustrates the corresponding piezoelectric actuator driver circuit. In addition, the manufactured parts and the corresponding piezoelectric actuator driver circuit are shown in Figures 4(b), and 5.

Figure 5 The piezoelectric actuator driver circuit

The transfer function in Equation 11 is therefore used to assist in the design of the linear feedback controller.

Estimation

of the Hysteresis Parameters

The estimated parameters for both P-I and MPI models, comprising a total

of 15 elementary models, where each element consists of two and four parameters

respectively, are shown in Table 2.

Hysteresis

Model Validation

Figure 10 Simulation and experiment results of the MPI model (a) position output vs time, (b) detailed section on the MPI model validation. The MPI model yields a better agreement between simulation and experiment compared to the P-I model (Figure 9(b))

Figure 11 Comparison of absolute position error between

the P-I and MPI models. RMSE of the P-I model is 0.703 , while RMSE of the MPI model is 0.217

Controller Design

The inverse hysteresis

model-feedforward was applied to the controller to compensate for the

hysteresis phenomenon in the piezoelectric actuator. Based on Equation 8, the

inverse hysteresis model is stated in Equation 14,

The control system proposed in this

research consists of a PID and hysteresis inverse model. The PID controller is

obtained using Equation 21,

where and Kd

where

Figure 12 Block

diagram of the proposed control system.

Tracking Results

The evaluation of the

piezoelectric actuator control system was carried out using two types of

controllers. The first experiment used the position control system without an

inverse hysteresis model. While the second analysis adopted a position control

system with an inverse hysteresis model. The desired position to evaluate the

performance of the proposed controller is stated in Equation 23,

Figure 14 shows the

response of the position control system without inverse hysteresis model

feedforward and the hysteresis phenomenon respectively.

Figure 14 (a) Plot of the desired and measured

positions using a PID controller only, (b) Hysteresis phenomenon on the PID

controller without the reverse hysteresis model feedforward. The hysteresis

phenomenon is around 5mm.

Figure 15 shows the response of the position control system with inverse hysteresis model feedforward and the hysteresis phenomenon, respectively.

Figure 15 (a) Plot

of the desired and measured positions using the PID controller with the

hysteresis inverse model feedforward, (a) Hysteresis phenomenon on the PID

controller with the inverse hysteresis model feedforward. The hysteresis

phenomenon is much reduced compared to the PID controller without the

feedforward compensation (Figure14(b))

Figure 16 shows

a comparison of responses between open loop control with and without inverse

model hysteresis compensation. In open loop control, hysteresis values of 4.87 mm and 0.97 mm were observed in without and

with the compensation, respectively. This shows that the hysteretic compensator

is able to reduce the hysteretic error significantly.

Figure 17 shows a comparison of absolute position errors between two control systems, one using only the PID controller and the other integrating PID controller with the feedforward compensator. It clearly shows that the application of the inverse hysteresis model feedforward can significantly improve the control system performance. Furthermore, the root mean square errors of 1.26 µm and 0.41 µm was obtained for the PID only and the one with feedforward.

Figure 16 Hysteresis comparison between open loop

response without compensator (

Figure

17 Comparison

of absolute position errors of the PID controller only and the PID with

feedforward compensation. RMSE of the PID controller is 1.26 mm dan for the PID controller with feedforward

compensation is 0.41 mm

In conclusion,

the design and manufacturing of a piezoelectric-based actuator and the

controller were presented. A significant asymmetric hysteretic phenomenon was observed

in the piezoelectric actuator. This was addressed by adopting a Modified

Prandtl-Ishlinskii (MPI) model and the inverse, which were proposed for

incorporation into the position control system, effectively capturing the

asymmetric displacement or voltage hysteresis. The parameters in the MPI model

were efficiently identified using the Levenberg-Marquardt method. Based on the

inverse MPI model, a closed loop control scheme with hysteresis feedforward

compensation was proposed. The results of the experiment showed the

effectiveness of the proposed MPI model and the inverse in describing the

displacement or voltage asymmetric hysteresis of the piezoelectric actuator. In

addition, the developed piezoelectric-based micro motion actuator showed good

performance with sufficient accuracy.

This research was supported by

PPMI Ado Lit KK FTMD – ITB.

Abdurrakhman, A., Soehartanto, T., Hadi,

H.S., Toriki, M.B., Widjiantoro, B.L., Sampurno, B., 2020. Design of Output

Power Control System Based on Mass Flow Rate Comparison of Air-Fuel Ratio (AFR)

on Dual Fuel Generator Set by Using PID Control Method. International

Journal of Technology, Volume 11(3), pp. 574–586

Akbar, M., Ramadhani, M.J., Izzuddin, M.A.,

Gunawan, L., Sasongko, R.A., Kusni, M., Curiel-Sosa, J.L., 2022. Evaluation on

Piezoaeroelastic Energy Harvesting Potential of a Jet Transport Aircraft Wing

with Multiphase Composite by means of Iterative Finite Element Method. International

Journal of Technology, Volume 13(4), pp. 803–815

Ang, W.T., Khosla, P.K., Riviere, C.N., 2007.

Feedforward Controller with Inverse Rate-Dependent Model for Piezoelectric

Actuators in Trajectory-Tracking Applications. IEEE/ASME Transactions on

Mechatronics, Volume 12(2), pp. 134–142

Apicella, V., Clemente,

C.S., Davino, D., Leone, D., Visone, C., 2019. Review of Modeling and Control

of Magnetostrictive Actuators. Actuators, Volume 8(2),

p. 45

Åström, K.J.,

Hägglund, T., 2004. Revisiting the Ziegler–Nichols Step Response

Method for PID Control. Journal of Process Control, Volume 14(6), pp.

635–650

Cao, Y., Chen, X.B., 2015. A Survey of

Modeling and Control Issues for Piezo-electric Actuators. Journal of Dynamic

Systems, Measurement, and Control, Volume 137(1), p. 014001

Changhai, R., Lining, S., 2005. Hysteresis

and Creep Compensation for Piezoelectric Actuator in Open-Loop Operation. Sensors

and Actuators A: Physical, Volume 122(1), pp. 124–130

Damjanovic, D., 2006. Hysteresis in

Piezoelectric and Ferroelectric Materials. The Science of Hysteresis,

pp. 337–465

Devos, S., Vijver, W.V.d., Mesonero-Romanos,

D., Reynaerst, D., Brussel, H.V., 2004. Piezoelectric Motors with a Stepping

and a Resonant Operation Mode. In: Proceedings 9th

International Conference on New Actuators, pp. 439–442

Fujii, Y., Endo, Y.,

Mitsuhata, S., Hayashi, M., Motoyama, H., 2020. Evaluation

of The Effect of Piezo?Intracytoplasmic Sperm Injection on The Laboratory,

Clinical, and Neonatal Outcomes. Reproductive Medicine and Biology,

Volume 19(2), pp. 198–205

Gomis-Bellmunt, O., Ikhouane, F.,

Montesinos-Miracle, D., 2009. Control of a Piezoelectric Actuator Considering

Hysteresis. Journal of Sound and Vibration, Volume 326(3–5), pp. 383–399

Ha, J.-L., Kung,

Y.-S., Fung, R.-F., Hsien, S.-C., 2006. A

Comparison of Fitness Functions for The Identification of a Piezoelectric

Hysteretic Actuator Based on The Real-Coded Genetic Algorithm. Sensors and

Actuators A: Physical, Volume 132(2), pp. 643–650

Hassani, V., Tjahjowidodo, T., 2011.

Integrated Rate and Inertial Dependent Prandtl-Ishlinskii Model for

Piezoelectric Actuator. In: 2011 2nd

International Conference on Instrumentation Control and Automation, IEEE, pp.

35–40

Hassani, V., Tjahjowidodo, T., 2013. Dynamic

Modeling of 3-DOF Pyramidal-Shaped Piezo-Driven Mechanism. Mechanism and

Machine Theory, Volume 70, pp. 225–245

Hassani, V., Tjahjowidodo, T., Do, T.N.,

2014. A Survey on Hysteresis Modeling, Identification and Control. Mechanical

Systems and Signal Processing, Volume 49(1–2), pp. 209–233

Heywang, W., Lubitz, K., Wersing, W., 2008.

Piezoelectricity - Evolution and Future of a Technology. In: Springer Series in Materials Science,

Springer-Verlag Berlin Heidelberg, Berlin

Irianto, B.G., Maghfiroh, A.M., Sofie, M.,

Kholiq, A., 2023. Baby Incubator with Overshoot Reduction System using PID

Control Equipped with Heart Rate Monitoring Based on Internet of Things. International

Journal of Technology, Volume 14(4), p. 811–822

Jani, J.M., Leary, M., Subic, A., Gibson,

M.A., 2014. A Review of Shape Memory Alloy Research, Applications and

Opportunities. Materials & Design (1980-2015), Volume 56, pp.

1078–1113

Karpelson, M., Wei,

G.-Y., Wood, R.J., 2012. Driving High Voltage

Piezoelectric Actuators in Microrobotic Applications. Sensors and Actuators

A: Physical, Volume 176, pp. 78–89

Kuhnen, K., 2003. Modeling, Identification

and Compensation of Complex Hysteretic Nonlinearities: A Modified

Prandtl-Ishlinskii Approach. European Journal of Control, Volume 9(4),

pp. 407–418

Leang, K.K., Devasia, S., 2006. Design of

Hysteresis-Compensating Iterative Learning Control for Piezo-Positioners:

Application to Atomic Force Microscopes. Mechatronics, Volume 16(3–4),

pp. 141–158

Li, Y., Xu, Q., 2009. Design and Optimization

of an XYZ Parallel Micromanipulator with Flexure Hinges. Journal of Intelligent

and Robotic Systems, Volume 55(4–5), pp. 377–402

Lin, C.-J., Yang,

S.-R., 2006. Precise Positioning of Piezo-Actuated Stages

Using Hysteresis-Observer Based Control. Mechatronics, Volume 16(7), pp.

417–426

Matsuda, S., Matsuo,

T., Ueyama, M., 2001. Micro Actuator with Two

Piezoelectric Elements Placed at Right Angles. Human Friendly Mechatronics,

Elsevier, pp. 143–148

MathWorks, 2018. Least-Squares (Model

Fitting) Algorithms, Accessed: December 5, 2022. Available:

https://www.mathworks.com/help/optim/ug/least-squares-model-fitting

algorithms.html

MATLAB, 2023, Version R2023b, License No: 40908710,

Natick, Massachusetts: The MathWorks Inc.

Polit, S., Dong, J.,

2011. Development of a High-Bandwidth XY

Nanopositioning Stage for High-Rate Micro-/Nanomanufacturing. IEEE/ASME

Transactions on Mechatronics, Volume 16(4), pp. 724–733

Qin, F., Zhang, D., Xing, D., Xu, D., Li, J.,

2020. Laser Beam Pointing Control with Piezoelectric Actuator Model Learning. IEEE

Transactions on Systems, Man, and Cybernetics: Systems, Volume 50(3), pp.

1024–1034

Qin, Y., Zhao, X., Zhou, L., 2017. Modeling

and Identification of the Rate-Dependent Hysteresis of Piezoelectric Actuator

Using a Modified Prandtl-Ishlinskii Model. Micromachines, Volume 8(4),

p. 114

Rodriguez-Fortun, J.M., Orus, J., Alfonso,

J., Buil, F., Castellanos, J.A., 2011. Hysteresis in Piezoelectric Actuators:

Modeling and Compensation. IFAC Proceedings Volumes, Volume 44(1), pp.

5237–5242

Tian, Y., Zhang, D., Shirinzadeh, B., 2011.

Dynamic Modelling of a Flexure-Based Mechanism for Ultra-Precision Grinding

Operation. Precision Engineering, Volume 35(4), pp. 554–565

Wang, D.H., Zhu, W., 2011. A Phenomenological

Model for Pre-Stressed Piezoelectric Ceramic Stack Actuators. Smart

Materials and Structures, Volume 20(3), p. 035018

Xie, S., Mei, J.,

Liu, H., Wang, Y., 2018. Hysteresis Modeling and

Trajectory Tracking Control of The Pneumatic Muscle Actuator Using Modified

Prandtl–Ishlinskii Model. Mechanism and Machine Theory, Volume 120, pp.

213–224

Xu, Q., Li, Y., 2010. Precise Tracking

Control of a Piezoactuated Micropositioning Stage Based on Modified

Prandtl-Ishlinskii Hysteresis Model. In: 2010 IEEE International

Conference on Automation Science and Engineering, IEEE, pp. 692–697

Zheng, J., Fu, M., Lu,

R., Xie, S., 2018. Design, Identification, and Control of a

Linear Dual-Stage Actuation Positioning System. Journal of the Franklin

Institute, Volume 355(12), pp. 5018–5036

Zhu, W., Rui, X.-T., 2016. Hysteresis

Modeling and Displacement Control of Piezoelectric Actuators with The

Frequency-Dependent Behavior Using a Generalized Bouc–Wen Model. Precision

Engineering, Volume 43, pp. 299–307

Zhu, W., Wang, D., 2012. Non-symmetrical

Bouc–Wen Model for Piezoelectric Ceramic Actuators. Sensors and Actuators A:

Physical, Volume 181, pp. 51–60