Bitewing Holder and Support Product Design Using Quality Function Deployment

Published at : 25 Mar 2025

Volume : IJtech

Vol 16, No 2 (2025)

DOI : https://doi.org/10.14716/ijtech.v16i2.6577

Ginting, R, Napitupulu, H, Ishak, A & Supranata 2025, ‘Bitewing holder and support product design using quality function deployment’, International Journal of Technology, vol. 16, no. 2, pp. 551-560

| Rosnani Ginting | Department of Industrial Engineering, Faculty of Engineering, Universitas Sumatera Utara, Medan, North Sumatra, 20222, Indonesia |

| Humala Napitupulu | Department of Industrial Engineering, Faculty of Engineering, Universitas Sumatera Utara, Medan, North Sumatra, 20222, Indonesia |

| Aulia Ishak | Department of Industrial Engineering, Faculty of Engineering, Universitas Sumatera Utara, Medan, North Sumatra, 20222, Indonesia |

| Supranata | Department of Industrial Engineering, Faculty of Engineering, Universitas Sumatera Utara, Medan, North Sumatra, 20222, Indonesia |

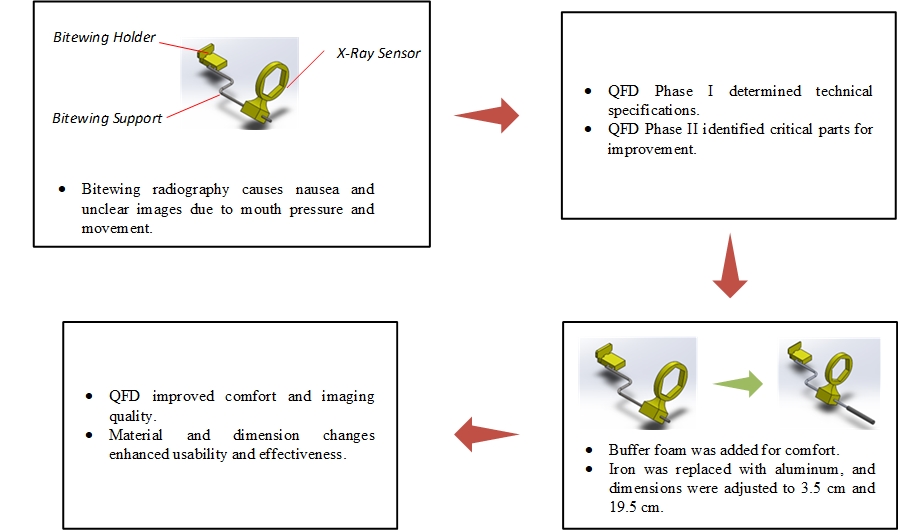

Conventional dental radiographic examination using bitewing is widely known to cause nausea and unclear radiographic images, due to pressure on the mouth wall and patient movement, respectively. This discomfort often leads to patient non-compliance, making it challenging to obtain accurate diagnostic results. These issues were observed in 10 dental clinics on Jalan Jamin Ginting. To address the problems, a product improvement design was implemented using Quality Functions Development (QFD). In Phase I, QFD produced technical specifications such as adding buffer foam and replacing iron material used in bitewing support with aluminium, while Phase II identified priority critical parts such as shortening the dimensions of the bitewing holder with a support. The product redesign includes the addition of buffer foam for enhanced comfort for patient, the substitution of iron with aluminium to reduce weight of the product, as well as the adjustment of bitewing holder and support dimensions to 3.5 cm and 19.5 cm, respectively.

Bitewing; Design; Dimension; Product; Quality function deployment

Medical

devices are instruments, equipment, machines used in

health services (Siddique et al., 2021). These devices serve as

tools for the prevention, diagnosis, or treatment of

disease, facilitating the

detection, measurement,

restoration, repair, or

change of the body

structure and functions for health purposes (Liu et al., 2019). An example is a radiograph, which is crucial for visualizing the

hard tissues of the oral cavity, enabling

differential diagnosis and evaluation of dental

abnormalities (Yusro and Sianturi, 2018).

Bitewing

is a radiographic tool designed to show the

crowns of maxillary and mandibular teeth in one film. It is primarily used by dentists in examining the

intraoral (oral cavity), detecting

patient complaints, and monitoring

the development of caries or cavities post-treatment (Moharrami et al., 2023). The procedure includes inserting the holder into the

mouth cavity, positioning the film

holder, and exposing the film to radiation for capturing the

examination images. However, issues can arise during

the usage, complicating the task of the

dentist (Astuti and Febriansyah, 2017). Complaints about

bitewing products present the need

for an improved design to enhance functionality and patient comfort. Addressing

these issues is critical to improving the ability of the dentist to administer

effective treatment. Bitewing

produced by PT. X, is sourced from

an online marketplace. The detailed specification are shown in

Figure 1.

The bitewing consists of several components with specific

specifications. The bitewing holder has a length of 4.1 cm, weighs 50 grams,

and is made of soft acrylic in yellow color. The bitewing support measures 20.3

cm in length, weighs 250 grams, and is made of iron with a silver color. The

x-ray sensor has a diameter of 6.5 cm, weighs 100 grams, and is made of plastic

in yellow color.

The

design of bitewing product improvements is based on complaints identified through survey

(Bahia et al., 2023). Data was collected by distributing preliminary

questionnaires to 10 dentists located on Jalan Jamin Ginting, Medan Selayang

District to obtain feedbacks. The most frequent complain was

nausea due to pressure on the mouth wall. Another significant issue was the clarity of radiographic images, which was often compromised by patient

movement. This necessitates a plan for product

improvement (Avikal et al., 2020). Supporting study by (Astuti and Febriansyah, 2017) also stated that bitewing products usage causes nausea in patients, presenting the need to shorten the

dimensions of the holder.

To address the issue, the Quality Functions Deployment (QFD) method was adopted. QFD is a structured methodology used in product planning and development to ensure that consumer needs and desires are met (Siwiec et al., 2023). This was conducted by integrating

user requirements with business goals, focusing on the

wants and needs of customers. (Ginting, 2022). In Phase I of QFD, the degree of importance of additional customer needs and

desires, referred to as

technical characteristics, was determined

(Abonyi and Czvetkó, 2022). Meanwhile, Phase II, the relative importance of design

requirements, known as critical parts, was examined (Wu and Liao, 2021).

In this study, the sample comprised of 10 dentists as respondents, determined using the Harry King Nomogram method with an error rate of 5% (Hartono et al., 2017). These respondents were selected to address problems such as patient nausea due to pressure on the mouth wall and unclear radiographic images attributed to movement. (Sugiyono, 2018).

Figure 1 Bitewing Parts and Product

Figure 1 Bitewing

Parts and Product

2.1. Quality Function Deployment Phase I

Phase I of QFD includes building a

House of Quality (HoQ) matrix according to the stages outlined in the

procedures of (Sugiono

et al., 2022)

1. Determine Consumer Needs (Neira-Rodado

et al., 2020)

Consumer needs were

identified

through surveys using open, closed, and canoe questionnaires. (Coskun

and Kazan, 2023)

2. Determine the Level of Importance of

Attribute / Customer Importance (Gavahi

et al., 2022)

The level of

importance was assessed to understand the extent of consumers

expectation (Sundaram

and Zeid, 2023). This was based on the mode value

from closed

questionnaire (Habib

et al.,

2023), signifying the frequency of the most responses

for each

variable (Przystupa,

2023)

3. Define product characteristics (Avikal

et al., 2020)

Technical

characteristics were determined through discussions and interviews with the company.

4. Establish the relationship between technical

characteristics (Shen

et al., 2022)

The

relationship between each technical characteristic was analyzed to determine the mutually supportive

(positive) or contradictory (negative) status. The following show the the degree of these relationships:

a. Relationship level exists.

b. The degree of positive relationship is strong.

c. Moderate level of positive relationship.

d. No connection.

e. Moderate level of negative relationship.

f. The degree of negative relationship is strong.

5. Determine the Level of Relationship Between Technical Characteristics and Consumer Needs (Zhang

et al., 2022)

Relation matrix was

used to evaluate the relationship between consumer desires and the technical

characteristics of the product. The level of relationship consists of a scale

of strong, medium, weak, and not related at all. The assessment was performed based on the following rules:

a. 9 : Shows a strong relationship.

b. 3 : Indicates a moderate relationship.

c. 1 : Indicates a weak relationship.

d. 0 : Indicates no relationship at all.

6. Determine the planning matrix (Shang

et al., 2022)

The planning

matrix was designed to assess consumer

satisfaction with the product. Furthermore, its preparation aimed to obtain

the order or priority of the consumer variable needs. The planning matrix is the result of calculations from several types of data and

consists of the following stages

a. Measuring

the level of consumer satisfaction with the product (Ishak

et al., 2020)

b.

Calculating the value of the improvement ratio (improvement ratio) for each

variable level of interest (expectation) (Rianmora

and Werawatganon, 2021)

c. Set a

"sales point" for each variable needs (de

Oliveira et al., 2020)

d.

Calculating the planning weight (absolute) for each variable (Ginting

et al., 2015)

e.

Calculating relative planning weights for each variable (Shvetsova

et al., 2021).

7. Build a Phase I House of Quality Matrix (Fazeli

and Peng, 2022)

The technical

matrix on performance measures from HoQ Phase I consists of three aspects,

namely the level of difficulty, importance, and

estimated costs.

a. Difficulty Level Determination (Neira-Rodado

et al., 2020)

The level of difficulty was

determined

from the relationship between technical characteristics. Furthermore, it

was calculated by translating all the relationship weights and dividing each technical characteristic weight by the total weights.

b. Determination of the Degree of Importance (Hridoy

et al., 2020)

The value of the degree of importance was calculated by first determining the total

weight for each relationship between product attributes and technical

characteristics.

c. Cost estimation (Murugan

and Marisamynathan, 2022)

The basis for cost estimates is the level of difficulty

factor. The more difficult a technical characteristic, the more expensive the

cost allocation. Cost estimates, expressed

in percent, were influenced by various

considerations from the designer.

Building Phase I of the

HoQ matrix set the stage for QFD Phase I (product planning). Data collected were integrated into the first step of QFD Phase II. Meanwhile, potential difficulties in QFD Phase I include obtaining data and conducting surveys.

2.2. Quality Function

Deployment Phase II

The

experimental procedure in this study was divided into several stages, as shown

in the schematic diagram in Figure 1. In Phase II of QFD, also known as the design phase, product

characteristics derived from the voice of the customer were compared with the essential requirements, in order to identify critical

parts of a product (Lo, 2021). It

is important to acknowledge that priority

technical characteristics were translated into critical parts to meet customer

needs. According to (Ginting, 2021), the

following were

stages of developing the Phase II QFD (Zulkarnain et al., 2023)

1. Establish Priority Technical Characteristics Based on QFD

phase I (Yuliani et al., 2019)

The technical

characteristics obtained from QFD phase I were used as input to conduct processing in phase II. Priority technical characteristics were determined

based on the ranking of the largest weight of the level of difficulty, degree

of importance, and estimated costs.

2. Determine the Critical Part (Purba et al., 2020)

Critical parts were identified as the main components or characteristics essential to the

product.

3. Determine the Level of Relationship Between Critical Parts (Azizah et al., 2018)

The next step

in preparing the design deployment matrix was to compare and analyze the relationship between each critical part.

4. Establish the Relationship Between Technical Characteristics and Critical Parts (Abonyi and Czvetkó, 2022)

The design

deployment matrix was prepared to compare the

relationship between critical parts and technical characteristics.

5. Determine the Technical Matrix (Lestari et al., 2020)

The technical matrix was determined based on performance measures from QFD phase II, which included the level of difficulty, the level of importance, and estimated

costs.

The results of QFD Phase II, provided the final specifications for the

proposed product, aiming to address bitewing problems. A practical challenge in

QFD Phase II was conducting effective surveys to obtain accurate data.

This study introduces a novel method in the design

of the bitewing product, by adopting QFD, a technique not previously utilized.

Additionally, it addresses consumer complaints by applying an engineering

approach to solve dentistry-related problems.

3.1. Quality Function Deployment Phase I

The analysis based on the House of Quality

(HoQ) signifies that the primary focus of improvement should be on technical

characteristics. Specifically, the convenience of use present a difficulty

level of 4, degree of importance of 17%, and estimated cost of 17. To enhance product comfort, the inclusion of

buffer foam is recommended.

According to (Anggita and Astuti, 2016), buffer foam can increase the comfort level of the user. Another area for improvement is the weight of the product which has a difficulty level, degree of importance, and estimated cost of 4%, 18%, and 17%, respectively. The proposed enhancement includes replacing the iron material used in bitewing support with aluminium. According to (Rohilla and Dhull, 2018) aluminium has a lighter density and stronger resistance than iron. By prioritizing these technical characteristics in QFD Phase I, the study aimed to address several patient complaints, such as nausea caused by pressure on the mouth wall and unclear radiographic images resulting from patient movement. The focus on improving the convenience of use and reducing product weight is shown on Figure 2.

Figure 2 House of Quality (HoQ) Phase I

3.2. Quality Function

Deployment Phase II

QFD phase II is the

stage of component planning (part deployment) or translation of technical

requirements into component characteristics. Based on the deployment part, the

difficulty level, degree of importance, and estimated cost were 5%, 35%, and

33%. These metrics signified that the most critical components requiring

immediate attention were the dimensions of the bitewing holder and support. The

proposed product improvements include shortening the dimensions and length of

the bitewing holder to 3.5 cm and 19.5 cm, respectively.

Based on the identification of critical parts with QFD Phase II, patient complaints of nausea caused by pressure on the mouth wall and unclear radiographic images due to patient movement, can be addressed by prioritizing critical components. According to (Astuti and Febriansyah, 2017), an improved design is needed by shortening the dimensions of the bitewing holder with a support. The focus on shortening the dimensions of the bitewing holder with a support is shown on Figure 3.

Figure 3 House of Quality (HOQ) Phase II

Comparison of the initial and proposed product resulting from the QFD Phase I and II, are presented in Table 1.

Table 1 Product Comparison of Initial Product and Proposed Product

In conclusion, Phase I QFD identified ease of use as the important technical characteristics, signifying a pressing need for product enhancement. The proposed improvement includes the incorporation of an additional function such as buffer foam. The technical characteristic with the highest score was the focus of another improvement, namely product weight. Product repair comprised replacement of iron material on the bitewing support with aluminium. This aimed to address complaints such as nausea due to pressure on the mouth wall and less clear radiographic images caused by patient movement. By and prioritizing these technical characteristics, user requirements were adequately met. Based on Phase II QFD analysis, the identification of critical parts present the bitewing holder and support dimensions as key areas for improvement. In line with the product improvements strategy, adjustment were proposed to shorten the dimensions and length of the holder to 3.5 cm and 19.5 cm, respectively. These modifications were designed to address user concerns regarding discomfort and image clarity.

The authors are grateful to Universitas Sumatera Utara (USU) for the invaluable assistance and contribution. The institution played a significant role in academic and personal development. Additionally, valuable opportunities and experiences were provided, contributing to growth.

Author Contributions

Rosnani Ginting: Conceptualization, formal analysis, data validation, writing – review & editing, visualization, supervision. Humala Napitupulu: Conceptualization, literature review, methodology, investigation, writing – original draft, writing – review & editing. Aulia Ishak: Writing – original draft, software, data collection, data analysis & interpretation. Supranata: Writing – original draft, software, data collection, data analysis & interpretation. All authors have read and agreed to the published version of the manuscript.

Conflict of Interest

The authors declare no conflicts of interest.

Abonyi, J & Czvetkó, T 2022, ‘Hypergraph and network flow-based quality function deployment’, Heliyon, vol. 8, no. 12, article12263, https://doi.org/10.1016/j.heliyon.2022.e12263

Anggita, D & Astuti, DA 2016, ‘Review of various materials and shapes’, Tinjauan material dan bentuk ragam, Jurnal Teknik Industri, vol. 3, no. 5, pp. 383–400

Astuti, T & Febriansyah 2017, ‘Product design of film dental holder “Bitewing” for anterior dental radiography’, SANITAS: Jurnal Teknologi dan Seni Kesehatan, vol. 8, no. 2, pp. 114–122

Avikal, S, Singh, R & Rashmi, R 2020, ‘QFD and Fuzzy Kano model based approach for classification of aesthetic attributes of SUV car profile’, Journal of Intelligent Manufacturing, vol. 31, no. 2, pp. 271–284, https://doi.org/10.1007/s10845-018-1444-5

Azizah, IN, Lestari, RN & Purba, HH 2018, ‘Penerapan metode quality function deployment dalam memenuhi kepuasan konsumen pada industri komponen otomotif (Implementation of the quality function deployment method in meeting consumer satisfaction in the automotive components industry)’, Jurnal Teknik Industri, vol. 19, no. 2, pp. 127–136, https://doi.org/10.22219/jtiumm.vol19.no2.127-136

Bahia, THA, Idan, AR & Athab, KR 2023, ‘The effect of quality function deployment (QFD) in enhancing customer satisfaction’, International Journal of Professional Business Review, vol. 8, no. 1, pp. 1–17, https://doi.org/10.26668/businessreview/2023.v8i1.1156

Co?kun, SS & Kazan, H 2023, ‘Bayesian analysis of the relationship between process improvement practices and procurement maturity’, Computers and Industrial Engineering, vol. 181, article 109297, https://doi.org/10.1016/j.cie.2023.109297

de Oliveira, LMV, Santos, HF, de Almeida, MR & Costa, JAF 2020, ‘Quality function deployment and analytic hierarchy process: A literature review of their joint application’, Concurrent Engineering Research and Applications, vol. 28, no. 3, pp. 239–251, https://doi.org/10.1177/1063293X20958936

Fazeli, HR & Peng, Q 2022, ‘Generation and evaluation of product concepts by integrating extended axiomatic design, quality function deployment and design structure matrix’, Advanced Engineering Informatics, vol. 54, no. 9, article 101716, https://doi.org/10.1016/j.aei.2022.101716

Gavahi, SS, Hosseini, SMH & Moheimani, A 2022, ‘An application of quality function deployment and SERVQUAL approaches to enhance the service quality in radiology centres’, Benchmarking, vol. 30, no. 8, pp. 2147–2166, https://doi.org/10.1108/BIJ-07-2021-0411

Ginting, R 2021, Kuesioner: alat ukur kepuasan terhadap produk (Questionnaire: product satisfaction measurement tool), USU Press

Ginting, R 2022, Metode Perancangan Produk (Konsep & Aplikasi) (Product Design Methods (Concept & Application)), USU Press

Ginting, R, Siregar, I & Ginting, TUH 2015, ‘Perancangan alat penyadap karet di Kabupaten Langkat Sumatera Utara dengan metode quality function deployment (QFD) dan model Kano (Design of rubber tapping tools in Langkat Regency, North Sumatra using the quality function deployment (QFD) method and the Kano' model)’, J@Ti Undip: Jurnal Teknik Industri, vol. 10, no. 1, pp. 33–40, https://doi.org/10.12777/jati.10.1.33-40

Habib, T, Omair, M, Habib, MS, Zahir, MZ, Khattak, SB, Yook, S-J, Aamir, M & Akhtar, R 2023, ‘Modular product architecture for sustainable flexible manufacturing in Industry 4.0: The case of 3D printer and electric toothbrush’, Sustainability, vol. 15, no. 2, p. 910, https://doi.org/10.3390/su15020910

Hartono, M, Santoso, A & Prayogo, DN 2017, ‘How Kansei Engineering, Kano and QFD can improve logistics services’, International Journal of Technology, vol. 8, no. 6, pp. 1070–1081, https://doi.org/10.14716/ijtech.v8i6.689

Hridoy, RM, Parvez, MS & Mohsin, N 2020, ‘Joining methods of Analytic Hierarchy Process (AHP), Kano model and Quality Function Deployment (QFD) to improve the tractor’s seat design for tractor drivers in Bangladesh’, American Journal of Industrial and Business Management, vol. 10, no. 5, pp. 1073–1083, https://doi.org/10.4236/ajibm.2020.105071

Ishak, A, Ginting, R, Suwandira, B & Fauzi Malik, A 2020, ‘Integration of Kano Model and Quality Function Deployment (QFD) to improve product quality: A literature review’, IOP Conference Series: Materials Science and Engineering, vol. 1003, no. 1, pp. 1–9, https://doi.org/10.1088/1757-899X/1003/1/012025

Lestari, R, Wardah, S & Ihwan, K 2020, ‘Analisis pengembangan pelayanan jasa TV kabel menggunakan metode Quality Function Deployment (QFD) (Analysis of cable TV service development using the Quality Function Deployment (QFD) method)’, JISI: Jurnal Integrasi Sistem Industri, vol. 7, no. 1, pp. 57–63

Liu, Y, Chen, PHC, Krause, J & Peng, L 2019, ‘How to read articles that use machine learning: Users’ guides to the medical literature’, JAMA - Journal of the American Medical Association, vol. 322, no. 18, pp. 1806–1816, https://doi.org/10.1001/jama.2019.16489

Lo, CH 2021, ‘Application of refined Kano’s model to shoe production and consumer satisfaction assessment’, Sustainability, vol. 13, no. 5, article 2484, https://doi.org/10.3390/su13052484

Moharrami, M, Farmer, J, Singhal, S, Watson, E, Glogauer, M, Johnson, AEW, Schwendicke, F & Quinonez, C 2023, ‘Detecting dental caries on oral photographs using artificial intelligence: A systematic review’, Oral Diseases, vol. 30, no. 2, pp. 1–19, https://doi.org/10.1111/odi.14659

Murugan, M & Marisamynathan, S 2022, ‘Elucidating the Indian customers’ requirements for electric vehicle adoption: An integrated analytical hierarchy process – Quality function deployment approach’, Case Studies on Transport Policy, vol. 10, no. 2, pp. 1045–1057, https://doi.org/10.1016/j.cstp.2022.03.017

Neira-Rodado, D, Ortíz-Barrios, M, de la Hoz-Escorcia, S, Paggetti, C, Noffrini, L & Fratea, N 2020, ‘Smart product design process through the implementation of a fuzzy Kano-AHP-DEMATEL-QFD approach’, Applied Sciences (Switzerland), vol. 10, no. 5, https://doi.org/10.3390/app10051792

Przystupa, K 2023, ‘Research on the durability and reliability of industrial layered coatings on metal substrate due to abrasive wear’, Materials, vol. 16, no. 5, https://doi.org/10.3390/ma16051779

Purba, HH, Sunadi, S, Suhendra, S & Paulina, E 2020, ‘The application of quality function deployment in car seat industry’, ComTech: Computer, Mathematics and Engineering Applications, vol. 11, no. 1, pp. 35–42, https://doi.org/10.21512/comtech.v11i1.6329

Rianmora, S & Werawatganon, S 2021, ‘Applying quality function deployment in open innovation engineering’, Journal of Open Innovation: Technology, Market, and Complexity, vol. 7, no. 1, pp. 1–20, https://doi.org/10.3390/joitmc7010026

Rohilla, S & Dhull, U 2018, ‘A review on optimization of the process parameters in friction stir welding of aluminium alloys (AA6082 and AA6105) by Taguchi technique’, International Journal of Advanced Engineering, Management and Science, vol. 4, no. 9, pp. 676–680, https://doi.org/10.22161/ijaems.4.9.6

Shang, K, Teng, S, Buchari, E, Lirn, T & Herno, R 2022, ‘Integration of safety quality function deployment in ferry services: Empirical study of Indonesia’, Research in Transportation Business & Management, vol. 52, pp. 100938, https://doi.org/10.1016/j.rtbm.2022.100938

Shen, Y, Zhou, J, Pantelous, AA, Liu, Y & Zhang, Z 2022, ‘A voice of the customer real-time strategy: An integrated quality function deployment approach’, Computers and Industrial Engineering, vol. 169, no. November 2021, p. 108233, https://doi.org/10.1016/j.cie.2022.108233

Shvetsova, OA, Park, SC & Lee, JH 2021, ‘Application of quality function deployment for product design concept selection’, Applied Sciences (Switzerland), vol. 11, no. 6, pp. 1–12, https://doi.org/10.3390/app11062681

Siddique, N, Paheding, S, Elkin, CP & Devabhaktuni, V 2021, ‘U-net and its variants for medical image segmentation: A review of theory and applications’, IEEE Access, vol. 9, pp. 82031–82057, https://doi.org/10.1109/ACCESS.2021.3086020

Siwiec, D, Pacana, A, & Gazda, A 2023, A new QFD-CE method for considering the concept of sustainable development and circular economy, Energies, vol. 16, no. 5, article 2474, https://doi.org/10.3390/en16052474

Sugiono, S, Pratomo, A & Willy, SN 2022, ‘House-of-Quality approach for the design of a minibus to transport visually impaired and wheelchair-bound passengers’, International Journal of Technology, vol. 13, no. 1, pp. 69–79, https://doi.org/10.14716/ijtech.v13i1.4290

Sugiyono 2018, Metode penelitian (Research methods), Alfabeta

Sundaram, S & Zeid, A 2023, ‘Artificial intelligence-based smart quality inspection for manufacturing’, Micromachines, vol. 14, no. 3, article 570, https://doi.org/10.3390/mi14030570

Wu, X & Liao, H 2021, ‘Customer-oriented product and service design by a novel quality function deployment framework with complex linguistic evaluations’, Information Processing and Management, vol. 58, no. 2, article 102469, https://doi.org/10.1016/j.ipm.2020.102469

Yuliani, ENS, Arwati, IGA & Riski, AR 2019, ‘Product development of Klikpak food packaging with Quality Function Deployment (QFD) method’, Journal of Scientific and Engineering Research, vol. 6, no. 7, pp. 173–178

Yusro, KA & Sianturi, RD 2018, ‘Penerapan metode median filtering dan histogram equalization untuk meningkatkan kualitas citra radiografi (Application of median filtering and histogram equalization methods to improve the quality of radiographic images)’, Jurnal Riset Komputer (JURIKOM), vol. 5, no. 3, pp. 254–260

Zhang, X, Su, J & Herrera-Viedma, E 2022, ‘A decision support model for estimating participation-oriented designs of crowdsourcing platforms based on quality function deployment’, Expert Systems with Applications, vol. 202, p. 117308, https://doi.org/10.1016/j.eswa.2022.117308

Zulkarnain, Machfud, Marimin, Darmawati, E & Sugiarto 2023, ‘Design of graphic concept model for specialty coffee packaging labels’, International Journal of Technology, vol. 14, no. 3, pp. 606–617, https://doi.org/10.14716/ijtech.v14i3.5116