Kinematic and Parametric Modeling of 6DOF(Degree-of-Freedom) Industrial Welding Robot Design and Implementation

Published at : 10 Jul 2024

Volume : IJtech

Vol 15, No 4 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i4.6559

Villaverde, L., Maneetham, D., 2024. Kinematic and Parametric Modeling of 6DOF(Degree-of-Freedom) Industrial Welding Robot Design and Implementation. International Journal of Technology. Volume 15(4), pp. 1056-1070

| Louie Villaverde | Department of Mechatronics Engineering, Rajamangala University of Technology Thanyaburi 39 Moo 1, Khlong 6, Khlong Luang Pathum Thani 12110 Thailand |

| Dechrit Maneetham | Department of Mechatronics Engineering, Rajamangala University of Technology Thanyaburi 39 Moo 1, Khlong 6, Khlong Luang Pathum Thani 12110 Thailand |

The increasing

demand for automated equipment for precision and versatility requires innovative methods in manufacturing. Despite the high demand, the design and development of industrial robot systems are costly, showing the

importance of improving design

conceptualization phase. Therefore, this study aimed to address the need by developing an industrial welding robot using a

parametric and kinematic modeling method. The

investigation focused on the design of six degree of

freedom (6DOF) industrial robotic arm for arc welding, exploring kinematic

model and dimensional parameters of robotic structure. Computer-aided design

(CAD) was

applied for modeling and analysis, using Denavit-Hartenberg (DH) convention

for mathematical analysis of link and frame movements. This study introduced forward kinematic simulation, which

included exploring the position and orientation of the end effector regarding the joint angular values and link

parameters. Furthermore, the development of kinematic model of robotic

mechanism was proposed to describe the behavior of

the physical system compared to an actual robot assembly. Due a reduction ratio of 80 from a rated

torque of 22 Nm at a 2000r/min

input harmonic drive, the system

mechanism was fabricated and assembled. The results showed

that robot successfully performed welding process, as indicated by tests carried out using a four-point movement. Moreover, further separate studies should be conducted to assess the quality of welds.

Industrial robot design; Kinematic model; Parametric modelling; Robotic simulation

Industrial robot applications are improving product quality due to their reliability and precision in motion

Consistency in

achieving high quality makes robotic welding advantageous to

manual operation, thereby

conferring a competitive edge

to industrial

applications, particularly

automating the process (Wu et al., 2015).

Examples of the demand for robotic arc welding are the automotive industry and

electronics manufacturing assembly lines(Kah et al., 2015). This robot

executes the programmed commands to perform welding operations with minimal

human intervention (Dinham and Fang, 2013), although there is a challenge in designing and fabrication. Recently, standard commercial robot has been

available for deployment in the industrial setup (Bilancia et al., 2023), leading to the development of

the mechanical design of robot in this study. Building

an industrial robot requires a significant

amount of initial financial investment,

as conceptualization

plays an essential role

in minimizing

developmental costs(Wang et al., 2024). Therefore, this study aimed to contribute to the

cost-effective and optimal development of custom industrial robot.

Based on

the background above, this

study focused on designing and assembling robot system for

welding applications,

considering standard methods (Vasilev et al., 2021).

The design of robot for industrial applications starts with the mechanical

structure (Zeng, Liu, and You, 2019), which includes the

configuration of robot mechanism using kinematic modeling. In this context, the configuration of six degree of

freedom (6DOF) robotic manipulator is suitable for industrial processes such as

welding. Therefore, the

analysis of the movement of end effector position and orientation is based on

the rigid component’s measurements and joint angle (Nektarios and Aspragathos, 2010).

The custom

mechanical design of robot also contributes to the concept of industrial

modularity and ease of fabrication. The

development process is carried out to construct a parametric model of

the industrial welding robot including the parameters’ topology (Zhang et al., 2022). To optimize the movement or

rigidity characteristics, adjustment was

made to these parameters, and selection was based on

the dimensions conceived from the developed kinematic model(Russo et al., 2024).

This study also applied a paradigm shift in the

optimization of robot characteristics through the derivation of parameters

using the developed kinematic model and simulation.

Several studies have been conducted on design of

industrial robot. For

example, (Li

and Wang, 2019) used genetic algorithm for optimization,

while (Jiang et al., 2020) focused on accuracy improvement using

artificial networks by algorithm with differential evolution. Furthermore,

there is a study on selecting industrial robot used for arc welding (Chodha et al., 2021) through the implementation and presentation

of simulated and actual experimental results. According to

This

study is significantly different from previous

investigations by including

comprehensive kinematic and parametric modeling in the development of industrial robot. Conceptualization

of new hardware components for industrial robot application is simplified using simulated

models. The use of computer system can

help save

the cost associated with the

building process. Moreover, modeling kinematic before developing robot control is significant, as these models are

categorized as forward and inverse kinematic (Farzan

and Desouza, 2013). The pose is described using a

set matrix or vectors in Cartesian coordinate system, with kinematic model having

constraints such as joint angle, link length, inertia, etc(Andersen, 2020). The joint variables measured in

angles for each link directly reflect end effector pose (Pham et al., 2018).

The challenge of this study is to design the dimensions and physical components

of each link based on analysis of kinematic model described using lengths and

Denavit-Hartenberg (DH) convention.

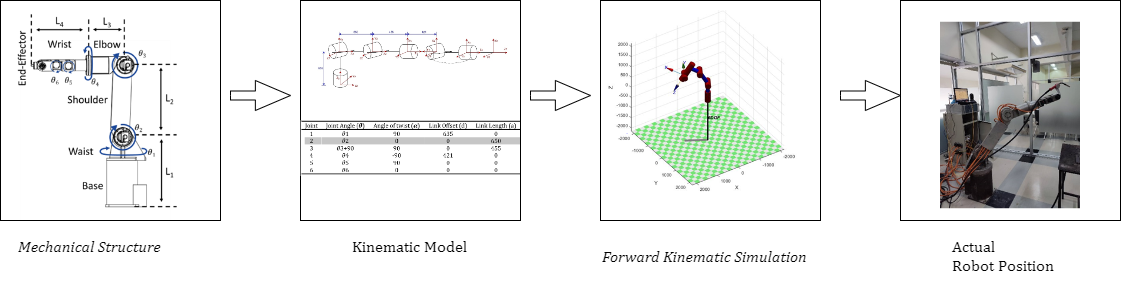

In this study, kinematic model leading to the physical structure is

presented using the software.

Establishing a conceptual kinematic model is important to design the desired

motion of robotic system

The contributions made in this

study included (1) the effect of kinematic on the

position of welding torch. (2) A new industrial welding robot design based on

revolute joint was fabricated and assembled along with essential parts

including links and servo motors, as a

custom-made welding robot developed first in Thailand. Changing the joint angles of each axis affected the position and orientation of

the end-effector, namely

welding torch. This was because the integration of robotic components

from a design in Thailand to fit an industrial application such as welding was

considered

more economical.

This study was organized as follows, Section 2 discussed methods of the mechanical structure, kinematic model, and forward

kinematic model. Section 3 presented

the results and discussion, while Section 4 concluded this study and presented

future endeavors.

2.1. Mechanical Structure

The

criteria for designing a custom-made robotic arm were established by considering a serial robot configuration and range of

motion to determine the dimensions of each link. Industrial robot joints could be prismatic or revolute, depending on the application. In

this study, the

configuration of joints is all revolute, which was in line with the common standard of industrial welding. The

anthropomorphic structure was

composed of the waist, shoulders, elbows, also wrists, which corresponded to the joints of the human arm

Figure 1 Anthropomorphic

Arm Configuration

Table 1 Robotic Arm Specification

|

Feature |

Description |

|

Range of Motion (ROM) |

Wrist - Pitch: 180°, Roll:180°, Yaw:180°,

Elbow: 130°, Shoulder: 110°, Waist: 180° |

Table 2 Link Lengths and Offsets

|

Joint |

Waist |

Shoulder |

Elbow |

Wrist |

|

Symbol |

L1 |

L2 |

L3 |

L4 |

|

Link Length (mm) |

635 |

650 |

455 |

421 |

2.2. Forward Kinematic (FK)

Forward

kinematic is the study

of describing the position and orientation of the end effector in terms of the

joint angular values and link parameters (Vacharakornrawut et al., 2016; Mehmood et al.,

2014). This can

be solved by determining the

homogeneous transformation matrix through

the combination of

the rotational matrix and the displacement vector. Moreover, the mathematical solution of forward

kinematic is based on DH parameters (Bian, Ye, and Mu, 2016). The

convention is a maturely recognized parameterization for industrial robot

modelling (Zhao et al., 2018), which is carried out by computing the product of the

homogeneous matrices resulting in the final transformation matrix (Ritboon

and Maneetham, 2019). The product is

used to identify

the pose of the end effector,

given the joint parameters,

in the form of Special Euclidean (SE) (3) or 4x4 homogeneous matrix

composed of the rotation matrix and displacement vector. The initial step in determining forward kinematic of the manipulator is categorizing each frame

using DH parameters (Bouzgou

and Ahmed-Foitih, 2014), which is called kinematic model as shown in Figure 3. The construction of kinematic model follows the right-hand rule and DH parameters can be found based

on the frame assignment, as

shown in Table 3. Each column is assigned for specified parameters, named joint angle angle of twist

link offset (d), and link length (a). This is carried out to precisely determine the spatial

configuration of robotic arm by establishing kinematic model and applying

forward kinematic simulation, thereby

contributing to the prototyping

process of 6DOF robotic arm (Ekrem and Aksoy, 2023).

Figure 2 Robotic Arm Configuration showing major

mechanical components and direction of articulation

Figure 3 Kinematic

Model of the Robotic Arm with dimension

Table 3 DH Parameter

Equation 1 shows the general formula of the transformation matrix,

The general formula was applied to respective components from DH parameter

table. The substitution of the values corresponding to

respective joint and link parameters led to individual transformation matrix per coordinate

frame. Simulation and modeling were made to validate the equation and analyze

kinematic of robot arm using MATLAB software.

Equations

2-7 are substitutions of the values each respective frame. The application of

the equation to 6DOF robotic arm manipulator includes the multiplication for respective

transformation matrix. The

result is reflected in matrix

2.3. Post Processor

The tasks of the system for

translating the joint angles to the specific tool location were designed in the

post processor stage. In this section, the mechanism of transformation was

discussed. Initially, the post processor of robotic arm was developed using

Programmable Logic Control (PLC), with servo motors executed through drivers as

the final actuating elements. The ladder logic design focused on transmitting

signal from GUI, which showed the joint angle of the axis, along with the tool

position. To ensure the program executed the intended position and orientation,

ROM was considered along with workspace requirements and coordinate system

relating to the physical world. Calibration of each axis joint angle with the

servo motor was carried out by checking the angle against the corresponding

feedback from drivers’ encoders. Simulating each corresponding angle by jogging

axis using robot pendant was performed to verify the response of the servo

motor driver and motors. Subsequently, data collection was carried out by

recording the angles versus input feedback from the servo motors’ absolute

encoder.

3.1. Forward Kinematic Simulation

Kinematic simulation model was

performed using MATLAB Robotics Toolbox. The numerical results, combined with a

visual plot of robot's pose in MATLAB software, provide a comprehensive

knowledge of the end

effector pose. The results have been plotted using various joint angles as

inputs to the forward kinematic

model and MATLAB Robotics Toolbox. Subsequently,

visual simulation is performed by feeding the four parameters

derived from the six links using the software.

The process is carried out with

several different joint configuration value scenarios. The first scenario, [0 0

0 0 0 0] results in the position of the xyz end effector at [421 0 1740] with a

yaw, pitch, and roll of

[0 90 180]. This is followed by

matrix value generated using the first scenario, while the results of robot arm

simulation plot are shown in

Figure 4 and Equation 9.

Figure 4 Visualization

from Plot function for [0 0 0 0 0 0] configuration

The second scenario with the value of the joint angle

configuration is set to [-15 -15 -15 0 0 0], followed by the xyz end effector position

[734 -196.8 1446.39] and the yaw pitch roll end effector value [28.2 56.8

155.9], as

shown in Figure 5 and Equation 10. Subsequently, matrix and simulation plots are

obtained from

scenario.

Figure 5 Visualization from Plot function for [-15 -15 -15 0 0 0] configuration

Figure 6 Visualization

from Plot function for [-30 -30 -30 0 0 0] configuration

Forward

kinematic is an essential requirement in building industrial robot to establish

the relationship between the joint angle and tool position. Furthermore,

it serves as a fundamental

theory during the development of

robotic arm, particularly when the application does not require autonomous

control. In this study, MATLAB was used for simulation and analysis

3.2. Parametric Modeling

This study is

divided into

two stages, namely design

and implementation. CAD software is used

during the design stage to create 3D models

One of the contributions of this study is a novel design of 6 DOF

industrial robotic arm,

presented in Figure 7, as

2D parametric model of (a) elbow

link (b) wrist link, and (c) shoulder link. Figures 8 (a), (c), (e), (g), (i), and

(k) are the results of 3D model design using CAD application, while (b), (d),

(f), (h), (j), and (l) are the actual robot implementation. The total weight of

the mechanism including the motors is

155 kilograms. There is an application of the harmonic gear concept in Figures

8 (i) and (j), while Figures 8 (k) and (l) are the

design of the end effector link model

to enable movement in

roll and pitch. Moreover, the system

has a reduction ratio of 80 from a rated torque of 22 Nm with a 2000r/min input.

Figure 7 2D

Parametric model. Components labeled as (a) Elbow link, (b) Wrist link, (c)

Shoulder link

Figure 8 3D model and Actual. These images

are components, which are labeled as (a)Base Model, (b) Actual Base,

(c)Shoulder Link Model, (d) Actual Shoulder Link, (e) Elbow Link Model, (f)

Actual Elbow Link, (g) Wrist Link, Model (h) Actual Wrist Link, (i) Servo Motor

and Harmonic Gear Model, (j) Actual Servo Motor and Harmonic Gear, (k) End Effector Link Model, (l) Actual

End-Effector Link

3.3. Implementation

Figure 9 shows the schematics and control box, which consists of six

servo motors connected to three servo drives, with robot's CPU being

a Beckhoff C5102-0040. Additionally,

the Ehave-CM350 serves as welding

machine that is connected to the IO Device through USB cable for

remote control. The arm is fully driven with each DOF achieved by a precision

servo motor equipped with a three-phase synchronous motor excited by a

permanent magnet. The specifications of

the servo motor used are shown

in Table 4.

Figure 9 Schematics of the Control Box:

(a) schematics, (b) actual devices

Table 4 Servo Motor Specification

|

Specification |

Servo 1 |

Servo 2 |

|

Motor type |

AM8023-wEyz |

AM8043-wHyz |

|

Nominal voltage |

100…480 V AC |

100…480 V AC |

|

Standstill torque |

1.20 Nm |

5.65 Nm |

|

Rated torque |

1.00 Nm |

4.90 Nm |

|

Peak torque |

6.36 Nm |

28.0 Nm |

|

Rated speed |

8000 min-1 |

5000 min-1 |

|

Rated power |

0.84 kW |

2.57 kW |

|

Standstill current |

2.20 A |

5.40 A |

|

Peak current |

11.40 A |

31.0 A |

|

Torque constant |

0.54 Nm/A |

1.04 Nm/A |

|

Rotor moment of inertia |

0.378 kgcm² |

kgcm² |

This study uses 6DOF robotic arm manipulator developed using Beckhoff

PLC with TWINCAT 3 software and CPU

is a Beckhoff C5102-0040. MEGMEET Ehave-CM350 is used as welding machine that

is connected to IO Device through a

serial communication cable for remote

control. The actual assembly is presented

in Figure 10, showing the

implementation of the parametric and kinematic modeling.

The developed system is subjected

to the same values from simulation. The joint angle parameters are set in

degrees, consistent with the

values from MATLAB simulations. Comparing the visualization of the simulated and actual values validates the

similarity in terms of the configurations. Positional

accuracy was obtained by comparing robotic position and the simulation, as presented in Figure 11. The

actual position of robot was

conducted using GUI designed to locate the angles of each axis according to the user’s input.

Figure

10 Actual

Assembly of Welding Robot

Robot

arm was subjected to implement welding process shown in Figure 12. The feedback from the servo motors corresponding to each axis was

analyzed by comparing the

numerical value against angle to assess the accuracy of robot. The results shown in

Figure 13 represent the actual collected data related to robot’s accuracy

characterized by the input angle. Since the motion is controlled by a

pendant graphical user interface, the collected data corresponded only with feedback from servo motors drive, as measured

using the Beckhoff software. The process

includes position

control of welding torch towards the plate to be tested. The four-point pose of

the industrial robot was recorded and

position graphs were drawn in Figure 13. Subsequently, robot performed a linear motion to assess welding accuracy.

Figure 13 shows the position graph regarding the four-point movement of each axis of robot. The vertical axis shows the time value in minutes and the horizontal axis represents angles programmed for welding process. The graph was generated from the sensors value from Beckhoff software TwinCAT 3 versus the angle user intends to locate the end effector of robot.

|

Figure 12 Actual Welding Process

Figure 13 Position Graphs (a) Joint Axis 1, (b) Joint Axis 2, (c)

Joint Axis 3, (d) Joint Axis 4, (e) Joint Axis 5, (f) Joint Axis 6

In

conclusion, this study successfully developed 6DOF

industrial robotic arm for metal arc welding, along with the structure. The

description and analysis of kinematic model were obtained using right hand

rule. Forward kinematic was solved

using the resultant of the final transformation matrix from DH parameter.

Mechanical structure was

drawn in the feature-based, parametric modeling software SolidWorks. Actual

implementation of robot was

also tested with the joints measured at four-point in the workspace. An industrial robotic articulated

jointed arm was designed and built along with the structure, with modeling kinematic serving as the fundamental step before developing parametric

design. Robot was simulated

in three different positions with angles and kinematic model was performed using MATLAB Robotics

Toolbox. The manipulator

was fabricated and assembled, showing

a reduction ratio of 80 from a rated torque of 22 Nm from a 2000r/min input.

Welding process was arc welding with the butt-weld method implemented for robot functionality. Therefore, further

studies were recommended

for the quality of welds.

The

authors are grateful to colleagues from the Doctor of

Engineering for diligently helping us write the draft of the study in terms of graphic designs. Furthermore, the authors are grateful to the

Department of Mechatronics Engineering, Faculty of Technical Education, for the

academic support which contributed to

the successful completion of this study.

Andersen, M.S., 2020. Introduction to musculoskeletal modelling. In

Computational Modelling of Biomechanics and Biotribology in the Musculoskeletal

System: Biomaterials and Tissues. Elsevier, pp. 41–80

Baskoro, A.S., Kurniawan, R.P., Haikal, 2019.

Evaluation of the 2-Axis Movement of a 5-Axis Gantry Robot for Welding

Applications. International Journal of Technology, Volume 10(5), pp.

1024–1032

Bian, Z., Ye,

Z., Mu, W., 2016. Kinematic Analysis and Simulation of 6-DOF Industrial Robot

Capable of Picking up Die-Casting Products. In: AUS 2016 - 2016

IEEE/CSAA International Conference on Aircraft Utility Systems, pp. 41–44

Bilancia, P.,

Schmidt, J., Raffaeli, R., Peruzzini, M., Pellicciari, M., 2023. An Overview of

Industrial Robots Control and Programming Approaches. Applied Sciences,

Volume 13(4), p. 2582

Bouzgou, K.,

Ahmed-Foitih, Z., 2014. Geometric Modeling and Singularity of 6 DOF Fanuc 200IC

Robot. In 4th International Conference on Innovative

Computing Technology, INTECH 2014 and 3rd International Conference on Future

Generation Communication Technologies, FGCT 2014, pp. 208–214

Chen, K., Cao,

G., Sun, J., Yang, J., 2016. A Path-Planning Algorithm of The Automatic Welding

Robot System for Three-Dimensional Arc Welding Using Image Processing. In:

2016 13th International Conference on Ubiquitous Robots and Ambient

Intelligence, URAI 2016, pp. 692–697

Chodha, V.,

Dubey, R., Kumar, R., Singh, S., Kaur, S., 2021. Selection of Industrial Arc

Welding Robot with TOPSIS and Entropy MCDM Techniques. In: Materials

Today: Proceedings. Elsevier Ltd, pp. 709–715

Crenganis, M.,

Tera, M., Biris, C., Gîrjob, C., 2019. Dynamic Analysis of a 7 DOF Robot Using

Fuzzy Logic for Inverse Kinematics Problem. Procedia Computer Science,

Volume 162, pp. 298–306

Dinham, M.,

Fang, G., 2013. Autonomous Weld Seam Identification and Localisation Using

Eye-In-Hand Stereo Vision for Robotic Arc Welding. Robotics and

Computer-Integrated Manufacturing, Volume 29(5), pp. 288–301

Ekrem, Ö.,

Aksoy, B., 2023. Trajectory Planning for A 6-Axis Robotic Arm with Particle

Swarm Optimization Algorithm. Engineering Applications of Artificial

Intelligence, Volume 122, p. 106099

Fan, X., Wang,

X., Xiao, Y., 2014. A Combined 2D-3D Vision System for Automatic Robot Picking.

In: International Conference on Advanced Mechatronic Systems, pp. 513–516

Farzan, S.,

Desouza, G.N., 2013. From D-H to Inverse Kinematics: A Fast Numerical Solution

for General Robotic Manipulators Using Parallel Processing. In: IEEE

International Conference on Intelligent Robots and Systems, pp. 2507–2513

Fazel, R.,

Shafei, A.M., Nekoo, S.R., 2024. Dynamic Modeling and Closed-Loop Control

Design for Humanoid Robotic Systems: Gibbs–Appell Formulation and SDRE

Approach. In Multibody System Dynamics

Jiang, Y., Yu,

L., Jia, H., Zhao, H., Xia, H., 2020. Absolute Positioning Accuracy Improvement

in an Industrial Robot, Sensors, Volume 20(16), p. 4354

Kah, P.,

Shrestha, M., Hiltunen, E., Martikainen, J., 2015. Robotic Arc Welding Sensors

and Programming in Industrial Applications. International Journal of

Mechanical and Materials Engineering, Volume 10(13), pp. 1–16

Kholil, A.,

Kiswanto, G., Al Farisi, A., Istiyanto, J., 2023. Finite Element Analysis of

Lattice Structure Model with Control Volume Manufactured Using Additive

Manufacturing. International Journal of Technology, Volume 14(7), pp.

1428–1437

Krishnan,

M.G., Sankar, A., 2022. Image Space Trajectory Tracking of 6-DOF Robot

Manipulator in Assisting Visual Servoing. Automatika, Volume 63(2), pp. 199–215

Li, G., Wang,

Y., 2019. Industrial Robot Optimal Time Trajectory Planning Based on Genetic

Algorithm. In: Proceedings of 2019 IEEE International Conference on

Mechatronics and Automation, ICMA 2019, pp. 136–140

Liu, Y., Liu, Y., Tian, X., 2019. Trajectory and Velocity Planning of The Robot

for Sphere-Pipe Intersection Hole Cutting with Single-Y Welding Groove.

Robotics and Computer-Integrated Manufacturing, Volume 56, pp. 244–253

Megalingam,

R.K., Katta, N., Geesala, R., Yadav, P.K., Rangaiah, R.C., 2018. Keyboard-Based

Control and Simulation of 6-DOF Robotic Arm using ROS. In: 2018 4th

International Conference on Computing Communication and Automation, ICCCA 2018,

pp. 2–6

Mehmood, N., Ijaz,

F., Murtaza, Z., Shah, S., 2014. Analysis of End-Effector Position and

Orientation for 2P-3R Planer Pneumatic Robotic Arm. In: 2014

International Conference on Robotics and Emerging Allied Technologies in

Engineering, iCREATE 2014 Proceedings, pp. 47–50

Nektarios, A.,

Aspragathos, N.A., 2010. Optimal Location of a General Position and Orientation

End-Effector’s Path Relative to Manipulator’s Base, Considering Velocity

Performance. Robotics and Computer-Integrated Manufacturing, Volume

26(2), pp. 162–173

Pham, H.L.,

Adorno, B.V., Perdereau, V., Fraisse, P., 2018. Set-Point Control of Robot

End-Effector Pose Using Dual Quaternion Feedback. Robotics and

Computer-Integrated Manufacturing, Volume 52, pp. 100–110

Pramujati, B.,

Syamlan, A.T., Nurahmi, L., Tamara, M.N., 2023. Study on the Application of Model-based

Control Algorithm for a Suspended Cable-Driven Parallel Robot. International

Journal of Technology, Volume 14(4), pp. 854–866

Ritboon, V.,

Maneetham, D., 2019. A New Industrial Robotics and Software Development

Resolved the Position and The Speed Control. In 2019 International

Conference on Information and Communications Technology, ICOIACT 2019, pp.

674–677

Russo, M.,

Zhang, D., Liu, X.J., Xie, Z., 2024. A Review of Parallel Kinematic Machine

Tools: Design, Modeling, and Applications. International Journal of Machine

Tools and Manufacture, Volume 196, p. 104118

Singh, A.,

Singla, A., 2017. Kinematic Modeling of Robotic Manipulators. In:

Proceedings of the National Academy of Sciences India Section A - Physical

Sciences, Volume 87(3), pp. 303–319

Vacharakornrawut,

N., Themanee, T., Rerkratn, A., Pongswatd, S., 2016. Converting TCP to Joints

Value of 6-DOF Robot Based on Forward and Inverse Kinematic Analysis. In:

2016 13th International Conference on Electrical

Engineering/Electronics, Computer, Telecommunications and Information

Technology, ECTI-CON 2016, pp. 1–6

Vasilev, M.,

Macleod, C.N., Loukas, C., Javadi, Y., Vithanage, R.K.W., Lines, D., Mohseni,

E., Pierce, S.G., Gachagan, A., 2021. Sensor-Enabled Multi-Robot System for

Automated Welding and In-Process Ultrasonic Nde. Sensors, Volume 21(15),

p. 5077

Wang, L.,

Peng, G., Yang, Y., Li, X., 2024. Industrial Robot Application and Enterprise

Financialization: Empirical Evidence from the Chinese Manufacturing Firm Level.

Journal of the Knowledge Economy, Volume 2024, pp. 1–25

Wu, Y., Ming

Go, J.Z., Ahmed, S.M., Lu, W., Chew, C., Pang, C.K., 2015. Automated Bead

Layout Methodology for Robotic Multi-Pass Welding. In: IEEE

International Conference on Emerging Technologies and Factory Automation, pp.

19–22

Xu, Y., Fang,

Gu., Du, S., Zhao, W., Ye, Z., Chen, S., 2017. Welding Seam Tracking in Robotic

Gas Metal Arc Welding. Journal of Materials Processing Technology,

Volume 248, pp. 18–30

Zeng, T., Liu,

P., You, D., 2019. Kinematics Simulation and Operation Space Analysis of Arc

Welding Six-Axis Robot Based on Matlab and Adams. In: Proceedings - 2019

2nd World Conference on Mechanical Engineering and Intelligent

Manufacturing, WCMEIM 2019, pp. 504–507

Zhang, Y.,

Xiao, J., Zhang, Z., Dong, H., 2022. Intelligent Design of Robotic Welding Process

Parameters Using Learning-Based Methods. IEEE Access, Volume 10, pp. 13442–13450

Zhao, R., Shi,

Z., Guan, Y., Shao, Z., Zhang, Q., Wang, G., 2018. Inverse Kinematic Solution

of 6R Robot Manipulators Based on Screw Theory and The Paden–Kahan Subproblem. International

Journal of Advanced Robotic Systems, Volume 15(6), pp. 1–11