Design of Adjustable Slider Controller in Combination with A* Algorithm in Motion Control for Mobile Robot

Corresponding email: vothuha.robot.dien.uneti@gmail.com

Published at : 18 Sep 2024

Volume : IJtech

Vol 15, No 5 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i5.6527

Ha, V.T., Thuong, T.T., Thanh, N.T., 2024. Design of Adjustable Slider Controller in Combination with A* Algorithm in Motion Control for Mobile Robot. International Journal of Technology. Volume 15(5), pp. 1487-1501

| Vo Thu Ha | Control and automation engineering technology, Faculty of Electrical-Automation Engineering, University of Economics - Technology for Industries (UNETI), Hanoi, Vietnam |

| Than Thi Thuong | Control and automation engineering technology, Faculty of Electrical-Automation Engineering, University of Economics - Technology for Industries (UNETI), Hanoi, Vietnam |

| Nguyen Thi Thanh | Control and automation engineering technology, Faculty of Electrical-Automation Engineering, University of Economics - Technology for Industries (UNETI), Hanoi, Vietnam |

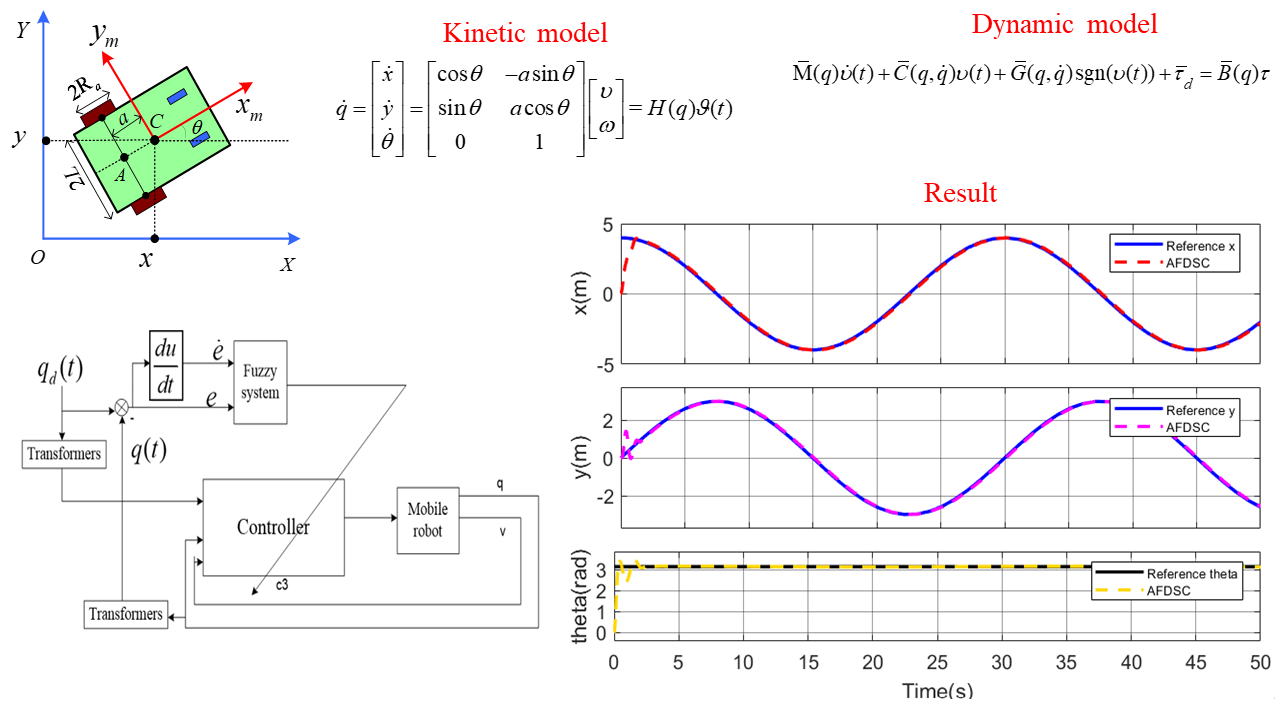

This article presents an Adaptive Fuzzy Logic

Dynamic Surface Controller (AFDSC) combined with the A* optimal path-finding

algorithm for mobile robots' following trajectory tracking with the nonlinear

system changes in robot parameters and is affected by wheel sliding friction

disturbances when operating on different terrains. This algorithm is built

based on the DSC dynamic sliding surface control algorithm, promoting the

effective advantages of DSC and using fuzzy logic to adaptively adjust the

coefficients of the virtual control signal and keep The system status signal

located on the sliding surface to overcome the instability of DSC when encountering

this state. The stability and convergence of the closed-loop system are

guaranteed based on Lyapunov analysis. The robot's path planning trajectory is

performed by the A* algorithm. At the same time, the content of the article

mentions programming and experimental operation for mobile robots using the

ROS2 Rolling with Focal (20.04) software operating system on the Jetson Nano 4G

embedded computer. The correctness, the proposed controller’s effectiveness,

and the possibility of practical applications. Orbits are set as two periodic

functions of period T as follows. Theoretical and experimental simulation

results with position deviation-axis from 0.0038(m) to 0.0063(m), y-axis from

0.0029(m) to 0.0049(m), from 0.0021(rad)

to 0.0035(rad). And experimental results with position error in the x-axis from

0.0062(m) to 0.0105(m), y-axis from 0.0042(m) to 0.0069(m), and 0.0031(rad) to 0.0053(rad)).

Adaptive controller; Adaptive Fuzzy Dynamic Surface Controlzy (AFDSC); Dynamic Surface Control (DSC); Mobile Robot; Robot operating system (ROS)

Nowadays, mobile

robots have been integrated into various modern intelligent systems, including

production systems, logistics, hospitals, smart factories and warehouses. For

example, there are unmanned logistics transportation systems that incorporate

receiving devices and automatic delivery. The problem of motion control for

wheel-type mobile robots has attracted the attention of scientists around the

world. Mobile robots are among the

systems subject to nonholonomic constraints (Rusdinar

et al., 2021; Xin et al., 2016). Furthermore, it is a

nonlinear many-input-many-out system (Li, Wang, and

Zhu, 2010).

Advancements in control theory have introduced various methods for designing control laws for mobile robots, including sliding control, (Park et al., 2009; Chwa, 2004) sustainable control (Jiang, 2000), adaptive control (Ye and Wang, 2020; Rubio, Valero, and Llopis-Albert, 2019; Nguyen et al., 2018), backstepping control (Liu et al., 2021; Feng and Wang, 2021), output feedback linearization (Aldo et al., 2021; Rabbani and Memon, 2021). These control laws were designed with the assumption that "the wheel only rolls without slipping." However, in practical applications, the condition that the wheels only roll without slipping can often be violated. That is, wheel slippage has occurred (Zhang et al., 2022; Liu, et al., 2021).

Wheel slippage can occur due to factors like low

friction on the floor or centrifugal forces during curved motion. Therefore, in

such situations, if control performance is to be improved, it is necessary to design

a controller capable of compensating for wheel slippage. The problem of wheel

slip compensation control for mobile robots has had many scientists worldwide

spend time researching and solving this problem. However, the majority of

studies are carried out under the assumption that the slip angle (Hoang and Kang, 2016; Lenain et al., 2010; Low and

Wang, 2008) and the friction coefficient between the wheel and the road

surface (Elsayed et al., 2019; Chen et

al., 2018) are always accurately measured through sensors.

Quantities, including translational acceleration, angular acceleration,

translational velocity, and angular velocity, can all be easily measured

directly through sensors, but the sliding angle and friction coefficient are

very small. difficult to measure (Bayar et al.,

2016). To measure these signals accurately and reliably, the system must

be integrated with complex and expensive sensors (Bayar

et al., 2016).

Several control methods have been proposed to

address wheel slippage without requiring precise parameter measurements.

Instead, the negative effect of wheel slippage on trajectory tracking

performance will be compensated indirectly by the controllers. The control law

in (Zhang et al., 2020) is designed

in the global coordinate system OXY, so it requires measuring velocities in

this global system. This velocity measurement task was solved using the

supper-twisting observer. The estimation results from this observer may contain

errors accumulated during robot operation. So the ability to implement the

control method in (Zhang et al., 2020)

is still limited. To overcome this drawback, the adaptive sustainable tracking

control method is based on the backstepping technique (Xu,

Yang, and Gadsden, 2020); creating

a reverse impact from kinematics into dynamics) based on a Gaussian wave

network for mobile robots to compensate for wheel slippage, model uncertainty,

and external noise, show smaller position tracking errors compared to the

control method (Zhang et al., 2020) ,

which has asymptotically converged to zero. However, the disadvantage of this

method is that it requires a very large input control signal (torque) at the

initial time, the amount of calculation is large and complex, and it takes a

lot of time to calculate due to having to calculate the derivative in each

iteration step.

Sliding

mode controller (SMC) has also been used (Attia and

Suan, 2024; Edalati et al., 2018) due to its superior properties

when compared to Backstepping, particularly when the system is exposed to

noise. Sliding control is preferred for its robustness, rapid response,

straightforward control rules, and ease of implementation. Sliding controllers

can be used for a wide class of nonlinear systems with uncertain parameters and

interference effects. However, the limitation of the SMC algorithm is the

chattering phenomenon, and reducing this phenomenon requires the object model

to be accurate. This goes against the properties of the robot model, which is

parameter uncertainty. To improve control quality in (Gore

et al., 2015), the structure and method of building a dynamic

sliding surface controller (DSC) were presented. In particular, when the system

contains uncertain components, research focuses on improving and developing the

multi-sliding surface controller (MSSC). The design method also determines the

control signal based on the Lyapunov control function, so DSC ensures a stable

closed system and can adapt to the uncertain composition of the system and

deviations within certain limits. The design steps are similar to the

Backstepping set design steps; however, to avoid having to take derivatives in

the iteration steps for the virtual control signal, DSC has added a low-pass

filter, both to get information about medium derivative to filter out

high-frequency internal noises appearing in the control object (Qi et al., 2018). To improve control

quality, an adaptive controller based on the dynamic sliding surface control

(DSC) technique combined with a fuzzy logic system (Wang,

Wang, and Han, 2021) is studied because the fuzzy adaptive controller

has a simple adjustment mechanism in design and installation (Rahman, Hassan, and Ihsan, 2022). This has opened

up a new possible research direction for wheeled mobile robots (WMR) with

horizontal sliding components; then integrating embedded programming on the

Jetson embedded computer platform and the robot operating system (ROS); the

STM32 microcontroller creates test autonomous vehicle system with the A*

pathfinding algorithm. For fixed environments (warehouses, farms, factories,

etc.), path planning algorithms such as Dijkstra, A*, and D* are commonly used.

Because these algorithms have the advantage of finding the fastest path in a

static environment, the computational methods of these algorithms are also

quite fast (Liu et al., 2023; Alshammrei Boubaker, and Kolsi, 2022; Hou et al.,

2022).

In

this article, the authors propose to use A*, D*, or Dijkstra search algorithms

to plan the path for autonomous robots in a static environment with fixed obstacles.

In the article (Chen et al., 2009),

the authors also analyze the expansion and development algorithms of the A*

algorithm to see the optimal usability of the algorithm in planning the path

for the robot when we use it using the A* algorithm. In this paper, the authors

will choose algorithm A* to plan the fastest path for an omnidirectional mobile

robot in a static environment. This article proposes a new control structure

with a kinematic and dynamic model of a mobile robot when sliding sideways using

only one control loop, and designs a trajectory tracking controller for

self-propelled vehicles based on the algorithm. Dynamic sliding surface control

and adaptive control structure based on a fuzzy logic system (AFDSC) with an A*

path-finding algorithm to ensure a stable closed system.

There

are five main sections on this page. Target research and kinetic and dynamic

models are introduced in Sections 1 and 2. Presenting the suggested controller

is Section 3. The simulation results of the suggested controller are included

in Part 4. The conclusion is the concluding section.

Kinetic Model of An Autonomous Vehicle

2.1. Kinetics of autonomous robots

Consider

a self-propelled robot as depicted in Figure 1. Where: is the radius of the

active wheel; A is the midway of two

active wheels; C is the robot's

center of gravity's coordinates;

The

position of the robot is determined by the identity vector are the point

coordinates C).

The state

vector can be represented by the following five generic coordinates (1):

With:

Figure 1 Kinetic

relationship of self-propelled robot

According to the reference

(Nardênio and Douglas, 2021; Mohareri, 2009) we

have the kinematic equation of the robot, which will be written as equation (2)

as follows:

Where

to its velocity in the inertial reference coordinate

system (XOY) are all.

Provide

sufficient detail methods to allow the work to be reproduced. Methods already

published should be indicated by a reference: only relevant modifications

should be described.

2.2. Dynamics of autonomous robots

The dynamic equation of a

mobile robot can be characterized as follows, according to documents (Nardênio

and Douglas, 2021; Chen et al., 2009)(3).

where (3): M(q)

is the friction matrix,

is the unknown noise component of the system,

is the Lagrange multiplier,

Motion control torque for mobile robots,

is the binding matrix,

represent the

generalized velocity and acceleration vectors, respectively.

where: m are the

friction force in the direction of translational motion, rotational direction,

and horizontal sliding friction, respectively,

From

equation (2), we can prove that the transformation matrix H(q)

We differentiate

the equation (2) we have (5):

From there, we

have the system's dynamic equation as follows (6):

3. Development of an A* pathfinding algorithm and

an adaptive Sliding-fuzzy controller for mobile robots

3.1.

Design in sliding

mode

According to documentation

[3], the recommended state variables are as follows:

Combining

the kinematics equation (2) and equation (7), we get:

From

equations (6), (7), and (8), we get the state model (9):

First,

the set

Assume

that the control signal is virtual in the design of the DSC controller. is the

input to the first-order low-pass filter with the expression (11):

with is the

appropriate diagonal constant matrix value whose elements are positive values.

After

calculating the virtual control law,

With

To

demonstrate the availability of virtual control signals, choose the first

Lyapunov function (14)

Consider

the derivative of

Next, the sliding

control technique is designed to obtain the control signal of the system and

ensure that it achieves the ideal value. The system's virtual control signal

bias (16):

Choose slide (17):

Where

The

derivative of S is calculated (18):

As mentioned earlier,

one advantage of a DSC controller is its ability to avoid the phenomenon of

"term explosion" that occurs when the derivative of a virtual control

signal is calculated repeatedly in each cycle. In order to ensure system

stability and calculate the control signal, the value of Alpha is derived from

the first-order filter (13). Additionally, the second Lyapunov function is

selected (19):

The system's control signal will be

calculated in the form of a sliding controller to increase the system's

robustness against noise. Therefore, the control signal will include two

components TT, which is the control signal to keep the system state on the sliding

surface TR obtained from the condition

However

(20),

Theorem

3.1:

WMR described using the model (6) is controlled by (22) with ensure the closed system is stable and the

tracking error approaches 0.

Proof:

The derivative

The advantage of the DSC method is to increase the

adaptability of the system and reduce the amount of controller computation. The

control signal used contains a sliding component, hence the robust stability of

the SMC. The low-pass filter used not only filters out endogenous

high-frequency noise but also provides information about the derivative of the

virtual control signal. Therefore, calculating the derivative of the virtual

control signal becomes unnecessary.

3.2.

Adaptive

fuzzy-sliding mode Design

During

the simulation to look for parameters suitable for slide controllers (Thi et al., 2019), I found that the adaptive slide controller

quality (13) largely depends on the selection of the control

parameter values, especially

Figure 2 Input fuzzy sets |

Table 1 Fuzzy inference coefficient for output

|

|

| ||||

|

NB |

NS |

Z |

PS |

PB | |

|

NB |

M(M) |

S(B) |

VS(VB) |

S(B) |

M(M) |

|

NS |

B(S) |

M(M) |

S(B) |

M(M) |

B(S) |

|

Z |

VS(VB) |

B(S) |

M(M) |

B(S) |

VS(VB) |

|

PS |

B(S) |

M(M) |

S(B) |

M(M) |

B(S) |

|

PB |

M(M) |

S(B) |

VS(VB) |

S(B) |

M(M) |

-

Fuzzy controller using

composition rule SumPROD

-

Defuzzification by the formula

From

equation (13), we have the control structure diagram as shown in Figure 3

below:

4. Simulation of the

adaptive fuzzy-sliding controller for autonomous vehicles

Perform the simulation of

the proposed controller to control the motion of mobile robot with the

following parameters and trajectory: set the trajectory for the robot to move

Perform

the simulation using the proposed controller. Motion control for the robot to

follow the trajectory in two cases: A) The robot runs normally without load

(m=10kg); B) Robot runs with added load resistance (m=30kg). The trajectory

tracking response is shown in two cases as shown in Figures 4 and 5 below:

- Simulation results on Matlab case A: Simulate with the above parameters

|

Figure 4 Orbital response and orbital

deviation in simulation with m=10k |

- Simulation results of

case B: When the robot's load is increased to 50 kg and there is more impact

noise

|

Figure 5 Trajectory response and orbital

deviation when simulating with m=30kg and with noise |

Table 2 Trajectory

tracking simulation results of AFDSC controller

4.1. Experimenting with operating a mobile robot using an adaptive sliding-fuzzy controller combined with real math A*

- Hardware structure of mobile robot system

Experiment

with the robot system, complete the hardware design and program the control algorithms on ROS

with the mobile robot model configured, as shown in Figure 6.

Figure

6

Schematic of the hardware structure to

control the self-propelled robot

The

mobile robot's steel body is constructed to specifications and measures 70 cm x

50 cm x 38 cm. Its 10-centimeter-wide tires can handle almost any indoor

surface. 12000-tick encoders are mounted on two motor shafts. The control

circuit hardware structure for the robot is used. Jetson Nano 4G (master)

high-performance processor, with the role of central processing, is a

specialized high-performance processor for artificial intelligence processing (WHO).

The microcontroller circuit (slave) (NCS uses ARM cortex M3 core STM32F407) is

the part that receives control signals from Jetson Nano 4G (master). The

H-bridge circuit (BTS7960 43A) uses MOSFETs as the power circuit to control the

4-wheel servo motors. The camera has a maximum RGB image resolution of up to

1280 x 720. RPLIDAR A1M8 360° Lidar is a laser scanner, which is combined with

the Astra 3D Camera that will send position, direction, and obstacle signals to

the Jetson Nano master processor and Sensor. The HWT901B IMU variable sends balanced

signals to the Jetson master processor.

Experiment for moving

robots to avoid static obstacles in the robot club room and technology 810_HA10

with scenario Starting

from the door to the middle of the room in front of the obstacle is a stack of

cartons. Perform robot control in 2 cases: A) Robot runs normally without load

(m = 10 kg); B) Robot runs with added load resistance (m=30kg).

To implement the global

migration planning approach, ROS provides three interfaces Areas include carrot_planner, navfn, and

global_planner. Including travel planning global transfer is the interface used to

execute the algorithm A * (Chung, Ojeda, and Borenstein. 2001). Algorithm A*

will be executed

by 2 nodes, a map (Map) and a location robot (Robot Pose), outputting data about the map and robot

position Figure 7.

The navigation system

designed in this paper combines information from encoder sensors, laser

scanning sensors, and IMUs. The structure diagram of the system in ROS is

developed using nodes, with each node having its own responsibility, services,

and functions. different services, and functions. The information exchanged

between each node is communicated through messages, the information transmitted

and received according to predefined protocols and a common standard for

communicating with external data packets. In addition, the tool supports visual

inspection of algorithms and data monitoring and ensures that data is processed

in real-time. The system structure diagram is designed on ROS including nodes

and the data transmission process is depicted as shown in Figure 8. Running the

experiment repeated 3 times for 2 cases (A and B) as suggested in the above

scenario, we can calculate the deviation between the real trajectory and the

planned trajectory as shown in Table 3.

Figure

7 WMR control

structure diagram with AFDSC controller combined with A* algorithm

Figure 8

Map button and location used in ROS

Figure 9 (a) Experimental image of mobile robot motion without load (m = 10 kg) and (b) Experimental image of mobile robot movement when there is an additional load (m = 30 kg)

Table 3 Trajectory

deviation results when running experiments

|

Run

times |

A |

Obstacle

avoidance time (s) |

B |

Obstacle

avoidance time(s) | ||||

|

|

|

|

|

|

| |||

|

1 |

0.0062 |

0.0045 |

0.0037 |

0.8102 |

0.0102 |

0.0075 |

0.0053 |

1.0032 |

|

2 |

0.0065 |

0.0051 |

0.0031 |

0.7834 |

0.0095 |

0.0081 |

0.0049 |

1.2143 |

|

3 |

0.0071 |

0.0042 |

0.0040 |

0.8621 |

0.0105 |

0.0069 |

0.0051 |

1.7302 |

5.

Evaluate

simulation results and experimental results

The

results show in Figure 9(a), 9(b), and Table 2 that in both cases, the

controller is guaranteed to follow the set trajectory, but the setting time and

the error value are slightly different. Specifically, with the same controller

as well as controller parameters, in the case of no external interference, the

orbital response approaches the set orbit after about 0.4 seconds with a very

small deviation of 0.0038 (m). Meanwhile, with changing model parameters and

adding uncertainty, the system is only stable after 0.8 seconds and the

determination error is 0.0063 (m). Whenever there is a change in the bias and

the bias derivative, the fuzzy rules are specifically designed to update the

parameters of DSC online. The newly proposed AFDSC set guarantees improved

quality in tracking the system's preset orbit. It enables faster attainment of

the set orbit and reduces the tracking error as well. However, the model deviation is large and

contains many factors uncertainty and noise. These factors, which affect the

robot with large amplitudes, mean that AFDSC no longer ensures quality. This

will be the next research direction of the author group.

The

results are shown in Table 2. The goal of the experiment was to successfully

verify the proposed algorithms through experimentation. To achieve this, the

robot is equipped with high-performance hardware and processing control

circuits, as well as programming support software based on the ROS robot

operating system. Synchronously design and manufacture hardware and peripheral

devices, manufacture electronic circuits, control, and peripheral communication

to be fast and strong enough to be expandable and upgradeable. Design

structure, program, install researched algorithms for robots, run tests, and

evaluate results. The experimental results show the correctness of the

theoretical analysis, the effectiveness of the proposed controller, and the

possibility of practical application. Experimental results show that when the

robot encounters an obstacle, it takes about 0.7834 to 1.7302 s to change the

local trajectory to avoid the obstacle. With the obstacle fixed in the

corridor, it shows the robot's responsiveness when moving flexibly to avoid

obstructions, calculate the optimal local trajectory, and navigate along the

local trajectory new with the allowed distance and distance and the movement

follows the specified trajectory with the position error in the x-axis from

0.0062 to 0.0105 m, the y-axis from 0.0042 to 0.0069 m, and from 0.0031 to

0.0053 rad.

This article successfully achieves

the goal of researching and proposing an algorithm based on the DSC (Dynamic

Sliding Surface Control) algorithm for differential self-propelled robots navigating

uncertain routes in a non-linear system. The algorithm focuses on improving

tracking quality and adapting to changes in robot parameters, as the robot

interacts with various objects and environments, and operates under noise on

different terrains. This algorithm takes advantage of efficiency DSC uses fuzzy

logic to adaptively adjust the coefficients of the virtual control signal and keeps

the system's status signal on the sliding surface to overcome the

disadvantages. DSC instability when encountering this state. This algorithm has

not been installed on any robot before at home or abroad, has high flexibility,

a simple structure, and is easy to program and install on the microprocessor.

It can adapt and Maximize efficiency by using the DSC platform it is especially

suitable for differential self-propelled robot models based on simulation

results and experimental runs. The next research direction of the authors is to

continue researching and improving adaptive algorithms when robots move on

sloping terrain (3D), as well as have movement patterns suitable for different

types of terrain with different complexities when operating in actual applications.

Optimize processing time, apply the ROS robot programming operating system for

intelligent programming, improving the system's tracking speed.

Aldo, J., Vicente, P., Anand, S., Juan, D., 2021. Adaptive Fuzzy Velocity Field Control for Navigation of Nonholonomic Mobile Robots. Journal of Intelligent & Robotic Systems, Volume 101, p. 8

Alshammrei, S., Boubaker, S., Kolsi, L., 2022. Improved Dijkstra Algorithm for Mobile Robot Path Planning and Obstacle Avoidance. Computers, Materials & Continua, Volume 72(3), pp. 5939–5954

Attia, H., Suan, S.T.K., 2024. Robust Sliding Mode Controller Design for Boost Converter Applications. International Journal of Technology, Volume 15(3), pp. 481–491

Bayar, G., Bergerman, M., Konukseven, E., Koku, A.B., 2016. Improving The Trajectory Tracking Performance of Autonomous Orchard Vehicles Using Wheel Slip Compensation. Biosystems Engineering, Volume 146, p. 149–164

Chen, C., Gao, H., Ding, L., Li, W., Yu, H., Deng, Z., 2018. Trajectory Tracking Control of WMRs with Lateral And Longitudinal Slippage Based on Active Disturbance Rejection Control. Robotics and Autonomous Systems, Volume 107, pp. 236–245

Chen, C., Li, T., Yeh, Y., Chang, C., 2009. Design and Implementation of An Adaptive Sliding-Mode Dynamic Controller For Wheeled Mobile Robots. Mechatronics, Volume19(2), pp. 156–166

Chung, H., Ojeda, L., Borenstein, J., 2001. Sensor Fusion for Mobile Robot Dead-Reckoning With a Precision-Calibrated Fiber Optic Gyroscope. In: Proceedings 2001 ICRA. IEEE International Conference on Robotics and Automation, Volume 4, pp. 3588–3593

Chwa, D.K., 2004. Sliding-Mode Tracking Control Of Nonholonomic Wheeled Mobile Robots In Polar Coordinates. IEEE Transactions on Control Systems Technology, Volume 12(4), pp. 637–644

Edalati, L., Sedigh, A.K., Shooredeli, M.A., Moarefianpour, A., 2018. Adaptive Fuzzy Dynamic Surface Control of Nonlinear Systems With Input Saturation and Time-Varying Output Constraints. Mechanical Systems and Signal Process, Volume 100, p. 311–329

Elsayed, M., Soe, M.T., Kit, W.W., Abdalla, H., 2019. An Innovative Approach to Developing a 3D Virtual Map Creator using an Ultrasonic Sensor Array. International Journal of Technology, Volume 10(7), pp. 1344–1354

Feng, X., Wang, C., 2021. Robust Adaptive Terminal Sliding Mode Control of an Omnidirectional Mobile Robot for Aircraft Skin Inspection. International Journal of Control, Automation and Systems, Volume 19, pp. 1078–1088

Gore, R., Reynolds Jr, P.F., Kamensky, D., Diallo, S., Padilla, J., 2015. Statistical Debugging For Simulations. ACM Transactions on Modeling and Computer Simulation (TOMACS), Volume 25(3), pp. 1–26

Hoang, N., Kang, H., 2016. Neural Network-Based Adaptive Tracking Control of Mobile Robots in The Presence of Wheel Slip and External Disturbance Force. Neurocomputing, Volume 188, pp. 12–22

Hou, Y., Gao, H., Wang, Z., Du, C., 2022. Path Planning for Mobile Robots Based on Improved A* Algorithm. In: International Conference on Neural Computing for Advanced Applications, Volume 1637, pp. 169–183

Jiang, Z.P., 2000. Robust Exponential Regulation of Nonholonomic Systems With Uncertainties. Automatic, Volume 36(2), pp. 189–209

Lenain, R., Thuilot, B., Cariou, C., Martinet, P., 2010. Mixed Kinematic and Dynamic Sideslip Angle Observer for Accurate Control of Fast Off-Road Mobile Robots. Journal of Field Robotics, Volume 27, pp. 181–196

Li, Y., Wang, Z., Zhu, L., 2010. Adaptive Neural Network PID Sliding Mode Dynamic Control of Nonholonomic Mobile Robot. In: Proceedings of the 2010 IEEE International Conference on Information and Automation, Harbin, China, pp. 753–757

Liu, C., Xie, S., Sui, X., Huang, Y., Ma, X., Guo, N., Yang, F., 2023. PRM-D* Method for Mobile Robot Path Planning. Sensors, Volume 23(7), p. 3512

Liu, J., Wang, Z., Zhang, L., Walker, P., 2021. Sideslip Angle Estimation of Ground Vehicles: A Comparative Study. IET Control Theory Application, Volume 14, pp. 3490–3505

Low, C.B., Wang, D., 2008. GPS-Based Tracking Control For A Car-Like Wheeled Mobile Robot With Skidding and Slipping. IEEE/ASME Transactions on Mechatronics, Volume 13(4), p. 480–484.

Mohareri, O., 2009. Mobile Robot Trajectory Tracking Using Neural Networks. Doctoral Dissertation, American University of Rajah

Nardênio, AM., Douglas, WB., 2021. Wheeled Mobile Robot Control: Theory, Simulation, and Experimentation. Springer

Nguyen, T., Nguyentien, K., Do, T., Pham, T., 2018. Neural Network-based Adaptive Sliding Mode Control Method for Tracking of a Nonholonomic Wheeled Mobile Robot with Unknown Wheel Slips, Model Uncertainties, and Unknown Bounded External Disturbances. Acta Polytechnica Hungarica, Volume 15, pp. 103–123

Park, B.S., Yoo, S.J., Park, J.B., Choi, Y.H., 2009. Adaptive Neural Sliding Mode Control Of Nonholonomic Wheeled Mobile Robots With Model Uncertainty. IEEE Transactions on Control Systems Technology, Volume 17(1), pp. 207–214

Qi, S., Zhang, D., Guo, L., Wu, L., 2018. Adaptive Dynamic Surface Control of Nonlinear Switched Systems with Prescribed Performance. Journal of Dynamical and Control Systems, Volume 24, pp. 269–286

Rabbani, M.J., Memon, A.Y., 2021. Trajectory Tracking and Stabilization of Nonholonomic Wheeled Mobile Robot Using Recursive Integral Backstepping Control. Electronics, Volume 10(16), pp. 1–22

Rahman, A., Hassan, N., Ihsan, S.I., 2022. Fuzzy Logic Controlled Two Speed Electromagnetic Gearbox for Electric Vehicle. International Journal of Technology, Volume 13(2), pp. 297–309

Rubio, F., Valero, F., Llopis-Albert, C., 2019. A Review of Mobile Robots: Concepts, Methods, Theoretical Framework, and Applications. Sage Journal, Volume 16(2), p. 1729881419839596

Rusdinar, A., Purnama, I., Fuadi, A.Z., Adiluhung, H., Wicaksono, M., Risnanda, Ningrum, R.A., 2021. Automated Ultraviolet C Light Mobile Robot for Room Sterilization and Disinfection. International Journal of Technology, Volume 12(4), pp. 854–864

Thi, K.D.H., Nguyen, M.C., Vo, H.T., Nguyen, D.D., Bui, A.D., 2019. Trajectory Tracking Control For Four-Wheeled Omnidirectional Mobile Robot Using Backstepping Technique Aggregated With Sliding Mode Control. In: 2019 First International Symposium on Instrumentation, Control, Artificial Intelligence, and Robotics (ICA-SYMP), pp. 131–134

Wang, C., Wang, D., Han, Y., 2021. Neural Network Based Adaptive Dynamic Surface Control for Omnidirectional Mobile Robots Tracking Control with Full-State Constraints and Input Saturation. International Journal of Control, Automation and Systems, Volume 19(12), pp. s4067–s4077

Xin, L., Wang, Q., She, J., Li, Y., 2016. Robust Adaptive Tracking Control Of Wheeled Mobile Robot. Robotics and Autonomous Systems, Volume 78, pp. 36–48

Xu, Z., Yang, S.X., Gadsden, S.A., 2020. Enhanced Bioinspired Backstepping Control for a Mobile Robot with Unscented Kalman Filter. IEEE Access, Volume 8, pp. 125899-125908

Ye, H., Wang, S., 2020. Trajectory Tracking Control for Nonholonomic Wheeled Mobile Robots with External Disturbances and Parameter Uncertainties. International Journal of Control, Automation and Systems, Volume 18, pp. 3015–3022

Zhang, J.J., Fang, Z.L., Zhang, Z.Q., Gao, R.Z., Zhang, S.B., 2022. Trajectory Tracking Control of Nonholonomic Wheeled Mobile Robots Using Model Predictive Control Subjected to Lyapunov-Based Input Constraints. International Journal of Control, Automation and Systems, Volume 20(5), pp. 1640–1651

Zhang, L., Chen, H., Huang, Y., Guo, H., Sun, H., Ding, H., Wang, N., 2020. Model Predictive Control For Integrated Longitudinal and Lateral Stability of Electric Vehicles With In-Wheel Motors. Emerg. IET Control Theory & Applications, Volume 14(18), pp. 2741–2751