Synthesis of Chemical Adsorbent for Purification of Heavy Oil Residue

Corresponding email: galimjan_87@mail.ru

Published at : 17 May 2024

Volume : IJtech

Vol 15, No 3 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i3.6507

Maldybayev, G., Shayakhmetova, R., Nurzhanova, S., Sharipov, R., Negim, E.-S., Alimzhanova, A., Osipov, P., Mukhametzhanova, A., Usman, A., 2024. Synthesis of Chemical Adsorbents for Purification of Heavy Oil Residues. International Journal of Technology. Volume 15(3), pp. 792-802

| Galymzhan Maldybayev | 1. National Center on complex processing of mineral raw materials of the Republic of Kazakhstan, 67 Jandossov Str., Almaty 050036, Republic of Kazakhstan, 2. School of Materials Science and Green Tech |

| Roza Shayakhmetova | National Center on complex processing of mineral raw materials of the Republic of Kazakhstan, 67 Jandossov Str., Almaty 050036, Republic of Kazakhstan |

| Saule Nurzhanova | Sokolsky Institute of Organic Catalysis and Electrochemistry, 142 Kunaev St., Almaty 050010, Republic of Kazakhstan |

| Rustam Sharipov | School of Materials Science and Green Technologies, Kazakh-British Technical University, St. Tole Bi, 59, Almaty 050000, Kazakhstan |

| El-Sayed Negim | 1. School of Materials Science and Green Technologies, Kazakh-British Technical University, St. Tole Bi, 59, Almaty 050000, Kazakhstan, 2. School of Petroleum Engineering, Satbayev University, 22 Satp |

| Aliya Alimzhanova | National Center on complex processing of mineral raw materials of the Republic of Kazakhstan, 67 Jandossov Str., Almaty 050036, Republic of Kazakhstan |

| Petr Osipov | National Center on complex processing of mineral raw materials of the Republic of Kazakhstan, 67 Jandossov Str., Almaty 050036, Republic of Kazakhstan |

| Anar Mukhametzhanova | National Center on complex processing of mineral raw materials of the Republic of Kazakhstan, 67 Jandossov Str., Almaty 050036, Republic of Kazakhstan |

| Anwar Usman | Department of Chemistry, Faculty of Science, University Brunei Darussalam, Jalan Tungku Link, Gadong BE1410, Brunei Darussalam |

This study

aimed to investigate synthesized wollastonite based on amorphous silicon

dioxide and calcium carbonate as adsorbent for cleaning hydrocarbon feedstock

from heavy organometallic compounds and sulfur. During the analysis,

physicochemical parameters including the specific surface area and intensity of

synthesized wollastonite were determined. The results showed that the optimal

temperature zone for demetallization of hydrocarbon raw materials was 653 - 683

K, with a contact time of 60 minutes, and pressure of 8 - 10 atm. Furthermore,

the content of vanadium, nickel, iron, and sulfur was found to decrease from

540 to 52 µg/kg, 50 to 26 µg/kg, 50 to 12 µg/kg, and 3.50% to 2.39%,

respectively.

Adsorbent; Asbestos waste; Demetallization; Heavy oil; Sulfur

Cracking of oil in zeolites is one of the most significant

industrial applications in oil refining. In this field, attention is focused on

developing catalytic systems using nanosized zeolites and micro-mesoporous

materials. The wide use of zeolites as a valuable tool in nanotechnology is

attributed to their unique properties, such as nanoscale of cavities, capacity

for precise arrangement of active centers, selectivity, and directional effect

on chemical groups of molecules (Johansson et

al., 2023; Ulfiati et al., 2022; Ongarbayev et

al., 2020; Li et al., 2020; Attia et al., 2020; Shang et al., 2016; Jo et

al., 2014).

Recently,

various inorganic substances such as hydroxides, silicates, phosphates, and

aluminosilicates, have gained significant attention. This is due to the

widespread availability of inorganic substances, along with high thermal and

chemical resistance, serving as effective and accessible sorbents. Although the

activity of sorbents containing zeolites depends on the concentration of

hydrogen ions and mobility, regulation can be

Sorbents are generally obtained

from natural minerals and secondary raw materials, such as waste from

extraction plants, which mainly contain silicate and aluminosilicate non-metallic minerals. Moreover, obtaining effective sorbents

based on anthropogenic raw materials can solve both technological issues by expanding the range of products and creating innovative technologies, as well as ecological problems through

purification and disposal of waste (Suryanti et

al., 2023; Solouki, Jaffer, and Chaouki, 2022; Li et al.,

2019; Zhang et al., 2016; Galarneau et al., 2014; Milinchuk and

Shilina, 2010). Due to the

huge amount of waste produced in various industries, there is a need for

asbestos mineral extraction plants to explore innovative technological

solutions focusing on the construction and diversification of materials for

other purposes. This strategic shift can expand the range of manufactured

products and solve environmental problems for the processing of deposited waste

(Baigenzhenov et al., 2024; 2022; Kraus et

al., 2018; Jenifer, 2015). Recent study has described the methods of

obtaining molecular sieves and zeolites from rice husks (Zainal et al., 2024; Zharmenov et al., 2018; Yefremova et

al., 2016; Jo et al., 2015), showing properties comparable

with commercial types. Therefore, the development of technologies for deep

processing of heavy oil with high metal and sulfur content is essential,

requiring the search for new efficient conversion and integrated technological

solutions.

The natural fibrous mineral serpentinite and waste generated can be considered as a potential source of

producing sorption-filtering materials.

Specifically, serpentinite consists mainly

of serpentine group minerals with

admixture of carbonates, amphiboles, talc, ore

minerals magnetite, and chromite, with composition described by the general formula Mg3Si2O5(OH)4.

The fibrous variety of serpentine, known as chrysotile asbestos, is widely used

in chemical industry for obtaining high-purity magnesium and silicon

oxides, heat-resistant ceramics,

refractories, and adsorbent (Lv et al., 2020; Yerdos et al.,

2019; Zakaria et

al., 2019; Lee, Jo, and Ryoo, 2017; Zhang et al., 2017;

Baigenzhenov et

al., 2015; Jo et al., 2013).

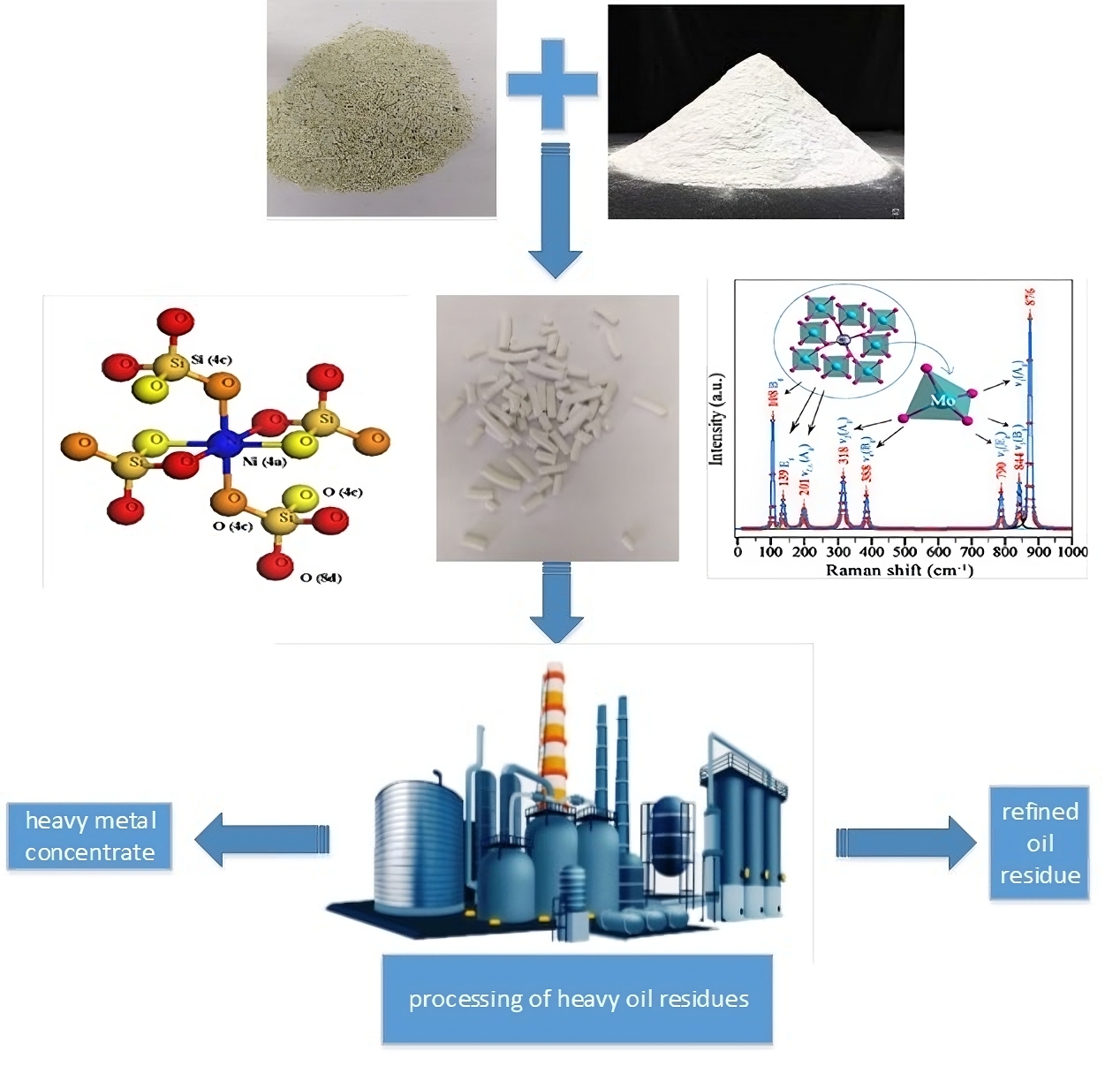

Based on the background above, this study aimed

to develop and create new zeolite chemical adsorbent using technogenic waste of

asbestos production for purification of heavy hydrocarbon feedstock. The

novelty of this study lies in the high-temperature synthesis of zeolite

chemical adsorbent using technogenic waste of asbestos production containing

SiO2, as the main mass, nickel sulfate (NiSO4·7H2O),

and molybdenum oxychloride (MoOCl2) for demetallization and

desulfurization of heavy oil feedstock.

In previous studies by Ongarbayev et al. (2019), demetallization and desulfurization of heavy vacuum fraction were carried out in the presence of zeolites adsorbent containing vanadium oxide xerogel at a temperature of 613 K, pressure 1 atm, and volumetric feed rate 1 h. The results showed a significant decrease in vanadium, nickel, and iron content by 90, 70, and 60%, respectively, along with a reduction in sulfur content from 1.97 to 1.36%.

2.1. Materials

The activity of chemical adsorbent used in this study depends on the

rate of formation and transformation of surface intermediates. This process is

determined by the nature of the interaction, including bond breaking through

spatial configuration. The basic principle of activation is that the material

is subjected to thermal treatment under appropriate conditions, inducing the

formation of numerous pores, gaps, and cracks to increase the surface area of

pores per unit mass. In engineering applications, both chemical and vapor-gas

methods of material activation are widely used. Therefore, the initial

materials used in this study for the charge preparation and production of the active chemical

adsorbent include asbestos waste (AW) obtained after hydrochloric acid leaching

provided by Kostanay Minerals (Republic

of Kazakhstan). Chemical composition of the asbestos waste is presented in Table 1, with particle size of the material being -2.0 + 1.0 mm.

Table 1 Chemical composition of AW after

leaching

|

Component |

Chemical formula |

Content, % wt. |

|

Silicon oxide |

SiO2·nH2O |

90.0 |

|

Magnesium oxide |

MgO |

6.5 |

|

Iron oxide |

Fe2O3 |

2.5 |

|

Remaining impurities |

- |

1.0 |

- calcium

carbonate CaCO3,

99-99.9%,). – Sigmatec;

- sodium

carbonate ("chemically pure" 99.8%)

– Sigmatec;

- liquid

glass, diluted to 10 % – Sigmatec.

2.2. Mixing

Asbestos waste from hydrochloric acid leaching was obtained using the

method of (Shayakhmetova et al.,

2019). The procedure for the preparation of mixed adsorbent is similar to ceramic production applications. This

includes initial components preparation. grinding,

followed by mixing and wetting, pellet molding, hardening, and calcination.

Grinding of the initial components is essential, ensuring that the material

dispersion is suitable for the process adopted and meets the requirements for

the properties of adsorbent. The active adsorbent was prepared

by adding soluble salts of nickel and molybdenum

as semi-hydrous nickel sulfate and ammonium paramolybdate to the base

material, namely serpentine after leaching

and calcium carbonate. The weight ratio of the materials to be added and the

active ingredient in mixed catalysts are given below:

Table 2 Composition of synthetic chemical adsorbent

|

Name of a

compound |

The formula |

Content, % |

|

Serpentine after

leaching |

SiO2 |

38.0 |

|

Calcium carbonate |

CaCO3 |

44.0 |

|

Baking soda |

Na2CO3 |

5.0 |

|

Nickel sulphate |

NiSO4·7H2O |

3.0 |

|

Ammonium

paramolybdate |

(NH4)6Mo7O24·7H2O |

10.0 |

|

Total |

|

100.0 |

As shown in

Table 2, the mixing of charge components and grinding to achieve a homogeneous

mass composition was carried out for 10 minutes in the dry state using a

grinder to reduce the particle size to less than 100 microns. Subsequently, plasticizers in the form of sugar molasses

(0.5% of the total mass), and

sodium lignosulphonate (2.0%) were added to the mixture. Plastic molding

with the addition

of water was carried out and the molded materials obtained were

subjected to a two-stage firing at 923 K for 60 minutes to form wollastonitic structure and 1323 K for 30

minutes. Consequently, this processing led to the formation of the synthetic

adsorbent with wollastonite structure.

2.3. Test

The following equipment was used to determine

the mineralogical composition, chemical composition,

and formation structure of the synthetic chemical adsorbent obtained with various activator additives. Specifically, X-ray data were

obtained using a BRUKER D8 ADVANCE machine. X-ray fluorescence analysis was performed

on a Venus 200 PANalyical

B.V. (Holland) spectrometer with wave

dispersion. Chemical analysis of samples was

performed on an optical emission spectrometer with inductively coupled

plasma Optima 2000 DV (USA, PerkinElmer). Mapping

of elemental and phase composition of samples was carried out on

electron-probe analyzer JXA-8230 by

JEOL (Japan). Thermal analysis was performed using Jupiter STA 449 F3 synchronous thermal analysis unit and the

results were processed with NETZSCH Proteus software.

To determine the value of the total specific surface

of meso- and macroporous substances and materials, the SORBTOMETR-M device was used by the method

of thermal desorption of gas-adsorbate - BET method

based on the Brunauer-Emmett-Teller equation. The specific surface area measurement range is 0.3-2000

m2/g, with a temperature of 323-573

K.

3.1.

Study of temperature regimes (thermal analysis) to produce synthetic chemical adsorbent

The prepared mixture was thermally heated to 1273 K with an exposure time of 1 hour to determine the decomposition products of calcium carbonate and secondary calcium silicates. The analysis was carried out using differential thermal analysis (DTA) and thermogravimetric analysis (TGA) on a Q-1000D derivatograph. When the sample was dynamically heated from 293 to 1273 K, a series of thermal peaks were observed on the DTA curve. Among these peaks, 413, 873, and 1093 K were identified as endothermic, formed by the release of hydroxyl and carbon dioxide water molecules into the atmosphere. The formation of the fourth peak at 998 K was due to the exothermic destruction of the hydro-silicate, which caused an influx of thermal energy into the system, as shown in Figure 1.

Figure 1 TGA of the sample

The morphology of the DTA-curve in the

interval of 623 - 1003 K was similar to the differential

curve of serpentine decomposition. Based on the configurations of TG and DTG

lines, the low intensity of dehydration of sample components and the weak similarity of trajectories

of thermal peaks concerning the peaks of classical serpentine can be traced. This discrepancy showed

that the structure of the supposed mineral was found to be very defective, and unable to fully meet the crystalloid-chemical requirements of the reference serpentine. Therefore, the

composition of the sample was determined using the amount of constitutional

water (OH), corresponding to the sum of weight loss ?m3/2+?m4

= 1.05%+2.5%, which is the addition of second part ?m3 and the whole

part ?m4, as shown in Table 3. Considering the stoichiometric formula

of serpentine, the amount of this mineral

in the composition of the sample was found to be 24.6%.

Table 3 Thermogravimetric readings

of the test sample between

293-1273 K

The other component encountered in the sample tested is calcite,

detected by the strong emission of carbon dioxide into the atmosphere. The

removal of calcite from the system occurs at the high temperature, forming a

plumb line of weight loss on the TG curve. In contrast, on the DTG-curve, the release of carbon dioxide from the system

formed a very deep peak at 1073 K,

showing a high dissociation rate. Consequently, the DTA

curve showed an intensive peak from

1093 K, indicating a substantial outflow of thermal energy from the sample as presented in Figure 1. The

thermal degradation pattern observed

for CaCO3 corresponded

with well-oxidized calcite.

According to the amount of

CO2 emission (1.05% + 22.5%) shown in Table 3 and the stoichiometric formula, the content in

the sample was found to be 53.5%.

Meanwhile, the 3.3% of water ejected from the sample at 293 – 473 K was not part of the serpentine and

calcite, leading to the classification as mechanically bound

water of impurity status. This

showed that di-calcium silicate Ca2SiO4

was formed at 773 K, while tri-calcium silicate Ca3Si2O7

and wollastonite CaSiO3 began at 1123 K. Based on these results, it

can be concluded that Ca2SiO4 and Ca3Si2O7 are unstable intermediate compounds. According to these thermograms, the formation of wollastonite commenced when Ca3Si2O7 formed at temperatures above

1173 K. The formation of the mineral wollastonite occurred at high

temperatures with the release of

carbon dioxide, as expressed by chemical equation 1, indicated by the thermodynamic

data of chemical reaction

presented in Table 4:

CaCO3 +SiO2 ? CaSiO3

+CO2 (1)

Table 4 Thermodynamics of the wollastonite formation reaction

|

T (K) |

deltaH |

deltaS |

deltaG |

Log (K) |

|

(kJ) |

(J/K) |

(kJ) |

| |

|

273 |

89.135 |

162.947 |

44.627 |

-8.535 |

|

473.0 |

87.550 |

158.744 |

12.441 |

-1.374 |

|

673.0 |

84.903 |

154.135 |

-18.853 |

1.463 |

|

873.0 |

80.404 |

148.380 |

-49.154 |

2.941 |

|

1073.0 |

77.377 |

145.263 |

-78.513 |

3.822 |

|

1173.0 |

73.652 |

141.875 |

-92.788 |

4.132 |

|

1273.0 |

71.827 |

140.382 |

-106.901 |

4.386 |

|

1373.0 |

69.907 |

138.931 |

-120.866 |

4.598 |

Based on the thermal analysis and thermodynamic reactions, the formation

of synthetic chemical adsorbent in

the form of mineral wollastonite

occurred at 1173-1373 K.

3.2. X-ray phase and analyses of

samples

X-ray diffraction analysis of synthetic chemical adsorbent in Figure 2 and Table 5 showed the formation of new mineral. Specifically, pavellite (CaMoO4) crystallized in tetragonal syngony was identified, forming dipyramidal and tabular crystals, which showed a density of 4.25 - 4.52 g/cm3, with 72% MoO2 and 10% Mo composition. Libenbergite (Ni2SiO4) was detected, characterized by fine pyramidal crystals, grains crystallized in rhombic syngony, and a density of 4.50 - 4.60 g/cm3, containing 56% nickel.

Figure 2 Diffractogram of the

obtained synthetic chemical adsorbent

Table 5 Results of semi-quantitative analysis of crystalline

phases

|

Phase name |

Formula |

SemiQuant [%] |

|

Wollastonite |

CaSiO3 |

85.0 |

|

Powellite, syn |

CaMoO4 |

6.0 |

|

liebenbergite, high,

syn |

Ni2SiO4 |

2.0 |

|

Silicon Oxide |

SiO2 |

7.0 |

The XRD data

showed that the high-temperature synthesis produced a well-formulated synthetic

material, with wollastonite CaSiO3 constituting 80 - 85% of the main mineral

composition. The integration of activators in the form of molybdenum oxychloride

(MoOCl2) and nickel sulfate

(NiSO4·7H2O) promoted the formation of new minerals in

the form of powellite (CaMoO4) and libenbergite (Ni2SiO4),

which are fully synthesized based on free calcium and silicon compounds. The presence of these compounds did not

impair the physicochemical properties of the synthesized material but promoted

the formation of a porous structure

due to its small density and specific surface

area. The resulting product also contained free amorphous silica in the form of cristoballite, constituting 7% of the

composition.

3.3. BET

method

In selecting adsorbent for a particular practical application,

information about porous structure is

essential. For appropriate selection, there is a need to know whether the inherent

pore radius distribution corresponds to the molecular

sizes of given sorbates and ensures rapid penetration of

substances deep into sorbent granules.

Adsorption potential in micropores is significant due to the

superposition from neighboring walls. Therefore, molecules capable of

penetrating micropores show significantly higher adsorption affinity compared

to those fixed in meso- or macropores. To determine the specific

surface area and pore radius distribution of porous bodies, the BET method was applied using SORBTOMETR-M device, as shown in Table 6.

As shown in Table 6, the values of the specific surface area and pore volume of the obtained active component are small.

Moreover, micropores are important

for the activity of material and demetallization process due to their diameters of approximately 2 nm, which corresponds

to the size of the adsorbing molecules. The presence of micropores also facilitates the development of the main part of

the inner surface of the active

component, positively influencing the properties of the synthetic

chemical adsorbent.

Table 6 Specific surface area, specific

volume, and average pore size of materials

|

Sample |

Specific surface

area, m2/g |

Specific pore

volume, cm3 |

Average pore

size, Å |

Weight, g |

|

Obtained chemical

adsorbent |

4.0-6.0 |

0.137 |

1.714 |

0.1345 |

3.4. Cleaning of heavy crude oil from metal

impurities

The destructive-adsorptive thermal contact

process of demetallization consists of short-term contact of oil feedstock with adsorbent

in the two-section reactor heated

at temperatures of 573 - 723 K. Due to the contact between the feedstock and the hot adsorbent,

hydrocarbon vapors are formed, which are mixed with water vapor and transported

to the gas venting line, as shown in Figure 3.

Figure 3 Process flow diagram for demetallization and desulfurization of heavy

oil residue

Testing was carried out using tar obtained from

the delayed coking unit of "Pavlodar petrochemical plant" LLP, a viscous slow-moving liquid with a mass

fraction of water of approximately 0.1 wt.%.

This tar contains metals, such

as vanadium 400-600.0 mkg/kg, nickel 50

– 70.0 mkg/kg, iron 30 – 70.0 mkg/kg,

the mass fraction of sulfur 2.5 – 3.5%, ash content – 0.02 wt. %, coking - 18 wt. %, density at 273K - 1000.0

kg/m3, the boiling point – 653 K. Furthermore, testing of demetallization of heavy

oil residue was carried out at temperature zone of 593 - 693 K,

contact time of 60 minutes, and the pressure was kept within 8 - 10 atm.

The results obtained were

presented in Table 7, where the optimum temperature zone of heavy oil demetallization was found to be 673 - 683

K. However, the tar commenced to boil and coke due to an increase in

temperature above 683 K, which adversely affected demetallization process. This

phenomenon also affected the content of vanadium, nickel, iron, and sulfur in

vacuum residue, which decreased from

540 to 52 mkg/kg, 50 to 26 mkg/kg, 50 to 12 mkg/kg, and 3.50 % to 2.39 %,

respectively. The maximum degree of extraction

at these metals was found to be 90.37%, 48.0%, 76.0%, and 31.7%,

respectively.

Table 7 Metal and

sulfur content of tar before and after testing as a function of process temperature

|

Raw material and type of adsorbent |

T, K |

Element content | |||

|

V, µg/kg |

Ni, µg/kg |

Fe, µg/kg |

S, % | ||

|

Initial tar |

- |

540.0 |

50.0 |

50.0 |

3.50 |

|

Tar after

contact with modified chemical adsorbent |

593 |

500.0 |

50.0 |

50.0 |

2.65 |

|

613 |

488.0 |

50.0 |

50.0 |

2.61 | |

|

633 |

450.0 |

43.0 |

40.0 |

2.58 | |

|

653 |

330.0 |

35.0 |

33.0 |

2.53 | |

|

673 |

70.0 |

31.0 |

21.0 |

2.45 | |

|

683 |

52.0 |

26.0 |

12.0 |

2.39 | |

|

693 |

23.0 |

22.0 |

7.0 |

1.50 | |

In conclusion, this study showed the developmental processes for

dehydrating and obtaining active components to create a matrix base of synthetic chemical adsorbent from composite materials using chrysotile asbestos production waste. The adsorption properties of

obtained composite catalysts were practically investigated. The results showed

that the optimal temperature zone for demetallization of heavy oil residue was 653-683 K, with a contact time

of 60 minutes and a pressure of 8-10 atm. Under these conditions, a significant

decrease was observed in the content of vanadium, nickel, iron, and sulfur from

540 to 52 mkg/kg, 50 to 26 mkg/kg, 50 to 12 mkg/kg, and 3.50% to 2.39%, respectively.

The authors are grateful for the financial support provided

by project NTP

No. O.003 (2021-2023) titled "Creation of new composite

materials with high-performance properties based on rare and rare earth

elements" funded by the Committee for Industrial Development of the Ministry of Industry

and Infrastructure

Development

of the Republic of Kazakhstan.

Attia, M., Farag, S., Shaffiq, A.J., Chaouki, J., 2020. Metal And Sulfur

Removal from Petroleum Oil Using a Novel Demetallization-Desulfurization Agent

and Process. Journal of Cleaner Production, Volume 275, pp. 1–14

Baigenzhenov, O., Khabiyev, A.,

Mishra, B., Aimbetova, I., Yulusov, S., Temirgali, I., Kuldeyev, Y.,

Korganbayeva, Z., 2022. Asbestos Waste Treatment—An Effective Process to

Selectively Recover Gold and Other Nonferrous Metals. Recycling, Volume 7(6), p. 85

Baigenzhenov,

O.S., Chepushtanova, T.A., Altmyshbayeva, A. Zh., Temirgali, I.A., Maldybayev,

G., Sharipov, R.H., Altaibayev, B.T., Dagubayeva, A.T., 2024. Investigation of

Thermodynamic and Kinetic Regularities of Asbestos Waste Leaching

Processes. Results in Engineering,

Volume 21, p. 102000

Baigenzhenov, O.S., Kozlov, V.A., Luganov, V.A., Mishra, B.,

Shayahmetova, R.A., Aimbetova, I.O., 2015. Complex Processing of Tailings Generated in Chrysotile

Asbestos Production. Mineral

Processing and Extractive Metallurgy Review, Volume 36(4), pp. 242–248

Baikonurova, A.O.,

Ussoltseva, G.A., Markametova, ?.S., Nurzhanova, S.B., 2021. Zeolite Modification by

Synthesized Vanadium Xerogel. Journal of the Balkan Tribological Association,

Volume 27(3), pp.

445–456

Farghadani,

M.H., Mahdavi, V., 2022. Novel Synthesis of Highly Dispersed

Molybdenum Oxide Over Nanorods Cryptomelane Octahedral Manganese

Oxide Molecular Sieve (MoOx/nanorod-OMS-2) As a High-Performance Catalyst

For Oxidative Desulfurization Process. Fuel Processing Technology, Volume 236, p. 107415

Galarneau, A., Villemot, F., Rodriguez, J., Fajula, F., Coasne, B.,

2014. Validity of the Tplot Method To Assess Microporosity In Hierarchical

Micro/Mesoporous Materials. Langmuir, Volume 30, pp. 13266–13274

Jenifer, A.C., Sharon, P., Prakash, A., Sande, P.C., 2015. A Review of

The Unconventional Methods Used for The Demetallization Of Petroleum Fractions

Over The Past Decade. Energy and Fuels, Volume 29(12), pp. 7743–7752

Jo, C., Cho, K., Kim, J., Ryoo, R., 2014. MFI Zeolite Nanosponges Possessing Uniform Mesopores Generated by Bulk

Crystal Seeding In The Hierarchical Surfactant-Directed Synthesis. Chemical

Communications, Volume 50, pp. 4175–4177

Jo, C., Lee, S., Cho, S.J., Ryoo, R., 2015. Synthesis Of Silicate

Zeolite Analogues Using Organic Sulfonium Compounds as Structure-Directing

Agents. Angewandte Chemie International Edition, Volume 54, pp.

12805–12808

Jo, C., Ryoo, R., ?Zilkov´a, N.,

Vitvarov´a, D., ?Cejka, J., 2013. The Effect of MFI Zeolite Lamellar and

Related Mesostructures on Toluene Disproportionation and Alkylation. Catalysis

Science & Technology, Volume 3, pp. 2119–2129

Johansson, A.C., Bergvall, N., Molinder, R., Wikberg,

E., Niinipuu, M., Sandström, L., 2023. Comparison of Co-Refining of Fast

Pyrolysis Oil from Salix Via Catalytic Cracking and Hydroprocessing. Biomass and Bioenergy. Volume

172, p. 106753

Kamal, M.S., Razzak, S.A., Hossain, M.M., 2016. Catalytic Oxidation of

Volatile Organic Compounds (VOCs)–A Review. Atmospheric Environment, Volume

140, pp. 117–134

Kraus, M., Trommler, U., Holzer, F., Kopinke, F.D., Roland, U., 2018.

Competing Adsorption Of Toluene And Water On Various Zeolites. Chemical

Engineering Journal, Volume 351, pp. 356–363

Lee, S., Jo, C., Ryoo, R., 2017. Tomographic

Imaging Of Pore Networks And Connectivity Of Surfactant-Directed Mesoporous

Zeolites. Journal of Materials Chemistry A, Volume 5(12), pp.

11086–11093

Li, R., Chong, S., Altaf, N., Gao, Y., Louis, B., Wang, Q., 2019.

Synthesis of ZSM-5/ Siliceous Zeolite Composites For Improvement Of Hydrophobic

Adsorption Of Volatile Organic Compounds. Frontiers in Chemistry, Volume

7, p. 505

Li, X., Zhang, L., Yang, Z., Wang, P., Yan, Y., Ran, J., 2020.

Adsorption Materials for Volatile Organic Compounds (VOCs) and the Key Factors

for VOCs Adsorption Process: A Review. Separation and Purification

Technology, Volume 235, p. 116213

Lv, Y., Sun, J., Yu, G., Wang, W., Song, Z., Zhao, X., Mao, Y., 2020.

Hydrophobic Design of Adsorbent for VOC Removal in Humid Environment and Quick

Regeneration by Microwave. Microporous and Mesoporous Materials, Volume

294, p. 109869

Markametova,

M.S., Baikonurova, A.O., Kozlov, V.A.,

Nurzhanova, S.B., Ermolaev, V., 2014.

Obtaining Vanadium Nanostructures by Sol-Gel Process. Industry in Kazakhstan,

Volume 3(66), pp. 73–75

Milinchuk, V.K., Shilina,

A.S., 2010. Sorption Purification of Natural and Industrial

Waters from Heavy Metal Cations and Radionuclides by A New Type of High-Temperature Aluminosilicate Adsorbent. Sorption and Chromatographic Processes, Volume 2. pp. 237–245

Ongarbayev, Y.,

Oteuli, S., Tileuberdi, Y., Maldybaev, G., Nurzhanova, S., 2020.

Demetallization Of Heavy Vacuum Residuum by Titanium –Vanadium Zeolite

Adsorbents. Studia Universitatis Babes-Bolyai, Volume 65(1), pp. 219-231

Ongarbayev, Y., Oteuli,

S., Tileuberdi, Y., Maldybayev, G., Nurzhanova, S., 2019. Demetallization and

Desulfurization of Heavy Oil Residues by Adsorbents. Petroleum Science and

Technology, Volume 37(9), pp. 1045–1052

Prihadiyono, F.I.,

Lestari, W.W., Putra, R., Aqna, A.N.L., Cahyani, I.S., Kadja, G.T.M., 2022.

Heterogeneous Catalyst based on Nickel Modified into Indonesian Natural Zeolite

in Green Diesel Production from Crude Palm Oil. International Journal

of Technology, Volume 13(4), pp. 931–943

Shang,

H., Liu, Y., Shi, J.-C., Shi, Q., Zhang, W.-H., 2016. Microwave-Assisted Nickel

and Vanadium Removal From Crude Oil. Fuel Processing Technology, Volume

142, pp. 250–257

Shayakhmetova, R.A. Mukhametzhanova A.A., Samatov I.B., Akbayeva D.N., 2019. Technogenic Raw Materials for The Production

of Magnesium and Silicon- Containing Compounds.

Machines. Technologies. Materials.

Volume 13(2), pp. 90–92

Solouki, A., Jaffer, S.A., Chaouki, J., 2022. Process Development and

Techno-Economic Analysis of Microwave-Assisted Demetallization and

Desulfurization of Crude Petroleum Oil. Energy Reports, Volume 8, pp.

4373–4385

Sudibandriyo, M., Putri, F.A.,

2020. The Effect of Various Zeolites as an Adsorbent for Bioethanol

Purification using a Fixed Bed Adsorption Column. International Journal of

Technology, Volume 11(7), pp. 1300–1308

Suryanti, V., Kusumaningsih, T., Safriyani, D., Cahyani, I.S., 2023. Synthesis

and Characterization of Cellulose Ethers from Screw Pine (Pandanus tectorius)

Leaves Cellulose as Food Additives. International

Journal of Technology. Volume 14(3), pp. 659–668

Ulfiati, R., Dhaneswara, D.,

Harjanto, S., Fatriansyah, J.F., 2022. Synthesis and Characterization ZSM-5

Based on Kaolin as a Catalyst for Catalytic Cracking of Heavy Distillate. International

Journal of Technology. Volume 13(4), pp. 860–869

Yefremova, S.V., Korolev, Y.M., Sukharnikov, Y.I., Kablanbekov, A.A.,

Anarbekov, K.K., 2016. Structural Transformations of Carbon Materials in The

Processes of Preparation from Plant Raw Materials. Solid Fuel Chemistry,

Volume 50, pp.

152–157

Yerdos, O., Shynar, O., Yerbol, T., Galymzhan, M., Saule, N., 2019.

Demetallization And Desulfurization of Heavy Oil Residues by Adsorbents. Petroleum

Science and Technology, Volume 37(9), pp. 1045–1052

Zainal,

Z.S., Hoo, P., Ahmad, A.L., Abdullah, A.Z., Qihwa N., Shuit, S., Rahim, S.K.E.,

Andas, J., 2024. Plant-Based Calcium Silicate from Rice Husk Ash: A Green

Adsorbent For Free Fatty Acid Recovery From Waste Frying Oil. Heliyon,

Volume 10(4), p. e26591

Zakaria, M.Y., Sulong, A.B., Muhamad, N., Raza, M.R., Ramli, M.I., 2019.

Incorporation Of Wollastonite Bioactive Ceramic with Titanium for Medical

Applications: An Overview. Materials Science and Engineering: Volume 97,

pp. 884–895

Zarraoa, L., Gonz´alez, M.U., Paulo, ´A.S., 2019. Imaging

Low-Dimensional Nanostructures by Very Low Voltage Scanning Electron

Microscopy: Ultra-Shallow Topography And Depth-Tunable Material Contrast. Scientific

Reports, Volume 9, p. 16263

Zhang, L., Peng, Y., Zhang, J., Chen, L., Meng, X., Xiao, F.S., 2016.

Adsorptive And Catalytic Properties in The Removal Of Volatile Organic

Compounds Over Zeolite-Based Materials. Chinese Journal of Catalysis, Volume

37, pp. 800–809

Zhang, X., Gao, B., Creamer, A.E., Cao, C., Li, Y., 2017. Adsorption of VoCs onto Engineered Carbon Materials: A Review. Journal of Hazardous Materials, Volume 338, pp. 102–123

Zharmenov, A., Yefremova, S., Sukharnikov, Y., Bunchuk, L., Kablanbekov, A., Anarbekov, K., Murtazayeva, D., Yessengarayev, Y., 2018. Carbonaceous Materials from Rice Husk: Production and Application in Industry and Agriculture. In?ynieria Mineralna, Volume 19(1), pp. 263–274