Thermal Welding in the Neck of Vacuum Flexible Container with Self-propelled Welding Module

Corresponding email: mkhazimov@gmail.com

Published at : 10 Jul 2024

Volume : IJtech

Vol 15, No 4 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i4.6486

Khazimov, K., Sagyndykova, Z., Khazimov, Z., Daurenova, I., Umbetkulov, Y., Khazimov, M., 2024. Thermal Welding in the Neck of Vacuum Flexible Container with Self-propelled Welding Module. International Journal of Technology. Volume 15(4), pp. 1088-1101

| Kanat Khazimov | 1. Machinery Use Department named after Ivan V. Sakharov, Kazakh National Agrarian Research University, Abai Avenue 8, 050010, Almaty, Republic of Kazakhstan 2. Suleyman Demirel University, Abylai kh |

| Zhadyra Sagyndykova | 1. Machinery Use Department named after Ivan V. Sakharov, Kazakh National Agrarian Research University, Abai Avenue 8, 050010, Almaty, Republic of Kazakhstan 2. Almaty University of Power Engineering |

| Zhanat Khazimov | Machinery Use Department named after Ivan V. Sakharov, Kazakh National Agrarian Research University, Abai Avenue 8, 050010, Almaty, Republic of Kazakhstan |

| Indira Daurenova | Almaty University of Power Engineering and Telecommunications named after G. Daukeyev, Baytursynuli 126/1, 050013, Almaty, Republic of Kazakhstan |

| Yertugan Umbetkulov | Almaty University of Power Engineering and Telecommunications named after G. Daukeyev, Baytursynuli 126/1, 050013, Almaty, Republic of Kazakhstan |

| Marat Khazimov | 1. Machinery Use Department named after Ivan V. Sakharov, Kazakh National Agrarian Research University, Abai Avenue 8, 050010, Almaty, Republic of Kazakhstan 2. Almaty University of Power Engineering |

This study aimed to investigate the stability of

weld seams in the neck of flexible containers made from polyethylene film for

silage and storage of fresh ground corn mass as feed during thermal welding

using a movable welding module. An analysis of the thermal conductivity of

polyethylene film was conducted to determine temperature change pattern in the

thin layer over time. The values obtained were used to establish optimal

operating limits for the heating device during welding process. Subsequently,

the resistance to rupture of the polyethylene film seams welded at different

temperatures was evaluated by generating vacuum pressure in a specially

designed installation. The results of polyethylene film PE-115 samples showed a

pattern of limiting vacuum pressure values corresponding to different welding

temperatures. The mathematical function obtained was used to identify the

maximum value of the burst pressure of weld seams, which corresponded to 61.8

kPa at a temperature of 177oC. These results allowed for the

determination of the optimal welding mode for sealing the container neck.

Ensiling; Flexible container; Polyethylene welded seams; Welding module

Climate change is

projected to reduce potential yields in most tropical and subtropical regions.

This is because the average global temperature by a few degrees can cause a

decrease in yields at mid-latitudes, failing to compensate for changes in high

latitudes, significantly in drylands

Kazakhstan, a traditional cattle-breeding country with a long history of animal husbandry, has faced difficult circumstances due to fodder scarcity. This situation is particularly challenging for a population that consumes the most livestock products. For example, an analysis of milk production data from the Committee of Statistics of the Republic of Kazakhstan showed that 78% of milk was produced by small-scale farms, while the remaining 22% was generated by large farms (Qazaq-Zerno, 2018). The average milk yield per cow is 2.341 kg/year, although this value varies significantly depending on the form of farms. For instant, large enterprises produce 4.338 kg/year peasant farms generate 1.849 kg/year, and subsidiary at 2.409 kg/year. However, farms in European countries such as Finland, Germany, Denmark, Sweden, and the Netherlands achieve approximately 10 thousand kg of milk per cow annually (EEC, 2018). In the U.S. and Canada, annual milk reaches 9.5 thousand kg per cow (AAFC, 2023). The main factors contributing to the success of family dairy farms abroad include a good full-fledged feeding base, technical equipment, and the availability of elite cattle.

In the animal breeding

environment, feed costs account for 55% of total costs and approximately 77% of

production costs. Meanwhile, enterprises buy approximately 45% of the feed and

produce 55% (Yessimzhanova and Kaliyaskarova, 2014). To obtain high yields from

intensive dairy cattle and realize genetic potential, each cow needs to be fed

high-quality feed throughout the year. This includes at least 10 cwt of hay, 60

cwt of silage, root 22 cwt, and concentrated feed 16 cwt. Moreover, silage is

the most important green canned fodder in winter, compacted and stored in

airtight conditions which is often provided year-round food for ruminants in

some regions (Victoria-Agro, 2020; Bondarev et

al., 2016).

The sustainability of

livestock production due to changes in climatic conditions requires the

development of a sufficient reserve of animal feed. One way to build up an

insurable stock of succulent feeds is by harvesting maize silage. This process

is carried out by acidification (anaerobic preservation by fermentation) of

green feed crops such as corn (Borreani et

al., 2007). Ensilage fodder is

stored in a structure called silo storage, which is a semi-hermetic or airtight

structure. Currently, ensilage fodder storage is carried out mainly in

stationary storage facilities according to global practice, which limits

transport to remote areas (Bueno et

al., 2020). Regardless of the

system, the main functions of silo and storage are to exclude air during the

silage and prevent air from entering the ensilage fodder during storage (Borreani et al., 2018).

The availability of

affordable modern polymer materials has allowed the development of innovative

methods for the production and storage of ensilage fodder (Niyazbayev et al., 2022; Khazimov et al.,

2021; 2011). These methods

include packaging in various volumes, which can be transported at any distance

and stored for approximately 3 years (Sagyndykova

et al., 2021a; Nekrashevich, 2020). However, several specific

operations during packing are associated with compacting green mass under

vacuum in flexible container made of polyethylene (flat) film. To obtain the

necessary ensilage fodder without air, the vacuum process is carried out at

negative pressures of 60-65 kPa (Sagyndykova et al., 2021a; Invention patent,

2019). The resulting

ensilage mass in flexible container may be 20% higher in density compared to

trench storage conditions. The required stability of the thickness of

polyethylene film during the vacuum process of the ensilage mass is

sufficiently substantiated, considering the elongation factor (Sagyndykova et al., 2019a). Moreover, it is recommended

that flexible container be made from finished sleeves of polyethylene film with

a thickness not less than 0.200 mm, 1 grade of PE-100, or PE-115, without seams

in length (Sagyndykova et al., 2019b). When silage of approximately 850 kg/m3 is sealed, the walls of

flexible container is subjected to a tensile stress. Similarly, weld

seams along the neck edge, which

are flat and two-sided in

shape, are subjected to tensile stress to break layers of the

film. The reliability of

polyethylene film connecting seams for flexible container, experiencing high

tensile stress in the field, is not well understood. Therefore, further

research is required considering sheet polymer welding technology.

Previous studies have

examined welding of polyethylene film made of sheet materials with a thickness

above 2 mm. These materials are widely used in industries such as geomembranes,

geotextiles, etc., with established carrying loads and appropriate standards

for tensile tests (Kryzhanovsky et al.,

2005). However, there is a

need to study welds of polymeric film of 0.5 mm thickness, which are mainly

used as packaging materials. Due to the absence of high tensile stress, strict

requirements are not set for this polymer film (Gov. Standard, 2015). Deviation in welding modes such as temperature, melting time, and

surface pressure for film strips can change the reliability of the weldable

layer near the joint. Weld seams of flexible container are subjected to bursting

voltage when sealed by vacuum. Therefore, improper heating or insufficient

pressure during welding can cause weld joints to fail, with overheating leading

to breaking near the welding strip.

The scientific

novelty of this study lies in the development of a technological

process for preparing and storing silage

mass in flexible container under

vacuum. Additionally, the study explains theoretical

and experimental substantiation of parameters and modes of compaction of a soft

container for vacuuming silage mass. The developed technological and technical solutions were confirmed by

patents of the Republic of Kazakhstan (Kaz

NAU, 2022; 2019a; 2019b; 2019c; Utility Model, 2022; 2021; 2020; 2019a) and the Russian Federation (Utility Model, 2019b; 2018).

The importance of

neck sealing technology for flexible container includes the limited volume of

the compacted silage mass in vacuum-operated container. This allows the

transportation of silage at any distance for a long time without damage. The

technology also allows reliable sealing during movement, loading, and unloading

operations, thereby preserving the vacuum condition to ensure quality silage

feed. Scientific significance of this study lies in determining parameters for

welding various thicknesses of polymer materials. This requires a comprehensive

examination of the reliability of welding process for flexible container neck

made from polyethylene film. Therefore, this study aimed to ensure the

reliability of weld when sealing the neck of flexible container using a mobile

welding module. To achieve the objective, several processes were carried out,

including analytical substantiation of modes (temperature from time) for neck

of flexible container made from polyethylene film with 0.2 mm thickness. Temperature

welding modes of the module were also optimized based on experimental data of

the reliability weld joint.

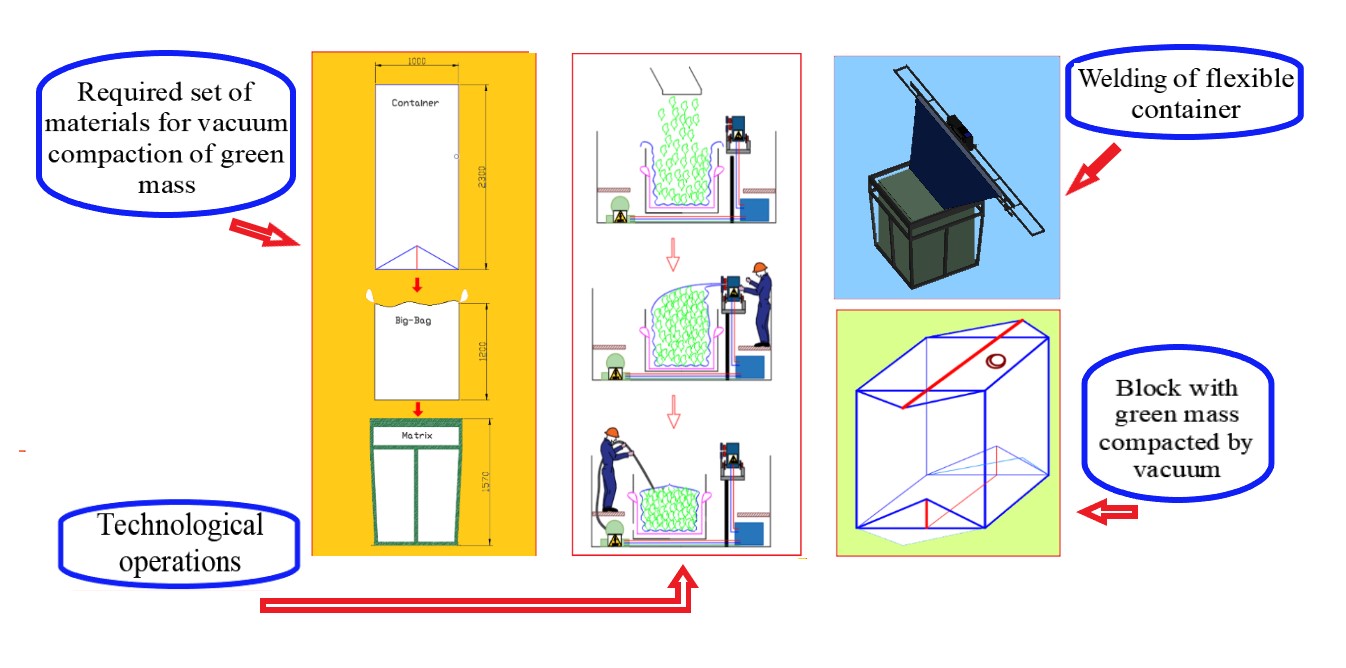

The proposed

technology for the preparation and storage of ensilage fodder in flexible

vacuum container made of polyethylene film in the field includes several

processes. These include ensilage fodder preparation and storage in

vacuum-operated container (Utility Model,

2018), which was carried

out on a tractor-trailer in field conditions during corn mowing, as shown in

Figure 1. The vacuuming of the silo consisted of loading the crushed corn mass

into the flexible container with the addition of the oxidizer. This was

followed by the densification of the loaded with ensilage fodder of the

flexible container by welding the loading neck. Subsequently, corn mass is

compacted in a pressurized flexible container by vacuum created through the

return valve by vacuum pump. The compressed flexible container was lifted from

the cartridge using a lifting device by hooking on the carrying Big-Bag (Sagyndykova et al., 2021a; Nekrashevich, 2020).

Figure 1 The

silage fodder preparation process in flexible container, where a - loading of crushed green mass into container; b - welding of the

container neck by welding machine; c – vacuuming; 1 - forage harvester; 2 –

crushed green mass; 3 – flexible container; 4- Big-Bag; 5- operator workplace;

6- matrix for a flexible container; 7- generator; 8- vacuum pump; 9- clamp; 10- heating elements; 11- welding

module; 12- sealer platform;13 - platform frame; 14- pressed container

When a freshly

crushed corn mass is loaded into flexible container on a mobile

tractor-trailer, sealing by welding the loading filler becomes a new and

crucial process (Utility Model,

2019b). The

process of welding the neck of flexible container consisting of a double layer

of 2.5 m polyethylene film is carried out at an elongated state to avoid folds

in the weld seams, as shown in Figure 2. Initially, one open side of the neck

is cut from the finished roll of polyethylene film and used as a sleeve for

pre-welding (Figure 2 a). This welded side is used as the bottom of a soft

container (directed down) when lowered into a metal matrix form along with

Big-Bag. Inside the Big-Bag and metal matrix, flexible container take the form

of an open upper cap for loading the silo mass (Figure 2b). When loading of

crushed fresh silage mass is achieved, soft container is sealed by welding the

upper neck (Figure 2c). After vacuum pumping the air inside the flexible

container with silo through the one-way valve, the soft container experience

size reduction (Figure 2d). For welding the double layer of the filler into a

single layer, a device is developed, facilitating the clamping of the extended

film layers using profile rulers (the lower line is

fixed, the upper detachable). This device enables the movement of welding

module along the clamped strip of film through a guide rail, which is propelled

by a drive roller integrated within the module.

Welding of protruding

film layers from clamping rulers along the entire length is facilitated during

movement by the welding module (Model DBF-900W,

power 0,65 kW). This movement includes heating to melting point using opposite

rotating tapes, followed by clamping of molten film layers under the necessary

pressure (Figure 3).

The welding module moves along a horizontal rail located at flexible container neck by velocity v. Furthermore, the axially arranged closed Teflon heating tapes with clamped layers are moved in a horizontal (opposite) direction to welding module. This leads to the formation of two layers of weldable neck film in a fixed state between the clamped heating tapes (Baskoro, Kurniawan, and Haikal, 2019). The linear velocities of the pressers’ layer two Teflon belts and the welding module are equal in magnitude but opposite in direction. The research procedure includes analytical substantiation of modes (temperature and time) welding of flexible container neck from polyethylene film of 0.2 mm thick and optimization of temperature welding modes based on experimental data.

Figure 2 Flexible container manufacturing procedure, where 1-loading neck of the flexible container; 2- back valve: 3- welded joint of the down base of the container; 4- welded joint of the up base of the container

Figure 3 Welding of the neck of a flexible container with a

self-propelled welding module, where a - diagram; b - general view of welding

module; c - sealing machine « DBF-900W», thermal imager «Amtast AMF101» and sealed film samples

«PE-115»

2.1. Method of analytical substantiation of welding

modes (temperature and time) of flexible container neck from polyethylene film

of 0.2 mm thick

The effective thermal

power (q) in the case of low-voltage precision liner heaters,

used for film welding, is expressed using formula 1 (Kataev,

2008):

where R - belt electrical

resistance, ohm;

Experimental data

show that the efficiency index

The spread of heat in products during welding occurs according to the law of thermal conductivity. The calculation of the temperature fields for the different methods of welding is based on the schematic determination of the tape processes. The process of heat propagation in an unlimited thermal-transfer body, according to the Fourier Thermal Conductivity Law, is expressed by the differential equation 2 (Popov and Popov, 2020).

where

c - heat capacity;

- density;

- heat conductivity coefficient;

T - temperature value;

t – running time;

x, y, z - coordinates of the considered point.

The majority of

problems related to the calculation of thermal processes in plastic welding

different methods can be reduced to the schema of a linear thermal field by

formula 3.

Dynamics of heating and cooling process of the

thermal field formed by the movement of the source or coolant along the product

during welding (ultrasonic, thermocone welding with a heated wedge, welding by

jet of heated gas with or without an addition agent, etc.) can be calculated

analytically using instantaneous point source method. The entire heating

process is divided into discretely acting independent heat sources, and their

effect is summed up (Burlutsky et al.,

2023). To simplify the

problem, tasks are considered with constant boundary conditions and reduced to

a one-dimensional type of heat propagation. In this case, the heating occurs

symmetrically on both sides and is considered a one-way process. When the

origin of the coordinates is located at the center of the joint, the edge

conditions for unilateral heating can be represented by formula 4:

where

In the presented analytic

function (4c), the input parameter is the time (t) in seconds, which

plays a key role in underheating or overheating a fixed film thickness (h).

The thickness of the film is a fixed value of the film produced according to

the standard.

The pressure at

welding on the seam depends on viscosity of melt and the geometry parameters of

polyethylene compound, including the width of the weld and film’s total

thickness. According to previous results (Kataev, 2008), the preliminary pressure is 0.09 MPa, and the temperature is within

160-170oC, with heating time of 3 seconds. Consequently, the

translational tape speed (Rahman, Shoukaku, and Iwai, 2021)

was selected from the

condition by formula 5:

where

t – belt

heating time.

Welding parameters are further

optimized experimentally, and corrections are related to the real property of

polyethylene film. The theoretical studies allowed the selection of indicative

limits of welding parameters for the experiment.

2.2. Method of experimental strength of polyethylene film seams for

flexible container

Samples of 200 µm

film with welded joints were tested to determine the strength of polyethylene

film used in vacuuming silage mass (Sagyndykova

et al., 2021a; Utility Model, 2019b). The connection of the two film layers, each

with a 200 µm thickness was made by thermal welding using the equipment

presented in Figure 2. During the welding operation, the temperature variations

used were 100oC, 125oC, 150oC, 200oC,

and 225oC.

The welding pressure

on this equipment was selected by adjusting the space between the upper and

lower heating Teflon belts (Rahman, Shoukaku, and Iwai, 2021). The adjustment was ensured by

changing the position of the tensioning roller of the Teflon heating tapes

before the appearance of the surfacing at the seam mouth on the welded surface.

The pressure on the welded film was determined after measuring the Teflon tape

roller force, which corresponded to 2.3 kg/cm2. At this pressure,

there was no overlap at the mouth of the suture, eliminating thinning of the

welded layers in seam area. Welding speed was calculated using the formula (5)

and was set to 0.066 m/s for the grade of polyethylene PE-115 (Kulik and Nilov, 2020; Utility Model, 2019a).

For the test, samples

of 100x200 mm in size with welded joints were cut from the welded strip of the

film. These samples were subjected to testing on a specially designed device,

as shown in Figures 4 a and b. Furthermore, seamed film samples were tested at

vacuum pressure from 40 kPa to 65 kPa. During the testing, vacuum was created

by vacuum pump (Model ERSTVAK VP80, capacities 80m3/h,

power 2.2 kW). The graduated open-top glass cylinder 1 designed device, a

sample of polyethylene film 2 with a welded seam, was secured tightly using a

steel clamp 3 with a rubber gasket, forming a sealed connection to the glass

cylinder (Madani et al., 2023).

Negative pressure was applied using a vacuum pump to test the strength of the weld joints in polyethylene film fixed to the end of the cylindrical receptacle. The test film with the weld joint was sucked into the glass vessel under the influence of vacuum, forming a paraboloid shape. The maximum vacuum value was fixed at the position of the vacuum meter needle. When the joint burst in the center of the stretched film, the needle returned to zero. This test was repeated five times for each sample at the same film welding temperature, as shown in Figure 5. The weld obtained before testing are presented in the second column of the table. The temperature conditions of the heating device of the mobile welding module were checked by thermal imaging «Amtast AMF101», with wave temperature ranging from 20°? to 300°C. In the third column, the breaking points of the welded seam are surrounded by the red circle, and the test repeat data is presented in column 4.

Figure 4 Diagram (a) and general view (b) of device for testing of welded plastic film, where 1 - graduated open-top glass cylinder; 2 - sample of polyethylene film; 3 - clamp; 4 - vacuum gauge; 5 - a shut-off valve; 6 - the vacuum line; 7 - vacuum pump

Figure 5 Samples of polyethylene film with weld seams at

different temperatures

The test data obtained were statistically

processed to assess error and reliability using standard methods (Gritsyuk, Mirzoeva, and Lysenko, 2007).

The calculation

results for one-dimensional heat distribution according to equations (3) and

(4) is presented as follows by formula 6 (Popov and Popov, 2020; Bukhmirov, 2014; Budak,

Samarsky, and Tikhonov, 2004; Korolev, 2022):

where,

The graphical interpretation of function (6)

facilitated the determination of heating time of the polyethylene film layer at

the initial temperature values at a remote point from the heater (Figure 6).

Since an excessive heating time increase could cause the film to melt, reducing

the heating time would lead to poor melting.

Figure 6 Temperature change of film layer from heating

time in polymer film thickness

Based on the results, the graphical dependence of polyethylene film resistance on peeling and tearing due to tensile pressure induced by vacuum was constructed, as shown in Figure 7

Discussion

The analysis of the

temperature field distribution in the welded polyethylene film layer of

approximately 0.3 mm was performed using analytical substantiation. Since the

heating element is completely in contact with the welded surface, the heat flow

was assumed to move in the direction of the film thickness. Consequently, a

one-dimensional time temperature distribution was assumed for different film

thicknesses (h = 0.1 mm, h = 0.15 mm, h = 0.2 mm, h = 0.25 mm, h = 0.3 mm). In

this analysis, the thickness of the film was considered boundary conditions,

while time served as the initial and final conditions. According to the

obtained equation (6), a graphical interpretation of the results was

constructed, which allowed the selection of the time parameter when heating the

necessary thickness of the layer. The welding module speed was determined

considering the length of the heating source, which was the Teflon film tape

length of touch.

To determine the

optimal temperature range, the first temperature T derivative of

the second-order P function (from formula 7) was obtained and

equaled to zero by formula 8.

Figure 7

Dependence of film weld seam braking (bursting) pressure on the temperature of

welding

Substituting

the temperature value

As a result of solving the equation obtained from the first-order

derivative, the roots found showed the optimum temperature T, which

corresponds to the maximum pressure P. This pressure corresponds to the apex of the

parabola represented in Figure 7.

According to the graphical model,

weld resistance (breaking) of 200 thick polyethylene film when vacuum silage

in flexible container can be recommended for welding modes 170oC –

200oC, with vacuum pressure of 60 kPa.

Figure 4

shows the stratification and seam fracture rates based on the data graph in

Figure 7. The left side of the curve from the maximum point is related to the

insufficient melting of polyethylene film. The damage is evident in the

pictures of the film samples, where higher temperature, correlates with

decreased damaged size. Therefore, as the welding temperature of the film seam

increases, burst pressure value is reduced.

This phenomenon occurs due to the closeness of the molten polymer layer

to the viscous current state area of the alloy, allowing a good

transition of two molten welded layers of film. After the transition of the

graph’s maximum point, burst pressure value is reduced. This shows that as the

welding temperature increases, the molten film layer moves from a viscous current

state

into the destruction state of

the thermoplastic

, with a significant decrease in

joint strength, and the weld seam edge becomes thin.

The provision of reliable tightness of the soft container by thermal welding of the loading neck after filling with green mass allows compacting with vacuum pressure of 61.8 kPa. The compacted green mass in the soft container is mainly 20% higher in nutritional value compared to blank in the classical method in trench conditions (Sagyndykova et al., 2021a). Moreover, energy consumption at the stage of sealing and transportation is reduced by an order of magnitude (Sagyndykova et al., 2021b). Distinctive operations such as welding, compacting, and transportation are presented according to the proposed and classic methods in Table 1 for comparative estimation of energy consumption.

Table 1 Comparative energy

intensity of different operations at silage preparation per 1.000 cattle in

different methods

|

Silage preparation methods |

The mass of silage feed, ton |

Sealing, kW

|

Densification, kW

|

Transportation, kW |

Unloading, kW

|

Total, kW

|

|

Densification with heavy tractors in trench |

72500.0 |

- |

487980.0 |

167280.0 |

90624.0 |

745 884.0 |

|

1.0 |

- |

6.73 |

2.3 |

1.25 |

10.38 | |

|

By vacuum densification on mobile unit |

72500.0

|

1570.4 |

43500.0 |

54360.0 |

181200.0 |

280 630.0 |

|

1.0 |

0.022 |

0.6 |

0.75 |

2.5 |

4.07 |

Based on the results, the total energy consumption of the proposed

technology is 2.5 times less than the old classical technology. This is because, at the compacted stage, the process

is continuous to avoid relaxation which occurs in the classical method. During transportation, the filling ratio of the transported cargo is increased by the compacted mass. These advantages are achieved when the flexible

thermoplastic container is securely sealed.

In conclusion, this

study was carried out to determine the optimum parameters and welding modes for

the loading neck of flexible polyethylene container designed for vacuum sealing

of silage mass. Based on theoretical studies, a time-dependent temperature

change in the form of a one-dimensional field for polyethylene film thicknesses

from 0.1 mm to 0.3 mm was obtained. For the standard thickness of 0.2 mm of

polyethylene film sleeve, the resulting dependence allowed the calculation of

kinematic parameters such as speed and movement time of the welding module,

including temperature regime of the mobile welding module. The tests performed

for six welding modes, with five repetitions each, for a 0.2 mm polyethylene

film enabled the determination of optimum weld breaking limits. These included

weld temperature of 177°C when polyethylene was melted at 225°C, which resisted

burst pressure of 61.8 kPa. Vacuum sealing of the silo in flexible container

was permissible at this vacuum pressure at a film thickness of 200 µm. This

temperature was identified as the minimum for welding open parts of a 200 µm

thick flat polyethylene flexible silo container. To perform similar welding of

different thicknesses, a further study should be conducted to determine the

temperature range for the welding machine. Additionally, investigations should

be carried out on the design of specialized mobile welding devices for

polyethylene film of 0.5 mm thick.

This study was funded

by the Committee of Science of the Ministry of Science and Higher Education of

the Republic of Kazakhstan (Years for research grant are 2022 -2024. Grant No.

AP13067761).

AAFC (Agriculture and Agri-Food Canada), 2023. Average

Production Per Cow and Breed for Selected Countries. Available online at: https://agriculture.canada.ca/en/sector/animal-industry/canadian-dairy-information-centre/statistics-market-information/dairy-animal-genetics/production-breed/per-cow,

Accessed on June 16, 2024

Baskoro, A.S., Kurniawan, R.P., Haikal., 2019.

Evaluation of the 2-Axis Movement of a 5-Axis Gantry Robot for Welding

Applications. International Journal of Technology, Volume 10(5), pp.

1024–1032

Bondarev, V.A., Kosolapov, V.M., Klimenko, V.P.,

Krichevsky, A.N., 2016. Preparation of Silage and Haylage Using Domestic

Biological Preparations. FGBNU All-Russian Research Institute of Feeds

named after. V.R. Williams

Borreani, G., Tabacco, E., Cavallarin, L. (2007). A New Oxygen Barrier Film Reduces Aerobic Deterioration in Farm-Scale Corn Silage. Journal of Dairy Science. 90(10), pp. 4701-4706.

Borreani, G., Tabacco, E., Schmidt, R.J., Holmes,

B.J., Muck, R.E., 2018. Silage Review: Factors Affecting Dry Matter and Quality

Losses in Silages. Journal of Dairy Science, Volume 101(5), pp. 3952–3979

Budak, B.M., Samarsky, A.A.,

Tikhonov, A.N., 2004. Collection of Problems on Mathematical Physics, 4th

Edition. Physizmatlith

Bueno, A.V., Lazzari, G., Jobim, C.C, Daniel J.L.,

2020. Ensiling Total Mixed Ration for Ruminants: A Review. Agronomy.

Volume 10(6), pp. 2–18

Bukhmirov, V.V., 2014. Heat and Mass Transfer:

Textbook. Manual. Ivanovo: Federal State Budgetary Educational Institution

of Higher Professional Education. Ivanovo State Energy University named after

V.I. Lenin

Burlutsky, E., Balzamov, D., Bronskaya, V.,

Kharitonova, O., Khairullina, L., Solovyeva, O., 2023. Influence of Temperature

on the Thermal Properties of the Core Material - the Coefficient of Temperature

Conductivity, Specific Heat Capacity, and Thermal Conductivity. International

Journal of Technology, Volume 14(2), pp. 443–454

EEC (Eurasian Economic Commission), 2018. Review

market of milk and dairy products Member States of the Eurasian Economic Union

for 2013 – 2017. Agricultural Policy Department?. Available online at:

https://eec.eaeunion.org/upload/

medialibrary/b5a/OBZOR-po-moloku_za-2013_2017-g.pdf, Accessed on November 15, 2022

ERA

(Economic Research Institute), 2021. Drought in Kazakhstan - A Consequence of

Global Climate Change. Available online at: https://economy.kz/ru/Novosti_instituta/id=3087#, Accessed on December 28, 2022

Gov. Standard, 2015. Gov. Standard 56155-2014. Welding thermoplastics. Extrusion

Welding of Pipes, Pipeline Parts and Sheets. Official edition. Standardinform

Gritsyuk, S.N., Mirzoeva, E.V., Lysenko, V.V., 2007.

Mathematical Methods and Models in Economics. UK: Cambridge University Press

Invention

Patent, 2019. Invention Patent No.33744. Set of

Machines and Equipment for The Silo of Green Material in Flexible,

Vacuum-Operated, Airtight Film Containers/Kaznaru

Kataev, R.F., 2008. Welding of

Plastics. Ekaterinburg:

USTU-UPI.

Kaz NAU, 2019a. Patent.

33415. Set For Loading, Transport, Vacuum, Silaging and Storage of Silage Feeds

(2017/0540.1). Republic of Kazakhstan

Kaz NAU, 2019b.

Patent. 33425. Valve For Container Used for Silage of Feeds (2017/0767.1).

Republic of Kazakhstan

Kaz NAU, 2019c. Patent. 33744. Set of

Machinery and Equipment For Silage of Green Plants in Soft Vacuum Containers

Made of Airtight Film (2018/0204.1). Republic of Kazakhstan

Kaz NAU, 2022. Patent. 35668. Method

of Preparation and Storage of Silage Feed (2021/0015.1). Republic of Kazakhstan

Khazimov, J.M., Khazimov, M.Z., To Justification of The Parameters of The Work Wheel of The Seedling Planting Device for Soil Mulching. Journal of the University of Chemical Technology and Metallurgy, Volume

Khazimov, K.M., Niyazbayev A.K., Shekerbekova Z.S.,

Urymbayeva A.A., Mukanova G.A., Bazarbayeva T.A., Nekrashevich V.F., Khazimov

M.Zh., 2021., A Novel Method and Device for Plastic Mulch Retriever. Journal

of Water and Land Development, Volume 49 (IV–VI), pp. 85–94

Korolev, V.N., 2022. Heat and Mass Transfer: Educational

Manual. Ekaterinburg: Ural Publishing House

Kryzhanovsky, V.K.,

Burlov, V.V., Panigatenko, A.D., Kryzhanovskaya, Yu.V., 2005. Technical

Properties of Polymeric Materials: Study on The Right Manual. 2nd Edition. Profession

Kulik, V.I., Nilov, A.S., 2020. Technology of Composites Based on

Thermoplastic Binders: Manual. State Technology

Lopatin, V.N., Muravychov, A.I., Gritsevich, I.G., 2005. Global

Climate Change, Problems, and Prospects of Implementation of the Kyoto Protocol

in the Russian Federation: Training Package on The Program of The Course

"State Environmental Management". WWF-Rusia

Madani, N.A., Purnamaningsih, R.W., Poespawati, N.R.,

Hamidah, M., Rahardjo, S., Wibowo, D.K., 2023. Detection of Low Hydrostatic

Pressure Using Fiber Bragg Grating Sensor. International Journal of

Technology. Volume 14(7), pp. 1527–1536

, 2020. Theory and Practice of Feed Silage in

Containers Made of Airtight Film. In: BIO Web Conference.

International Scientific-Practical Conference “Agriculture and Food Security,

Volume 17. Available online at: https://doi.org/

10.1051/ bioconf/20201700041,

Accessed on February 28, 2023

Niyazbayev, A., Pegna, F.G., Khazimov, K., Sagyndykova, Z., Khazimov, M., 2022. Power Need of an Implement for Removing Polymer Residues

from The Soil Surface in Kazakh Horticulture. Journal

of Agricultural Engineering, Volume 53(3), p.

1382

Popov, A.I., Popov, I.Yu., 2020. Basic

Equations of Mathematical Physics. Tutorial. St. Petersburg: ITMO

University

Qazaq-Zerno, 2018. Average Milk Yield in Kazakhstan.

Available online at: https://kazakh-zerno.net/137679-srednij-nadoj-moloka-v-kazakhstane-v-proshlom-godu-sostavil-2341-kg/,

Accessed on February 12, 2023

Rahman, J., Shoukaku, Y., Iwai, T.,

2021. An

Experimental Study of the Effect of Load and Moving Speed on Free Rotating

Rubber Contact using Fluorescence Microscopy. International Journal of

Technology, Volume 12(4), pp. 781–790

Sagyndykova, Zh., Nekrashevich, V., Khazimov, K., Kassymbayev, B., Khazimov, M., Research and Development of Essentials for Silage Preparation, Transport and Storage in Flexible Containers of Optimal Volume. Acta Technologica Agriculturae, Volume

Sagyndykova, Zh.B., Necrashevich, V.F., Khazimov,

K.M., Khazimov, M.Z., 2019b. Food. Ecology. Quality. In: Conference

Materials XVI Mezhunar. Scientific And Practical Conference. Barnaul, Volume 2,

pp. 158–161

Sagyndykova, Zh.B., Necrashevich, V.F., Torzhenova,

T.V., Khazimov, K.M., Khasimov, M.Z., 2019a. Theory and Practice of Silage of

Feed in Containers of Airtight Film. Research,

Results, Volume 3, pp. 375–382

Utility Model, 2018. Utility Model No. 183627. Airtight Film Container

for Silage Feed/Russia

Utility Model, 2019a. Utility Model

No. 4520. Container For the Preparation and Storage of

Silage Feed/Republic of Kazakhstan

Utility Model, 2019b. Utility Model No. 193970.

Container For the Preparation and Storage of Silage Feed / Russia

Utility Model, 2020. Utility Model No.

5469. Air-Tight Film Container

Cassette for Feed Silage (2020/0470.2)/Republic of Kazakhstan

Utility Model, 2021. Utility Model No.

6308. Silage Harvesting Hose of

Forage Harvester (2021/0032.2) Republic of Kazakhstan

Utility Model, 2022. Utility Model No.

7437. Vehicle (Container Vessel)

For Receiving the Ground Mass from The Harvester) and The Russian Federation

(2022/0407.2)/Republic of Kazakhstan

Victoria-Agro, 2020. Status and Prospects for

Improving Dairy Cattle Farming. Available Online at:

http://www.viktoriy.ru/sostoyanie-perspektivi, Accessed on

February 12, 2023

Yessimzhanova, S.R., Kaliyaskarova, E.A., 2014. Analysis of Meat Market and Meat Products Market in Kazakhstan. Procedia

- Social and Behavioral Sciences, Volume 109, pp. 1216 – 1219