Study on the Application of Model-based Control Algorithm for a Suspended Cable-Driven Parallel Robot

Corresponding email: pramujati@me.its.ac.id

Published at : 28 Jun 2023

Volume : IJtech

Vol 14, No 4 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i4.6458

Pramujati, B., Syamlan, A.T., Nurahmi, L., Tamara, M.N., 2023. Study on the Application of Model-based Control Algorithm for a Suspended Cable-Driven Parallel Robot. International Journal of Technology. Volume 14(4), pp. 854-866

| Bambang Pramujati | Department of Mechanical Engineering, Institut Teknologi Sepuluh Nopember, Surabaya, Indonesia, 60111 |

| Adlina T. Syamlan | Department of Mechanical Engineering, De Nayer Campus, Jan Pieter de Nayerlaan 5, 2860 Sint-Katelijne-Waver, KU Leuven, Belgium |

| Latifah Nurahmi | Department of Mechanical Engineering, Institut Teknologi Sepuluh Nopember, Surabaya, Indonesia, 60111 |

| Mohamad Nasyir Tamara | Department of Mechatronics Engineering, Electronic Engineering Polytechnic Institute of Surabaya, Surabaya, Indonesia, 60111 |

This paper introduces a model-based control

scheme for controlling the position of a suspended cable-driven parallel robot.

The robot is designed to have a fixed frame base with four cables. The cables

are attached to winches on one end, driven by stepper motors, and to a moving

platform at the other end. The control scheme consists of two systems: the

reference model and the implemented control. The implemented control hosts the

stepper motor to drive the winch based on the requirements derived from the

reference model. The reference model converts the desired Cartesian trajectory

into joint spaces, which are then translated into the number of required steps.

The number of steps will act as a set point for the stepper motor. Three

trajectories are generated to test the compliance of the controller with its

position. The error compensation scheme is introduced to increase the

positional accuracy of the previous controller, especially on the z-axis. This

algorithm uses the nature of discrete stepper motor movement to estimate the

actual cable length, which is then fed back to the control system as an error.

The control simulation results indicate a significant improvement in control

performance, i.e. reduced position error, was achieved.

Cable-Driven Parallel Robot (CDPR); Error compensation; Model-based control; Stepper motor

Nowadays, many different

types of robots are used in industries, for example, arm and gantry robots.

However, the use of these robots frequently comes with a number of issues

related to their movement. (Baskoro, Kurniawan and Haikal, 2019). A new type of parallel

manipulator that has emerged since the 1980s is a Cable-Driven Parallel Robot

(CDPR). CDPR is a new type of manipulator where the rigid links are replaced by

cables, giving it numerous advantages. Cables can bear a higher payload (Qian et al., 2018) due to their ability to withstand high tension.

Unlike rigid links, cables can be actuated by coiling and uncoiling, which does

not take up space, expanding their workspace (Gosselin, 2013). Moreover, cables have lower inertia and can be

driven at high speeds (Qian et al., 2018). Capabilities possessed by CDPR have been realized

in several industrial applications, such as material handling in port logistics

(Holland and Cannon, 2003), aircraft maintenance (Nguyen and Goutterfarde, 2014), offshore sandblasting (Gagliardini et al., 2014), structural painting (Nguyen et al., 2014), large scale construction (Hussein, Santos,

and Gouttefarde, 2018), rescue operation (Daney and Merlet, 2010), etc. CDPR can also be introduced as an

alternative technology for search-and-rescue operations since

it can cover a wide range of areas and has a high payload-to-weight ratio (Nurahmi et al., 2017).

Thus far, numerous topics

related to CDPR, such as kinematics and path planning, have been extensively

covered, but there is relatively limited information available on its control

system. The control system of CDPR faces a significant challenge due to the

flexible nature of cables, which can only exert force. Position of the moving

platform is harder to control due to its flexibility, which leads to lower

accuracy (Jung et al., 2016). The need to be in tension

also implies that an under-constrained configuration cannot be fully controlled

(Qian et al., 2018). A number of feedback control laws have been

developed to tackle these issues, such as PD (Kawamura et al., 1995), Lyapunov-based and

feedback linearization-based Proportional Derivative, PD (Alp and Agrawal, 2002), and Proportional Integral

and Derivative, PID (Khosravi and Taghirad, 2014, Khosravi, Taghirad, and Oftadeh, 2013) to control the position of the end effector.

However, the major drawback of these methods is that they do not consider the

dynamics due to payload, thus leading to high position error. To solve this

issue, more complex control has been introduced, such as sliding mode control (Hu et al., 2014), force control (Kraus et al., 2014), differential flatness (Yoon et al., 2018), and active stabilizer (Lesellier et al., 2018). Feed-forward compensators

are also used for cable elasticity (Piao et al., 2017) and vibration reduction (Baklouti et al., 2019).

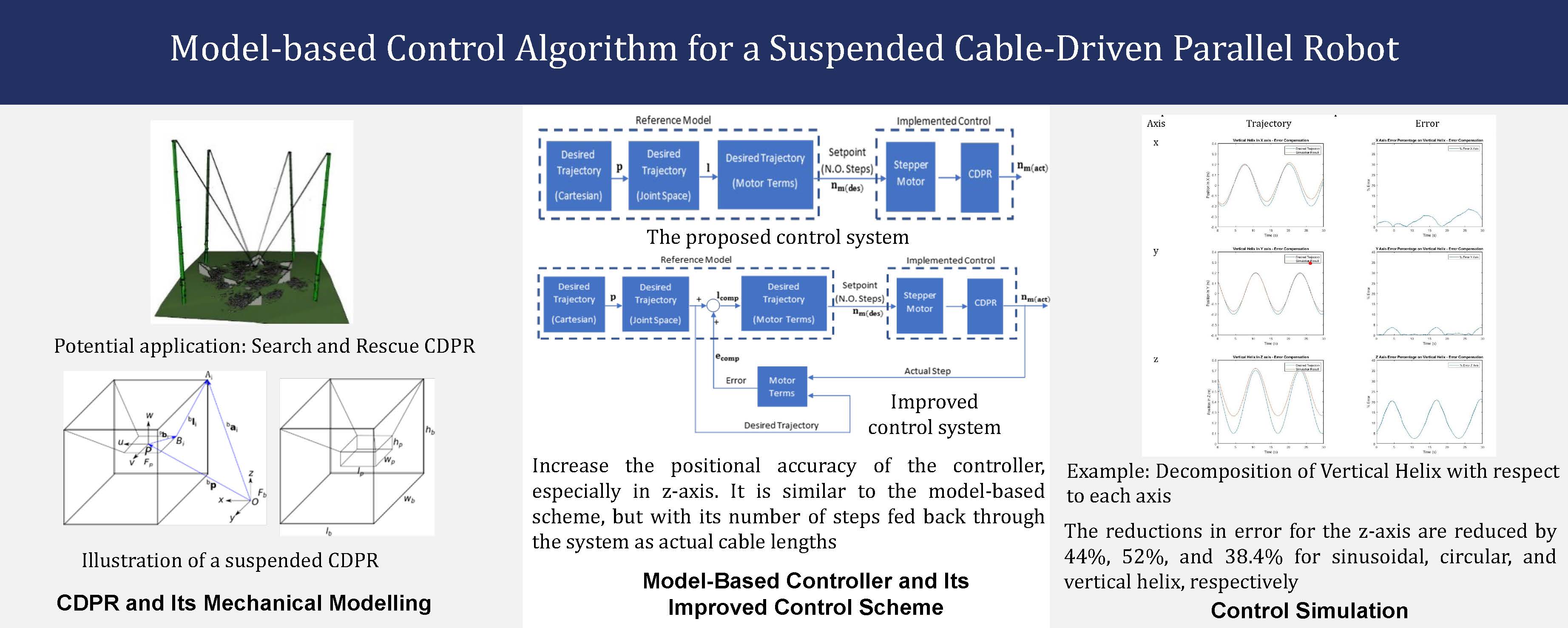

Figure 1 Illustration of Search – and – Rescue CDPR

Mechanical Modelling

2.1. Geometric and Dynamic Analyses

The suspended CDPR understudy comprises four cables, a cube moving platform, and a cube base frame, as shown in Figure 2. Each cable connects the cube-moving platform at the point

For more detailed

mathematical expressions of the reconfigurable pulley at the contact point , the readers may refer to (Syamlan et al., 2020).

The unit vector of cables

is derived as:

The cable mass and stiffness are negligible since the cable is relatively lighter than the rigid links. The unit vector of the cable

2.2. Motor Modelling

The cable lengths obtained from the geometric model need to be

represented in terms of its actuators. In this case, stepper motors are used to

drive the cables. Stepper motors are chosen because they move by number of

steps, which is the multiplication of their step angle. Therefore, actual steps

can be gathered without the need for an additional sensor. Before deriving this

relationship, some assumptions are taken into account as follows:

1. Pulley and cables are

assumed mass-less and friction between pulley and cables is assumed negligible.

2. Winches are assumed

to always coil only one layer of cable.

3. Transmission loss

within the actuator is assumed negligible.

4. No missed steps were

generated by the stepper motor.

The current control

scheme applied to the robot focuses solely on position control. The rotation of

the shaft angle acts as the set point to the control scheme. The stepper motor

moves the shaft to the desired angle determined by the number of steps

that must be generated according to its step

angle

, and mathematically can

be expressed as:

Rearranging the

equation to find a number of steps gives:

Three trajectories,

namely sinusoidal, circular, and vertical helix trajectories, are generated in

this paper based on (Gosselin, 2010). The design

parameters of the CDPR model shown in Table 1 are referenced from previous work

on the suspended CDPR conducted by (Syamlan, 2020). The results corresponding to

the platform position between the desired values versus the actual one and its

error will be presented for each trajectory.

The moving platform following the sinusoidal trajectory oscillates in the

The velocities

and accelerations are obtained by deriving Equation (10) with respect to time.

The trajectory parameters for the sinusoidal wave used in this paper are based

on (Syamlan, 2020), as shown in Table 2.

Table 2 Trajectory Parameters for the Sinusoidal

Motion

The second trajectory generated in this paper is a circular trajectory lying on the xy-plane. The position of the moving platform tracing this trajectory is expressed with respect to the base frame. The initial height of the moving platform is denoted by

Table 3 Trajectory Parameters for the Circular Trajectory

The vertical helix trajectory is a more complex. The platform rotates with respect to the

By performing the time derivative for Equation

(12), the velocities and accelerations of point P can be defined. The values assigned to each

parameter are based on (Syamlan, 2020), as summarized in Table 4.

Table 4

Trajectory Parameters for the Vertical Helix

4.1. Proposed Control Scheme

The proposed control scheme comprised two sub-systems, a reference model and an implemented control. The reference model generates set points for the controller. It converts Cartesian trajectory into the required cable lengths for each motor. These values are then translated into equivalent shaft angles. A number of steps obtained from the shaft angle will be used as a set point for the Implemented control. The proposed block diagram of the system is shown in Figure 4.

Figure 4 Block Diagram of the Proposed Control Scheme.

Each cable will be driven by a Sumtor 57HS6425A4D8

stepper motor. The specification of the stepper motor is shown in Table 5.

Table 5 Motor

Specification

The proposed control scheme is enhanced by the

error compensation scheme. This control strategy was created to improve the

controller's position precision, particularly on the z-axis. It is analogous to

the model-based scheme, with its number of steps being fed back through the

system as an actual cable length, as shown in Figure 5.

Multiplying the number of steps by the shaft radius will give the actual cable length as follows:

Figure 7 Errors from Sinusoidal Motion (a) Model-based

control, (b) Error compensation control.

Figure 8 Results from

Circular Horizontal Motion (a) Model-based control, (b) Error compensation

control.

Table 6 Decomposition of Circular Trajectory with respect to each axis.

Figure 9 Results from Vertical Helix Motion (a) Model-based control, (b) Error

compensation control.

Figure 9(a) presents a

comparison between the desired and actual trajectories for the vertical helix

achieved through model-based control. It is noteworthy that the actual

trajectory exhibits a smaller radius and higher position in comparison to the

desired trajectory. Overall, it is observed that the actuator is able to track

the set point in less than 5 seconds. There is a slight difference between the

desired and the actual pose in the x and y axis, but in general, the y-axis

performs better than the x-axis. In terms of error, the overall error is less

than 5% and 5.5% for both axes, respectively. As for the z-axis, the major

difference is seen between the desired and the actual pose, with errors as high

as 32.8%. Based on

these results, it can be concluded that, in general, the control scheme

performs well on the x and y-axis but not on the z-axis. Therefore, an

improvement termed an error compensation control scheme was proposed. Significant improvement is seen in the vertical helix when using an

error compensation scheme, as shown in Figure 9(b). The circular radius becomes

wider, and the robot is now able to follow the z-axis trajectory. The

trajectory for each axis is summarized in Table 9. Using the error compensation

scheme reduces the error on y-axis by 26%, but a slight increase of 29% to 7.1%

for the x-axis. The error reduction is also seen on the z-axis of the vertical

helix at 38.4%, from 32.5% to 20.5%. The highest error is still registered at

the downward motion, especially in the lowest position.

A control

scheme and its improvement for suspended cable-driven parallel robots have been

developed, namely model-based and error compensation control. The robot is

designed to have a fixed frame base with four cables. The cables are attached

to winches at one end, which are driven by stepper motors, and a moving

platform at the other end. Both control schemes consist of two systems, namely

the reference model and the implemented control. The main difference between

the model-based and error compensation control is that the latter uses the

nature of the stepper motor to acquire the actual cable length without the need

to use sensors. The actual cable length is fed back into the system as an

error. Both schemes are tested on three trajectories, sinusoidal, circular, and

vertical helix. In general, the model-based control scheme has reduced

performance in z-axis, with errors as high as 32.5% when performing the

vertical helix. The error compensation scheme shows better control performance

as compared to the model-based ones, reducing errors for all trajectories

noticeably in the z-axis. The reduction in error for z-axis is reduced by 44%,

52%, and 38.4% for sinusoidal, circular, and vertical helix, respectively.

This work is supported by

the Ministry of Research and Higher Education of Indonesia, under the scheme of

Fundamental Research 2019, No. T/208/IT2.VII/HK.00.02/xi/2019.

Alp, A.B., Agrawal,

S.K., 2002. Cable Suspended Robots: Feedback Controllers with Positive Inputs. In:

Proceedings of American Control Conference, Volume 1, pp. 815–820

Baklouti, S.,

Courteille, E., Lemoine, P., Caro, S., 2019. Vibration Reduction of

Cable-Driven Parallel Robots through Elastodynamic Model-Based Control. Mechanism

and Machine Theory, Volume 139, pp. 329–345

Baskoro, A.S., Kurniawan, R.P., Haikal, 2019. Evaluation of the

2-Axis Movement of A 5-Axis Gantry Robot for Welding Applications. International

Journal of Technology, Volume 10(5), pp. 1024–1032

Berawi, M.A.,

Leviakangas, P., Muhammad, F., Sari, Gunawan, Yatmo, Y. A., Suryanegara, M.,

2019. Optimizing Search and Rescue Personnel Allocation in Disaster Emergency

Response Using Fuzzy Logic. International Journal of Technology, Volume

10(7), pp. 1416–1426

Berawi, M.A., 2021.

Philosiphy of Technology Design: Creating Innovation and Added Value. Internation

Journal of Technology, Volume 12(3), pp. 444–447

Daney, D., Merlet,

J.P., 2010. A Portable, Modular Parallel Wire Crane for Rescue Operations. In:

2010 IEEE International Conference on Robotics and Automation, pp. 2834–2839

Gagliardini, L.,

Caro, S., Gouttefarde, M., Wenger, P., Girin, A., 2014. Optimal Design of

Cable-Driven Parallel Robots for Large Industrial Structures. In: IEEE International Conference on Robotics

and Automation (ICRA), pp. 5744–5749

Gosselin, C., 2013.

Cable-Driven Parallel Mechanism: State of the Art. Bulletion of JSME

Gosselin, C.M., 2010.

Global Planning of Dynamically Feasible Trajectories for Three-DOF Spatial

Cable Suspended Parallel Robots. Mechanisms

and Machine Science, Volume

12, pp. 3–22

Holland, C.S.,

Cannon, D.J., 2003. Cable Array Robot for Material Handling. USA: United

States Patent. US6826452B1

Hu, Y., Tao, L., Jia,

J., Lv, W., 2014. Control and Simulation of Cable-Driven Parallel Robots in

Offshore Cargo Handling. In: Proceeding

of the 11th World Congress on Intelligent Control and Automation,

pp. 2451–2455

Hussein, H., Santos, J.C., Gouttefarde, M., 2018. Geometric Optimization of a Large Scale CDPR Operating on a Building

Façade. In: International Conference on Intelligent Robots and Systems

(IROS), pp. 5117–5124

Jung, J., Piao, J.,

Park, S., Park, J.-O., Ko, S.Y., 2016. Analysis of Cable Tension of High-Speed Parallel Cable Ro-bot: High

Speed Position Tracking of Winch. In: 16th International Conference on Control. Automation and

Systems (ICCAS), pp. 1053–1056

Kawamura, S., Choe,

W., Tanaka, S., Pandian, S.R., 1995. Development of an Ultrahigh Speed Robot

FALCON Using Wire Drive System. In: Proceedings of IEEE International Conference on Robotics and

Automation, Volume 1, pp. 215–220

Khosravi, A.M.,

Taghirad, H.D., 2014. Robust PID Control of Fully Constrained Cable Driven

Parallel Robots. Mechatronics, Volume

24(2), pp. 87-97

Khosravi, A.M., Taghirad, H.D., Oftadeh, R., 2013. A Positive Tensions

PID Controller for a Planar Cable Robot: An Experimental Study. In: First RSI/ISM International Conference on

Robotics and Mechatronics (ICRoM), Tehran, pp. 325–330

Kraus, W., Schmidt, V.,

Rajendra, P., Pott, A., 2014. System Identification

and Cable Force Control for a Cable Driven Parallel Robot with Industrial Servo

Drives. In: 2014 IEEE

International Conference on Robotics and Automation (ICRA), pp.

5921–5926

Lesellier, M.,

Cuvillon, L., Gangloff, J., Gouttefarde, M., 2018. An Active Stabilizer for

Cable-Driven Parallel Robot Vibration Damping. In: 2018 IEE/RSJ International

Conference on Intelligent Robots and Systems (IROS), Madrid, pp. 5063–5070

Nguyen, D.Q.,

Gouttefarde, M., Company, O., Pierrot, F., 2014. On the Analysis of

Large-Dimension Reconfigurable Suspended Cable-Driven Parallel Robots. In:

2014 IEEE International Conference on Robotics and Automation (ICRA),

pp. 5728–5735

Nurahmi, L.,

Pramujati, B., Caro, S., Jeffrey, 2017. Dimension Synthesis of Suspended Eight

Cables-Driven Parallel Robot for Search-and-Rescue Operation. In: 2017 International Conference on Advanced Mechatronics, Intelligent

Manufacture, and Industrial Automation (ICAMIMIA), pp. 237–241

Piao, J., Jin, X.,

Jung, J., Choi, E., Park, J.-O., Kim, C.-S., 2017. Open-Loop Position Control

of a Polymer Cable–Driven Parallel Robot via a Viscoelastic Cable Model for

High Payload Workspaces. Advances in

Mechanical Engineering. Volume 9(12), pp. 1–12

Qian, S., Zi, B.,

Shang, W.-W., Xu, Q.-S., 2018. A Review on Cable-driven Parallel Robots. Chinese Journal of Mechanical, Volume 31(1), pp. 1–11

Nguyen, D.Q.,

Goutterfarde, M., 2014. Study of Reconfigurable Suspended Cable—Driven Parallel

Robots for Airplane Maintenance. In: IEEE International Conference on Intelligent Robots and System,

pp. 1682–1689

Syamlan, A.T.,

Nurahmi, L., Pramujati, B., Tamara, M.N., 2019. Dynamic Trajectory Generation

of Suspended Cable-Driven Parallel Robot. In: AIP Conference Proceedings, Volume 2187(1), p. 050006

Syamlan, A.T.,

Nurahmi, L., Tamara, M.N., Pramujati, B., 2020. Dynamic Trajectory Planning of Reconfigurable Suspended Cable Robot. International Journal of Dynamics and

Control, Volume 8, pp. 887–897

Syamlan, A.T., 2020. Mechanical

Modelling and Control of Suspended Cable Driven Parallel Robot (CDPR) for

Search and Rescue Operation. Master Thesis,

Graduate Program, Institut Teknologi Sepuluh Nopember, Surabaya, Indonesia

Yoon, J., Hwang,

S.W., Bak, J.-H., Park, J.H., 2018. Vibration Suppression of CDPRs Based on

Differential Flatness. In: IEEE

Conference on Control Technology and Applications (CCTA), Copenhagen, pp. 259–264