Effect of Oxidants in the Utilization of Polysulfone Hollow Fiber Membrane Module as Bubble Reactor for Simultaneously Removal of NOx and SO2

Corresponding email: sutrasno@che.ui.ac.id

Published at : 25 Jan 2024

Volume : IJtech

Vol 15, No 1 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i1.6415

Kartohardjono, S., Karamah, E.F., Hayati, A.P., Talenta, G.N., Ghazali, T.A., Lau, W.J., 2024. Effect of Oxidants in the Utilization of Polysulfone Hollow Fiber Membrane Module as Bubble Reactor for Simultaneously Removal of NOx and SO2 . International Journal of Technology. Volume 15(1), pp. 63-74

| Sutrasno Kartohardjono | Process Intensification Laboratory, Department of Chemical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok 16424 |

| Eva Fathul Karamah | Process Intensification Laboratory, Department of Chemical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok 16424 |

| Adinda Puspa Hayati | Process Intensification Laboratory, Department of Chemical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok 16424 |

| Grace Natalie Talenta | Process Intensification Laboratory, Department of Chemical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok 16424 |

| Thoriq Ahmad Ghazali | Process Intensification Laboratory, Department of Chemical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok 16424 |

| Woei Jye Lau | Advance Membrane Technology Research Center, Universiti Teknologi Malaysia, 81310 Skudai, Johor, Malaysia |

Air pollution has become a global issue and

contributes significantly to climate change, mainly due to the massive energy

consumption in industry and the transportation sector. Emissions of harmful gases from burning fuels such

as NOx and SO2 are the most significant sources of

environmental pollution, which have negative impacts on the environment, such

as the greenhouse effect, damage to the ozone layer, photochemical smog, and

acid rain, and can interfere with the respiratory system in humans. This study

utilizes hollow fiber membrane modules, which act as a reactor on the shell

side of the membrane module and a gas distributor by the membrane fiber to

remove NOx and SO2 spontaneously. The oxidant solutions

used were a pair of hydrogen peroxide and sodium hydroxide (H2O2-NaOH)

solutions, a pair of sodium chlorite and sodium hydroxide (NaClO2-NaOH)

solutions, and a pair of sodium chlorate and sodium hydroxide (NaClO3-NaOH)

solutions. Based on the results of experiments, SO2 can be removed

entirely in the process, while NOx depends on the feed gas flow rate and the concentration of the oxidant

solution used. H2O2 is the most effective oxidizing agent

in removing NOx and SO2 because of its higher oxidative

properties than NaCLO2 and NaClO3. The increase in feed

gas flow rate resulted in a decrease in the efficiency of NOx

removal even though the NOx mass transfer flux and NOx

loading increased. Meanwhile, an increase in the concentration of oxidants

increases the efficiency of NOx removal and mass transfer flux but

decreases NOx loading. Based on the experimental results, the

maximum NOx removal efficiency achieved by the oxidant solutions is

93.9, 91.1, and 88.3% for H2O2-NaOH, NaClO2-NaOH, and NaClO3-NaOH, respectively.

Climate change; Harmful gases; NOx; Removal efficiency; SO2

Air pollution has become a global issue and contributes significantly to

climate change due to the industry and transportation sector's massive energy

consumption (Manisalidis et al., 2020). In many countries, such as

Indonesia, the emission of air pollutants from industrial and transportation

activities is increasing due to the burning of fossil fuels. Emissions of

harmful gases from the fuels burning process, such as NOx and SO2,

are the most significant causes of environmental pollution, which have negative

impacts on the environment, such as the greenhouse effect, damage to the ozone

layer, photochemical smog, and

acid rain, and can interfere with the respiratory system in humans (Kartohardjono et al., 2019; Ma et al., 2019). One promising strategy to reduce exhaust

gas pollutants such as NOx and SO2 is to control the

source of the pollution (Zhu et al., 2023). Removing

NOx and SO2 in flue gases, such as those from coal burn

boilers and marine diesel engines, is currently attracting much attention (Zhao et al., 2022; Yan et

al., 2020). In 2020, analysis tools revealed a

significant increase in the trend of NOx and SO2 emissions from

Indonesian coal-fired power plants. The emissions for SO2 and NOx

were reported as 798.5 kton/year and 120.02 kton/year, respectively (Sunarno, Purwanto, and Suryono, 2021).

Considering the losses that SO2 and NOx gases can cause,

the Indonesian Government has set various regulations related to the quality

standard of the two gases, which is 200 or 0.16 and 0.076 ppm for NO and SO2, respectively (Ministry of Environment and Forestry, 2019).

Several

technologies have been developed to control pollutant emissions in many

industries, including Selective Catalytic Reduction (SCR) and Selective

Non-Catalytic Reduction (SNCR) for NOx removal (Karamah et al., 2021)

and Flue Gas Desulfurization for SO2 removal (Sharma et al., 2012). The

conventional technology of SCR for NOx and FGD for SO2

has been widely adopted in various countries (Xu et al., 2022). With increasing environmental

awareness, the government and society need strict legislation and regulations

to minimize NOx and SO2 emissions into the air (Jia et al., 2022; Chen et

al., 2021). Although the removal rate is relatively

high, several problems are faced, such as the catalyst used in the SCR system

is quite expensive, must be replaced periodically, and requires a large area of

land for its application (Guo et al., 2018). Therefore,

it has prompted the search for suitable alternative technologies to remove SO2

and NOx simultaneously. The simultaneous removal of SO2 and

NOx through two different technologies needs high operational and

investment costs because the process is becoming more complex (Zhao et al., 2021b; Cheng and

Zhang, 2018) and has a high working area (Zhao et al., 2021a). NOx

and SO2 are both acidic gases, but the solubility of NOx

in water is less than SO2, so a different technique is needed to

remove the two gases (Fang et al., 2011).

Several

approaches that can be used to remove NOx and SO2

simultaneously include the oxidation approach, the reduction approach, the

absorption or adsorption approach, and the microbial approach (Chen et al., 2021). Oxidation

approaches include gas-liquid oxidation, gas-liquid oxidation, and gas-solid

oxidation. The gas oxidation approach can use ozone (Sun et al., 2013), oxygen (Atkinson et al., 2004), the

oxidant chlorine (Cl2) and chlorine dioxide (ClO2) (Mostafa et al., 2018), and

non-thermal plasma (Feng et al., 2018). The

gas-liquid oxidation approach, also known as the wet process, includes

gas-liquid oxidation using H2O2 (Kartohardjono et al., 2023; Waclawek et

al., 2017), Peroxydisulfate/Peroxymonosulfate (Matzek and Carter, 2016), and

NaClO/NaClO2 (Zhitao et al., 2019). Meanwhile,

for the gas-solid oxidation approach through a photocatalytic process using

catalysts such as TiO2 (Su et al., 2013), ZnO (Boyjoo et al., 2017), CeO2 (Tsang et al., 2019), Bi2WO6

(Wang et al., 2017), and BiOX

(Cl, Br, I) (Xia et al., 2015). The reduction approach includes gas-liquid

reduction, gas-liquid reduction, and gas-solid reduction. Reduction of gases

can use reductants such as CO (Makeev and Peskove, 2013), H2

(Ge et al., 2018), and CxHy (Pan et al., 2015). The

gas-liquid reduction can use ammonia, urea, and sodium sulfide (Na2S)

(Mok and Lee, 2006), while

gas-solid reduction can use carbon materials (Ma et al., 2013). Absorption/adsorption

approaches include Alkaline solution absorption (Sun et al., 2015), complex

absorption (Guo et al., 2014), carbon-based adsorption (Xiong et al., 2015),

zeolite-based adsorption (Rezaei et

al., 2015), metal oxide-based adsorption (Vikrant et al., 2017). Meanwhile,

the microbial approach uses autotrophic micro-organisms under anoxic conditions (Xiao et al., 2017).

The wet

method approach is becoming more commonly applied to remove NOx and

SO2 simultaneously because of its high efficiency and low cost (Johansson, Normann, and

Andersson, 2021). The wet method includes wet scrubbing

technology, widely used in SO2 gas removal processes, and a bubble

reactor to remove NOx (Zhang et al., 2021). Bubble reactors are multiphase

reactors widely used in various industries, such as the chemical,

petrochemical, and biochemical industries. These reactors play a

pivotal role in numerous chemical processes encompassing oxidation,

chlorination, alkylation, polymerization, and hydrogenation reactions. In these

reactors, the feed gas is introduced into the system and then dispersed into

bubbles as part of the technical process. Meanwhile, the liquid phase or

liquid-solid suspension can be operated in batch mode or flowed in the

direction/opposite direction of the gas flow so that contact or reaction will

occur in the reactor column (Jakobsen, Linborg, and Dorao, 2005).

The wet

method facilitates the removal of gaseous pollutants through contact between pollutant

gas and oxidant liquid, which triggers a reaction between pollutant gas and

oxidant liquid, becoming other species (Jin et al., 2006). The main

obstacle in removing NOx gas through the wet method is that NOx

gas is a species that cannot be dissolved in the oxidant (Kang et al., 2020). To address

this issue, an oxidizing agent is introduced to convert the NOx

species into more soluble forms, such as hydrogen peroxide (H2O2), sodium

chlorite (NaClO2), and sodium chlorate (NaClO3). At the

same time, an alkaline solution such as NaOH can be applied to remove SO2 (Purnawan et al., 2021).

Membrane

technology is a non-conventional technique that can simultaneously remove NOx

and SO2. The membrane is a porous medium in the form of a thin film

that can diffusely transfer certain gas compounds due to a driving force in the

form of concentration toward the solvent through the membrane pore (Wang and Yu, 2017). A membrane

contactor has several advantages, such as ease of operation and scale-up, low

separation costs and energy consumption, and high efficiency (Kartohardjono et al.,

2020). This study utilized a hollow fiber membrane module (HFMM) that

functions as a reactor and gas distributor to remove NOx and SO2

spontaneously. Using an HFMM as a bubble reactor enhances the area for

gas-liquid contact, providing a better removal reaction between NOx

and SO2 gases with the applied oxidant solutions. The oxidant

solutions used were a pair of H2O2-NaOH solutions, a pair

of NaClO2-NaOH solutions, and a pair of NaClO3-NaOH

solutions.

The

reactions between NOx and SO2 with a pair of H2O2

and NaOH solutions are presented in Equations

(1) – (4) (Purnawan et al., 2021; Sun, Zwoli?ska,

and Chmielewski, 2016):

The reactions that occur between NOx and SO2 with a pair of NaClO2 and NaOH solutions are presented in Equations (5) – (8) (Zhao et al., 2010; Chien, Chu, and Hsueh, 2003):

The CV Bandung

Indonesia supplied the polysulfone hollow fiber membrane module consisting of

50 fibers used in the study. The analytic grade H2O2,

NaClO2, NaClO3, and NaOH are provided by Merck Indonesia.

Meanwhile, the feed gas in the form of a gas mixture of 600 ppm NOx

and 500 ppm SO2 in nitrogen was provided by PT EIN Indonesia. The

feed gas flow rate was regulated during the experiments using the CX Series

mass flow controller, which can precisely control the gas flow rate. In

addition, the concentration of gases entering and leaving the membrane was

measured using an ECOM-D Gas analyzer.

The HFMM

operates on a principle similar to that of a bubble reactor. The oxidant, which

contains a pair of 200 mL solutions of H2O2-NaOH, NaClO2-NaOH,

or NaClO3-NaOH, is located on the shell side of the HFMM. The feed

gas stream containing SO2 and NOx entered the membrane module

through a silicone hose connection to the lumen fibers. A CX Series mass flow

controller regulated the gas flow rates and made contact with oxidant solutions

in the shell side of HFMM. The ECOM-D Gas Analyzer measured the NOx

and SO2 composition, as it leaving the

membrane module.

The NOx

or SO2 removal efficiency, flux, and gas loading were calculated by Equations (11-14) (Kartohardjono et al.,

2020):

Cin and Cout are the NOx

or SO2 concentrations in the feed gas and gas left from the HFMM,

respectively. Meanwhile, GasAbs,

Am, Coxidant, QG,

P, T, and R are NOx

or SO2 absorbed by the oxidant, membrane area, concentration of H2O2,

NaClO2, or NaClO3, feed gas flowrate, pressure,

temperature, and ideal gas constant, respectively. The series of experimental

equipment is shown in Figure 1. All experiments were conducted three times, and

the experimental results' standard deviation was less than 6%.

Figure 1 Experimental equipment set up: 1. Feed gas

tank, 2. Gas regulator, 3. Mass flow controler, 4. HFMM, 5. Gas Analyzer, 6.

Data storage

This study

used a feed gas with initial concentrations of NOx and SO2

of 600 ppm and 500 ppm, respectively. The oxidant solutions used were H2O2-NaOH

solutions, NaClO2-NaOH solutions, and NaClO3-NaOH

solutions with a concentration of 0.1M and 0.5M of 200 mL each. The gas flow in

the experiments varied from 0.1 to 0.2 L/minute at a constant temperature and

pressure of 28? and 1 atm, respectively. The process of NOx and SO2

gases transfer through the HFMM during the experiment occurred in three stages:

(i) gas diffusion to the inner surface of the fiber membrane; (ii) gas

diffusion through the membrane pores to the outer surface of the membrane

fibers; and (iii) gas absorption by the oxidant (Kartohardjono et al.,

2019).

For all

experiments, the SO2 removal efficiency is generally 100%, as it has

a high solubility in water and better chemical reactivity (Liu, Shi, and Wang, 2022), so its presence in the feed gas

will be examined to see the influence on NOx removal. Figure 2 shows

the impact of varying feed gas flow rates on NOx gas's absorption

efficiency (%R) with various oxidants.

As

demonstrated in Figure 2, the removal efficiency of NOx for all

oxidants decreases with increasing feed gas flow. Increasing the feed gas flow

causes an increase in the NOx absorbed by the oxidant solutions,

thereby increasing the efficiency of NOx removal. However,

increasing the feed gas flow led to less gas residence time in the HFMM, which

caused a decrease in the removal efficiency of NOx. The decline in

the removal efficiency of NOx to the gas flow indicates that the

effect of gas residence time in the membrane module is more influential than

the increase in the adsorbed NOx (Xu et al., 2022). The removal efficiency of NOx

decreased from 93.9 to 81.3%, 91.1 to 79.5%, and 88.3 to 71.0% for H2O2-NaOH,

NaClO2-NaOH, and NaClO3-NaOH adsorbents, respectively.

Oxidant solutions containing H2O2 have the highest

removal efficiency because of their higher

oxidative properties than NaClO2 and NaClO3. The standard reduction potentials for H2O2, NaClO2,

and NaClO3 are 1.77, 0.76, and 0.62 Volt, respectively (Purnawan et al., 2021; Lide, 2004). Previous

studies showed a slight decrease in the removal efficiency of NOx

from about 99.8 to 98.8%, 99.4 to 98.6%, and 99.3 to 98.3% for H2O2-HNO3,

NaClO2-NaOH, and NaClO3-NaOH oxidant pairs, respectively,

under the same conditions as this study using feed gas containing 600 ppm NOx

without SO2 and flow rates from 100 to 200 mL/min (Purnawan et al., 2021). Thus, it

is clear that the presence of SO2 in the feed gas reduces the NOx

removal efficiency due to the influence of competition in consuming the oxidant

solution (Kartohardjono et al., 2023), as shown in Equations (3), (8), and (10). In addition, the wet

method has the disadvantage that it can only be used indirectly if the exhaust

gas temperature is high enough because the wet process is only adaptable to

operate at ambient temperature.

Figure 2 NOx

removal efficiency, R-NOx,

at various feed gas flow rates, QG

The NOx mass transfer flux, as

presented in Figure 3, rises with increasing the feed gas flow, indicating that

increasing gas flow contributes to an increase in oxidant performance in

absorbing NOx passing through the membrane. With the feed gas flow

increase from 100 CC/min to 200 CC/min, the NOx mass transfer flux

rose from 4.9 to 8.4×10-8 mmol/cm2.s, 4.7 to 8.2 ×10-8

mmol/cm2.s, and 4.6 to 7.4 ×10-8 mmol/cm2.s, for the H2O2-NaOH,

NaClO2-NaOH, and NaClO3-NaOH oxidant pairs, respectively.

Increasing the gas flow enhances the absorbed NOx, as presented in

Figure 3, so it increases the flux in the end. A similar phenomenon also occurs

for NOx loading, the ratio between NOx absorbed and the

amount of oxidant (H2O2, NaClO2, or NaClO3),

where the NOx loading appears to increase with the higher feed gas

flow rate, indicating that the feed gas flow also contributes to the rise in

the uptake of NOx by the oxidant solutions, as presented in Figure

4. When the feed flow raised from 100 to 200 CC/min, the NOx loading

increased from 0.0019 to 0.0033 mmol/mol.s, 0.0019 to 0.0032 mmol/mol.s, and

0.0018 to 0.0026 mmol/mol.s, for the H2O2-NaOH, NaClO2-NaOH,

and NaClO3-NaOH solvent pairs, respectively. In previous studies,

under the same conditions using feed gas containing 600 ppm NOx

without SO2 and flow rates from 100 to CC mL/min, the mass transfer

flux increased from about 0.54 to 1.1 ×10?7 mmol/cm2.s

for all pairs of oxidants as their NOx removal efficiency only

slightly different. Meanwhile, NOx loading increased from 0.002 to

0.004 mmol/mol.s for all pairs of oxidants (Purnawan et al., 2021). It reveals that the NOx

mass transfer flux and NOx loading using feed gas without SO2

is higher than that in the feed gas with SO2 due to the competition

in oxidant consumption, as shown in Equations (5), (6), (11), (14), and (19).

Figure 4 NOx Loading at various feed

gas flow rates, QG

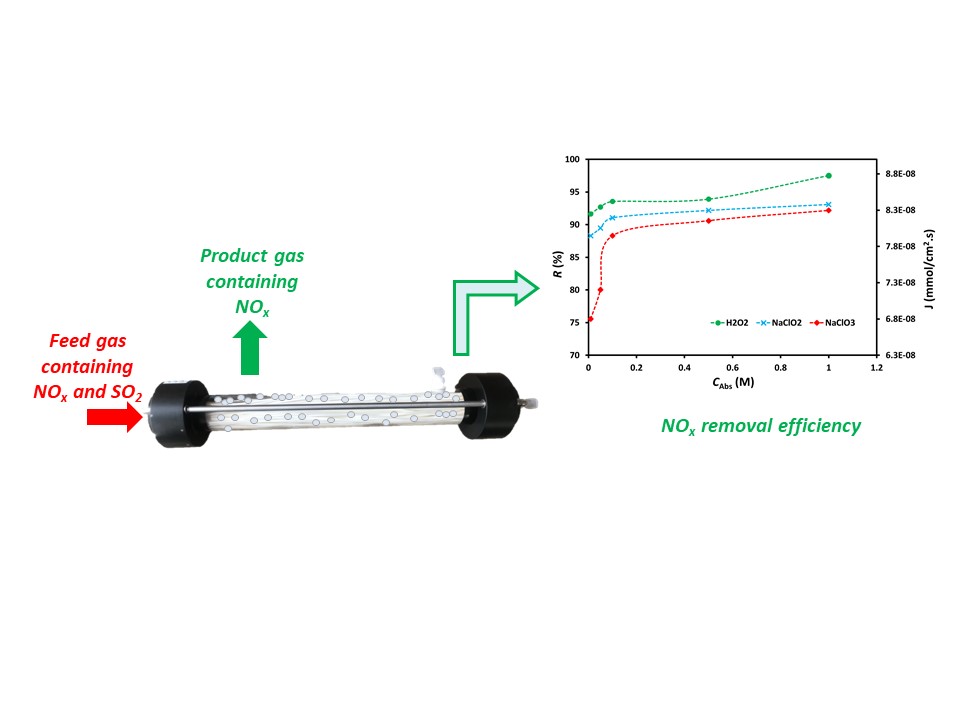

Figure 5

shows the effect of oxidant concentration on NOx removal efficiency

and mass transfer flux. The absorption efficiency of NOx by the

oxidant solution increases with raising the oxidant solution concentration. The

higher the concentration of the oxidant solution, the more chemical compounds

are available to react with NOx; thereby, it can increase the number

of chemical reactions between NOx and chemical compounds in the

oxidant to boost the NOx removal efficiency. The increase in NOx

mass transfer flux is also proportional to the increase in NOx

removal efficiency, as the feed gas flow rate used is the same for each

concentration of the oxidant solution (Zhao et al., 2020). NOx

removal efficiency and flux increased significantly at oxidant concentrations

between 0.01 and 0.1 M while only slightly increased at oxidant concentrations

greater than 0.1 M. The efficiency of NOx removal is still

relatively low, around 75.6, 88.3, and 91.6% for NaClO3, NaClO2,

and H2O2, respectively, with a concentration of around

0.01 M. Hence, an increase in oxidant concentration up to 0.1 M still gives a

significant increase. However, at 0.1 M oxidant concentration, the NOx

removal efficiency was relatively high, around 88.3, 91.1, and 93.5% for NaClO3,

NaClO2, and H2O2, respectively. Hence, an

increase in oxidant concentration above 0.1 M gave a not as sharp rise in NOx

removal efficiency as in the oxidant concentration area between 0.01 and 0.1 M.

Similar findings were also reported in the previous studies using NOx

feed gas without SO2, where NOx removal increased with

increasing oxidant concentration using a PVDF HFMM consists of 40 fibers. The

NOx removal efficiency increased from 93.3 to 99.0%, 98.7 to 99.2%,

and 98.9 to 99.7% with the raised of oxidant concentration from 0.05 to 0.25M,

0.01 to 0.05M, and 0.015 to 0.075 M, for the oxidants NaClO3, NaClO2,

and H2O2, respectively (Purnawan et al., 2021). Shi et

al. reported a rise in NOx removal from about 34.5 to 91.7% when

the concentration of NaClO3 solution as an oxidant increased from

0.005 to 0.1 M in a bubble column reactor (Shi, Sun, and Cui, 2019). Meanwhile, Zhitao et al.

reported that increasing the NaClO2 concentration from 0.005 to 0.15

M could improve the efficiency of the NO removal process with an initial

concentration of 800 ppm

through a cyclic scrubbing process from 62.5 to 85% (Zhitao et al., 2019). It is seen that the presence of SO2 in the feed gas

affects reducing the efficiency of NOx removal.

Figure 5 NOx

removal efficiency, R, and NOx mass transfer flux, J, at various concentration of oxidant

present in oxidant solutions, CAbs

NOx

loading in the NOx removal process using an oxidant solution is the

ratio between the absorbed NOx by the oxidant solution and the

number of moles of oxidant in the oxidant solution. As presented in Figure 6,

an increase in the concentration of oxidants in the NOx removal

process decreases gas loading because more oxidants are used, while the

increase in NOx absorbed is much smaller (Karamah et al., 2021). These

results indicate that a low oxidant concentration is preferable because it

provides a high NOx loading. However, the desired NOx

removal target also influences the decision to determine the oxidant

concentration in the oxidant solution used. In this study, the NOx

loading declined from around 0.015 to 0.0002 mmol/mol.s, 0.018 to 0.0002

mmol/mol.s, and 0.019 to 0.0002 mmol/mol.s for NaClO3, NaClO2,

and H2O2, respectively, when the oxidant concentration in

the oxidant solutions was increased from 0.01 to 1 M. Figure 6 also

demonstrates that the three oxidants used have almost the same NOx

loading, so the images coincide. It indicates

that the type of oxidant used does not have a significant effect on NOx

loading due to the insignificant difference in the amount of NOx

absorbed, as also reported previously (Purnawan et al., 2021). Table 1 summarizes the experimental results at a feed gas flow rate of 100

mL/min and an oxidant concentration of 0.1 M.

Figure 6 NOx

loading at various concentration of oxidant

Table 1 The results of NOx

removal efficiency, flux, and NOx loading at the concentration of

the oxidant 0.1 M and feed gas flow rate of 100 mL/min

|

Oxidants |

NOx Removal efficiency (%) |

Flux (mmol/cm2.s) |

NOx loading (mmol/mol.s) |

|

H2O2 |

93.9 |

4.9 x 10-8 |

0.0019 |

|

NaClO2 |

91.1 |

4.7 x 10-8 |

0.0019 |

|

NaClO3 |

88.3 |

4.6 x 10-8 |

0.0018 |

H2O2,

NaClO2, and NaClO3 are all capable of removing NOx

and SO2 from flue gases, but their effectiveness depends on feed gas

flow and concentration. All experimental results show that the efficiency of SO2

removal is generally 100% due to its high solubility in water and better

chemical reactivity. H2O2 is a highly effective oxidizing

agent and has been shown to be capable of removing both NOx and SO2

because of its higher oxidative properties than NaClO2 and NaClO3.

Based on the experimental results, it can be seen that a rise in the feed gas

flow rate decreases the NOx removal efficiency even though the NOx

mass transfer flux and NOx loading increase. Meanwhile, increasing

the oxidant concentration increases NOx removal efficiency and mass

transfer flux but decreases NOx loading. The three oxidant solutions

used relatively have the same NOx loading at the same oxidizing

concentration.

The authors

wish to acknowledge the funding of this research by The Directorate General of

the Higher Education Republic of Indonesia through Universitas Indonesia with

contract No. NKB 858 /UN2.RST/HKP.05.00/2022.

Atkinson, R., Baulch, D., Cox,

R. A., Crowley, J., Hampson, R., Hynes, R., Jenkin, M.E., Rossi, M.J., Troe, J., 2004. Evaluated Kinetic and Photochemical

Data for Atmospheric Chemistry: Volume I-Gas Phase Reactions of Ox, HOx, NOx

and SOx Species. Atmospheric Chemistry and Physics, Volume 4(6), pp. 1461–1738

Boyjoo, Y., Sun, H., Liu, J.,

Pareek, V.K., Wang, S., 2017. A Review on Photocatalysis for Air Treatment:

From Catalyst Development to Reactor Design. Chemical

Engineering Journal, Volume 310, pp. 537–559

Chen, R., Zhang, T., Guo, Y.,

Wang, J., Wei, J., Yu, Q., 2021. Recent Advances in Simultaneous Removal of SO2

and NOx from Exhaust Gases: Removal Process, Mechanism and Kinetics. Chemical

Engineering Journal, Volume 420, p. 127588

Cheng, G., Zhang, C., 2018.

Desulfurization and Denitrification Technologies of Coal-fired Flue Gas. Polish

Journal of Environmental Studies, Volume 27(2), pp.

481–489

Chien, T.W., Chu, H., Hsueh,

H.T., 2003. Kinetic Study on Absorption of SO2 and NO x with acidic

NaClO2 Solutions Using the Spraying Column. Journal

of Environmental Engineering, Volume 129(11), pp. 967–974

Fang, P., Cen, C., Tang, Z.,

Zhong, P., Chen, D., Chen, Z., 2011. Simultaneous Removal of SO2 and

NOx by Wet Scrubbing Using Urea Solution. Chemical

Engineering Journal, Volume 168(1), pp. 52–59

Feng, X., Liu, H., He, C., Shen,

Z., Wang, T., 2018. Synergistic Effects and Mechanism of a Non-Thermal Plasma

Catalysis System in Volatile Organic Compound Removal: a Review. Catalysis

Science & Technology, Volume 8(4), pp. 936–954

Ge, T.,

Zuo, C., Wei, L., Li, C. 2018. Sulfur Production from

Smelter Off-Gas Using CO–H2 Gas Mixture as The Reducing Agent Over

Modified Fe/?-Al2O3 Catalysts. Chinese

Journal of Chemical Engineering, Volume 26(9), pp. 1920–1927

Guo, L., Han, C., Zhang, S.,

Zhong, Q., Ding, J., Zhang, B., Zeng, Y., 2018. Enhancement Effects of O2?

and OH Radicals on NOx Removal in the Presence of SO2 by Using

an O3/H2O2 AOP System with Inadequate O3

(O3/NO Molar Ratio= 0.5). Fuel, Volume 233, pp. 769–777

Guo, Q., He, Y., Sun, T., Wang,

Y., Jia, J., 2014. Simultaneous Removal of NOx and SO2 from Flue Gas

Using Combined Na2SO3 Assisted Electrochemical Reduction and Direct

Electrochemical Reduction. Journal of Hazardous Materials, Volume

276, pp. 371–376

Jakobsen, H.A., Linborg, H., Dorao, C.A., 2005. Modelling of Bubble

Column Reactors: Progress and Limitation. Industrial

and Engineering Chemistry Research,

Volume 44, pp. 5107–5151

Jia, S.,

Pu, G., Gao, J., Yuan, C., 2022. Oxidation-Absorption

Process for Simultaneous Removal of NOx and SO2 over Fe/Al2O3@SiO2 Using Vaporized

H2O2. Chemosphere, Volume 291,

p. 133047

Jin, D.-S., Deshwal, B.-R.,

Park, Y.-S., Lee, H.-K., 2006. Simultaneous Removal of SO2 And NO By

Wet Scrubbing Using Aqueous Chlorine Dioxide Solution. Journal

of Hazardous Materials, Volume 135(1-3), pp. 412–417

Johansson, J., Normann, F.,

Andersson, K., 2021. Techno-Economic Evaluation of Co-Removal of NOx and SOx

Species from Flue Gases via Enhanced Oxidation of NO by ClO2—Case

Studies of Implementation at a Pulp and Paper Mill, Waste-to-Heat Plant and a

Cruise Ship. Energies, Volume 14(24), p.

8512

Kang, M.S., Shin, J., Yu, T.U.,

Hwang, J., 2020. Simultaneous Removal of Gaseous NOx and SO2 by Gas-Phase

Oxidation with Ozone and Wet Scrubbing with Sodium Hydroxide. Chemical

Engineering Journal, Volume 381, p. 122601

Karamah, E.F., Arbi, D.S.,

Bagas, I., Kartohardjono, S., 2021. Hollow Fiber Membrane Modules for NOx

Removal using a Mixture of NaClO3 and NaOH Solutions in the Shell Side as

Absorbents. International Journal of Technology, Volume 12(4), pp. 690–699

Kartohardjono, S., Karamah,

E.F., Talenta, G.N., Ghazali, T.A., Lau, W.J., 2023. The Simultaneously Removal

of NOx and SO2 Processes through a Polysulfone Hollow Fiber Membrane Module. International

Journal of Technology, Volume 14(3), pp. 576–583

Kartohardjono, S., Merry, C.,

Rizky, M.S., Pratita, C.C., 2019. Nitrogen Oxide Reduction Through Absorbent

Solutions Containing Nitric Acid and Hydrogen Peroxide in Hollow Fiber Membrane

Modules. Heliyon, Volume 5(12), p. e02987

Kartohardjono, S., Rizky, M.S.,

Karamah, E.F., Lau, W., 2020. The Effect of the Number of Fibers in Hollow

Fiber Membrane Modules for NOx Absorption. International Journal of

Technology, Volume 11(2), pp. 269–277

Lide, D.R., 2004. CRC

Handbook of Chemistry and Physics. Volume 85. CRC press

Liu, Y., Shi, S., Wang, Z.,

2022. A Novel Double Metal Ions-Double Oxidants Coactivation System for NO and

SO2 Simultaneous Removal. Chemical Engineering Journal, Volume

432, p. 134398

Ma, C., Yi, H., Tang, X., Zhao,

S., Yang, K., Song, L., Zhang,

Y., Wang, Y. 2019. Improving

Simultaneous Removal Efficiency of SO2 and NOx from Flue Gas by

Surface Modification of MgO with Organic Component. Journal

of Cleaner Production, Volume 230, pp. 508–517

Ma, S.C., Yao, J., Ma, X., Gao,

L., Guo, M., 2013. Removal of SO2 and NOx Using Microwave Swing

Adsorption Over Activated Carbon Carried Catalyst. Chemical

Engineering & Technology, Volume 36(7), pp. 1217–1224

Makeev, A.G., Peskov, N.V.,

2013. The Reduction of NO by CO Under Oxygen-Rich Conditions in a fixed-bed

Catalytic Reactor: A Mathematical Model That Can Explain the Peculiar

Behavior. Applied Catalysis B: Environmental, Volume 132,

pp. 151–161

Manisalidis, I., Stavropoulou,

E., Stavropoulos, A., Bezirtzoglou, E., 2020. Environmental and Health Impacts

of Air Pollution: A Review. Frontiers in Public Health,

Volume 8, p. 14

Matzek, L.W., Carter, K.E.,

2016. Activated Persulfate for Organic Chemical Degradation: A Review. Chemosphere,

151, pp. 178–188

Ministry of Environment and Forestry,

R.I., 2019. Regulation of the Minister of Environment and

Forestry Number P.15/MENLHK/SETJEN/KUM.1/4/2019 concerning Quality Standards

for Thermal Power Generation Emissions. Jakarta

Mok, Y.S.,

Lee, H.-J., 2006. Removal Of Sulfur

Dioxide and Nitrogen Oxides by Using Ozone Injection and Absorption–Reduction

Technique. Fuel Processing Technology, Volume 87(7),

pp. 591–597

Mostafa, E., Reinsberg, P.,

Garcia-Segura, S., Baltruschat, H., 2018. Chlorine Species Evolution During

Electrochlorination on Boron-Doped Diamond Anodes: In-Situ Electrogeneration of

Cl2, Cl2O and ClO2. Electrochimica

Acta, Volume 281, pp. 831–840

Pan, H., Guo, Y., Jian, Y., He,

C., 2015. Synergistic Effect of Non-Thermal Plasma on NOx Reduction by CH4

Over an In/H-BEA Catalyst At Low Temperatures. Energy &

Fuels, Volume 29(8), pp. 5282–5289

Purnawan, I., Kartohardjono, S.,

Wibowo, L., Ramadhani, A. F., Lau, W. J., Febriasari, A., 2021. Effect of

Absorbents on NOx Removal through Polyvinylidene Fluoride (PVDF)

Hollow Fiber Membrane Modules. International Journal of Chemical

Engineering, Volume 2021, pp. 1–8

Rezaei, F., Rownaghi, A.A.,

Monjezi, S., Lively, R.P., Jones, C.W., 2015. SOx/NOx Removal from Flue Gas

Streams by Solid Adsorbents: A Review of Current Challenges and Future

Directions. Energy & Fuels, Volume 29(9),

pp. 5467–5486

Sharma, A.K., Prasad, D.,

Acharya, S., Sharma, R., 2012. Utility and Application of FGD System (Flue Gas

Desulphurization) In Chemical and Environmental Engineering. International

Journal of Chemical Engineering and Applications, Volume 3(2), p.

129

Shi, D., Sun, G., Cui, Y., 2019.

Study on The Removal of NO from Flue Gas by Wet Scrubbing Using NaClO3. Journal

of the Serbian Chemical Society, Volume 84(10), pp. 1183–1192

Su, C.,

Ran, X., Hu, J., Shao, C., 2013. Photocatalytic

Process of Simultaneous Desulfurization and Denitrification of Flue Gas by TiO2–Polyacrylonitrile

Nanofibers. Environmental Science & Technology, Volume

47(20), pp. 11562–11568

Sun, C., Zhao, N., Wang, H., Wu,

Z., 2015. Simultaneous Absorption of NOx and SO2 Using Magnesia

Slurry Combined with Ozone Oxidation. Energy & Fuels, Volume 29(5),

pp. 3276–3283

Sun, W.-Y., Wang, Q.-Y., Ding,

S.-l., Su, S.-J., 2013. Simultaneous Absorption of SO2 and NOx with

Pyrolusite Slurry Combined with Gas-Phase Oxidation of NO Using Ozone: Effect

of Molar Ratio of O2 (SO2+ 0.5 NOx) in Flue Gas. Chemical

Engineering Journal, Volume 228, pp. 700–707

Sun, Y., Zwoli?ska, E.,

Chmielewski, A.G., 2016. Abatement Technologies for High Concentrations of NOx

and SO2 Removal from Exhaust Gases: A Review. Critical Reviews

in Environmental Science and Technology, Volume 46(2), pp.

119–142

Sunarno, S., Purwanto, P.,

Suryono, S., 2021. Trend Analysis of NOx and SO2

Emissions in Indonesia from the Period of 1990-2015 using Data Analysis

Tool. Advances in Science, Technology and

Engineering Systems Journal, Volume 6(1), pp. 257–263

Tsang, C.H.A., Li, K., Zeng, Y.,

Zhao, W., Zhang, T., Zhan, Y., Xie,

R., Leung, D.Y.C., Huang, H., 2019.

Titanium Oxide Based Photocatalytic Materials Development and Their Role of in

The Air Pollutants Degradation: Overview and Forecast. Environment

International, Volume 125, pp. 200–228

Vikrant,

K., Kumar, V., Kim, K.-H., Kukkar, D., 2017. Metal–Organic Frameworks (MOFs): Potential and Challenges for

Capture and Abatement of Ammonia. Journal of Materials Chemistry A, Volume

5(44), pp. 22877–22896

Wac?awek, S., Lutze, H.V.,

Grübel, K., Padil, V.V., ?erník, M., Dionysiou, D.D., 2017. Chemistry of

Persulfates in Water and Wastewater Treatment: A Review. Chemical

Engineering Journal, Volume 330, pp. 44–62

Wang, L., Sun, B., Wang, W.,

Feng, L., Li, Q., Li, C. 2017. Modification of Bi2WO6 Composites with rGO for

Enhanced Visible Light Driven NO Removal. Asia?Pacific

Journal of Chemical Engineering, Volume 12(1), pp. 121–127

Wang, Y., Yu, X., 2017. Removal

of NO Research in A Polypropylene Hollow Fiber Membrane Contactor. In:

6th International Conference on Energy, Environment and Sustainable

Development (ICEESD 2017), pp. 1015–1022

Xia, D., Hu, L., He, C., Pan,

W., Yang, T., Yang, Y., Shu, D., 2015. Simultaneous Photocatalytic Elimination

of Gaseous NO and SO2 in a BiOI/Al2O3-Padded

Trickling Scrubber Under Visible Light. Chemical Engineering Journal, Volume 279,

pp. 929–938

Xiao, C., Ma, Y., Ji, D., Zang,

L., 2017. Review of Desulfurization Process for Biogas

Purification. In: IOP Conference Series: Earth and

Environmental Science, Volume 100, p. 012177

Xiong, Y., Tang, C., Yao, X.,

Zhang, L., Li, L., Wang, X., Deng,

Y., Gao, F., Dong, L. 2015. Effect

Of Metal Ions Doping (M= Ti4+, Sn4+) on The Catalytic

Performance of MnOx/CeO2 Catalyst for Low Temperature Selective

Catalytic Reduction of NO with NH3. Applied Catalysis A: General, Volume

495, 206–216

Xu, X.-J., Wu, Y.-N., Xiao,

Q.-Y., Xie, P., Ren, N.-Q., Yuan, Y.-X., Lee, D.J.,

Chen, C., 2022. Simultaneous Removal of NOx

and SO2 from Flue Gas in an Integrated FGD-CABR System by Sulfur

Cycling-Mediated Fe (II) EDTA Regeneration. Environmental

Research, Volume 205, p. 112541

Yan, Y.-G.,

Mao, Z.-J., Luo, J.-J., Du, R.-P., Lin, J.-X., 2020. Simultaneous Removal of SO2, NOx and Hg0 by O3

Oxidation Integrated with Bio-Charcoal Adsorption. Journal

of Fuel

Chemistry and Technology, Volume 48(12), pp. 1452–1460

Zhang, Z., Zhou,

S., Xi, H., Shreka, M., 2021. A Prospective Absorption System for Marine NOx

Removal from Simulated Gas Using Na2SO3/urea Composite

Absorbents in Bubble Reactor. Fuel, Volume

288, p. 119709

Zhao, J., Wei, Q.,

Bi, D., Liu, L., Wang, S., Ren, X., 2022. A Brand New Two-Phase Wet Oxidation

Absorption System for The Simultaneous Removal of SO2 and NOx From Simulated Marine Exhaust

Gas. Chemosphere, Volume 307,

p. 135830

Zhao, K., Sun, X.,

Wang, C., Song, X., Wang, F., Li, K., Ning, P., 2021a. Supported Catalysts for

Simultaneous Removal of SO2, NOx, and Hg0 from Industrial Exhaust

Gases: A Review. Chinese Chemical Letters, Volume

32(10), pp. 2963–2974

Zhao, L., Sun, Y.,

Chmielewski, A.G., Pawelec, A., Bu?ka, S., 2020. NO Oxidation with NaClO, NaClO2,

and NaClO3 Solution Using Electron Beam and A One-Stage Absorption

System. Plasma Chemistry and Plasma

Processing, Volume 40, pp. 433–447

Zhao, M., Xue, P.,

Liu, J., Liao, J., Guo, J., 2021b. A Review of Removing SO2 and NOx by Wet Scrubbing. Sustainable Energy Technologies and Assessments, Volume 47,

p. 101451

Zhao, Y., Guo,

T.-X., Chen, Z.-Y., Du, Y.-R., 2010. Simultaneous Removal of SO2 and

NO Using M/NaClO2 Complex Absorbent. Chemical Engineering Journal, Volume 160(1),

pp. 42–47

Zhitao, H., Yu, G., Shaolong, Y., Jingming, D., Xinxiang, P., Tian, L., Liguo, S., Zhijun, Y., Deping, S., Kaixuan, N., 2019. NO Removal from Simulated Diesel Engine Exhaust Gas by Cyclic Scrubbing Using NaClO2 Solution in A Rotating Packed Bed Reactor. Journal of Chemistry, Volume 2019, p. 3159524

Zhu, C., Ru, J., Gao, S., Li, C. 2023. The Simultaneous Removal of NOx and SO2 from Flue Gas by Direct Injection of Sorbents in Furnace of Waste Incinerator. Fuel, Volume 333, p. 126464