Study of Solid–Liquid Extraction Kinetics of Oil from Dried Avocado (Persea Americana) Flesh Using Hexane as A Solvent

Corresponding email: satriana@unsyiah.ac.id

Published at : 28 Jul 2023

Volume : IJtech

Vol 14, No 5 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i5.6370

Satriana, Maulida, A., Qardhawi, R., Lubis, Y.M., Moulana, R., Mustapha, W.A.W., Arpi, N., 2023. Study of Solid–Liquid Extraction Kinetics of Oil from Dried Avocado (Persea Americana) Flesh Using Hexane as A Solvent. International Journal of Technology. Volume 14(5), pp. 982-992

| Satriana | 1. Department of Agricultural Product Technology, Universitas Syiah Kuala, Banda Aceh 23111, Indonesia, 2. Halal Research Center, Universitas Syiah Kuala, Banda Aceh 23111, Indonesia |

| Amrina Maulida | Natural and Energy Resource Laboratory, Department of Chemical Engineering, Universitas Syiah Kuala, Banda Aceh 23111, Indonesia |

| Rizky Qardhawi | Department of Agricultural Product Technology, Universitas Syiah Kuala, Banda Aceh 23111, Indonesia |

| Yanti Meldasari Lubis | Department of Agricultural Product Technology, Universitas Syiah Kuala, Banda Aceh 23111, Indonesia |

| Ryan Moulana | Department of Agricultural Product Technology, Universitas Syiah Kuala, Banda Aceh 23111, Indonesia |

| Wan Aida Wan Mustapha | Department of Food Sciences, Faculty of Science and Technology, Universiti Kebangsaan Malaysia 43600 UKM Bangi, Selangor DE, Malaysia |

| Normalina Arpi | Department of Agricultural Product Technology, Universitas Syiah Kuala, Banda Aceh 23111, Indonesia |

In the present study, solid–liquid extraction of

dried avocado flesh was investigated using hexane as a solvent for three

pre-treatment methods (uncooked, cooked with CaCO3, and cooked with

water) and two material sizes (8 mm × 5 mm × 5 mm and 1.19 mm). Based on the

highest yield of avocado oil obtained, the kinetics of oil extraction for a

material size of

1.19 mm for the various pre-treatment methods was studied.

Two stages, namely rapid oil extraction and slow oil extraction, were observed.

Three kinetics models (Peleg, power law, and unsteady-state diffusion model)

were used to describe the extraction of avocado oil. At conditions with the

highest oil yield, the Arrhenius equation was used to calculate the activation

energy at three different temperatures (25, 40, and 50°C). Based on the R2 value obtained, the

unsteady-state diffusion model (R2 = 0.6236–0.8752) is most

suitable to describe the avocado oil extraction process. A positive value of

the activation energy (47.51 kJ/mol) confirmed that the avocado oil extraction

process is endothermic.

Avocado oil; Kinetics model; Pre-treatment; Solid–liquid extraction

Avocado (Persea americana) belongs to the

Lauraceae family and originated in Mexico. It is widespread and farmed around

the world in tropical and subtropical climates. Avocados are edible, and their

oil yield is significantly higher than that of other edible oil crops, including

rapeseed, sunflower, sesame, and jatropha (Satriana

et al., 2019). Avocados have the potential to produce valuable

and useful products, one of which is avocado oil. Avocado oil finds common use

in both food and non-food industries, such as cooking oil and cosmetic

formulations. It contains a high level of monounsaturated and polyunsaturated

fatty acids, making it a natural ingredient suitable for various applications (Ge et al., 2021). Avocado oil contains a

mixture of compounds, including antioxidants, vitamins, and phytosterols, that

are beneficial for a healthy diet (Satriana et

al., 2019). Demand for avocado oil has grown significantly over time

as consumers have become aware of its health advantages.

Several studies report that

the development of extraction techniques can produce avocado oil with a high

content of bioactive compounds in addition to maintaining its properties and

nutritional value after extraction and during storage (Satriana

et al., 2019; dos Santos et al., 2014). Avocado oil has characteristics

similar to olive oil (Barros et al., 2016)

and is extracted from the dried

fruit's fleshy pulp. Although solvent-free extraction is a currently trending

environmentally-friendly process, the traditional lipid extraction method of

solid-liquid solvent extraction is still widely applied in industrial-scale

processes due to its efficiency (Mgoma, Basitere, and

Mshayisa,

2021). This

method involves the penetration of the solvent into the lipid membrane while

matching the polarity of the target chemicals. However, since the solvents come

into direct contact with the lipids, it is necessary to pre-treat the raw

material before adding the solvent to improve the extraction yield.

Pre-treatment, including size reduction

and heat treatment, of raw material is one of the primary methods for enhancing

oil recovery during the extraction process. Size reduction is used because the contact area between the material and

the solvent increases as the size of the material decreases (Yusuff, 2021). Heat treatment, on the other hand,

increases the yield of extracted oil by destroying the oil cells, thereby

lowering the viscosity and moisture content of the oil and causing the flour

proteins to coagulate. It also inactivates enzymes in ingredients that may

affect the quality of the extracted oil (Evangelista, Isbell, and

Cermak, 2012). Treatment with water combined with

processing aids, such as enzymes and calcium carbonate (CaCO3), also

weakens the oily cell walls and helps prepare the plant matrix for optimal oil

extraction (Satriana et al., 2019). Squeo et al. (2016) reported that CaCO3

could be used as a coadjuvant to increase the extraction yield of extra

virgin olive oil. However, there was no clear trend regarding the impact on oil

quality. More recently, Arpi et al. (2023) reported

the effect of a precooking treatment with water and CaCO3 on the

properties of dried avocado pulp and its oil extract.

Solid–liquid extraction of avocado oil

is a multiphase and unsteady-state mass transfer process in which the solute

concentration in the solid is continuously varied. A model of avocado oil

extraction and an estimate of its extraction rate is necessary for analyzing

and designing extraction processes on an industrial scale. The available

literature contains limited information on the kinetics of avocado oil

extraction. This is likely due to the fact that many avocado oil manufacturers

still rely on traditional technology and may not prioritize process

optimization. Mgoma Basitere, and Mshayisa, (2021) studied the kinetics and

thermodynamics of oil extraction of Hass avocados from South Africa. Arimalala, Herve, and Rafihavanana (2022) reported

that the second-order kinetics model provides a good representation of the

experimental results of the oil extraction of avocados from Madagascar.

Understanding the kinetics of avocado oil extraction is essential for

conducting technical and economic analyses of the process. Kinetic knowledge

aids in fundamental comprehension of the process, allowing for better process

control and higher efficiency. Additionally, studying kinetics is crucial for

scaling up the process, as noted by Prihutami et

al. (2021).

Previous studies suggested that avocado

oil extraction could be improved using various pre-treatment methods (Arpi et al., 2023; Santana et al.,

2015). The novelty of this work resides in the investigation of the

kinetics of avocado oil extraction using raw material cooking pre-treatment and

the addition of a coadjuvant. To the best of the authors' knowledge, there is

little information in the published literature about the pre-treatment of raw

material using coadjuvant in avocado oil extraction processes. The primary goal

is to examine the solid–liquid extraction yield and kinetics of oil from dried

avocado flesh using hexane as a solvent. The experimental data obtained will be

compared to published kinetics models.

2.1. Materials

A fully ripe Hass avocado fruit was

obtained from agricultural resources in Central Aceh, Indonesia.

Analytical-grade hexane and CaCO3 of 99.95% purity were procured

from Merck (Indonesia). All compounds were utilized without further

purification.

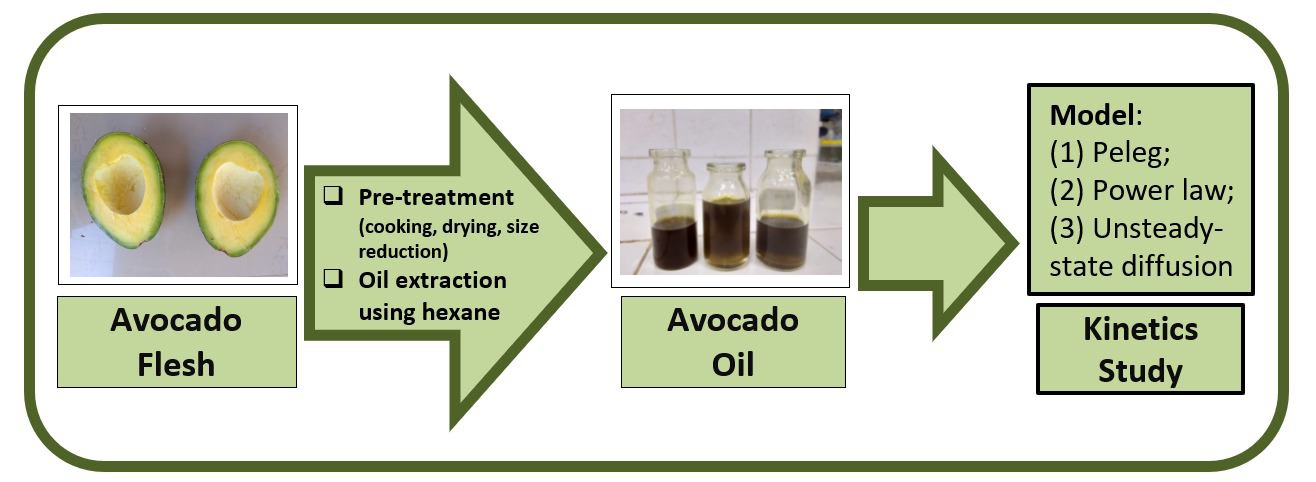

Figure 1 Schematic of the

experimental procedure.

2.2.1. Sample

Preparation

The experiment required approximately 8

kilograms of ripe avocado. Three different pre-treatment methods, as reported

by Arpi et al. (2023), were applied

to the avocado flesh. In the first sample group, the avocado flesh was cooked

in water. In the second sample group, the avocado flesh was cooked with water

containing 5% CaCO3 (w/w of flesh). The last sample group was

uncooked as a control. After completing the three pre-treatment methods, the

resulting dried avocado was shaped into two sizes: 8 mm × 5 mm × 5 mm and 1.19

mm.

2.2.2. Avocado

Oil Extraction

The influence of

the three pre-treatment methods (uncooked, cooked with CaCO3, and

cooked with water) and two material sizes (8 mm × 5 mm × 5 mm and 1.19 mm) on

the avocado oil yield were investigated in the first series of trials.

Evaluation of the extraction kinetics was carried out based on the highest

yield of avocado oil obtained in the first series of trials for the various

pre-treatment methods. The influence of temperature (25, 40, and 50°C) on the

extraction yield was investigated using the highest avocado oil yield obtained

in the first series of trials.

2.3. Kinetic Model of Avocado Oil Extraction

Various kinetic models have been developed

to describe the oil extraction mechanism. The phenomena of mass transfer

through solid plant materials and from their surfaces into the bulk of the

solvent are the basis for physical kinetic models. Several kinetic models for

avocado oil extraction have been reported, including second-order, Peleg,

logarithmic (Arimalala, Herve, and Rafihavanana 2022), first-order reaction, Fick's law, and Van't

Hoff's (Mgoma, Basitere, and Mshayisa, 2021). The most

frequently used models are based on film theory and the concept of

unsteady-state diffusion through particles. The Peleg model is an empirical and classical

hyperbolic model that was initially designed to describe moisture sorption

curves. The Peleg model has been modified and applied to represent the

solid–liquid extractions of numerous plant metabolites in general and in

phenolics, particularly due to the similarity between the extraction and

sorption curves (Milicevic et al., 2021).

2.3.1. Peleg

Model

The Peleg model can provide an accurate

estimation of the kinetics of the solid–liquid extraction process (Liao, Guo, and Yu, 2021). The mathematical model introduced by Peleg (Eq. [2]) was adopted as

the kinetic model for the extraction of plant material.

In Eq. (2), t

is the extraction time (min), C0 is the initial concentration

of avocado oil (g/g), Ct is the concentration of avocado oil

at t (g/g), k1 is Peleg’s rate constant (min.g/g), and

k2 is Peleg’s capacity constant (g/g). The constants k1

and k2 indicate the initial extraction rate and the maximum

solute concentration achieved during the process, respectively (Anbalagan et al., 2019). A modified Peleg

equation to plot solute concentration in the extraction solvent is presented in

Eq. (3).

2.3.2. Power Law Model

The

power law model (Eq. [4]) has previously been applied to the extraction process

(Natolino and Porto, 2020; Alara and Abdurahman,

2019).

In Eq. (4), Ct is the concentration (g/L) of avocado oil at any time

t (s), B denotes the extraction coefficient (L/g.s), and n denotes the power law exponent.

Equation (4) can be further simplified to Eq. (5).

Plotting ln Ct

against ln (t) gives n and ln B as the slope and intercept, respectively.

2.3.3. Unsteady-state

Diffusion Model

The unsteady-state

diffusion model was developed based on a solvent extraction technique that

included concurrent evaporation and diffusion processes. The model defined by

Eq. (6) contains two parameters: the quick oil extraction stage, represented by

b (evaporation coefficient), and the slow oil extraction stage,

represented by k (diffusion coefficient). This model can be applied to

simulate the oil extraction kinetics of any plant material.

In Eq. (6), q0 represents the initial oil content (g/g), q represents the oil yield (g/g) at time

t, b represents the evaporation coefficient, k represents the diffusion coefficient (1/min), and t represents the extraction period

(min). The linearized form of Eq. (7) can be used to determine b and k.

2.4. Activation Energy (Ea)

The

activation energy (Ea) is the minimum energy required to initiate the

extraction process (Abed et al., 2019),

and it can be calculated using the Arrhenius equation. Equation (8) presents

the correlation between the extraction rate constant (k) and the temperature of extraction (T).

where k

represents the diffusion coefficient (min-1), Ea represents

the activation energy (kJ/mol), A represents the Arrhenius constant (s-1),

T represents the absolute temperature (K), and R represents the

universal gas constant (kJ/mol.K). A linear relationship between ln k

and 1/T can be obtained (Eq. 9).

Plotting ln k

against 1/T gives -Ea/R and ln A as the slope and intercept, respectively.

3.1. Influence of Process

Variables

The avocado oil obtained from each experiment

was similar in appearance; it was dark green and had a distinctive viscosity.

The avocado oil yield was significantly affected by extraction time. Figure 2

depicts the influence of time on the oil yield for each pre-treatment method

and material size. There was a marked correlation between extraction time,

pre-treatment method, material size, and oil yield under the given conditions.

The avocado oil yield increased as the

extraction time increased. This was because longer extraction times led to

longer contact between the solvent and plant material, thereby increasing mass

transfer. The yield of oil increased significantly initially, then gradually

decreased as the extraction progressed. As shown in Figure 2, increasing the

extraction time after approximately 30 min did not further increase the oil

yield. It may be inferred that 30 min after extracting the material, the

remaining oil in the avocado was reduced to a minimum value. Many studies have

observed similar trends, such as in the extraction of alpha-glucosidase

inhibitors from lemongrass (Widiputri et al.,

2020) and the extraction of bioactive compounds from avocado seeds (Corral-Perez, and Almajano, 2016).

As expected, the yield increased as the material size decreased.

The oil yield obtained by material size 1.19 mm was higher than that obtained

by the 8 mm × 5 mm × 5 mm material. By reducing the size of the materials, the

surface area increases, which increases

the mass transfer of the active principle from the plant material to the

solvent and makes extraction more efficient. In addition, the extraction yield

increases because the dispersion distance of the solute in the solid decreases

when the particle size is small; therefore, a shorter time is required for the

solute to reach the surface. It should also be noted that very small particle

sizes can cause difficulties during the screening process (Makanjuola, 2017). Santos et al. (2015) discovered a similar pattern when

using ethanol as a solvent to extract oil from Jatropha curcas L.

However, as the size of the material increased, the influence of pre-treatment

on oil yield became more significant. It has been suggested that pre-treatment

of the material provides several advantages, such as easier penetration of the

solvent into the plant cell to release the oil from the cell (Arpi et al., 2023).

Figure 2 Influence of extraction time on avocado oil yield at various

extraction conditions (extraction temperature of 25°C; a solid-to-solvent ratio

of 1:15 g/mL; 400 rpm).

Figure 3 depicts the

influence of temperature on avocado oil yield. Extraction temperature was

critical to maximize the extraction yield, and the results obtained indicate

that the amount of oil extracted increased with extraction temperature. This

relationship was predicted because the driving force for extraction increases

as temperature increases. As the temperature increases, oil solubility and

solvent diffusivity increase, and the viscosity of both solute and solvent

decreases, facilitating mass transfer processes and resulting in a change in

oil yields (Mgoma, Basitere, and Mshayisa, 2021; Anbalagan et

al., 2019). Moreover, increased temperature promotes the

spread of oil and reduces its viscosity (Meziane

and Kadi, 2008).

Figure 3 Influence of temperature on avocado oil yield (experimental

conditions: cooking pre-treatment with water and material size 1.19 mm).

Figures

2 and 3 depict the time course of the change in avocado oil yield during the

extraction process for various process variables. There is a typical curve for

extracting oil from plants. Avocado oil extraction can

be divided into two stages: rapid oil extraction and slow oil extraction.

The rapid oil extraction stage occurred during the early stages of extraction,

during which oil was rapidly released and evaporated from the outer surface of

the plant material. During this time, the yield of avocado oil increased

rapidly. As the extraction process progressed, the extraction rate decreased

until a nearly constant oil yield was reached. During the slow oil extraction

stage, oil extraction was followed by slow molecular diffusion of the oil from

the undamaged cells to the surfaces of the plant materials. Oil production

slowed down because the oil spread slower. This mechanism was critical for

further extraction kinetics modeling. Some researchers, including Anbalagan et al. (2019) in the mangiferin

extraction from Mangifera indica

leaves and Santos et al. (2015) in

the oil extraction from Jatropha curcas,

reported a similar trend.

3.2. Kinetic Model of Avocado Oil Extraction

The kinetic model is a method used to

describe the process of mass transfer and diffusion in the extraction process (Alara and Abdurahman, 2019). Figure 4 displays

graphs of the kinetics of the Peleg, power law, and unsteady-state diffusion

models for various cooking pre-treatment methods. The slope and intercept of

each curve were utilized to calculate the kinetic parameters of each model and

are presented in Table 1.

The

coefficient of determination (R2)

was used to select the best mathematical model for avocado oil extraction (Arimalala, Hervé, and Rafihavanana, 2022).

In the present study, the unsteady-state diffusion model had the highest R2

value, indicating that this model provided the most accurate prediction of the

results of the extraction process. Both kinetic parameters of the

unsteady-state diffusion model were greater for the cooking pre-treatment than

for the control sample. These results are in line with the obtained oil yield

trend. It was also discovered that the value of k was less than the

value of b for all experimental variables, implying that the slow oil

extraction stage influenced the process rate. The coefficients for the rapid

oil extraction periods were 86–120 times larger than those for the slow oil

extraction periods, indicating that diffusion is much slower than evaporation.

This trend has also been reported for oil extraction from avocado seeds (Segovia, Corral-Perez, and Almajano, 2016) and sunflower seeds (Perez, Carelli, and Crapiste, 2011). The performance of an

extraction process can be represented by the k value. It was observed

that the increase in temperature led to an increase in extraction rate. The k

value obtained was comparable to those published in the available literature

for avocado oil extraction (Table 2).

Table 1 Kinetic parameter for Peleg, power law, and unsteady-state

diffusion models.

Figure 4 (A) Peleg model, (B) power law model, and

(C) unsteady-state diffusion model (experimental

conditions: material size 1.19 mm and extraction temperature of 50°C).

Table 2 Comparison

of kinetic model parameters for avocado oil extraction.

3.3. Activation Energy

Figure

5 depicts the relationship between k and 1/T. The estimated

Arrhenius parameters are presented in Table 3. The value of

R2 from the graph of ln k versus 1/T in Figure 5 is

0.9014, and the value of Ea was

calculated from the linear correlation between ln k and 1/T. The Arrhenius parameters of the process for

material size 1.19 mm and the cooking pre-treatment with water were 47.51

kJ/mol and 21,111,692 min-1 for Ea and A,

respectively. Table 3 provides a comparison of Ea values for various vegetable oils. It can be observed that the value

of Ea obtained is low and reasonable compared with the value reported in

the literature. A high Ea reduces the extraction process rate, while a

low Ea helps to increase the extraction process rate. The lower the Ea value, the less energy is required

for oil extraction to begin (Ramesh, Yasin, and

Arshad,

2020).

Furthermore, a positive Ea indicates that the process is endothermic (Rahma and Hidayat, 2023). The energy required to

overcome the endothermic nature of the process is provided by heating during

extraction. Previous work has demonstrated that Ea values of certain vegetable oils are in the range of 79 to 104

kJ/mol, indicating that they have varying fatty acid profiles (Tan et al., 2001). Oils with lower Ea values are expected to require higher

temperatures to trigger certain changes to the oxidation rate (Aktar and Adal, 2019).

Figure 5 Plot of ln k against

1/T to determine the activation energy.

Table 3 Comparison of the estimated activation energy of various vegetable

oils.

Kinetic studies contribute to a fundamental understanding of the

process and enable better process control and process scaling. In this study,

the solid-liquid extraction kinetics of dried avocado flesh using hexane as a

solvent was investigated. Experimental results showed that there was a clear

correlation between extraction time, pre-treatment method, material size,

extraction temperature and oil yield. Avocado oil extraction can be divided

into two stages, rapid oil extraction and slow oil extraction. The coefficients

for the rapid oil extraction stages were 86–120 times larger than those for the

slow oil extraction stages, suggesting that diffusion is much slower than

evaporation. Based on the magnitude of R2 values, the

unsteady-state diffusion model was shown to adequately represent the rate of

avocado oil extraction. A positive Ea value of 47.51 kJ/mol was

obtained, indicating that the extraction process is endothermic. This research

is necessary to develop and implement a complete and improved industrial

avocado oil extraction process.

The

authors are thankful for the support of the Universitas Syiah Kuala through Lektor Kepala

research grant (No. 145/UN11/SPK/PNBP/2022).

Abed, K.M., Kurji, B.M., Rashid, S.A., Abdulmajeed, B.A., 2019.

Kinetics and Thermodynamics of Peppermint Oil Extraction from Peppermint Leaves.

Iraqi Journal of Chemical and Petroleum

Engineering, Volume 20(4), pp. 1–6

Aktar, T., Adal, E., 2019. Determining the Arrhenius Kinetics of Avocado

Oil: Oxidative Stability under Rancimat Test Conditions. Foods, Volume 8(7), p. 236

Alara, O.R., Abdurahman, N.H., 2019. Microwave-assisted Extraction

of Phenolics from Hibiscus sabdariffa

Calyces: Kinetic Modelling and Process Intensification. Industrial Crops and Products, Volume 137, pp. 528–535

Anbalagan, K., Kumar, M.M., Ilango, K., Mohankumar, R., Priya,

R.L., 2019. Prelusive Scale Extraction of Mangiferin from Mangifera Indica Leaves: Assessing Solvent Competency, Process Optimization,

Kinetic Study and Diffusion Modelling. Industrial

Crops and Products, Volume 140, p. 111703

Arimalala, A.F., Herve, R.P.,

Rafihavanana, R., 2022. Modeling and Kinetics Study of Avocado Oil

Extraction from Madagascar Using Different Mathematical Models. South

African Journal of Chemical Engineering, Volume 41, pp. 93–97

Arpi, N., Satriana, Mustapha, W.A.W., Syamsuddin, Y., Putra, T.W.,

Supardan, M.D., 2023. Effect of Cooking Pre-Treatment on The Properties of

Dried Avocado Flesh and Its Oil Extract. South

African Journal of Chemical Engineering, Volume 43, pp. 1–8

Barros, H.D.F.Q., Coutinho, J.P., Grimaldi, R., Godoy, H.T.,

Cabral, F.A., 2016. Simultaneous Extraction of Edible Oil from Avocado and

Capsanthin from Red Bell Pepper Using Supercritical Carbon Dioxide as Solvent. Journal of Supercritical Fluids, Volume

107, pp. 315–320

dos Santos, M.A.Z., Alicieo, T.V.R., Pereira, C.M.P., Ramis-Ramos,

G., Mendonca, C.R.B., 2014. Profile of Bioactive Compound in Avocado Pulp Oil: Influence

of The Drying Processes and Extraction Methods. Journal of the American Oil Chemists’ Society, Volume 91, pp. 19–27

Evangelista, R.L., Isbell, T.A., Cermak, S.C., 2012. Extraction of Pennycress

(Thlaspi arvense L.) Seed Oil by Full Pressing. Industrial Crops and Products, Volume 37, pp. 76–81

Ge, Y., Dong, X., Liu, Y., Yang, Y., Zhan, R., 2021. Molecular and Biochemical

Analyses of Avocado (Persea Americana)

Reveal Differences in The Oil Accumulation Pattern Between The Mesocarp and

Seed During The Fruit Developmental Period. Scientia

Horticulturae, Volume 276, p. 109717

Liao, J., Guo, Z., Yu, G., 2021. Process Intensification and

Kinetic Studies of Ultrasound-Assisted Extraction of Flavonoids from Peanut

Shells. Ultrasonics Sonochemistry,

Volume 76, p. 105661

Makanjuola, S.A., 2017. Influence of Particle Size and Extraction

Solvent on Antioxidant Properties of Extracts of Tea, Ginger, and Tea–Ginger

Blend. Food Science & Nutrition, Volume 5, pp. 1179–1185

Meziane, S., Kadi, H., 2008. Kinetics and Thermodynamics of Oil

Extraction from Olive Cake. Journal of the American Oil Chemists' Society,

Volume 85, pp. 391–396

Mgoma, S.T., Basitere, M., Mshayisa, V.V., 2021. Kinetics and Thermodynamics

of Oil Extraction from South African Hass Avocados Using Hexane as A Solvent. South African Journal of Chemical

Engineering, Volume 37, pp. 244–251

Milicevic, N., Kojic, P., Sakac, M., Misan, A., Kojic, J.,

Perussello, C., Banjac, V., Pojic, M., Tiwari, B., 2021. Kinetic Modelling of

Ultrasound-Assisted Extraction of Phenolics from Cereal Brans. Ultrasonics

Sonochemistry, Volume 79, p. 105761

Natolino, A., Porto, C.D., 2020. Kinetic Models for Conventional and

Ultrasound Assistant Extraction of Polyphenols from Defatted Fresh and

Distilled Grape Marc and Its Main Components Skins and Seeds. Chemical Engineering Research and Design,

Volume 156, pp. 1–12

Perez, E.E., Carelli, A.A., Crapiste, G.H., 2011. Temperature-Dependent

Diffusion Coefficient of Oil from Different Sunflower Seeds during Extraction with

Hexane. Journal of Food Engineering,

Volume 105(1), 180–185

Prihutami, P., Sediawan, W.B., Prasetya, A., Petrus, H.T.B.M.,

2021. A Product Diffusion Model for The Extraction of Cerium and Yttrium from

Magnetic Coal Fly Ash Using Citric Acid Solution. International Journal of Technology, Volume 13(4), pp. 921–930

Rahma, F.N., Hidayat, A., 2023. Biodiesel Production from Free

Fatty Acid Using Zro2/Bagasse Fly Ash Catalyst. International Journal of Technology, Volume 14(1), pp. 206–218

Ramesh, N., Yasin, N.M., Arshad, Z.M., 2020. Kinetics Studies and

Thermodynamics of Oil Extraction from Immobilized Microalgae Cells of Chlorella Vulgaris: The Effect of The

Different Matrix System. IOP Conference

Series: Materials Science and Engineering, Volume 991, p. 012003

Santana, I., dos Reis, L.M., Torres, A.G., Cabral, L.M. and

Freitas, S.P., 2015. Avocado (Persea americana Mill.) Oil Produced by

Microwave Drying and Expeller Pressing Exhibits Low Acidity and High Oxidative

Stability. European Journal of Lipid

Science and Technology, Volume 117 (7), pp. 999–1007

Santos, S.B., Martins, M.A., Caneschi, A.L., Aguilar, P.R.M.,

Coimbra, J.S.R., 2015. Kinetics and Thermodynamics of Oil Extraction from Jatropha Curcas L. Using

Ethanol as A Solvent. International

Journal of Chemical Engineering, Volume 2015, p. 871236

Satriana, Supardan, M.D., Arpi, N., Mustapha, W.A.W., 2019.

Development of Methods Used in The Extraction of Avocado Oil. European Journal of Lipid Science and

Technology, Volume 121, p. 1800210

Segovia, F.J., Corral-Pérez, J.J., Almajano, M.P., 2016. Avocado Seed:

Modeling Extraction of Bioactive Compounds. Industrial

Crops and Products, Volume 85, pp. 213–220

Squeo, G., Silletti, R., Summo, C., Paradiso, V.M., Pasqualone, A.,

Caponio, F., 2016. Influence of Calcium Carbonate on Extraction Yield and

Quality of Extra Virgin Oil from Olive (Olea europaea L. cv. Coratina). Food

Chemistry, Volume 209, pp. 65–71

Supardan, M.D., Misran, E., Mahlizar, Satriana, Mustapha,

W.A.W., 2019. Effect of Material Length on Kinetics of Essential Oil

Hydrodistillation from Lemongrass (Cymbopogon

citratus). Journal of Engineering

Science and Technology, Volume 14(2), pp. 810–819

Tan, C.P., Che Man, Y.B., Selamat, J., Yusoff, M.S.A., 2001. Application of

Arrhenius Kinetics to Evaluate Oxidative Stability in Vegetable Oils by Isothermal Differential Scanning Calorimetry. Journal of the American Oil

Chemists' Society, Volume 78(11), pp. 1133–1138

Widiputri, D.I., Julisantika, I., Kartawiria, I.S., Gunawan-Puteri,

M.D.P.T. Ignatia, F., 2020. Upscaling the Cymbopogon

Citratus (Lemongrass) Extraction Process to Obtain Optimum

Alpha-Glucosidase Inhibitor (AGI) Levels. International Journal of Technology, Volume 11(3), pp.532–543

Yusuff, A.S., 2021. Parametric Optimization of Solvent Extraction of

Jatropha Curcas Seed Oil Using Design of Experiment and Its Quality

Characterization. South African Journal

of Chemical Engineering, Volume 35, pp. 60–68