The Effect of Gas Flow Rate, Solid-To-Solvent Ratio, and Temperature on Micro-Carbon Synthesis from Pine Resin using Spray Pyrolysis and The Application as Masks Coating Material

Corresponding email: yessie.sari@apps.ipb.ac.id

Published at : 28 May 2025

Volume : IJtech

Vol 16, No 3 (2025)

DOI : https://doi.org/10.14716/ijtech.v16i3.6252

Jayadi, J, Widayatno, WB, Wismogroho, AS, Mulya, MAJ, Maddu, A & Sari, YW 2025, ‘The effect of gas flow rate, solid-to-solvent ratio, and temperature on micro-carbon synthesis from pine resin using spray pyrolysis and the application as masks coating material’, International Journal of Technology, vol. 16, no. 3, pp. 949-959

| Jayadi Jayadi | 1. Department of Physics, Faculty of Mathematics and Natural Sciences, IPB University, Bogor, 16680, Indonesia. 2. National Research and Innovation Agency, Tangerang Selatan, 15310, Indonesia |

| Wahyu B. Widayatno | National Research and Innovation Agency, Tangerang Selatan, 15310, Indonesia |

| Agus S. Wismogroho | National Research and Innovation Agency, Tangerang Selatan, 15310, Indonesia |

| Marga A. J. Mulya | National Research and Innovation Agency, Tangerang Selatan, 15310, Indonesia |

| Akhiruddin Maddu | Department of Physics, Faculty of Mathematics and Natural Sciences, IPB University, Bogor, 16680, Indonesia |

| Yessie W. Sari | Department of Physics, Faculty of Mathematics and Natural Sciences, IPB University, Bogor, 16680, Indonesia |

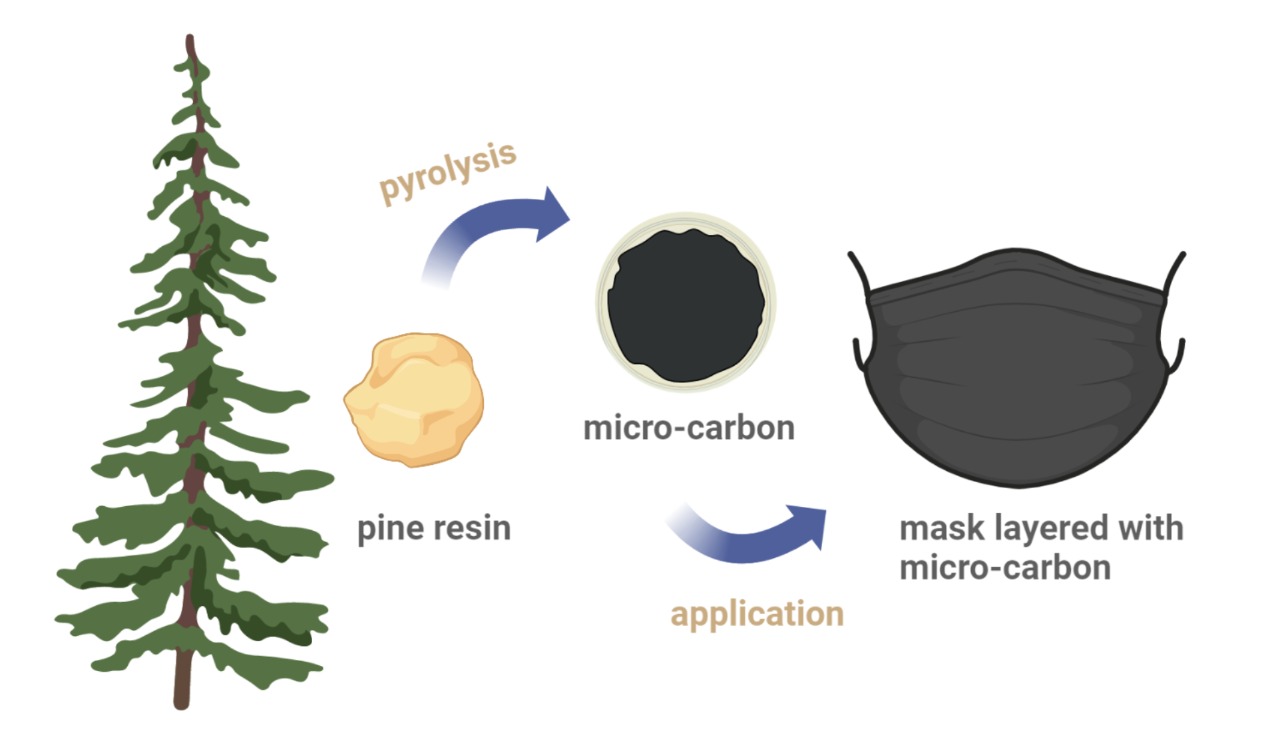

This study aims to develop

an additional layer in masks using micro-carbon to enhance protection against

inhalation of droplets. Carbon microstructures were obtained using spray

pyrolysis method, with the precursor being resina colophonium dissolved in acetone

and ethyl acetate. Subsequently, the effect of varying the precursor-solvent

ratio, heating temperature, and nitrogen flow rate on the shape, size, and

content of the products was assessed. The results showed that the highest

carbon content achieved was approximately 96%, with the smallest size measuring

139 nm. The penetration test results after applying the product on masks fabric

revealed a significant reduction in penetration up to level 2. In addition, the

contact angle test showed that the addition of carbon led to a lower reduction

(6.7°) compared to regular masks fabric with a 20.4° decrease. This improvement

could contribute to reducing the risk of droplet inhalation during masks

application.

Carbon; Mask; Penetration level; Resina colophonium; Spray pyrolysis

Severe acute

respiratory syndrome coronavirus 2 (SARS-CoV2) is primarily transmitted through

the inhalation of aerosol particles or droplets containing the virus, which are

emitted during breathing and speaking

According to

previous studies, carbon-based precursor materials are traditionally

synthesized using a solution of methanol (Fang et al., 2018), benzene (Melati and

Hidayati, 2016), xylene (Singhal et al., 2019), or toluene (Khabushev et al.,

2022) derived from fossil fuels. However, the limited nature of these

resources

In line with

these results, Liu et al. conducted a study on the ultrasonic spray pyrolysis

method for synthesizing nitrogen-doping carbon nanotubes. The procedures were

carried out at injection rates of 0.25, 0.5, and 0.75 ml/minute, while the gas

flow rate at each inlet was maintained at 150 sccm

2.1. Materials

Pine resin (resina colophonium), which was essential for the

experiments, was obtained from the local market. The solvents used were acetone

(pro analysis 99.75%, Mallinckrodt Chemicals) and ethyl acetate (pro analysis

99.8%, Merck KGaA).

2.2. Micro-Carbon Preparation

Micro-carbon

materials, which were crucial for the study, were obtained through spray

pyrolysis of pine resin. In this process, pine resin was dissolved in either

acetone (GAC) or ethyl acetate (GEA). Pine resin was firstly crushed by a Hamer

mill (5000 rpm German) until it reached a size of 60 mesh to facilitate the

dissolving process.

The

in-house spray pyrolysis was utilized for the experiment. This instrument was

configured to allow the precursor (GAC or GEA) into the inlet, atomized, and

subsequently conveyed into a heating reactor with the aid of nitrogen gas.

During the heating process, pine resin underwent decomposition, which yielded

carbon granules that were deposited onto a 1000-wire mesh positioned at the

outlet of the heating reactor. Spray pyrolysis was set for 20 minutes for each

variation. This study involved varying the ratio of pine resin to

solvent and adjusting the nitrogen gas flow rate during micro-carbon synthesis.

Specifically, the ratios of pine resin to solvent were set at 1:4, 1:8, and

1:16 (g/ml). The heating temperature was varied at 800, 1000, and 1200°C, while

the nitrogen gas flow rates were adjusted to 0.5, 1, and 1.5 liter/minute.

These parameters were selected to achieve the highest percentage of carbon

content while maintaining a smooth carbon surface to repel droplets.

2.3. Application of Micro-Carbon as Mask Layer

Polypropylene

sheet, which was a common medical mask, (80 x 80 cm), was used as masks.

Micro-carbon was deposited on this sheet using vacuum chambers with a volume of

1 liter (VC1621SG, VacuumChambers.ue., Poland).

Before deposition, the product was first dissolved in acetone with a

ratio of 0.3 g/ml. The dissolved micro-carbon was placed in the vacuum chamber

at around 25 ± 2°C and under a pressure of 50 kPa for 30 minutes. Micro-carbon

coated masks were further dried using the conventional oven at 60°C for 24

hours

2.4. Sample Characterization

2.4.1. Morphological Analysis

The synthesized micro-carbon

powder was separated from the surface of wire mesh 1000 for morphological

analysis using Field Emission Scanning Electron Microscopy (FESEM, JIB-4610F,

Jeol Ltd Japan). Images obtained from FESEM were further analyzed using ImageJ

to obtain the average particle size. As many as 20 particles were evaluated to

obtain this parameter, FESEM analysis was also combined with energy-dispersive

X-ray spectroscopy to evaluate the carbon content.

2.4.2. Penetration

Test

Penetration test was performed according to

ISO 16603:2004 about measuring the penetration resistance of clothing materials

to blood and body fluids. There were 6 pressure levels involved in this test

(Table 1), and to imitate saliva penetration on a surface, chicken egg white

was utilized as it was considered to have a surface tension close to saliva.

The surface tension of egg white without yolk contamination was 50 mN/m

The penetration test was conducted by applying varying pressure levels

after egg white was applied to the test samples. The test was terminated once

egg white penetrated through the test sample. When penetration did not occur,

the test proceeded to the next level by increasing the pressure. Table 2 listed

samples involved in this study.

Table 1

Test level in penetration test

and waiting time for each level

|

Level |

Pressure (kPa) |

Time (Minutes) |

|

1 |

0 |

5 |

|

2 |

1.75 |

|

|

3 |

3.5 |

|

|

4 |

7 |

|

|

5 |

14 |

|

|

6 |

20 |

2.4.3. Contact Angle

Test

Assessing the absorption property of masks coated with micro-carbon

involved conducting contact angle test on the samples. This test entailed

dropping a liquid onto the test samples, capturing an image of the sample, and

observing the angle formed between the liquid and the sample

Table 2 Sheet samples code used

|

Code |

Sample |

|

PS sample |

polypropylene sheet

without any coating |

|

PAC sheet |

commercial polypropylene

sheet coated with activated carbon |

|

GAC sheet |

polypropylene sheet coated

with carbon dissolved in GAC |

|

GEA sheet |

polypropylene sheet coated

with carbon dissolved in GEA |

3.1. Micro-Carbon

Synthesis: Effect of Solid-To-Solvent Ratio

The

morphologies of micro-carbon resulting from pyrolysis at 1000°C with various

solid-to-solvent ratios (1:4, 1:8, and 1:16) were shown in Figure 1. FESEM results

indicated that micro-carbon particles had round and smooth surfaces. In this

test, the value of carbon content in the sample could also be known. As shown

in Table 3, all samples were rich in carbon content with a value of more than

90%. The highest carbon content was obtained in samples from GAC precursors

with a composition ratio of 1:8, which reached 96.8% wt.

Figure 1 FESEM images of micro-carbon particles size

obtained with pine resin solvent ratio of (a) 1:4 (b) 1:8 (c) 1:16 from GAC

samples and (d) 1:4 (e) 1:8 (f) 1:16 from GEA samples

Particle size could

be determined quantitatively based on the measuring scale performed on FE-SEM

test results. Micro-carbon of GAC samples had a smaller particle size than

micro-carbon from GEA samples (Figure 2). Micro-carbon from precursor GAC with

pine resin to acetone ratio of 1:8 had the smallest average particle size,

which was 0.12 µm. Figure 2 showed the normal

distribution, the average value (µ), and the standard deviation (?) of all samples. The

distribution of carbon diameter of GAC samples indicated less distribution

compared to GEA counterpart. This could be due to the agglomeration of crushed

pine resin in ethyl acetate. Previous studies indicated that agglomeration in

ethyl acetate was quicker to form rather than in ethanol

Table 3 Carbon content in samples with pine resin to solvent ratio

|

Pine resin to solvent

ratio |

Relative carbon content (%

wt) | |

|

GAC |

1:4 |

95.625 |

|

1:8 |

96.862 | |

|

1:16 |

96.525 | |

|

GEA |

1:4 |

96.275 |

|

1:8 |

96.037 | |

|

1:16 |

96.337 |

Figure 2

Particle size distribution of GAC and GEA from 20 particles of each sample

3.2. Micro-Carbon

Synthesis: Effect of Pyrolysis Temperature

Figure 3, the

measurement scale of FE-SEM test resulting from carbon samples synthesized at

various heating temperatures with GAC at pine resin to solvent ratio of 1:16

and a nitrogen gas flow rate of 1 liter/minute. Additionally, it was observed

that synthesis at 800°C resulted in micro-carbon with the lowest particle size,

0124 ± 0.008 µm. However, the particle sizes in these samples were observed to

have a heterogeneous morphology. An improved morphology heterogeneity was

observed at micro-carbon obtained from pyrolysis at 1000 and 1200°C (Figures 3b

and c, respectively). Micro-carbon synthesized at 1200°C had the highest

particle size homogeneity, and the particle surface had an imperfection. Figure

3c showed that the surface of these particles was not smooth, and the

distribution of particle size was obtained from various pyrolysis temperatures.

Pyrolysis

temperature also influenced the content of the resulting carbon, and the sample

at a synthesis temperature of 1000°C had the highest carbon content, reaching

96.5% wt (Table 4). The increase in carbon content at 1000oC and

1200oC compared to 800oc reflected the increasing degree

of carbonization

3.3. Micro-Carbon

Synthesis: Effect of Nitrogen Flow

Table

5 showed that samples synthesized at 1200°C had similar carbon content to the

sample at 1000°C but had bigger particle sizes (Figure 6) and rougher surfaces

(Figure 5). Exploring whether adjusting the nitrogen gas flow rate could

improve either carbon content, particle size, or surface characteristics, the

nitrogen flow rate variation test was conducted on GAC 1:16 sample heated at

1200°C.

Figure 3 FESEM images of GAC samples obtained from pine resin, a solvent ratio of 1:16, nitrogen gas flow rate of 1 liter/minute, and synthesis temperature, (a) 800°C, (b) 1000°C, and (c) 1200°C

Figure

4 Particle size distribution of GAC precursor

1:16 with nitrogen gas flow rate of 1 liter/minute at

a varied synthesis temperature

Table

4 Carbon content in samples of GAC 1:16 precursors

with variations in synthesis temperature

|

Synthesis

temperature (°C) |

Relative

carbon content (% wt) |

|

800 |

92.475 |

|

1000 |

96.525 |

|

1200 |

96.275 |

Based on the image

processing of FESEM images, the smallest particle size was formed at a flow

rate of 0.5 liter/minute, which was 0.167 ± 0.008 µm. All carbon materials were

synthesized at a pyrolysis temperature of 1200°C with varied nitrogen flow

rates showing rough surfaces as shown in Figure 5.

Table 5 Carbon content in samples from GAC 1:16

precursors with a synthesis temperature of 1200°C and variations in nitrogen

flow rate

|

Nitrogen flow rate (liter/ minute) |

Relative carbon content

(at%) |

|

0.5 |

14.48 |

|

1 |

96.28 |

|

1.5 |

97.15 |

An

interesting observation was made regarding the significant influence of

nitrogen flow rate on the carbon content of the samples. As shown in Table 5,

at a nitrogen flow rate of 0.5 l/minute, micro-carbon with a content of 14.48%

wt was obtained, suggesting the presence of volatiles that acted as catalysts

for secondary reactions, potentially reducing carbon yield

Figure

5 Carbon particle size of GAC precursor 1:16 with

synthesis temperature 1200°C and nitrogen gas flow rate (a) 0.5 liter/minute

(b) 1 liter/minute (c) 1.5 liter/minute

3.4. Application of

Micro-Carbon as Masks Layer

Both GAC and GEA micro-carbon obtained at pine resin to solvent ratio of 1:8, 1000°C pyrolysis temperature, and 1 liter/minute of nitrogen flow rate were tested for their application as masks coating materials. The selection was based on the data discussed in sections 3.1, 3.2, and 3.3, indicating that at this condition, the product had the smallest particle size, the smoothest surface, and the highest carbon content. The small particle size was preferred as micro-carbon particles were expected to be able to close the gap in polypropylene sheet.

Figure

6 Particle size distribution of GAC precursor 1:16

with synthesis temperature 1200°C and varied nitrogen gas flow rate

Figures 7 a, b, c, and d showed the dropped

water on polypropylene sheet coated with the product, and the yellow line on

these figures indicated the contact angle. Observations were conducted for 1

hour and contact angle data were recorded every 10 minutes. Table 6 indicated

the data from the contact angle observations. Based on the data in Figure 8a,

all samples had initial contact angles above 90°, indicating that all paper

masks were hydrophobic

The

contact angle was observed to decrease along with the observation time.

Comparison between all samples in this test at minute 0 and minute 60 could be

seen in Figure 8b. A significant decrease was experienced by PS sample, from an

initial contact angle of 118.221° to 97.802° (20.4° difference). The least

decrease in contact angle was experienced in GAC sheet from 121.530° to

114.744° (6.786° difference). This indicated that the presence of a carbon

layer on polypropylene sheet could reduce or slow down the absorption process.

GEA sheet had less performance in this test (10.8° drop from 120.4°) compared

to GAC sheet. This result designated that the difference in size affected the

results of this test. PAC sheet, which was polypropylene coated with commercial

activated carbon, had a higher contact angle drop from 118.852° to 101.162°

(17.69° difference) compared to polypropylene coated with GAC and GEA

micro-carbon. Activated carbon was generally used as an adsorbent which relied

on the porous surface

The

contact angle was observed to decrease along with the observation time.

Comparison between all samples in this test at minute 0 and minute 60 could be

seen in Figure 8b. A significant decrease was experienced by PS sample, from an

initial contact angle of 118.221° to 97.802° (20.4° difference). The least

decrease in contact angle was experienced in GAC sheet from 121.530° to

114.744° (6.786° difference). This indicated that the presence of a carbon

layer on polypropylene sheet could reduce or slow down the absorption process.

GEA sheet had less performance in this test (10.8° drop from 120.4°) compared

to GAC sheet. This result designated that the difference in size affected the

results of this test. PAC sheet, which was polypropylene coated with commercial

activated carbon, had a higher contact angle drop from 118.852° to 101.162°

(17.69° difference) compared to polypropylene coated with GAC and GEA

micro-carbon. Activated carbon was generally used as an adsorbent which relied

on the porous surface

Figure 7 Initial contact angle for (a) PS sample, (b)

PAC sheet, (c) GEA sheet, (d) GAC sheet

In Table 6, presented below, the result of the

penetration test showed that both PS sample and PAC sheet were effectively

penetrated by egg white at level 1 or without any pressure applied. Activated

carbon coated on polypropylene sheet proved unable to withstand the penetration

of egg white in the test. This could occur because the pores in the activated

carbon could serve as a pathway for egg white to penetrate the sheet.

Table 6 Penetration test results for all samples and carbon weight applied

|

Test

Sample |

Carbon

weight (g) |

Penetration

level |

Pressure

(kPa) |

|

PS

sample |

- |

Level

1 |

0 |

|

PAC

sheet |

n.d |

Level

1 |

0 |

|

GAC

sheet |

0.0043 |

Level

1 |

0 |

|

0.0150 |

Level

1 |

0 | |

|

0.0167 |

Level

2 |

1.75 | |

|

GEA

sheet |

0.0044 |

Level

1 |

0 |

|

0.0166 |

Level

2 |

1.75 | |

|

0.0206 |

Level

3 |

3.5 |

Figure 8 Contact angle test data (a) taken every 10 minutes for 1 hour, (b) test data distribution after 20 measurements at minutes 0 and 60

Penetration was also experienced by both GAC and GEA

sheets. However, it was observed that a pressure of min 1.75 kPa was required

to let egg white penetrate these sheets. This result showed the potential of

micro-carbon synthesized from pine resin as masks coating materials. At GEA

sheet, it was observed that an increase in the mass of the product resulted in

an increase in required pressure for the egg white penetration. This indicated

that the amount of micro-carbon had an effect on masks adsorption properties.

Therefore, further studies were needed to evaluate the optimum micro-carbon

mass required for the optimum adsorption.

In conclusion, the study analysis indicated that

micro-carbon was successfully synthesized using a mixture of resina colophonium

mixed with acetone and ethyl acetate as solvents. The precursor composition,

synthesis temperature, and nitrogen flow rate played significant roles in

shaping the size, and carbon content during spray pyrolysis method.

Specifically, a 1:8 ratio of resina colophonium to acetone resulted in

particles measuring 139 nm with a carbon content of 96.682%, while the same

ratio with ethyl acetate produced larger particles (301 nm) with a slightly

lower content of 96.037%. Furthermore, coating polypropylene sheets with the

product led to improved performance. This was evidenced by superior contact

angle and penetration test results compared to non-coated and commercially

coated sheets. The addition of micro-carbon effectively reduced the risk of

droplet inhalation.

The authors are grateful to the National Research and Innovation Agency for the facilities and funding provided with contract number B-392/III/HK.01.00/2/2022.

Author

Contributions

All authors contributed to the study conception and design. Material preparation and data collection were performed by Jayadi, Wahyu B. Widayatno and Agus S. Wismogroho. The first draft of the manuscript was written by Jayadi and Marga A. J. Mulya. Akhiruddin Maddu and Yessie W. Sari carried out thorough data analysis and interpretation. All authors commented on previous versions of the manuscript.

Conflict of Interest

The authors declare that they have no known competing financial interests

or personal relationships

that could have appeared to influence the work reported in this paper.

Afre, RA, Soga,

T, Jimbo, T, Kumar, M, Ando, Y, Sharon, M, Somani, PR & Umeno, M 2006,

'Carbon nanotubes by spray pyrolysis of turpentine oil at different

temperatures and their studies', Microporous and Mesoporous Materials,

vol. 96, no. 1–3, pp. 184–190, https://doi.org/10.1016/j.micromeso.2006.06.036

Anfinrud, P,

Stadnytskyi, V, Bax, CE & Bax, A 2020, 'Visualizing speech-generated oral

fluid droplets with laser light scattering', New England Journal of Medicine,

vol. 382, no. 21, pp. 2061–2063, https://doi.org/10.1056/NEJMc1913036

Aristri, MA,

Lubis, MAR, Laksana, RPB, Falah, F, Fatriasari, W, Ismayati, M, Wulandari, AP,

Nurindah, N & Ridho, MR 2021, 'Bio-polyurethane resins derived from liquid

fractions of lignin for the modification of ramie fibers', Jurnal Sylva

Lestari, vol. 9, no. 2, article 223, http://dx.doi.org/10.23960/jsl29223-238

Chatterjee, R,

Sajjadi, B, Chen, WY, Mattern, DL, Hammer, N, Raman, V & Dorris, A 2020,

'Effect of pyrolysis temperature on physicochemical properties and

acoustic-based amination of biochar for efficient CO2 adsorption', Frontiers

in Energy Research, vol. 8, article 85, https://doi.org/10.3389/fenrg.2020.00085

Cheng, Y, Ma, N,

Witt, C, Rapp, S & Wild, PS, Andreae, MO, Pöschl, U, & Su, H 2021,

'Face masks effectively limit the probability of SARS-CoV-2 transmission', Science,

vol. 372, no. 6549, pp. 1439–1443, https://doi.org/10.1126/science.abg6296

Dizbay-Onat,

M 2023, 'Evaluation of physical adsorption properties of the activated carbon

layers used in the commercial face mask inserts', Eng, vol. 4, no. 1,

pp. 434–443, https://doi.org/10.3390/eng4010026

Efiyanti,

L, Rifa'i, FA, Maslahat, M, Indrawan, DA, Wibowo, S, Darmawan, S, Pari, R,

Pasaribu, G, Rahmila, YI, Agustarini, R, Aswandi, A, Kholibrina, CR, Santoso,

A, Djarwanto, Komarayati, S, Gusmalina, Pari, G & Hendra, D 2023,

'CO/activated carbon from Paraserianthes falcataria as a green catalysts for

plastic waste pyrolysis', RASAYAN Journal of Chemistry, vol. 16, no. 3,

pp. 1149–1162, https://doi.org/10.31788/RJC.2023.1638347

Fang,

R, Huang, H, Ji, J, He, M, Feng, Q, Zhan, Y & Leung, DY 2018, 'Efficient

MnOx supported on coconut shell activated carbon for catalytic oxidation of

indoor formaldehyde at room temperature', Chemical Engineering Journal,

vol. 334, pp. 2050–2057, https://doi.org/10.1016/j.cej.2017.11.176

Gittings,

S, Turnbull, N, Henry, B, Roberts, CJ & Gershkovich, P 2015,

'Characterisation of human saliva as a platform for oral dissolution medium

development', European Journal of Pharmaceutics and Biopharmaceutics,

vol. 91, pp. 16–24, https://doi.org/10.1016/j.ejpb.2015.01.007

Harahap,

M, Daulay, N, Zebua, D & Gea, S 2023, 'Nanofiber cellulose/lignin from oil

palm empty fruit bunches and the potential for carbon fiber precursor prepared

by wet-spinning', International Journal of Technology, vol. 14, no. 1,

pp. 152–161, https://doi.org/10.14716/ijtech.v14i1.5082

Ionescu,

MI, Zhang, Y, Li, R, Sun, X, Abou-Rachid, H, & Lussier, LS 2011,

'Hydrogen-free spray pyrolysis chemical vapor deposition method for the carbon

nanotube growth: Parametric studies', Applied Surface Science, vol. 257,

no. 15, pp. 6843–6849, https://doi.org/10.1016/j.apsusc.2011.03.011

Jayadi,

Widayatno WB, Wismogroho AS, Firdharin C, Maddu, A, Alatas, H & Sari, YW

2024, 'Effect of precursor solvent on the carbon micro-structures derived from

spray pyrolysis of pine resin (gondorukem): Preliminary study', Jurnal Sains

Materi Indonesia, vol. 25, no. 2, pp. 67–76, https://doi.org/10.55981/jsmi.2024.893

Khabushev,

EM, Krasnikov, DV, Goldt, AE, Fedorovskaya, EO, Tsapenko, AP, Zhang, Q,

Kauppinen, EI, Kallio, T & Nasibulin, AG 2022, 'Joint effect of ethylene

and toluene on carbon nanotube growth', Carbon, vol. 189, pp. 474–483, https://doi.org/10.1016/j.carbon.2021.12.052

Li, X, Wang, Y, Lv, J & Yang, Y 2022,

'Investigations of foaming, interfacial and structural properties of

dispersions, batters and cakes formed by industrial yolk-contaminated egg white

protein', LWT, vol. 154, pp. 1–9, https://doi.org/10.1016/j.lwt.2021.112776

Liu,

J, Zhang, Y, Ionescu, MI, Li, R & Sun, X, 2011, 'Nitrogen-doped carbon

nanotubes with tunable structure and high yield produced by ultrasonic spray

pyrolysis', Applied Surface Science, vol. 257, no. 17, pp. 7837–7844, https://doi.org/10.1016/j.apsusc.2011.04.041

Melati,

A, & Hidayati, E 2016, 'Synthesis and characterization of carbon nanotube

from coconut shells activated carbon', Journal of Physics: Conference Series,

vol. 694, article 012073, https://doi.org/10.1088/1742-6596/694/1/012073

Miranda, J, Partal, P, Cordobés, F & Guerrero,

A, 2002, ‘Rheological characterization of egg yolk processed by spray-drying

and lipid-cholesterol extraction with carbon dioxide’, Journal of the

American Oil Chemists Society, vol. 79, no. 2, pp. 183-190

Papaioannou,

N, Marinovic, A, Yoshizawa, N, Goode, AE, Fay, M, Khlobystov, A, Titirici, MM

& Sapelkin, A 2018, 'Structure and solvents effects on the optical

properties of sugar-derived carbon nanodots', Scientific Reports, vol.

8, no. 1, article 6559, https://doi.org/10.1038/s41598-018-25012-8

Park,

J-S, Kim, JK, Hong, JH, Cho, JS, Park, S-K & Kang, YC 2019, 'Advances in

the synthesis and design of nanostructured materials by aerosol spray processes

for efficient energy storage', Nanoscale, vol. 11, no. 41, pp.

19012–19057, https://doi.org/10.1039/C9NR05575D

Politaeva,

N, Taranovskaya, E, Mukhametova, L, Ilyashenko, S, Atamanyuk, I, Al Afif, R,

& Pfeifer, C 2020, 'Cotton fiber and carbon materials filters for efficient

wastewater purification', International Journal of Technology, vol. 11,

no. 8, pp. 1608-1617, https://doi.org/10.14716/ijtech.v11i8.4538

Rashidi,

NA, & Yusup, S 2019, 'Production of palm kernel shell-based activated

carbon by direct physical activation for carbon dioxide adsorption', Environmental

Science and Pollution Research, vol. 26, no. 33, pp. 33732–33746, https://doi.org/10.1007/s11356-018-1903-8

Reza,

MS, Hasan, ABMK, Ahmed, AS, Afroze, S, Bakar, MSA, Islam, SN & Azad, AK

2021, 'COVID-19 prevention: Role of activated carbon', Journal of

Engineering and Technological Sciences, vol. 53, no. 4, pp. 628–638, https://doi.org/10.5614/j.eng.technol.sci.2021.53.4.4

Rucitra,

AL & Amna, AUF 2021, 'Integration of statistical quality control (SQC) and

fault tree analysis (FTA) in the quality control of resina colophonium

production in company X', In: IOP Conference Series: Earth and

Environmental Science, vol. 924, no. 1, article 012062, https://doi.org/10.1088/1755-1315/924/1/012062

Shukla,

S, Bhattacharjee, S, Weber, AZ & Secanell, M 2017, 'Experimental and

theoretical analysis of ink dispersion stability for polymer electrolyte fuel

cell applications', Journal of The Electrochemical Society, vol. 164,

no. 6, pp. F600–F609, https://doi.org/10.1149/2.0961706jes

Singhal,

S, Dixit, S & Shukla, AK 2019, 'Structural analysis of carbon nanospheres

synthesized by CVD: An investigation of surface charges and its effect on the

stability of carbon nanostructures', Applied Physics A, vol. 125,

article 80, https://doi.org/10.1007/s00339-018-2372-0

Song,

L 2019, The overview of today’s pine chemical industry in China, Pine

Chemicals Association, Vancouver

Suhas,

Gupta, VK, Carrott, PJM, Singh, R, Chaudhary, M & Kushwaha, S 2016,

'Cellulose: A review as natural, modified and activated carbon adsorbent', Bioresource

Technology, vol. 216, pp. 1066–1076, https://doi.org/10.1016/j.biortech.2016.05.106

Sujiono,

EH, Zabrian, D, Zharvan, V & Humairah, NA 2022, 'Fabrication and

characterization of coconut shell activated carbon using variation chemical

activation for wastewater treatment application', Results in Chemistry,

vol. 4, article 100291, https://doi.org/10.1016/j.rechem.2022.100291

Sukumar,

V, Manieniyan, V, Senthilkumar, R & Sivaprakasam, S 2020, 'Production of

bio oil from sweet lime empty fruit bunch by pyrolysis', Renewable Energy,

vol. 146, pp. 309–315, https://doi.org/10.1016/j.renene.2019.06.156

Sulistya,

EH, Hui-Hui, L, Attenborough, NK, Pourshahrestani, S, Kadri, NA, Zeimaran, E,

Razak, NAbA, Horri, BA & Salamatinia, B 2020, 'Hydrothermal synthesis of

carbon microspheres from sucrose with citric acid as a catalyst:

Physicochemical and structural properties', Journal of Taibah University for

Science, vol. 14, no. 1, pp. 1042–1050, https://doi.org/10.1080/16583655.2020.1794566

Ueki,

H, Furusawa, Y, Iwatsuki-Horimoto, K, Imai, M, Kabata, H, Nishimura, H &

Kawaoka, Y, 2020, 'Effectiveness of face masks in preventing airborne

transmission of SARS-CoV-2', mSphere, vol. 5, no. 5, article e00637-20, https://doi.org/10.1128/msphere.00637-20

Vishwanathan,

LG, Bhowmik, S & Sharon, M 2018, 'Natural precursors for synthesis of

carbon nano materials by chemical vapor deposition process: A review', International

Journal of Science and Research, vol. 7, no. 2, pp. 1475–1485, https://doi.org/10.21275/ART2018338

Wang,

M, Wang, Q, Li, T, Kong, J, Shen, Y., Chang, L, Xie, W & Bao, W, 2021,

‘Catalytic upgrading of coal pyrolysis volatiles by porous carbon materials

derived from the blend of biochar and coal’, ACS Omega, vol. 6, no. 5, pp.

3800–3808

Whulanza,

Y, Supriadi, S, Chalid, M, Kreshanti, P, Agus, AA, Napitupulu, P, Supriyanto,

JW, Rivai, E & Purnomo, A 2020, 'Setting acceptance criteria for a national

flocked swab for biological specimens during the COVID-19 pandemic', International

Journal of Technology, vol. 11, no. 5, pp. 888–899, https://doi.org/10.14716/ijtech.v11i5.4335

Yan,

Q, Toghiani, H, Yu, F, Cai, Z & Zhang, J 2011, 'Effects of pyrolysis

conditions on yield of bio-chars from pine chips', Forest Products Journal,

vol. 61, no. 5, pp. 367–371, https://www.doi.org/10.13073/0015-7473-61.5.367

Yuan,

Y & Lee, TR, 2013, 'Contact angle and wetting properties', Springer

Series in Surface Sciences, vol. 51, no. 1, pp. 3–34, https://doi.org/10.1007/978-3-642-34243-1_1