Model of State Support for The Digital Transformation of The Manufacturing Industry in Russian Regions

Corresponding email: kulkaev_g@spbstu.ru

Published at : 27 Dec 2022

Volume : IJtech

Vol 13, No 7 (2022)

DOI : https://doi.org/10.14716/ijtech.v13i7.6219

Anna, T., Marina, I., Grigory, K., Evgenii, T., 2022. Model of State Support for The Digital Transformation of The Manufacturing Industry in Russian Regions. International Journal of Technology. Volume 13(7), pp. 1538-1547

| Tanina Anna | Peter the Great St. Petersburg Polytechnic University, St. Petersburg, Russia, St. Petersburg, Polytechnicheskaya, 29, 195251, Russia |

| Ivanova Marina | Peter the Great St. Petersburg Polytechnic University, St. Petersburg, Russia, St. Petersburg, Polytechnicheskaya, 29, 195251, Russia |

| Kulkaev Grigory | Peter the Great St. Petersburg Polytechnic University, St. Petersburg, Russia, St. Petersburg, Polytechnicheskaya, 29, 195251, Russia |

| Tanin Evgenii | Peter the Great St. Petersburg Polytechnic University, St. Petersburg, Russia, St. Petersburg, Polytechnicheskaya, 29, 195251, Russia |

The digitalization of

industrial enterprises has an impact on the development of Russian regions. One

of the factors for increasing the efficiency of the digital transformation of

the industry is government support. The issues of the impact of state support

on the digital transformation of industry in the context of regional

development have not been fully studied. The authors’ aim was to study the

relationship between federal and regional measures to support the

digitalization of industrial enterprises and regional development. The subject

of the study is the transformation of the digital industry. The authors used

correlation and regression analysis, and calculations showed a significant

correlation between digitalization and the development of the manufacturing

industry. The impact of digitalization on this industry was further

investigated using the example of the regions of the Northwestern Federal

District. The analysis allowed us to identify three groups of regions,

depending on the correspondence of the level of digitalization in the region

and the balanced financial result of manufacturing enterprises. An analysis of

the digitalization support was also carried out. It was concluded that the

achieved level of digitalization of the region and the digital transformation

of their industry are provided by federal support measures (mainly financial).

In these regions, there is a duplication of federal support instruments, a

discrepancy between the measures used and the needs of enterprises in the

region. The support measures used do not fully consider the regional specifics

of industrial development, and the peculiarities of the Russian Federation as a

federal state. Given the results of the study, the authors propose an updated

model of state support for the digital transformation of the industry,

eliminating the listed problems while maintaining a common strategic approach.

Digital transformation; Digitalization; Government support model; Manufacturing industry; State support measures

The

introduction of the principles of Industry 4.0 and the implementation of

sustainable development goals in the global economy required changes in

approaches to the industrial development of Russian regions. It should be noted

that the digitalization of production can have significant differences

depending on the country, industry, or the chosen digital transformation

strategy (Rodionov et al., 2022; Babkin et al., 2021a; Babkin et

al., 2021b; Burova et al., 2021; Tereshko et al. 2021;Tanina et al., 2020).

The

questions about the degree of influence of digital technologies on regional

development, the positive correlation between the development of the digital

economy, and the productivity of enterprises are debatable (Krakovskaya & Korokoshko, 2021). In one

work (Huang

et al., 2022) a study was

made onthe development of the digital economy in increasing the productivity of

enterprises in the region.

Other studies show links between

digitalization use and innovation activity, and between innovation and

productivity growth (Gaglio et al., 2022). Separate studies

show the dependence of key indicators of digitalization on the marginal income

of an enterprise, and offer a comprehensive assessment of the level of

digitalization of industrial enterprises (Abushova et al., 2022; Ershova et al., 2022). It is

necessary to assess the barriers to the digital transformation of enterprises (Borovkov et al., 2021).

A significant role in improving the

regional digital infrastructure is played by the authorities, which determine

the main directions for supporting the digitalization of individual industries

and enterprises (Tanina

et al., 2022; Ivanova & Putintseva, 2020). Research

shows that government programs to support digitalization are most effective

when they take into account the types of digital technologies and their

availability for various enterprises (Gaglio et al., 2022; Malkowska et al., 2021; Bessonova & Battalov, 2020).

Russian authors address problems of

assessing the digital maturity of organizations, taking into account regional

characteristics (Chursin & Kokuytseva, 2022; Krakovskaya &

Korokoshko, 2021). An

important success factor is the digitalization of public services themselves,

including measures to support digital transformation. But not all government

support measures show their effectiveness, which requires the use of different

approaches depending on the characteristics of enterprises (Endr?di-Kovács & Stukovszky, 2022; Mirolyubova &

Voronchikhina, 2022).

In our opinion, the digital transformation strategy of the

industry should consider national and other territorial differences, including

when choosing measures to support digitalization by the state to achieve

sustainable development goals. According to the results of the study of

sources, it can be seen that there is a gap in assessing the effectiveness of

state support for digital transformation, taking into account the specifics of

individual industries, regions, and countries. As part of this study, the authors

set themselves the task of assessing the effectiveness of state support

measures for the digitalization of industry in Russia (using the example of a

group of regions included in the Northwestern Federal District). The authors

propose to consider the specifics of the Russian Federation as a country with a

federal state system and take these specifics into account when forming a model

of state support for the digital transformation of the industry.

The authors propose to conduct a correlation and regression analysis to identify the relationship between digitalization indices and the economic performance of industrial enterprises in Russia. First of all, the paper proposes to determine which of the Russian industries has experienced the greater impact from digitalization based on international and federal integral indices. For a more detailed analysis, the impact of digitalization on the selected industries will be considered based on regional indicators. After identifying the most influential factor, a regression analysis will be carried out and a regression equation will be compiled to analyze the effectiveness of state support measures for the digitalization of industry in Russia.

2.1. Assessing the impact of digitalization

on Russian industries

At this stage of the study, the authors

propose to conduct a correlation analysis to assess the impact of digital

interactions and transformations on labor productivity in the main sectors of

Russian industry, since high labor productivity values improve the quality of

the final product, the stability of the enterprise, and its competitiveness,

etc. (Novotna, 2017). For calculations,

it is proposed to use the statistical data of the Global Connectivity Index -

GCI and labor productivity indices by industry (mining, manufacturing, energy

production). For analysis, the authors propose to consider a time interval of 5

years with a step equal to 1 year from 2015 to 2020. The results of the

correlation analysis are shown in Table 1. When performing these calculations,

the Multiple R is equal to 0.91, and R2 is equal to 0.83. That is to

say, the initial data show a strong dependence, so the results obtained can be

trusted.

Table 1 The results of a correlation analysis of the relationship between the impact of digital interactions and transformations on labor productivity in the Russian industry (compiled by the authors)

|

GCI |

Labor productivity |

Labor productivity in |

Labor productivity in |

|

|

GCI |

1,00 |

-0,43 |

0,87 |

0,14 |

|

Labor

productivity in mining |

-0,4 |

1,00 |

-0,17 |

0,31 |

|

Labor

productivity in the manufacturing industry |

0,87 |

-0,17 |

1,00 |

0,26 |

|

Labor

productivity in the energy sector |

0,14 |

0,31 |

0,26 |

1,00 |

Thus,

Table 1 shows that digitalization in Russia mainly affects the manufacturing

industry (correlation index 0.87).

2.2. The impact of digitalization on the

manufacturing industry at the regional level

Based on this, it is proposed to consider

the impact of digitalization indicators on the manufacturing industry using the

example of the Northwestern Federal District of Russia. The Northwestern

Federal District plays an important role in the economic development of the

entire country (Shkiperova & Kurilo, 2021). The

regions of this federal district are different in their socio-economic and

financial situation, in the types of manufacturing industry, and the level of development

of the industry as a whole, which makes the analysis comprehensive.

For calculations based on the proposed

state strategic documents indicators, the authors have selected the following

indicators, which are necessary to simplify further illustration of the

calculation results, are proposed to be designated: X1 – Use of digital

technologies in organizations, %; X2

–Use of broadband Internet access in organizations, %; X3 – Use of the Internet

by the population, %; X4 – Number of personal computers per 100 employees, pcs;

X5 – Use of electronic document management in organizations,%; X6 – Index of

manufacturing production; X7 – Investments in fixed capital in the

manufacturing industry per capita, thousand rubles; X8 – The average annual

number of employees in the manufacturing industry, thousand people; X9 – Number

of manufacturing enterprises and organizations, thousand; X10 – Balanced

financial result of manufacturing enterprises, billion rubles. These indicators

were highlighted by the authors, as they fully reflect the dynamics of the

areas under study, and statistical data are published officially by government

authorities. For analysis, the authors propose to consider the statistical data

of the above indicators for the Northwestern Federal District of Russia over

five years with a step of 1 year from 2015 to 2020. The results of the

correlation analysis are presented in Table 2.

Table 2 Results of a

correlation analysis of the impact of the development of information and

communication technologies in the region on the economic performance of

manufacturing enterprises in the Northwestern Federal District (compiled by the

authors)

|

X1 |

X2 |

X3 |

X4 |

X5 |

X6 |

X7 |

X8 |

X9 |

X10 | |

|

X1 |

1,00 |

0,98 |

-0,63 |

0,21 |

-0,62 |

0,41 |

-0,41 |

0,53 |

0,66 |

-0,66 |

|

X2 |

0,98 |

1,00 |

-0,49 |

0,16 |

-0,51 |

0,53 |

-0,27 |

0,63 |

0,52 |

-0,53 |

|

X3 |

-0,63 |

-0,49 |

1,00 |

-0,32 |

0,89 |

0,25 |

0,87 |

0,09 |

-0,95 |

0,96 |

|

X4 |

0,21 |

0,16 |

-0,32 |

1,00 |

0,12 |

0,44 |

-0,19 |

-0,02 |

0,30 |

-0,31 |

|

X5 |

-0,62 |

-0,51 |

0,89 |

0,12 |

1,00 |

0,34 |

0,79 |

-0,10 |

-0,80 |

0,86 |

|

X6 |

0,41 |

0,53 |

0,25 |

0,44 |

0,34 |

1,00 |

0,44 |

0,78 |

-0,28 |

0,21 |

|

X7 |

-0,41 |

-0,27 |

0,87 |

-0,19 |

0,79 |

0,44 |

1,00 |

0,24 |

-0,86 |

0,94 |

|

X8 |

0,53 |

0,63 |

0,09 |

-0,02 |

-0,10 |

0,78 |

0,24 |

1,00 |

-0,21 |

0,04 |

|

X9 |

0,66 |

0,52 |

-0,95 |

0,30 |

-0,80 |

-0,28 |

-0,86 |

-0,21 |

1,00 |

-0,94 |

|

X10 |

-0,66 |

-0,53 |

0,96 |

-0,31 |

0,86 |

0,21 |

0,94 |

0,04 |

-0,94 |

1,00 |

The

results obtained in Table 2 show a direct dependence of indicators of

digitalization on the following: indicators of investment in fixed assets in

the manufacturing industry per capita, the number of enterprises and

organizations in the manufacturing industry, and the balanced financial result

of manufacturing enterprises. Meanwhile the use of the Internet by the

population and the use of electronic document management in organizations has a

large degree of influence.

2.3. Regression analysis of industry

digitalization in the regions of the Northwestern Federal District

The authors propose to form a statistical

base for 2020 of the regions of the Northwestern Federal District, according to

the digitalization indicators indicated in the work, and the balanced financial

result of manufacturing enterprises (resulting factor, Y), as an indicator

having the highest values ??of dependency coefficients. Based on this

statistical base, it will be possible to derive a regression equation that will

display the calculated value of the resulting factor, which can be compared

with the actual one to assess measures of state support for the digitalization

of industry. For an array of statistical data, Multiple R is 0.72, and R2 is 0.71, indicating a high degree of

determination of the selected indicators and the reliability of the information

that we will receive in the course of further research.

Thus, based on the data obtained, we can derive the following regression equation:

In

this model, there is partial multicollinearity, but it is due to the fact that

the value of the indicators is calculated in the organization. In this

regression model, the multiple R value is 0.74 and R2 is 0.7.

P-values for constants and variables do not exceed 0.043. The probability of

accepting the null hypothesis is 0.047. These values indicate the validity of

the construction of this model and its statistical significance.

When calculating the Durbin-Watson

coefficient, a value of 2.4 was obtained, which indicates a slight negative

autocorrelation. Also, using the Broish-Godfrey theorem, the value of the

student’s criterion was 0.588 (with a critical value of 1.833). This fact

allows us to reject the null hypothesis, and to conclude that there is no

autocorrelation in the model, which once again confirms the reliability of the

constructed regression model.

Applying the White Test, the probability

of accepting the null hypothesis (which says that the variables are not

significant per squared residuals) was 0.887, which indicates the absence of

heterodescatism.

Based on the resulting regression

equation, you can get the calculated value of the resulting factor.

Thus,

this method of mathematical and statistical analysis made it possible to

determine the most significant indicators in the field of industry

digitalization. Regression analysis shows the calculated value of this

indicator, or in other words, at what level the resulting indicator should be

at the current level of development of digitalization.

For a visual comparison of the calculated and actual values of the resulting factor, consider Figure 1. Thus, Figure 1 compares the actual financial result of manufacturing enterprises in the regions under study and the calculated financial result, that is to say, the value that should hypothetically be reached according to the current development of information technology in the regions.

Figure 1 Comparison of calculated and actual values of the resulting factor

(compiled by the authors)

Thus,

the financial result of manufacturing enterprises in such regions as the

Republic of Komi, the Murmansk Oblast, and the Novgorod Oblast corresponds to

the achieved level of digitalization. In the regions of the Arkhangelsk Oblast,

the Nenets Autonomous Okrug, the Vologda Oblast, and St. Petersburg, the

manufacturing industry is ahead of the development of information and

communication technologies. In the regions of the Republic of Karelia, the

Kaliningrad Oblast, the Leningrad Oblast, and the Pskov Oblast, the

manufacturing industry lags behind in development compared to the level of

development of digitalization of the regions.

Based on the results of the analysis, it

can be concluded that three groups of regions are formed in the Northwestern

Federal District:

1.

Regions

in which the financial result of the manufacturing industry is lower than the

overall level of digitalization of the region - this group is characterized by

a low level of effectiveness of state support measures for the digital

transformation of manufacturing enterprises, since the result of activity is

lower than the result of neighboring regions, provided that support measures

are equally accessible for all the studied regions.

2.

Regions

in which the result of the manufacturing industry is higher than the general

level of digitalization of the region - this group is characterized by the

so-called "super-efficient" state support measures, since the result

of the activity is much higher than the result of neighboring regions, provided

that support measures are equally accessible for all the studied regions.

3.

Regions

in which the result of the manufacturing industry as a whole corresponds to the

general level of digitalization of the region - this group is characterized by

a sufficient level of effectiveness of state support measures for the digital

transformation of industrial enterprises, since the result of the activities of

these enterprises corresponds to the plan (calculated value).

Based on this grouping of regions, we

will consider a system of tools to support digital transformation, which are

implemented in the Russian Federation and in the regions of the North-Western

Federal District. The system of state support for the digital transformation of

the industry at the federal level is based on the departmental project

"Digital Industry". The project primarily aims to develop the

regulatory environment in the field of digitalization. In this direction, the

state sees the development of state standards in the field of the application

of new technologies as the main instrument of support. To date, 6 new standards

have been prepared and developed.

The project also provides for the

formation of a unified digital environment for the digital transformation

process. Within this area of state support, the state information system of

industry (GISP) has been created and is functioning. GISP was developed as a

digital platform for interaction between authorities and enterprises, building

digital processes of cooperation and production chains, providing services for

investing in industry, services for supporting the creation and development of

the production of industrial enterprises, selecting a set of state support

measures, obtaining them and monitoring the achievement of project performance

indicators, services for providing production and promotion of industrial

products in the domestic market, foreign markets, increasing export volumes,

services for analyzing and forecasting the development of production based on

objective statistical data. To date, GISP provides in one form or another all

the listed services for enterprises of all regions, industries and forms of

ownership. The portal also implements the “Digital Passport of the Enterprise”

tool - a standardized assessment of the levels of digitalization of a

particular enterprise and the possibility of offering relevant IT solutions for

implementation.

Another support tool implemented both at the

federal and regional levels is debt financing of digitalization projects. At

the federal level, this tool is implemented by the Industry Development Fund as

part of the Industry Transformation program. Enterprises are provided with loan

financing for specific digitalization projects in the amount of 20 to 500

million rubles. at a reduced rate of 1 to 3%. The federal level also offers to

subsidize part of the costs of developing digital platforms and software

products, for which it is planned to allocate 2 billion rubles in a year. The

subsidy is provided to developers of digital platforms and software products

for further implementation at industrial enterprises operating in the

manufacturing sectors of the economy. For small and medium-sized enterprises, a

discount of up to 50% is financed for Russian SaaS solutions for production

(their list is formed by the state). The program also declares the target area

"Creating retraining and advanced training programs for each branch of the

manufacturing industry".

The authors also analyzed the state

support measures for the digital transformation of the industry in the studied

regions of the Northwestern Federal District. For comparative analysis, the

following tools and elements of the digital transformation support structure

were selected: the existence of a program to support the digital transformation

of the industry (similar to the federal level); the use of a tool for the

development of the digital environment (the existence of a common portal for

the development of industry was considered); use of a financial support tool

(loan financing of digitalization projects); use of the instrument of

subsidizing platforms and products; the existence of organizational support

(functioning of regional business development institutions); the existence of

advisory support in the field of digitalization of industry; organization of

training in the field of digital transformation.

The analysis showed the following

results:

1. None of

the North-Western regions has its own digital transformation program.

2.

In the

studied regions, there are no digital platforms that are analogs of GISP; the

portals of the My Business system for small and medium-sized enterprises are

mainly functioning, and all the tools on the portals are aimed at such

enterprises. My Business is more of an information portal than a tool for

interaction with the state.

3.

Debt

financing of industrial development projects through regional funds exists in

all regions and is, in fact, the main regional support tool. In the North-West

Federal District, only the Nenets Autonomous Okrug is without an industrial

development fund (although it exists in the Arkhangelsk Region, which also

finances the Autonomous Okrug). The agreement with the federal fund allows the

regional one to co-finance industrial development projects in 4 areas (there

are no digitalization projects among them). The fund implements the remaining

directions of financing at the expense of its own, regional funds. As a support

measure for digitalization, the analysis considered only regional loans

specifically for digitalization projects in the region’s industry. It can be

concluded that all regions have their own regional loans for various industrial

development projects. Of these, only the Leningrad Region and St. Petersburg

have loans specifically for digitalization projects. The maximum amount of an

available loan in the Leningrad region is ten times lower than the federal one;

in St. Petersburg it is 60% of the federal maximum.

4.

The

regions have an extensive system of business development support institutions

(from 3 to 10 organizations involved in various types of business assistance in

each of the studied regions). The services of these organizations are aimed

exclusively at small and medium-sized businesses, and they have relevant areas

of activity: consultations on starting a business, on reporting, etc. There is

no opportunity to receive support and advice on digital transformation in the

regions. The exception here is the Leningrad region, where advisory assistance

is provided on digitalization projects.

There are no examples of using the tool

for subsidizing platforms and products, as well as organizing training in the

field of digital transformation in the studied regions. Comparing the results of calculations of

the expected/actual financial results of manufacturing enterprises at the

current level of ICT development in the Northwestern regions, and the analysis

of support measures implemented by the federal and regional levels of

government, we can conclude that there is no connection between the presence of

a developed system of regional support measures and the positive result of the

digital transformation of the industry in the region. The regions of the

leading group, Arkhangelsk and Vologda Oblasts, do not have an industry

digitalization program, do not purposefully finance digital transformation

projects, and nor do they implement organizational support tools. The Leningrad

region, which has a relatively developed system of regional support, does not

show results that differ from, for example, the Republic of Karelia, where

there is no similar system of measures. The authors conclude that the final

level of digitalization of the region's industry and the degree of success in

digital transformation are more dependent on federal support measures. The

potential of the regional level in this process, on the one hand, remains

unused, on the other hand, simply the introduction of a duplicate level with

the same tools shows low results (see the example of the Leningrad Region).

Researchers indicate it is advisable to

implement such measures as stimulating the full deployment of local

digitalization, ensuring flexible monitoring of the problems and successes of

digitalization and active dialogue with production, development of cooperation

between companies and digital companies and research centers, creation of a

unified state long-term strategy for the modernization of industry, training

the digital skills of personnel, and promoting the development of digital

companies to accelerate the digital transformation of the industry. In the

draft strategy for the digital transformation of the manufacturing industries,

the Ministry of Industry and Trade also indicates that “in matters of digital

transformation of the Russian industry, it is especially important not to be

limited to direct financial support measures. On their own, isolated from a

supportive institutional environment, they will not have an impact, and they

will not be able to provide wide coverage and stimulate massive growth in both

demand for digital technologies and related investments”. The current

situation, where the emphasis is on financial measures, must be changed.

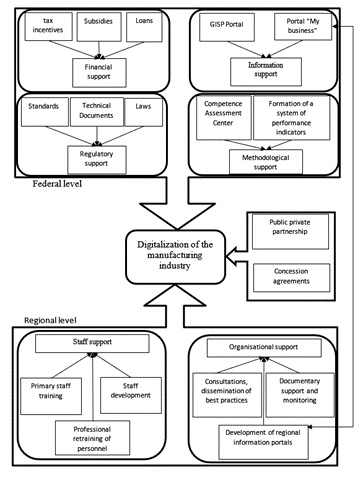

In this regard, the authors propose an

updated model of state support for the digital transformation of industry (in

particular, the manufacturing industry), taking into account the specifics of a

federal state and the requirements for effective support. The model is shown in

Figure 2.

Figure 2 An updated model of state support for the digital transformation of the

manufacturing industry

It

is proposed to abandon the duplication of support measurs at the federal and

regional levels and divide the implemented tools between levels while maintaining

a common strategic approach. In particular, the promising support measures

proposed by the scientific community, as well as the financial incentives

already being implemented, are proposed to be distributed between the levels as

follows: 1. Personnel training: federal level + regional level. 2. Infrastructure of

digital interaction between the state and companies: federal level through the

GISP portal. 3. Stimulation of local digitalization (primarily through the

dissemination of IT solutions and experience): regional level. 4. Flexible

monitoring of problems and successes of digitalization: regional level. 5.

Active dialogue with industry: regional level. 6. Financial support for digital

transformation: federal level. 7. Development of the regulatory environment:

federal level.

The

regions currently have an extensive network of business support institutions in

various areas. It is proposed, on the basis of the existing infrastructure, to

develop organizational, advisory and other non-financial support tools, which

will make it possible to take into account regional and sectoral specifics to a

greater extent than when implementing non-financial measures at the federal

level. The centralization of information interaction, issues of the regulatory

environment and financing at the federal level allows you to unload regional

finances and ensure that there is no duplication of tasks while maintaining a

common strategic vision.

The

study showed that the digital transformation of the industry has a significant

impact through direct financial support from the federal authorities. But these

measures do not consider regional and industry specifics of economic

development. This approach leads to the duplication of some support areas and the

absence of relevant others to a particular region, industry, or enterprise. The

model proposed by the authors will establish the necessary strategic guidelines

for the digital transformation of federal support of industrial enterprises and

allow to consider the regional specifics through coordination with regional

authorities. Further research areas may include an interaction of both federal

and regional authorities in the digital transformation of industry,

interregional cooperation (which is especially relevant for St. Petersburg and

the Leningrad Region), state support for the digital transformation of industry

in the context of achieving sustainable development goals.

The research is partially funded by the Ministry of Science and

Higher Education of the Russian Federation under the strategic academic

leadership program 'Priority 2030' (Agreement 075-15-2021-1333 dated

30.09.2021).

Abushova, E., Burova, E.,

Stepanchuk, A., Suloeva, S., 2022. Development of a Method for Assessing the

Industrial Enterprise Digitalization Level. In International Scientific

Conference on Innovations in Digital Economy, Volume 1619, pp. 171–187

Babkin, A., Glukhov, V., Shkarupeta, E., Kharitonova, N.,

Barabaner, H., 2021. Methodology for Assessing Industrial Ecosystem Maturity in

the Framework of Digital Technology Implementation. International Journal of

Technology, Volume 12(7), pp. 1397–1406

Babkin, A., Tashenova, L., Mamrayeva, D., Andreeva, T., 2021. A

Structural Functional Model for Managing the Digital Potential of a Strategic

Innovatively Active Industrial Cluster. International Journal of Technology,

Volume 12(7), pp. 1359–1368

Bessonova, E., Battalov, R., 2020. Digitalization as A Tool for

Innovative Economic Development. Economic Annals-XXI, Volume 186(11-12),

pp. 66–74

Borovkov, A., Rozhdestvenskiy, O., Pavlova, E., Glazunov, A.,

Savichev, K., 2021. Key Barriers of Digital Transformation of the High-Technology

Manufacturing: An Evaluation Method. Sustainability, Volume 13, p. 11153

Burova, E., Grishunin, S., Suloeva, S., Stepanchuk, A., 2021. The

Cost Management of Innovative Products in an Industrial Enterprise Given the

Risks in the Digital Economy. International Journal of Technology,

Volume 12(7), pp. 1339–1348

Chursin, A.A., Kokuytseva, T.V., 2022. Development of Methods for

Assessing the Digital Maturity of Organisations Considering the Regional

Aspect. Ekonomika Regiona [Economy of Regions], Volume 18(2), pp.

450–463

Endr?di-Kovács, V., Stukovszky, T., 2022. The Adoption of Industry

4.0 and Digitalisation of Hungarian Smes. Society and Economy, Volume 44(1),

pp. 138–158

Ershova, I.V., Poloskov, S.S., Norkina, O.S., Amosov, N.A., 2022.

Industry Efficiency Indicators 4.0 for Medium-Sized Engineering Enterprises. AIP

Conference Proceedings, Volume 2456(1), p. 030001

Gaglio, C., Kraemer-Mbula, E., Lorenz, E., 2022. The Effects of

Digital Transformation on Innovation and Productivity: Firm-Level Evidence of South

African Manufacturing Micro and Small Enterprises. Technological Forecasting

and Social Change, Volume 182, p. 121785

Huang, J., Shen, Y., Chen, J., Zhou, Y., 2022. Regional Digital

Economy Development and Enterprise Productivity: A Study of the Chinese Yangtze

River Delta. Regional Science Policy & Practice, Special Issue: Regional

Development in China, Volume 14 (S2), pp. 118 –137

Ivanova, M., Putintseva, N., 2020. Approaches to Evaluation of

Digital Transformation of Government, in: Proceedings of the 2nd

International Scientific Conference on Innovations in Digital Economy: SPBPU

IDE-2020. ACM, New York, NY, USA, pp. 1–8

Krakovskaya, I., Korokoshko, J., 2021. Assessment of the Readiness

of Industrial Enterprises for Automation and Digitalization of Business

Processes. Electronics, Volume 10(21), p. 2722

Ma?kowska, A., Urbaniec, M., Kosa?a, M., 2021. The Impact of

Digital Transformation on European Countries: Insights from A Comparative

Analysis. Equilibrium. Quarterly Journal of Economics and Economic Policy,

Volume 16(2), pp. 325–355

Mirolyubova, T., Voronchikhina, E., 2022. Assessment of The Digital

Transformation Impact on Regional Sustainable Development: The Case Study in Russia.

International Journal of Sustainable Economy, Volume 14 (1). pp. 24–54

Rodionov, D., Kryzhko, D., Tenishev, T., Uimanov, V., Abdulmanova,

A., Kvikviniia, A., Aksenov, P., Solovyov, M., Kolomenskii, F., Konnikov, E.,

2022. Methodology for Assessing the Digital Image of an Enterprise with Its

Industry Specifics. Algorithms. Volume 15 (6), p. 177

Shkiperova, G.T., Kurilo, A.E., 2021. Assessment of The

Sustainability of Regional Socio-Ecological-Economic Systems. Market economy

problems, Volume 1, pp. 47–61

Tanina, A., Konyshev, E., Tsahaeva, K., 2020. Agritourism

Development Model in Digital Economy. In Proceedings of the 2nd

International Scientific Conference on Innovations in Digital Economy: SPBPU

IDE-2020. ACM, New York, NY, USA, pp. 1–6

Tanina, A., Tashenova, L., Konyshev, Y., Mamrayeva, D., Rodionov,

D., 2022. The Tourist and Recreational Potential of Cross-Border Regions of

Russia and Kazakhstan during the COVID-19 Pandemic: Estimation of the Current

State and Possible Risks. Economies, Volume 10 (8), p. 201

Tereshko, E., Rudskaya, I., Dejaco, M.C, Pastori, S., 2021.

Validation of Factors for Assessing The Digital Potential of The Regional

Construction Complex as A Basis for Sustainable Development. Sustainable

Development and Engineering Economics, Volume 1, pp. 34–53