Development of Auto-PIVOT: Automated Platform In Vitro for Cell Tissue Culture

Corresponding email: yudan.whulanza@ui.ac.id

Published at : 30 Dec 2022

Volume : IJtech

Vol 13, No 8 (2022)

DOI : https://doi.org/10.14716/ijtech.v13i8.6176

Irsyad, M., Whulanza, Y., Katili, P.A., Antarianto, R.D., Jasirwan, C.O.M., Bugtai, N., 2022. Development of Auto-PIVOT: Automated Platform In Vitro for Cell Tissue Culture. International Journal of Technology. Volume 13(8), pp. 1651-1662

| Muhammad Irsyad | Department of Mechanical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, West Java 16424 Indonesia |

| Yudan Whulanza | 1. Department of Mechanical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, West Java 16424 Indonesia, 2. Research Center for Biomedical Engineering, Faculty of Engineerin |

| Puspita Anggraini Katili | 1. Research Center for Biomedical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, West Java 16424 Indonesia, 2. Biomedical Engineering Study Program, Department of Electri |

| Radiana Dhewayani Antarianto | Department of Histology, Faculty of Medicine, Universitas Indonesia, Jakarta 10430, Indonesia |

| Chyntia Olivia Maurine Jasirwan | Division of Hepatobilliary, Department of Internal Medicine, Faculty of Medicine, Universitas Indonesia, Jakarta 10430, Indonesia |

| Nilo Bugtai | Department of Manufacturing Engineering and Management, Gokongwei College of Engineering, De La Salle University, 1004 Manila, Philippines |

Bioreactors are growing in popularity among network

engineers. Bioreactors are generally chambers used for cell culture processes

with predetermined parameters. Pivot is a bioreactor system for cell culture

that is controlled automatically and remotely using multi-chambers that allow

inflow of fresh liquid or output for sample collection. This system facilitates

gas exchange between the culture medium and ambient gas. The system provides a

storage bag for fresh media and a peristaltic pump is used to move the media in

a closed loop during perfusion and stirring in the cell culture chamber. The

flow rates used is 2 mL/min. The system has a container for direct sample

measurement to obtain pH, oxygen, and carbon dioxide parameters. The bioreactor

system is also equipped with a mixing vessel which allows the addition of

desired nutrients or additives to the system. The results of a computational

fluid dynamics (CFD) and shear stress-based flow analysis have been conducted.

The simulation results demonstrate that the applied Pivot parameters correspond

to an ideal environment to hepatocyte cell viability and growth. This research

is expected to increase the number of cells produced without reducing the

quality of each chamber and be carried out simultaneously, automatically, and

remotely controlled.

Automated system; Bioreactor; Cell culture; PIVOT; Remotely controlled

Tissue

engineering triggers the rapid development of various technology in medical

applications (Hinman et al., 2020;

Birla, 2014). Currently, engineered tissues realized in a

laboratory have been used at the clinical level (Mason et al., 2011). This advancement was supported by the

establishment of the triad of tissue engineering: cells, scaffolding, and signals (Jain & Bansal, 2015). Bioreactor represents a

device that transmits signals in tissue engineering. A bioreactor carries out

biological and/or biochemical processes, including microbial and mammalian cell

culture processes in a monitored and controlled environment. Moreover, bioreactors

also enable us to realize an operating condition by intervening in the culture

environment (Birla, 2014).

Compared to petri dishes,

bioreactors have been proven to have better performance in the sense that

bioreactors are able to facilitate tissue culture in three dimensions (3D) with

the help of biomaterial scaffolds (Costa et al.,

2020; Paez?Mayorga et al., 2019; Nadhif et al., 2017). In this 3D environment, the cultured

tissues produce properties that resemble the targeted mimetic tissue (Valls-Margarit

et al., 2019; Villa-Diaz et al., 2013). In addition, tissue culture in

bioreactors can be carried out dynamically (Nadhif et al.,

2017), allowing the perfusion process

of growth factors, nutrients, medicines, metabolites, and other culture media (Petrenko et al.,

2017). The perfusion process can also

be carried out to flow oxygen (O2) (Schmid et al.,

2018) and carbon dioxide (Schuerlein et al.,

2017) in a controlled manner that

affects cell respiration and acidity (pH) of the environment (Be?karde? et al.,

2018; Petrenko et al., 2017). Some bioreactors include electrical

electrodes for stimulation and signal recording (Whulanza et al.,

2022). The cells given by this

electrical stimulant are cells that can be excited, such as nerve and muscle

cells (Khodabukus et al.,

2019; Huang et al., 2012). Meanwhile, recording electrodes

were used to identify cell activity, such as nerve cells and cardiac wall cells

in bioreactors (Li et al., 2018;

Sagita et al., 2018).

During the operation, a bioreactor is

often put into incubators to maintain the culture temperature (Bilgen et al.,

2013), considering that there are

still few bioreactors that integrate thermal modules (Liu et al., 2019). In fact, the placement of bioreactors that

consist of several components in the incubators often makes it difficult for

researchers to run experiments. Nadhif et al. developed a thermal control

module that can be integrated with bioreactors (Nadhif et al.,

2019). Therefore, the development of a

bioreactor with integrated temperature control IoT system became our research

of interest in this phase. One of the examples also found is from Rahmat et

al., who monitored microalgae cultivation inside a photobioreactor using an IoT

system (Rahmat et al.,

2020). Long-term exposure to high

temperatures may have detrimental effects on cells, such as inhibiting cell

proliferation and increasing the number of necrotic cells (Zhu et al., 2015; Reissis

et al., 2013). An automated system is required

to be implemented in a bioreactor to maintain a suitable temperature for the

cells over time (Wang et al., 2020). As is well known, the incubation period for

cell culture may range from 24 hours to 7 days (Schmid et al.,

2018; Meinert et al., 2017). However, research on cell culture bioreactors

that can be observed remotely in real-time is still few and with limited

parameters.

The aseptic requirements of the cell

culture procedure necessitate a closed system; therefore, clean room access is

necessary for manual operations. In biopharmaceutical production facilities,

the high costs and demand for cleanroom space are obstacles to reserving

certain room sections exclusively for the bioreactor system. Research using

mini cleanrooms so far is one of the implementations used on

micro-electromechanical systems (MEMS). Vutla et.al reported the results of an

analysis based on airflow simulation in a MEMS clean room aimed at predicting

the distribution of 0.5 um airborne particles according to ISO-5 standards (Rao Vutla et al.,

2019). ISO-5 or Classification 100

Cleanrooms are a stricter classification of cleanrooms across a smaller

cross-section of industries and applications. ISO 5 Cleanrooms are used in

biotechnology, pharmaceutical, nanotechnology, and precision manufacturing

industries. The installment of cleanroom is costly due to its operation with

normally large area that contain 5-100 working people.

Regarding the constraints mentioned, our

approach here is minimizing the space by applying the automatic and remote

controlled system in the mini cleanroom to maintain the sterility of all

bioreactor components. In this study, experiments using thermal, pressure and

pH modules as case studies to be connected with the Internet of Things (IoT)

system and using the finite element method to determine airflow and temperature

in a clean room.

2.1. Pivot System Configuration

In this system component, cell culture chamber is the bioreactor's

heart: It contains the monolayer of cells or the scaffold upon which cells are

seeded. Polydimethylsiloxane (PDMS), a biocompatible silicone polymer, is used

to construct the entire chamber (Sylgard 184, Dow Corning). The bioreactor

system includes the following components: 1) bioreactor cell chamber; 2) mixing

chamber; 3) peristaltic pump; 4) air supply device with filter and 5)

electrical system.

2.2. Electrical

System Configuration

The

backbone of the structure mainly consisted of five components: a DC power

supply with emergency battery as optional, a heating system included the

driver, environment sensing included: temperature, pH, humidity sensors, and

microcontroller altogether with IoT platform as previously developed by our

group (Assyarify et al., 2022). This is accomplished using an Arduino microcontroller and

custom-designed software to maintain the required cell environment parameter

values. Multiple input ports on the Arduino microcontroller receive feedback

regarding all controlled parameters. Through a series of lines of code, the

software compares the feedback input to a predetermined value deemed optimal

for the growth of the cells. By sending a signal through the output port to the

water heater, pressure regulator, solenoid valve and others, any action

required to maintain system balance and correct any parameter changes can be

performed.

In

this study, Wi-Fi microcontrollers were employed: ESP-Arduino Mega; Arduino

microcontroller, which have been utilized in various studies. The temperature

sensor transmitted the measured chamber temperature to the microcontroller. In

this setup, a 60 W (12V, 5A) DC power supply was selected as the heater consumed

50 W power. This circuit forms a logic to control the temperature input with

occurred disturbance, resulting in required values. Thus, the heater conveyed

the heat to the water and transferred it to the bioreactor chamber.

2.3.

Internet-of-Things (IoT) Platform

The

thermal module, pH module, and pH module were remotely monitored and presented

in a control panel with a commercial user interface Blynk. Blynk provides data

communication between the bioreactor system and the internet mainframe.

Built-in equipment and IoT implementation enable real-time automatic parameter

control and monitoring of real-time processes. The sensor's output will be

transmitted to the Blynk server through a Wi-Fi connection and displayed on a

web browser platform and smartphone application. Users are able to specify

download parameters for retrieving data from the database.

2.4. Clean Room

Installation

A

clean room is specifically designed and controlled to minimize particulate

matter levels complied with the standard of the International Organization for

Standardization (ISO) 14644-1. The clean room was designed equipped with

ducting (HEPA H13 filter). The clean room will contain the PIVOT system to

ensure the air quality and sterility with positive pressure environment.

Important assumed data that needed in order realizing the cleanroom is good air

exchange standards for rooms; the amount of air flow intake corresponds to the

volume of the room; estimated cooling load from indoors and outside air

temperature and good airflow input and output location

2.5. Modelling and Simulation of PIVOT system

There

were two stages of model and simulation that were conducted in this study. The

first one is the study of mini cleanroom as the outer containment of the

system. The second one was the simulation of cell culture chamber due to the

fluid dynamic in the chamber. The 3D model of the mini cleanroom was drawn

using an Autodesk Inventor 2022 software and exported to Ansys Fluent Student

License 2022 R2 in STEP file format.

Furthermore, finite element modeling (FEM) model of cell culture chamber

was simulated to observe the shear stress reacted on the surface of the

bioreactor that directly affect to the living cell cultured on it.

2.6. Trial Test

Auto-PIVOT

trials were conducted to characterize temperature and monitor air pressure and

pH for 30 minutes (1,800 seconds). In order to characterize the temperature,

four temperature sensors are placed in each corner of the water heating

chamber. Using a Digital 4-Channel K-Type Thermocouple Thermometer,

measurements were taken. The measurement results from the bioreactor's built-in

thermistor will be compared and analyzed. The controlled temperature was set to

37°C following the reference temperature for liver cell culture. Injecting a mixture of air from the

compressor and CO2 gas into the mixing chamber allows for pH

regulation. Air from the compressor is used in place of oxygen to avoid

potential fire hazards. The pH control's actuator is a solenoid valve connected

to the CO2 gas hose. When the pH of the mixing chamber falls below

7, the CO2 gas hose is shut off by a solenoid valve. If the value is

greater than seven, the solenoid valve will open and CO2 gas will be

mixed with air from the compressor.

3.1. The

PIVOT system

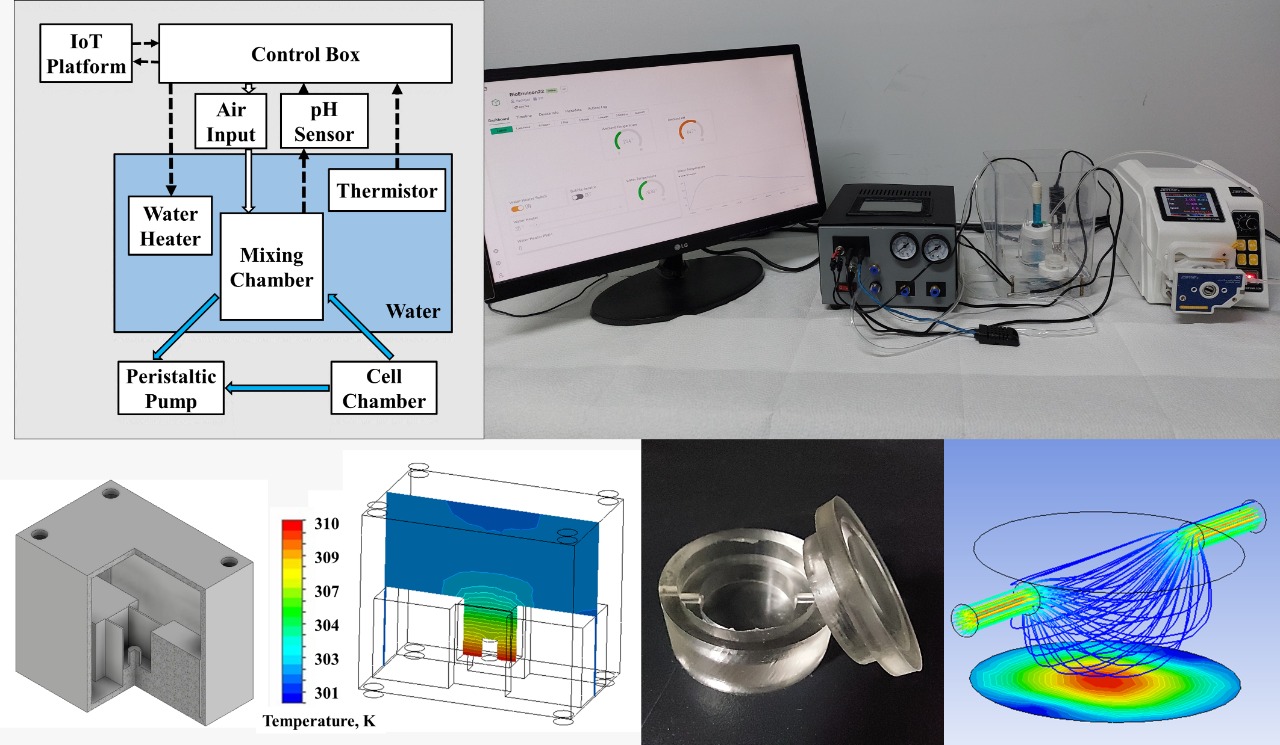

The PIVOT platform consists of these main components: 1) cell culture chamber; 2) reservoir/ mixing chamber; 3) heating medium; peristaltic pump; 4) electrical system and 5) mini cleanroom box with HEPA filter and air supply. The electrical system provides the power supply, controller and sensors temperature, pH, humidity and the IoT platform. All of this component was presented in schematic diagram as in Figure 1a and realized in Figure 1b and 1c.

Figure 1 a)

Schematic of Auto-Pivot Platform; b) bioreactor cell culture configuration and

c) complete setup of the platform

The cell culture chamber

made of polydimethylsiloxane elastomeric polymer (PDMS) serves as bioreactors

(inset Figure 1c). An extra chamber serves as reservoir that allows the oxygen

and temperature sensors tapped into the liquid. Another chamber can be

connected to this reservoir chamber to flow important nutrients as required.

This reservoir acted as a conditioning environment that finally flowed to the

cell cultured bioreactor.

Culture chambers were heated

using a water bath heating system that utilized the distilled water's heat

capacity to keep the culture chamber in desired temperature. The water bath was

heated by resistive heaters placed directly in the heating pod. An electronic unit

controls the resistive heaters through a power regulator.

The pressure is controlled

through the serial to PWM board that generates the analog 0-10V control signal

for the pressure regulator. Typically, the pressure regulators are designed to

be used in a closed system and the imposed pressure is guaranteed for a static

environment. The pressure in the mixing chamber is obtained with a low

resistance imposed by a sensor. An IoT system was successfully implemented by

transmitting the measured temperature data from the culture chamber sensor.

Since external disturbances to a bioreactor system could be detrimental to the

cultured tissue, the measurement data was sent to a web server every second to

allow for the early detection and correction of any errors. A real-time

sequential graph of the measured temperature is displayed at a dashboard to

provide an easily comprehensible data visualization (as featured in Supplementary

Material 1).

Simultaneously with the data

collected during the experiment, the web server received and stored the data in

its database. In addition, the data could be retrieved using the history panel,

as depicted in Supplementary Material 1. In this regard, a user could set a

specific time frame for the result to be displayed. Unfortunately, the data

could only be displayed within a single frame for a maximum of 15 minutes. As

presented in Supplementary Material 1, this web-based application offered a

history management function for downloading the desired timeframe in a

spreadsheet file format. Consequently, the user could view all measured data

for further analysis.

3.2. Clean Room Installation and Simulation

This phase realized an installment

parameter for the clean room system of the bioreactor environment. This

parameter shall formulate good and sterilized air exchange standards for the

workspace of the cell culture. The amount of airflow intake corresponds to the

volume of the room that needs to be conditioned. Estimation of cooling load

from indoor and outside air temperatures was estimated.

Table 1 Simulation Parameters of Mini Cleanroom

|

Physical Features |

Value |

Unit |

|

Heat

conduction in solid |

Off |

-- |

|

Time

dependent |

On |

-- |

|

Gravitational

effect |

Off |

-- |

|

Rotation

|

Off |

-- |

|

Flow

type |

Laminar

and turbulent |

-- |

|

Relative

humidity |

50.0 |

% |

|

Default

roughness |

0 |

Micrometer |

|

Default

wall condition |

Adiabatic

wall |

-- |

|

Static

pressure |

101325 |

Pa |

|

Temperature

|

300.0 |

K |

The

mini cleanroom roof has four fan filter units (FFUs) in each corner and

parallel to the four air vents on the floor. In this study, we used clean rooms

that refer to ISO 5 which can be implemented in biotechnology, pharmaceuticals,

nanotechnology, and various clean technology manufacturing applications. In a

typical ISO-5 cleanroom, airflow occurs at v=0.5 ms-1 from the top vent to the

bottom vent. Since particles with a diameter of 0.5 m have a negligible mass,

it is assumed that their flow is governed by the fluid flow, making it possible

to predict the path and presence of particles in the domain. A detail input

parameter for the simulation environment was summarized in table 1.

According to the simulation results was sufficient to ensure the clean air transmission within the minichamber. With a constant of 6 Air Changes per Hour (ACH), subjects shall get fresh air by adding a 25 x 25 cm 450 cfm inlet fan to the room. This could be realized using a 400 cfm exhaust fan. The simulation was realized successfully and found that the humidity of the room was relatively constant at 50-60% RH. Hypothetically, room temperature reaches the targeted temperature at an average of 33oC. The visualization results were presented at Figure 2.

Figure 2 Clean room air transmission simulation

visualization result a) velocity profile in perspective view and b) pressure

profile in the side view

The cleanroom was

successfully designed with floor dimensions of 40x60 cm, a height of 50 cm, and

an estimated volume of 38.5 cm2 of free space after deducting the

volume of the Pivot device. The four vents at each top and bottom corner (as

inlet and outlet holes) of the cleanroom have a diameter of 5 cm, and a HEPA

filter is installed at each vent to maintain cleanroom sterility.

The results of the

simulation utilizing the mini cleanroom model demonstrate laminar airflow from

the inlet to the outlet, as presented in Figure 2a and 2b. Maintaining the

temperature equilibrium on the water chamber's surface is dependent on laminar

airflow. Supplementary material 2 depics the velocity of airflow in the mini

cleanroom. Similarly, the simulation visualization shows that the temperature

at the inlet with 300K (26°C) to the water surface can be maintained at 310K.

(37°C). This is also due to the fact that the outlet is designed to be

perpendicular to the inlet at every corner, preventing turbulence that can

lower the water's room temperature and affect the bioreactor's flow

temperature.

3.3. Finite Element Analysis of Bioreactor

The simulation in the second phase is

conducted to observe the temperature profile, and fluid dynamic in the

bioreactor. Note that the bioreactor was seated on the heating source in this

system which affect the temperature profile in the mini cleanroom. The simulation

environment employed the parameter shown in Table 2.

Here, the actual shear stress on the wall depends linearly on the density and viscosity of the culture medium employed. The default element size used for meshing the model is 4.16 x 10-3 m, resulting in 11081 nodes and 53064 elements. The resulting meshing model is imported into the Fluent module and analyzed using a three-dimensional double-precision model.

Table 2 Finite element parameters of bioreactor chamber simulation

|

Boundary Condition |

Value |

Unit |

|

Viscosity |

103 |

Pa.s |

|

Fluid

density |

1,000 |

kg/m3 |

|

Flow

rate |

2-3 |

mL/min |

|

Pressure

|

1 (760)

|

Atm

(mmHg) |

|

Temperature

|

37 |

°C |

|

Slip

condition |

no-slip

boundary |

-- |

|

Reference

fluid |

water |

-- |

A

model of the bioreactor chamber's within the cleanroom is also represented in

Figure 3a. The realization of the bioreactor in the cleanroom was represented

in the figure 3c. Furthermore, the

placement of supporting equipment such peristaltic pump and electrical system.

These two supporting systems was also inserted in the simulation since its

connected directly to the cell culture chamber trough a plastic hose. The

dynamic of fluid shall contribute to the connection system of this fluid

connection. It is assumed that that the heat generated by peristaltic and the

electrical system is neglected at this moment. Therefore, figure 3b shows that

the heat source is limited to the heating system of the bioreactor.

The numerical study also highlights the shear stress that involved in the cell culture chamber. Our previous study indicated that cell viability corresponds with the shear generated on the bioreactor’s substrate. The standard transport equation is utilized to determine the flow rate ensuring shear stress in our bioreactor chamber, particularly in the surface area where the cell culture mainly occured (Kehtari et al., 2018).

Figure 3 a) CAD

model Isometric view of an auto-PIVOT system within the mini cleanroom; b). the

profile temperature in the chamber that used the heating system in the culture

chamber; and c) realization of the PIVOT within the mini cleanroom

The simulation results indicate that the shear stress experienced by hepatocytes in the cell chamber at a flow rate parameter of 2 mL/min is well above the minimum limit. As the simulation and visualization results in Figure 4, the resulting shear stress is only 4.6x10-7 Pa. In order to prevent cell death caused by stress and inadequate nutrient input due to a too-slow flow rate. According to previous research, the shear stress in normal hepatic sinusoids does not exceed 0.2 Pa. Using a shear stress of 0.05 Pa on iPSCs-derived hepatocytes (iPSCs-Heps) cultured in a bioreactor device, Kehtari et al. observed a higher level of hepatic markers than in static conditions. Flow cytometry and immunocytochemistry analysis revealed that iPSCs cultured in the device successively gained the features of definitive endodermal cells, hepatoblasts, and mature hepatocytes. During the experiment, albumin and urea secretion were significantly greater in the micro-bioreactor device than in the culture plates (Kehtari et al., 2018). In addition to the shear stress and flow velocity parameters, paying attention to the surface roughness and wettability parameters on the cell chamber's surface is an additional way to ensure high viability. The currently utilized cell chamber is molded from PDMS, which can be enhanced by the biomachining procedure (Whulanza et al., 2016).

Figure 4 a) Cell

culture chamber; b) CAD model of PDMS cell chamber and c) Velocity and wall

share on the chamber

3.4. Trial Test

Temperature measurements at

the four corners of the water-heating chamber using a 4-Channel K-Type thermocouple

and in the center of the water-heating chamber using a thermistor Pivot show a

similar trend. The rise times of thermistor, ch1, ch2, ch3, and ch4 are 855,

763, 825, 772, and 782 seconds, respectively. The average rise time required to

reach the target temperature is about 13 minutes. According to the graph and

rise time, it is known that ch1 has a higher temperature. It is due to its

proximity to the water heater.

The monitoring outcomes

showed no change in the pH value, which averaged approximately 6.78. It is

presumably because the air supply from the compressor contains little dissolved

O2, which is insufficient to alter the pH considerably. To

counteract this, the regulated addition of huge volumes of O2 is

required, hence the usage of O2 tanks cannot be avoided. Due to the

possible fire hazards posed by the use of O2, security protocols

must also be enhanced. The monitoring results are shown in Figure 5b

Furthermore, developing the pivot parameter also requires precise PID control of the heater. The highest temperature at the end of the measurement session reached 38.6°C at ch1, ch3, and ch4. Due to a temperature deviation of 1.6°C, some consideration may be required regarding the type of cell used. The measurement duration also needs to be increased to ensure the steady-state value of the temperature PID control, where bioreactors are usually used for days. As a result, some evaluation and development of the algorithms used for PID control are required.

Figure 5 a) measurement of temperature profile during the

testing of Auto-PIVOT and b) view window in the Blynk software during the

operation

The

3D cell culture which is the main feature of this bioreactor has become new

standard (Khafaga et al., 2022; Pichler et al.,

2022). Moreover, the substrate

and cell interaction are being optimized in current setting such as using the

perfusion of fludic movement for benefit of cell viability (Yu et al 2022; Nadhif et al., 2020). The observation of single cell has also put

important milestone in the trend of bioreactor (Czosseck et al., 2022; Clement et al 2022; Whulanza

et al., 2014). The progress of microfluidic device fabrication enables

this observation nowadays (Charmet et al., 2020; Suwandi

et al., 2014). This micro-scale environmental control method has

the potential to be applied to a broader range of cell and tissue types in the

future. Though since different cells and tissues have different environmental

parameter needs. This trend in micronization technology is not restricted to

the cellular level; instead, it is slowly moving towards the molecular level (Utomo et al., 2021; Whulanza

et al., 2016). Moreover, the

development of PIVOT is also one of the steps required to advance tissue

engineering into technology 4.0 and a method for preventing the spread of COVID-19

within the laboratory (Berawi et al., 2020a; 2020b).

The Internet of Things system has been successfully integrated

with PIVOT's thermal control, pH, and pressure monitoring to enable remote

monitoring. The server also stores measurement results data so that the data

can be reviewed for further analysis. The simulation results indicate that the

design parameters of shear stress less than 0.2 Pa and fluid velocity of 2

mL/min are compatible with and reliable for developing hepatocyte cells.

Adjusting the thermal control to achieve a steady state at a predetermined

temperature is necessary for further research. Designing and testing a pressure

control module for remote air and CO2 input using hepatocyte cells

is required.

Authors thanks to the Grant of RIIM

(Riset dan Inovasi untuk Indonesia Maju) 2022.

Assyarify, H., Nadhif, M.H., Gates, W.,

Whulanza, Y., 2022. IoT-Enabled Tissue-Engineering Bioreactors for Real-Time

Remote Monitoring: A Trial Using a Thermal Module. AIP Conference

Proceedings, Volume 2537(1), p. 050011

Berawi, M.A., Suwartha, N., Kusrini, E.,

Yuwono, A.H., Harwahyu, R., Setiawan, E.A., Yatmo, Y.A., Atmodiwirjo, P.,

Zagloel, Y.T., Suryanegara, M., Putra, N., Budiyanto, M.A., Whulanza, Y., 2020.

Tackling the COVID-19 Pandemic: Managing the Cause, Spread, and Impact. International

Journal of Technology, Volume 11(2), p. 209

Berawi, M.A., Suwartha, N., Surjandari,

I., Zagloel, T.Y.M., Asvial, M., Harwahyu, R., Suryanegara, M., Setiawan, E.A.,

Maknun, I.J., Kusrini, E., Kartohardjono, S., Sofyan, N., Yuwono, A.H., Harjanto,

S., Putra, N., Budiyanto, M.A., Whulanza, Y., 2020. Accelerating Sustainable

Energy Development through Industry 4.0 Technologies. International Journal

of Technology, Volume 11(8), p. 1463

Be?karde?, I.G., Ayd?n, G., Bekta?, ?.,

Cengiz, A., Gümü?derelio?lu, M., 2018. A Systematic Study for Optimal Cell

Seeding and Culture Conditions in a Perfusion Mode Bone-Tissue Bioreactor. Biochemical

Engineering Journal, Volume 132, pp. 100–111

Bilgen, B., Chu, D., Stefani, R., Aaron,

R.K., 2013. Design of a Biaxial Mechanical Loading Bioreactor for Tissue

Engineering. Journal of Visualized Experiments: JoVE, Volume 74, p.

50387

Birla, R., 2014. Introduction to

Tissue Engineering: Applications and Challenges. IEEE Press

Costa, J., Ghilardi, M., Mamone, V., Ferrari,

V., Busfield, J.J.C., Ahluwalia, A., Carpi, F., 2020. Bioreactor with

Electrically Deformable Curved Membranes for Mechanical Stimulation of Cell

Cultures. Frontiers in Bioengineering and Biotechnology, Volume 8, p. 22

Charmet, J., Rodrigues, R., Yildirim, E.,

Dallmann, R., Whulanza, Y., 2020. Low-Cost Microfabrication Toolbox. Micromachines, Volume 11(2), p. 135

Clément, V., Roy,

V., Paré, B., Goulet, C.R., Deschênes, L.T., Berthod, F., Bolduc, S. and

Gros-Louis, F., 2022. Tridimensional Cell Culture of Dermal

Fibroblasts Promotes Exosome-Mediated Secretion of Extracellular Matrix

Proteins. Scientific Reports, Volume 12(1), p. 19786

Czosseck, A., Chen,

M.M., Nguyen, H., Meeson, A., Hsu, C.C., Chen, C.C., George, T.A., Ruan, S.C.,

Cheng, Y.Y., Lin, P.J. and Hsieh, P.C., 2022. Porous Scaffold for Mesenchymal Cell Encapsulation and Exosome-Based

Therapy of Ischemic Diseases. Journal

of Controlled Release, Volume 352,

pp. 879–892

Hinman, S.S., Kim, R., Wang, Y.,

Phillips, K.S., Attayek, P.J., Allbritton, N.L., 2020. Microphysiological

System Design: Simplicity Is Elegance. Current Opinion in Biomedical

Engineering, Volume 13, pp. 94–102

Huang, J., Lu, L., Zhang, J., Hu, X.,

Zhang, Y., Liang, W., Wu, S., Luo, Z., 2012. Electrical Stimulation to

Conductive Scaffold Promotes Axonal Regeneration and Remyelination in a Rat

Model of Large Nerve Defect. PLOS ONE, Volume 7(6), p. e39526

Jain, A., Bansal, R., 2015. Applications

of Regenerative Medicine in Organ Transplantation. Journal of Pharmacy and

Bioallied Sciences, Volume 7(3), p. 188

Kehtari, M., Zeynali, B., Soleimani, M.,

Kabiri, M., Seyedjafari, E., 2018. Fabrication of a Co-Culture Micro-Bioreactor

Device for Efficient Hepatic Differentiation of Human Induced Pluripotent Stem

Cells (HiPSCs). Artificial Cells, Nanomedicine, and Biotechnology,

Volume 46(sup2), pp. 161–170

Khafaga, A.F.,

Mousa, S.A., Aleya, L., Abdel-Daim, M.M., 2022. Three-dimensional (3D) Cell

Culture: A Valuable Step In Advancing Treatments for Human Hepatocellular

Carcinoma. Cancer Cell International, Volume 22(1), p. 243

Khodabukus, A., Madden, L., Prabhu,

N.K., Koves, T.R., Jackman, C.P., Muoio, D.M., Bursac, N., 2019. Electrical

Stimulation Increases Hypertrophy and Metabolic Flux in Tissue-Engineered Human

Skeletal Muscle. Biomaterials, Volume 198, pp. 259–269

Li, R.A., Keung, W., Cashman, T.J.,

Backeris, P.C., Johnson, B.V., Bardot, E.S., Wong, A.O.T., Chan, P.K.W., Chan,

C.W.Y., Costa, K.D., 2018. Bioengineering an Electro-Mechanically Functional

Miniature Ventricular Heart Chamber from Human Pluripotent Stem Cells. Biomaterials,

Volume 163, pp. 116–127

Liu, C., Sun, Y., Li, N., Zhang, B.,

Zhen, F., 2019. Impact of Temperature Fluctuation on Anaerobic Fermentation

Process of Upgrading Bioreactor under Solar Radiant Heating. Applied Thermal

Engineering, Volume 156, pp. 382–391

Mason, C., Brindley, D.A.,

Culme-Seymour, E.J., Davie, N.L., 2011. Cell Therapy Industry: Billion Dollar

Global Business with Unlimited Potential. Regenerative Medicine, Volume

6(3), pp. 265–272

Meinert, C., Schrobback, K., Hutmacher,

D.W., Klein, T.J., 2017. A Novel Bioreactor System for Biaxial Mechanical

Loading Enhances the Properties of Tissue-Engineered Human Cartilage. Scientific

Reports, Volume 7(1), p. 16997

Nadhif, M.H., Assyarify, H., Waafi,

A.K., Whulanza, Y., 2020. Reflecting on Mechanical Functionalities in

Bioreactors for Tissue Engineering Purposes. International Journal of

Technology, Volume 11(5), p. 1066

Nadhif, M.H., Hadiputra, A.P., Utomo,

M.S., Whulanza, Y., 2019. Fabrication and Characterization of an Affordable

Conditioned Bio-Specimen Transporter (Conbiport) for Urban Areas. International

Journal of Technology, Volume 10(8), p. 1626

Nadhif, M.H., Whulanza, Y., Istiyanto,

J., Bachtiar, B.M., 2017. Delivery of Amphotericin B to Candida Albicans

by Using Biomachined Lab-on-a-Chip. Journal of Biomimetics, Biomaterials and

Biomedical Engineering, Volume 30, pp. 24–30

Paez?Mayorga, J., Hernández?Vargas, G.,

Ruiz?Esparza, G.U., Iqbal, H.M.N., Wang, X., Zhang, Y.S., Parra?Saldivar, R.,

Khademhosseini, A., 2019. Bioreactors for Cardiac Tissue Engineering. Advanced

Healthcare Materials, Volume 8(7), p. 1701504

Petrenko, Y.A., Petrenko, A.Y., Martin,

I., Wendt, D., 2017. Perfusion Bioreactor-Based Cryopreservation of 3D Human

Mesenchymal Stromal Cell Tissue Grafts. Cryobiology, Volume 76, pp.

150–153

Pichler, R., Rizzo,

L., Tröndle, K., Bühler, M., Brucker, H., Müller, A.L., Grand, K., Farè, S.,

Viau, A., Kaminski, M.M. and Kuehn, E.W., 2022. Tuning The 3D Microenvironment of Reprogrammed Tubule Cells

Enhances Biomimetic Modeling of Polycystic Kidney Disease. Biomaterials, Volume 291, p.

121910

Rahmat, A., Jaya, I., Hestirianoto, T.,

Jusadi, D., Kawaroe, M., 2020. Design a Photobioreactor for Microalgae

Cultivation with the IOTs (Internet of Things) System. Omni-Akuatika,

Volume 16(1), p. 53

Rao Vutla, S., Prakash Regalla, S.,

Ramaswamy, K., 2019. A Laminar Fluid Flow Model for Study of Ventilation

Systems in Micro-Electromechanical Systems (MEMS) Clean Room. Journal of

Physics: Conference Series, Volume 1276(1), p. 012057

Reissis, Y., García-Gareta, E., Korda,

M., Blunn, G.W., Hua, J., 2013. The Effect of Temperature on the Viability of

Human Mesenchymal Stem Cells. Stem Cell Research & Therapy, Volume

4(6), p. 139

Sagita, I.D., Whulanza, Y., Dhelika, R.,

Nurhadi, I., 2018. Designing Electrical Stimulated Bioreactors for Nerve Tissue

Engineering. AIP Conference Proceedings, Volume 1933(1), p. 040019

Schmid, J., Schwarz, S., Meier-Staude,

R., Sudhop, S., Clausen-Schaumann, H., Schieker, M., Huber, R., 2018. A

Perfusion Bioreactor System for Cell Seeding and Oxygen-Controlled Cultivation

of Three-Dimensional Cell Cultures. Tissue Engineering Part C: Methods,

Volume 24(10), pp. 585–595

Schuerlein, S., Schwarz, T., Krziminski,

S., Gätzner, S., Hoppensack, A., Schwedhelm, I., Schweinlin, M., Walles, H.,

Hansmann, J., 2017. A Versatile Modular Bioreactor Platform for Tissue

Engineering. Biotechnology Journal, Volume 12(2), p. 1600326

Suwandi, D., Whulanza, Y., Istiyanto, J.,

2014. Visible Light Maskless Photolithography for Biomachining Application. Applied Mechanics and Materials, Volume 493, pp.

552–557

Utomo, M.S., Nadhif, M., Bayani, G.F.E.,

Whulanza, Y., 2021. A Low Cost, off-the-Shelf Bioreactor as Enabling Technology

for Physiological Modeling. In: The 5th Biomedical Engineering's Recent

Progress in Biomaterials, Drugs Development, and Medical Devices: Proceedings

of the 5th International Symposium of Biomedical Engineering (ISBE) 2020.

Depok, Indonesia, p. 050017

Valls-Margarit, M., Iglesias-García, O.,

Di Guglielmo, C., Sarlabous, L., Tadevosyan, K., Paoli, R., Comelles, J.,

Blanco-Almazán, D., Jiménez-Delgado, S., Castillo-Fernández, O., Samitier, J.,

Jané, R., Martínez, E., Raya, Á., 2019. Engineered Macroscale Cardiac

Constructs Elicit Human Myocardial Tissue-like Functionality. Stem Cell

Reports, Volume 13(1), pp. 207–220

Villa-Diaz, L.G., Ross, A.M., Lahann,

J., Krebsbach, P.H., 2013. Concise Review: The Evolution of Human Pluripotent

Stem Cell Culture: From Feeder Cells to Synthetic Coatings. STEM CELLS,

Volume 31(1), pp. 1–7

Wang, B., Wang, Z., Chen, T., Zhao, X.,

2020. Development of Novel Bioreactor Control Systems Based on Smart Sensors

and Actuators. Frontiers in Bioengineering and Biotechnology, Volume 8,

p. 7

Whulanza, Y., Aditya, R., Arvialido, R.,

Utomo, M.S., Bachtiar, B.M., 2017. Ease Fabrication of PCR Modular Chip for

Portable DNA Detection Kit. In: Biomedical Engineering’s Recent Progress in

Biomaterials, Drugs Development, and Medical Devices: Proceedings of the First

International Symposium of Biomedical Engineering (ISBE 2016). Depok City,

Indonesia, p. 040006

Whulanza, Y., Arafat, Y.B., Rahman,

S.F., Utomo, M.S., Kassegne, S., 2022. On-Chip Testing of a Carbon-Based

Platform for Electro-Adsorption of Glutamate. Heliyon, Volume 8(5), p.

e09445

Whulanza, Y., Nadhif, H., Istiyanto, J.,

Supriadi, S., Bachtiar, B., 2016. PDMS Surface Modification Using Biomachining

Method for Biomedical Application, Journal of Biomimetics, Biomaterials and

Biomedical Engineering, Volume 26, pp. 66–72

Whulanza, Y., Widyaratih, D.S.,

Istiyanto, J., Kiswanto, G., 2014. Realization and Testing of Lab-On-Chip for

Human Lung Replication. ARPN Journal of Engineering and Applied Sciences,

Volume 9(11), pp. 2064–2067

Zhu, S., Wang, J., Xie,

B., Luo, Z., Lin, X., Liao, D.J., 2015. Culture at a Higher Temperature Mildly

Inhibits Cancer Cell Growth but Enhances Chemotherapeutic Effects by Inhibiting

Cell-Cell Collaboration. PLOS ONE, Volume 10(10), p. e0137042