Optimization Concentration of Irgacure® 2959 as Photo-initiator on Chitosan-Kappa-Carrageenan Based Hydrogel for Tissue Sealant

Corresponding email: nugrahenips@ugm.ac.id

Published at : 30 Dec 2022

Volume : IJtech

Vol 13, No 8 (2022)

DOI : https://doi.org/10.14716/ijtech.v13i8.6166

Kamala, F.Z., Budhijanto, W., Purnomo, E., Nugraheni, P.S., 2022. Optimization Concentration of Irgacure® 2959 as Photo-initiator on Chitosan-Kappa-Carrageenan Based Hydrogel for Tissue Sealant. International Journal of Technology. Volume 13(8), pp. 1715-1725

| Fiskina Zulfa Kamala | Department of Fisheries, Faculty of Agriculture, Universitas Gadjah Mada, Sleman, Yogyakarta, 55281, Indonesia |

| Wiratni Budhijanto | Department of Chemical Engineering, Faculty of Engineering, Universitas Gadjah Mada, Sleman, Yogyakarta, 55281, Indonesia |

| Eko Purnomo | Division of Pediatric Surgery, Department of Surgery, Faculty of Medicine, Public Health, and Nursing, Universitas Gadjah Mada, Yogyakarta, 55281, Indonesia |

| Prihati Sih Nugraheni | Department of Fisheries, Faculty of Agriculture, Universitas Gadjah Mada, Sleman, Yogyakarta, 55281, Indonesia |

Hydrogel

is a three-dimensional network of hydrophilic polymers widely used in the

biomedical field, one of which is a tissue sealant. The material that can be

used in the manufacture of hydrogels is chitosan. The ability of chitosan in

the formation of hydrogel is still limited by its swelling and adhesive

properties, so it requires other materials such as crosslinkers, one of which

is kappa-carrageenan which can stabilize and increase the viscosity of the

hydrogel. The addition of Irgacure® 2959 as a photo-initiator to the

hydrogel can produce free radicals that can bind to the active group of the

polymer. This study aims to determine the effect of adding Irgacure®

2959 in the manufacture of hydrogel based on a chitosan-kappa-carrageenan

solution formulated as a colon tissue adhesive. The treatments given were the

addition of Irgacure® 2959 as much as 0%, 1%, 2%, 3%, and 4%. The

characteristics of the hydrogel tested qualitatively (simulation adhesion

test), degree of swelling, resistance to water, degree of crystallinity, and

ability to inhibit bacterial growth. The addition of Irgacure® 2959

did not show significantly different results from the control that indicating

it cannot increase the crosslinking between chitosan and kappa-carrageenan.

This is predicted due to the presence of steric hindrance from

kappa-carrageenan, causing very limited crosslinking due to the molecular size

difference between chitosan and kappa-carrageenan. Further, it is necessary to

optimize the ratio of the chitosan and kappa-carrageenan to get the balance

ratio that supports the occurrence of cross-linking.

Carrageenan; Chitosan; Hydrogel; Irgacure® 2959; Photo-initiator

Hydrogels

are three-dimensional networks of hydrophilic polymers with 90-99% moisture

content that facilitate efficient mass and oxygen transfer and endogenous

regeneration, drug delivery, and wound healing (Yegappan

et al., 2018). One of the materials that can be used as raw material for

making hydrogels is chitosan which has flexible, non-toxic, hydrophilic,

anti-bacterial properties and provides wound healing effects, so it is widely

used in biomedical and tissue engineering (Zhang et

al., 2018). The properties of chitosan make it potential to be used as a

raw material for making tissue sealant.

Tissue

sealant is a substance with the ability to bind two tissue substrates together.

One of these tissue sealants can be applied to glue the tissue in the wound

that is produced after the operation process on the colon tissue. Materials

that are usually used as tissue sealants are macromolecules (Nayeb et al., 2011) which have biocompatible and

biodegradable properties (Bao et al, 2020), one of which is chitosan (Asadpour et al., 2020). Chitosan was chosen as an

alternative to reduce the shortcomings that arise from tissue sealants with

previously used materials, namely cyanoacrylate, fibrin, and gelatin.

Chitosan-based hydrogels are still limited by their swelling and adhesive

properties and are weak in charge interactions without forming bonds between

related chains (Phuong et al, 2019), thus

requiring the addition of other materials as crosslinkers. Crosslinker material

is added to form crosslinks between the polymers used which can affect the

shape of the cavity in the hydrogel and affect the hydrogel's ability. The use

of this crosslinker can help increase swelling ability and more stable bond

strength (Ding et al., 2020). One of the

materials that can be used as a crosslinker in chitosan hydrogel is carrageenan

with good mechanical properties, biocompatible and non-toxic (Derkach et al., 2018) and can stabilize and form

viscosity that it can be used as a gelling agent by forming a helical network

with double molecule resulting from the sulfate group (Wang

et al, 2018). There are various carrageenan types, including iota-,

kappa-, and lambda-carrageenan (Darmayanti et al.,

2016). In this study, we used kappa carrageenan as the basis for the

hydrogel.

The use of chitosan and carrageenan in

the manufacture of hydrogels is based on the properties of each polymer needed

in medical applications. Chitosan-carrageenan film hydrogel has been made to be

applied to fibroblast cells (Yu et al., 2018),

showing that chitosan-carrageenan can heal cells because it is non-toxic, which

causes cells to grow well. Chitosan-carrageenan-based hydrogel has the

potential to produce a more flexible hydrogel so that it can be an alternative

to tissue sealant that has previously been used but have brittle and less

flexible properties. According to intestinal surgeons, 80% of cases of

postoperative failure of the colon occur due to the use of adhesive tissue that

is brittle and inflexible so that it is not compatible with peristalsis in the

intestines so that chitosan-carrageenan hydrogel can be used as a tissue

sealant, especially to be applied to the colon. Preparation hydrogels as tissue

sealant by using crosslinking will produce better mechanical strength and

hydrophilicity. The hydrogel produced by the crosslinking method produces a

cross-linked structure that is not easily soluble in water, and the gel form

can be maintained (Yu et al., 2018). The

crosslinking method used in the manufacture of hydrogels, namely the

photo-crosslinking method, refers to the research that used Irgacure®

2959 which has benzoyl and ketone active ingredients as photo-initiators in the

manufacture of hydrogels (Qi et al., 2013).

The addition of Irgacure® 2959 will change the crosslink strength,

which can affect the results of the hydrogel characteristics test. Therefore,

the chitosan-carrageenan-based hydrogel formulation was carried out with the

optimization of Irgacure® 2959 as a photo-initiator with the aim of

knowing the characteristics of the hydrogel as a colonic tissue adhesive.

The research

was started by optimizing the concentration of chitosan and carrageenan

solutions to find the concentrations to be used as the basis for making

hydrogels which were selected based on the level of viscosity produced. Next,

optimization of the solution mixing method was carried out to find the right

method to use in the manufacture of hydrogels based on the homogeneity of the

resulting hydrogels. The next step is to optimize the concentration of Irgacure®

2959 to determine the concentration range to be selected for further

characterization of the hydrogel.

2.1. Optimization of chitosan

and carrageenan solutions

Optimization

of chitosan and carrageenan solutions needs to be done to determine the right

concentration of chitosan and carrageenan for hydrogel manufacture.

Optimization of the concentration of chitosan solution was carried out by

dissolving chitosan powder (DD. 98 from Bio Chitosan Indonesia) with 0.5%

acetic acid (Merck) at a concentration of 1%, 2%, and 3%. The optimization of

the carrageenan solution was carried out by dissolving the carrageenan powder

(CV Karagen Indonesia) using distilled water at a temperature of 50oC

with a concentration of 1%, 2%, and 3%.

2.2. Optimization of the mixing

method

Optimization of the mixing method was

carried out by several methods, such as mixing the chitosan solution with the

carrageenan solution directly, done by adding a solution of carrageenan (2%)

into a solution of chitosan (2%) with a ratio of 1:1 then stirring using a

magnetic stirrer. Mixing the chitosan and carrageenan solutions dropwise, done

by adding a solution of carrageenan (2%) into a solution of chitosan (2%)

dropwise while stirring continuously at a temperature of 60oC. Also,

mixing the chitosan solution with carrageenan powder by using chitosan solution

(2%) and carrageenan powder (2%, 3%, 4%, and 5%) was carried out by adding

carrageenan powder into the chitosan solution slowly at a temperature of 50oC

and stirring continuously. The observed results from the optimization of the

mixing method were observed qualitatively, namely the homogeneity and viscosity

of the hydrogel by tilting the hydrogel at an angle of approximately 45oC.

The selected results based on hydrogel will be used to optimize the

concentration of Irgacure® 2959.

2.3. Optimization concentration

of Irgacure® 2959

The manufacture of hydrogels with the

addition of Irgacure® 2959 refers to the earlier research (Qi et al., 2013) by dissolving chitosan (2%),

which was stirred at 45-50oC for 1 hour. Then in a warm state,

carrageenan powder (4%) was added little by a little while stirring for 15

minutes at 45-50oC. Irgacure® 2959 powder (Jinan

Huijinchuan Chemical CO., Ltd) was added in the dark at a concentration of 1%,

2%, 3%, 4%, and 5% and continuously stirred at 40oC for 15 minutes.

The hydrogel was irradiated with 8-watt UV light with a wavelength of 235nm for

15 minutes. The resulting hydrogel was observed for homogeneity, and then the

concentration was chosen to be used in the chitosan-carrageenan hydrogel

characteristics test. Based on the hydrogel produced, the concentration of

Irgacure® 2959 was chosen to be used in the study with the following

research design below (Table 1).

Table

1 Research design of chitosan-carrageenan hydrogel

|

Treatment |

Chitosan (%) (solution) |

Carrageenan (%) (powder) |

Irgacure® 2959 (%) |

|

A |

2% |

4% |

0% |

|

B |

2% |

4% |

1% |

|

C |

2% |

4% |

2% |

|

D |

2% |

4% |

3% |

|

E |

2% |

4% |

4% |

2.4. Chitosan-carrageenan

hydrogel analysis and characterization

2.4.1. Swelling

ratio

Swelling ratio testing was

carried out using a hydrogel film that was cut to a size of 1cmx1cm and weighed

(wo). The hydrogel film was put into a phosphate buffer saline (PBS) solution

and soaked for 24 hours in a water bath shaker at 37oC. After 24 h,

the films were lifted, dried, and weighed (w). The swelling ratio is calculated

by the formula:

Where w is

hydrogel film weight after soaked (g) and wo is hydrogel film before soaked

(g).

2.4.2. Water

resistance

Water resistance testing

is done by forming a hydrogel into a layer that is printed on silicone. The

water resistance was tested by cutting the hydrogel film (1cmx1cm) and weighing

it (W0), then putting it in aquadest at room temperature. The hydrogel is

lifted, dried, and weighed (W) per one minute, then repeated until the weight

is constant. Water resistance is calculated by the formula:

Where w is the

hydrogel film’s constant weight after soaked (g) and wo is dried hydrogel film

(g).

2.4.3. Adhesion

simulation on smoked beef

Simulation of adhesion was

carried out by applying chitosan-carrageenan hydrogel between two pieces of

smoked beef measuring 2x5 cm and then allowed to stick (Ono

et al., 2000). Smoked beef is pulled on both sides to measure its

adhesive qualitatively.

2.4.4. Degree

of crystallinity (X-Ray Diffraction)

Testing the degree of

crystallinity with X-Ray Diffraction (XRD) was carried out using a sample with

a size of 1.9 x 1.4 cm with a thickness of 1 mm according to the size of the

sample holder. The sample was placed in a holder and then analyzed with an

X-ray diffraction tool for 6 minutes. The results will appear on the monitor

screen. Furthermore, the degree of crystallinity is calculated using the

formula:

2.4.5.

Antibacterial activity

Antibacterial activity

testing was carried out using the paper disk diffusion method using Escherichia coli bacteria. The bacteria to be used were first

rejuvenated in a solution of Nutrient broth (NB) and incubated for 24 hours at

37°C. The bacteria that had grown on the NB were then taken to be poured and

spread over the Nutrient Agar (NA). Furthermore, to test the antibacterial

ability, paper discs with a size of 0.5 cm were immersed in a hydrogel sample

aseptically, then placed on NA and incubated with an incubator (Isuzu Sesakusho

Co., LTD) for 24 hours at 37°C. Antibacterial activity can be calculated by

measuring the clear zone (inhibition zone) that appears around the paper disc.

3.1. Optimization of chitosan

and carrageenan solutions

Based on the characteristics of the hydrogel, the concentration of the chitosan and carrageenan solution selected was 2%. This concentration was chosen because it has a viscosity that is neither too liquid nor too thick, so it can be suitable for its use as a tissue adhesive in wounds in the intestine. The gel used as a wound dressing should have a viscosity that is neither too liquid nor thick so that it can be easily applied (Sularsih, 2013). In addition, the selection of 2% chitosan concentration is expected to provide a good antibacterial effect (Damayanti et al., 2016); 2% chitosan has an optimal ability to form gels and has good antibacterial ability.

3.2. Optimization of the mixing method

The

method chosen was based on the viscosity and homogeneity of the hydrogel.

Hydrogel with a viscosity that is not too liquid and homogeneous is predicted

to improve the mechanical characteristics of the hydrogel. Based on the

resulting hydrogel, mixing chitosan and carrageenan in the form of a solution,

either mixed directly or dropwise, will produce an inhomogeneous hydrogel

characterized by the presence of lumps, and the resulting hydrogel is too

liquid. The formation of lumps in the mixture was predicted because, in the

form of a solution, the carrageenan sulfate group with a negative charge had

bound to cationic water, thus triggering the formation of lumps when added to

the chitosan solution. Therefore, optimization was carried out with another

method, namely by adding carrageenan in powder form to the chitosan solution.

Optimization

of the mixing method by adding carrageenan in powder using a solution

concentration of 2% chitosan and 2% carrageenan produces a liquid solution so

that optimization is carried out by increasing the concentration of carrageenan

to 3%, 4%, and 5%. The addition of carrageenan in powder form to the chitosan

solution can form a homogeneous hydrogel because it is predicted that the

sulfate group of carrageenan can directly bind to the amine group of chitosan

to form a crosslink. Based on the characteristics of the hydrogel produced, the

use of a concentration of 4% carrageenan powder was chosen to be mixed in a 2%

chitosan solution to add Irgacure® 2959 and test its

characteristics.

3.3. Optimization concentration of

Irgacure® 2959

The

addition of Irgacure® 2959 was carried out to strengthen the

crosslinking of the hydrogel (Qi et al., 2013) so

that the characteristics of the hydrogel produced would be better. Also, the

use of Irgacure® 2959 in hydrogels applied in the medical field is

due to its good ability to tolerate fibroblasts. Then Irgacure® 2959

was also successfully used in an in vitro condrocytes encapsulation experiment.

Photopolymerization reactions are becoming a system that is increasingly being

used in medical applications as tissue engineering. it was stated that Irgacure®

2959 is a material that has a tolerance with a wide susceptibility to various

cell types and chemical concentrations (Williams et

al., 2005). So, the addition of Irgacure® 2959 is appropriate

for the manufacture of the hydrogel as a tissue adhesive. The addition of

Irgacure® 2959 to the hydrogel causes a change in the viscosity of

the hydrogel. The more Irgacure® 2959 is used, would make the more

hydrogel become thicker. Based on the characteristics of the viscosity and

homogeneity of the hydrogel. The selected concentration of Irgacure®

2959 is 1%, 2%, 3%, and 4%. Hydrogels with good homogeneity or well-mixed are

predicted to form more regular bonds in hydrogels so that they can strengthen

bonds and produce better characteristic values. Irgacure® 2959 which

is active and exposed to UV light will abstract protons and produce free

radicals, namely benzoyl and ketyl to form intermolecular covalent bonds. These

bonds will form a hydrogel network which is a growth mechanism for the

photopolymerization chain (Pei et al., 2018).

The hydrogel, with the addition of the selected Irgacure® 2959

concentration, was then tested for its characteristics, including swelling

ratio, water resistance, degree of crystallinity (XRD), simulation of adhesion,

and antibacterial ability.

3.4. Chitosan-carrageenan

hydrogel analysis and characterization

3.4.1. Swelling

ratio

The swelling ratio test is presented in Figure 1. The hydrogel forms a three-dimensional macromolecular network able to absorb the water beyond its own volume (Barleany et al., 2020). Based on the results of statistical analysis, the addition of Irgacure® 2959 in the manufacture of hydrogels does not have a significant effect on the swelling ratio value. An increase in the concentration of Irgacure® 2959 will cause the swelling ratio value to decrease due to an increase in intermolecular forces that strengthen crosslink (Qi et al., 2013). The higher the crosslinking that occurs, the denser the intermolecular walls and the lower the swelling ratio value (Cui et al., 2014). The higher the crosslinking, the denser the network and the smaller the pores formed so that the volume of solvent that can occupy the cavities and hydrogel can be used to swell less so that the swelling ratio value is small. However, in this study, the swelling ratio value did not decrease as the concentration of Irgacure® 2959 was added. This is because it is predicted that there will be a steric hindrance that occurs due to the size of the carrageenan molecule that is too large (Sedayu et al, 2019) so that it inhibits the formation of crosslinks in the hydrogel and does not provide a significant difference to the swelling ratio value.

Figure 1 Swelling ratio test

3.4.2. Water

resistance

The water resistance test is presented in Figure 2. Based on the results that have been statistically analyzed, the addition of Irgacure® 2959 to the manufacture of chitosan-carrageenan hydrogel did not give a significant difference to water resistance values. The water resistance of hydrogels is influenced by the bonds formed on the hydrogels. The addition of Irgacure® 2959 can cause the formation of crosslinks in the hydrogel (Qi et al., 2013). The crosslinks formed will make the intermolecular cavities smaller so that the volume of the cavities that can be occupied by the solvent will be smaller and cause the value of water resistance to increase. However, in this study, the increase of Irgacure® 2959 did not increase the water resistance value, which was predicted to occur due to the presence of steric hindrance in the hydrogel due to the large difference in the molecular size of the polymer used. The steric hindrance causes no increase in crosslinking that occurs in the hydrogel as the concentration of Irgacure® 2959 is added so that the water resistance value of the hydrogel produced is not significantly different.

Figure 2 Water resistance test

3.4.3. Adhesion

simulation on smoked beef

Hydrogel adhesion simulation

was carried out by testing using smoked beef (Ono

et al., 2000). The results showed that the increase of concentration of

Irgacure® 2959 added to the manufacture of hydrogels did not give a

significant difference when used to glue smoked beef. The hydrogel used to glue

smoked beef produces a weak adhesion. The simulation shows that the resulting

hydrogel has not shown the desired results because, qualitatively, the hydrogel

is considered not strong enough to bind two tissues together. Qualitatively,

the smoked beef that has been applied with hydrogel already feels attached to

each other but is not too strong and is still easy to separate. This is in line

with the results of the swelling and water resistance of the

chitosan-carrageenan hydrogel, which showed no significant difference with the

increase in the concentration of Irgacure® 2959 added.

3.4.4. Degree of

crystallinity (X-Ray Diffraction)

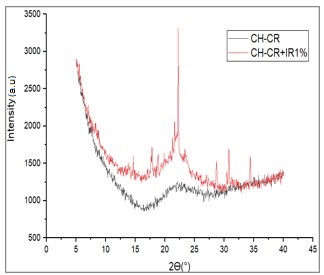

Degree of crystallinity test of the hydrogel was carried out using X-Ray Diffraction (XRD), which aims to determine the crystalline phase formed and changes in the crystal structure that occur in the chitosan-carrageenan hydrogel. The test is carried out with X-Ray Diffraction and then connected to an interface on a computer to find out the results obtained (Kurniawan & Setiyorini, 2014). The results of the XRD test are in the form of crystallinity and amorphous value data that compose the test sample (Warsiki et al., 2020). Based on the results of the degree of crystallinity test, which showed changes in the crystal structure, it could be seen that the bonding occurred in the chitosan-carrageenan hydrogel. XRD test results can be seen in Figure 3.

Figure 3 Hydrogels X-Ray Diffraction result

Based on the XRD results, chitosan does

not have a diffraction peak or can be referred to as amorphous according to the

earlier research (Nugroho et al., 2011),

which shows that there is no diffraction peak in chitosan because it is

predicted that the chitosan has dissolved well. The XRD results of carrageenan

also show that there is no diffraction peak as in the study because the

carrageenan polymer is non-crystalline material, so it does not produce a

diffraction peak (Ulfah & Nugraha, 2014).

The diffractogram of the chitosan-carrageenan hydrogel sample also showed no

peak appearance because both materials were non-crystalline materials. XRD test

results on Irgacure® 2959 showed a diffraction peak with a degree of

crystallinity of 63.39%. Then the chitosan-carrageenan hydrogel with the

addition of 1% Irgacure® 2959 was chosen because it has the lowest

swelling and the highest water resistance value showing diffraction peaks with

a degree of crystallinity of 25.84%. The appearance of diffraction peaks on XRD

results of chitosan-carrageenan hydrogel with the addition of 1% Irgacure®

2959 indicates that there are crosslinks formed but in small amounts. These

peaks can be formed, indicating the level of crystallinity due to changes in

the bonds between polymers due to the addition of Irgacure® 2959.

Based on the data, it shows a change in the bond that occurs so that the

resulting test value changes even though it is not significantly different.

3.4.5.

Antibacterial activity

Antibacterial test was carried out to

determine the ability of chitosan-carrageenan hydrogel to inhibit bacterial

growth. Wounds on the body are susceptible to infection by bacteria that can

hinder the wound-healing process, so tissue adhesive is needed that can inhibit

bacterial growth (Kurniawaty & Putranta, 2019).

The ability to inhibit bacteria can be seen from the resulting clear zone,

which is formed to show the effectiveness of chitosan in inhibiting bacterial

growth (Amanda et al., 2020). The results of

the ability chitosan-carrageenan hydrogel test with the addition of Irgacure®

2959 to inhibit bacterial growth can be seen in Figure 4. In the test, the

negative control used nutrient broth solution, and the positive control used 2%

chitosan solution.

Table 2 Inhibition diameter zone

|

Concentration of Hydrogel |

Control - |

Control + |

0% |

1% |

2% |

3% |

4% |

|

Clear Zone (cm) |

0.00 |

1.33 |

1.33 |

1.17 |

1.00 |

1.00 |

0.83 |

Figure 4 Antibacterial activity test

The clear zone formed in NA

is included in the weak category in inhibiting bacterial growth (Surjowardojo et al., 2015). Based on the results

of statistical analysis, the addition of Irgacure® 2959 to the

hydrogel was not significantly different from the hydrogel without the addition

of Irgacure® 2959. Although not significantly different, increasing

the concentration of Irgacure® 2959 used is known to decrease the

hydrogel's ability to inhibit bacteria. The ability to inhibit bacteria in

hydrogels comes from the polycationic amine group of chitosan, which will

interact with the bacterial cell wall so it can disrupt the metabolism of

bacteria and inhibit their growth (Nurainy et al.,

2008). The non-formation of these bonds causes the number of amine

groups to remain unchanged so that the chitosan-carrageenan hydrogel has the

same ability as the chitosan solution to inhibit bacterial growth. While the

chitosan-carrageenan hydrogel with the addition of Irgacure® 2959

decreased the ability to inhibit bacteria due to the amine group in chitosan

partially bound to Irgacure® 2959.

The absence of significant

differences in the test results for each parameter is thought to be due to the

presence of steric hindrance formed due to the large difference in molecular

size between chitosan and carrageenan, making it difficult for interactions to

occur (Chang et al., 2018). The use of a

higher ratio of carrageenan resulted in more molecules of carrageenan sulfate

groups, thus inhibiting the formation of bonds in the hydrogel, and resulting

in less crosslinking, so that the hydrogel density distance did not change and

resulted in the degree of swelling, which was not significantly different from

the control. The steric hindrance in the hydrogel causes a cavity to form due

to the bond does not change so the water resistance of the hydrogel and the

ability of the cavity in the hydrogel to store the solvent to be used for the

development of the hydrogel was not significantly different for each hydrogel

with the addition of Irgacure® 2959.

The changes in test values in

the test of the characteristics of the chitosan-carrageenan hydrogel with the

addition of Irgacure® 2959 can occur due to changes in the bonds that

occur in chitosan and Irgacure® 2959. This change in bonding is

indicated by the XRD results of the chitosan-carrageenan hydrogel with the

addition of Irgacure® 2959 as much as 1%, which changes by showing

the presence of a distraction peak or the presence of crystalline in the

hydrogel is different from the chitosan-carrageenan hydrogel. This change was

supported by the antibacterial test results on the hydrogel, which showed a

decrease in the value of the chitosan-carrageenan hydrogel with the addition of

Irgacure® 2959. This decrease in antibacterial ability was due to

the free amine group in chitosan, which played a role in attacking cell

membranes in bacteria due to its binding to Irgacure® 2959. The

amine groups that attack the protein on the bacterial cell membrane are the

same, causing the antibacterial properties of the chitosan solution and the

chitosan-carrageenan hydrogel to have the same value. The glueing ability which

was assessed qualitatively from the chitosan-carrageenan hydrogel with the

addition of Irgacure® 2959, showed the same results in each

treatment, which means that the results of the quantitative test on the

hydrogel showed no significant difference. It is necessary to optimize the

chitosan-carrageenan ratio with a higher amount of chitosan or reduce the

amount of carrageenan used so that the sulfate group molecules no longer

inhibit the formation of bonds so that cross-links can occur and form stronger

bonds.

Based on the research that

has been done, it is known that the addition of Irgacure® 2959 to

the manufacture of chitosan-carrageenan-based hydrogel with a ratio of 1:2

using the photo-crosslinking method has not shown good potential as a tissue

adhesive based on the results of characteristic tests. It is necessary to

optimize the ratio to eliminate steric barriers in the hydrogel so that it can

produce cross-links that will improve the water resistance properties and

degree of swelling of the hydrogel. The application of tissue adhesive hydrogel

to be used in the intestine must have good water resistance because the

location of the intestine is in an environment that is always wet to minimize

damage and failure during the process of glueing the tissue. The degree of

swelling is an important indicator to determine the success of the treatment

procedure. Hydrogels are designed to help reconstruct damaged tissues, so the

increased volume will contribute to hemostasis without disturbing surrounding

tissues. Further, it is necessary to optimize the ratio of the chitosan and

kappa-carrageenan to get the balance ratio that supports the occurrence of

cross-linking so that it can help determine which hydrogel is good to use as a

tissue adhesive, especially to be applied to the colon.

The Irgacure® 2959 concentration that added to the

chitosan-carrageenan-based hydrogel did not significantly affect the values for

swelling ratio, water resistance, simulation of adhesion, and antibacterial

activity. This is predicted because there is steric hindrance due to

differences in the size of the chitosan and carrageenan molecules, thus

inhibiting the formation of crosslinks in the hydrogel. Further research is

needed to obtain hydrogel results that can be used as tissue sealants.

This paper was

funded by the Lecturer Research Grant of Agriculture Faculty 2021, Universitas

Gadjah Mada so this research that became part of the first author's thesis

could be carried out properly.

Amanda, E.,

Khoirun, N., Yulianto, A.,

2020. Development of Antibacterial Morganella morganii Bioplastic for Food

Packaging. Jurnal

Kimia dan Kemasan

(Journal of Chemistry and Packaging), Volume 42(1), pp. 29?36

Asadpour, S.,

Kargozar,

S., Moradi,

L., Ai,

A., Nosrati,

H., Ai,

J.,

2020. Natural Biomacromolecule Based Composite Scaffolds from Silk Fibroin,

Gelatin And Chitosan Toward Tissue Engineering Applications. International Journal of Biological

Macromolecules, Volume 154, pp. 1285?1294

Bao, Z., Gao,

M., Sun, Y., Nian, R., Xian, M.,

2020. The Recent Progress of

Tissue Adhesive in

Design Strategies, Adhesive Mechanism and Applications. Materials Science & Engineering: C, Volume 111, p. 110796

Barleany, D.R., Ananta, C.V., Maulina,

F., Rochmat, A., Alwan, H., Erizal, 2020. Controlled Realease of Metformin

Hydrogen Chloride from Stimuli-responsive Hydrogel Based on

Poly(N-Isopropylacrylamide)/Chitosan/Polyvinyl Alcohol Composite. International Journal of Technology, Volume 11(3), pp.

511?521

Chang, S.H., Wu, C.H., Tsai, G.J., 2018.

Effects of Chitosan Molecular Weight on Its Antioxidant and Antimutagenic

Properties. Carbohydrate polymers, Volume 181, pp.1026 ? 1032

Cui, L., Jia, J., Guo, Y., Liu, Y., Zhu,

P., 2014. Preparation and Characterization of IPN Hydrogels

Composed of

Chitosan and

Gelatin Crosslinked by

Genipin. Carbohydrate Polymers, Volume 99, pp. 31?38

Damayanti, W.,

Rochima,

E., Hasan,

Z.,

2016. Application of Chitosan as Antibacterial for Pangasius Fillet at Low Temperature Storage. Jurnal Pengolahan Hasil Perikanan Indonesia (Journal of Processing of Indonesian Fishery Products), Volume 19(3), pp. 321?328

Darmayanti,

M.G., Radiman, C.L., Sudarma, I.M., 2016. Kappa-Carrageenan as an Attractive

Green Substitute for Polyacrylamide in Enhanced Oil Recovery Applications. International Journal of

Technology, Volume 7(3), pp. 431?437

Derkach, S.R.,

Voronko, N.G., Kuchina, Y.A, Kolotova, D.S., Gordeeva, A.M., Faizullin, D.A., Gusev, Y.A., Zuev, Y.F., Makshakova, O.N., 2018. Molecular

Structure and

Properties of

KAPPA-Carrageenan-Gelatin Gels. Carbohydrate Polymers, Volume 197, pp. 66?74

Ding, H., Geng, Y., Lu

J., Zhao,

Y., Bai,

B.,

2020. Impacts of

Crosslinker Concentration on

Nanogel Properties And Enhanced Oil Recovery Capability. Fuel, Volume

267, p. 117098

Kurniawan, B.E.,

Setiyorini,

Y.,

2014. Effect of Holding Time Variation on Quench Annealing Heat Treatment on

Mechanical and Microstructural Properties of AISI 3401 Manganese Steel. Jurnal Teknik Pomits (Journal of Engineering Pomits), Volume 3(1)

Kurniawaty, E., Putranta, N.R., 2019. Potency

of Chitosan Biopolymer for Wound Treatment. Medula, Volume 9(3), pp. 459?464

Nayeb, H.F., Salahshoor, K.S., Afshar, T.F., Shariatinia, Z., 2011. A Novel

Topical Biocompatible Tissue Adhesive Based on Chitosan-Modified Urethane

Pre-Polymer. Iranian Polymer Journal, Volume 20, pp.671?680

Nugroho, A.,

Nurhayati,

N.D.,

Utami,

B., 2011.

Synthesis and Characterization of Chitosan

Membranes for Application as A Heavy Metal Detection Sensor.

Molekul, Volume

6(2), pp. 123?136

Nurainy, F., Rizal, S., Yudiantoro, 2008. The

Effect of Chitosan Concentrations on The Antibacterial Activity with Gel Diffusion/Well

Method. Jurnal

Teknologi Industri dan Hasil Pertanian (Journal of Industrial Technology and Agricultural

Products), Volume

13(2)

Ono, K., Saito, Y., Yura, H., Ishikawa,

K., Kurita, A., Akaike, T., Ishihara, M., 2000.

Photocrosslinkable Chitosan as

A Biological Adhesive. Journal of Biomedical Materials Research: An Official Journal of

The Society for Biomaterials and The Japanese Society for Biomaterials, Volume

49(2), pp. 289?295

Pei, M., Mao, J., Xu, W., Zhou, Y.,

Xiao, P.,2018. Photocrosslinkable

Chitosan Hydrogels and Their Biomedical

Applications. Journal of Polymer Science Part A: Polymer Chemistry, Volume

57(18), pp.1862?1871

Phuong, P.T.M., Won, H.J., Oh, Y.J.,

Lee, H.S., Lee, K.D., Park, S.Y., 2019.

The Chemistry and

Engineering of

Mussel-Inspired Glue Matrix for

Tissue Adhesive and

Hemostatic. Journal of Industrial and

Engineering Chemistry, Volume 80, pp. 749?756

Qi, Z., Xu, J., Wang, Z., Nie, J., Ma,

G., 2013.

Preparation and

Properties of

Photo-Crosslinkable Hydrogel Based on Photopolymerizable Chitosan

Derivative. International Journal of Biological Macromolecules, Volume 53, pp. 144?149

Sedayu, B.B., Cran, M.J., Bigger, S.W., 2019. A Review of Property

Enhancement Techniques For Carrageenan-Based Films and Coating. Carbohydrate Polymers, Volume 216, pp. 287?302

Sularsih., 2013. The

Effect of Viscosity Chitosan Gel to The Application Wound Healing Process.

Jurnal Material Kedokteran Gigi (Journal of Dentistry Materials), Volume 2(1), pp. 60?67

Sumarni, W.,

Prasetya, A.T., Rahayu

E.F.,

2017. Effect of

Glycerol on

Physical Properties of

Biofilm Gembili Starch (Dioscorea esculenta)-Chitosan. In Proceeding of Chemistry Conference. Volume 2, pp. 5665

Surjowardojo, P.,

Tri, E.,Gabriel, R.,

2015. Inhibitor Power of Manalagi Apple Skin Decook (Malus sylvestrs Mill) on The Growth of Staphylococcus aureus and Pseudomonas sp. Causes of Mastitis in Dairy Cow.

Journal of Tropical Animal Production, Volume 16(2), pp. 40?48

Ulfah, F., Nugraha, I., 2014. Effect

of Montmorillonite Addition to Mechanical Properties of

Carrageenan-Montmorillonite Film Composite. Molekul, Volume

9(2), pp. 155?165

Wang, Y., Yuan, C., Cui,

B.,

Liu,

Y.,

2018. Influence of

Cations on

Texture, Compressive Elastic Modulus, Sol-Gel Transition and Freeze-Thaw

Properties of

Kappa-Carrageenan Gel. Carbohydrate Polymers, Volume 202, pp. 503?535

Warsiki, E.,

Setiawan, I., Hoerudin., 2020. Synthesis

of Cassava Skin Starch-Silica Nanoparticles Bioplastic Composite and Its

Characterization. Jurnal

Kimia dan Kemasan (Journal

of Chemistry and Packaging), Volume

42(2), pp. 37-45

Williams, C.G., Malik, A.N., Kim, T.K.,

Manson, P.N., Elisseeff, J.H., 2005. Variable Cytocompatibility of Six Cell

Lines with Photoinitiators Used for Polymerizing Hydrogels and Cell

Encapsulation. Biomaterials, Volume 26(11),

pp.1211?1218

Yegappan, R., Selvaprithiviraj, V.,

Amirthalingam, S., Jayakumar, R., 2018. Carrageenan

Based Hydrogels for

Drug Delivery, Tissue Engineering and Wound Healing. Carbohydrate Polymer, Volume 198, pp. 385?400

Yu, H.C., Zhang, H., Ren, K., Ying, Z.,

Zhu, F., Qian, J., Ji, J., Wu, Z.L., Zheng, Q., 2018. Ultrathin ?-carrageenan/chitosan

Hydrogel Films with High Toughness and Antiadhesion Property. ACS

applied materials & interfaces, Volume 10(10),

pp.9002?9009

Zhang, Y., Wang, X., Xu, C., Yan, W.,

Tian, Q., Sun, Z., Yao, H., Gao, J., 2018. Fabrication Of Chitosan

Gel Droplets Via Crosslinking Of Inverse Pickering Emulsifications. Carbohydrate Polymers, Volume 186, pp. 1?8