Optimization of Irgacure® 2959 Concentration as Photo-Initiator on Chitosan-Alginate Based Hydrogel for Colon Tissue Sealant

Corresponding email: nugrahenips@ugm.ac.id

Published at : 30 Dec 2022

Volume : IJtech

Vol 13, No 8 (2022)

DOI : https://doi.org/10.14716/ijtech.v13i8.6164

Puspitasari, D., Budhijanto, W., Purnomo, E., Nugraheni, P.S., 2022. Optimization of Irgacure® 2959 Concentration as Photo-Initiator on Chitosan-Alginate Based Hydrogel for Colon Tissue Sealant. International Journal of Technology. Volume 13(8), pp. 1704-1714

| Diah Puspitasari | Department of Fisheries, Faculty of Agriculture, Universitas Gadjah Mada, Jl. Flora Gd. A4, Bulaksumur, Yogyakarta, 55281, Indonesia |

| Wiratni Budhijanto | Faculty of Medicine, Public Health, and Nursing, Universitas Gadjah Mada, Senolowo, Jl. Farmako, Sekip Utara, Depok, Sleman, Yogyakarta, 55281, Indonesia |

| Eko Purnomo | Department of Chemical Engineering, Faculty of Engineering, Universitas Gadjah Mada, Sendowo, Sinduadi, Sleman, Yogyakarta, 55281, Indonesia |

| Prihati Sih Nugraheni | Department of Fisheries, Faculty of Agriculture, Universitas Gadjah Mada, Jl. Flora Gd. A4, Bulaksumur, Yogyakarta, 55281, Indonesia |

Tissue sealant is a material that is used as an

adhesive to bond two tissue surfaces used during surgery. Chitosan and alginate

are natural macromolecules used to manufacture hydrogels as tissue sealants

because these two materials can strengthen bonds and the mechanical properties

of tissue sealants.

Irgacure®

2959, as a photo-initiator, can strengthen the cross-linking between

chitosan-alginate to produce a tissue sealant with good mechanical strength.

Therefore, this study aims to determine the effect of adding Irgacure® 2959

to chitosan-alginate hydrogel with different concentrations as a tissue sealant

designed for the colon. The experimental design used a completely randomized

design (CRD) with the addition of Irgacure® 2959 0; 1; 2; 3; 4%. The

characteristics of the hydrogel as a tissue covering observed in this study

include the degree of swelling, water resistance, simulated adhesion, degree of

crystallinity, and ability to inhibit bacteria. The results of this study

showed that the addition of 4% Irgacure® 2959 reduced the degree of

swelling, increased the hydrogel's resistance to water, and increased adhesion.

The interaction of chitosan and alginate with the addition of Irgacure®

2959 produces cross-links, as evidenced by a degree of crystallinity of 26.21%.

Based on these results, the chitosan-alginate hydrogel with the addition of

Irgacure® 2959 showed good potential in tissue sealant formulations,

even though the inhibition of bacteria in all treatments showed low results,

namely < 5 mm.

Alginate; Chitosan; Hydrogel; Irgacure® 2959; Photo-initiator

Chitosan

is a polymer with a polycationic linear chain consisting of one primary amine

and two free hydroxyl groups (Bakshi et al., 2020).

Chitosan is used in the biomedical field in the form of a hydrogel, which can

be used as a tissue sealant to combine tissue surfaces during the operation

process (Jarret et al., 2013). Hydrogels are

hydrophilic and can absorb and release water. These properties make hydrogels

usable as sealants because they have a moist environment, are flexible, have

mechanical muscle strength, and are non-toxic, so they have the potential to be

applied in the large intestine (Ehterami et al., 2019). Hydrophilic properties of hydrogels can

influence cellular attachment between two surfaces (Dewi

et al., 2020). Tissue

sealants are more advantageous than sutures and clamps because the wound closure process becomes more

accessible, faster, and less painful to minimize problems during the

application and removal of sutures (Nayeb et al., 2011).

Chitosan is one of

the biomacromolecules utilized. Chitosan has biocompatible, biodegradable

properties, good tensile strength properties, is easily modified when applied

to physiological pH, can act as an adhesive, is antibacterial, can help heal

wounds quickly, and is non-toxic. As a result, it is suitable for use as a

material in the production of hydrogels (Asadpour

et al., 2020; Bagher et al., 2020; Bektas et al., 2020). Chitosan

requires a crosslinker to increase its cross-linking strength so that the

resulting hydrogel has strong adhesion and is not easily brittle. Alginate can

play the role of a crosslinker because it has good biocompatibility, low

toxicity, and can be modified easily via photocrosslinking (Lee & Mooney, 2012). According to Wang et al. (2017), who tried to make hydrogels

from chitosan-alginate by physically cross-linking methods applied to olfactory

nerve cells, which shows that the hydrogels were able to stimulate cell

proliferation. Based on this study, chitosan-alginate can be used as a tissue

sealant.

The

hydrogel can use both materials in the form of chitosan-alginate to make

hydrogels through the photocrosslinking method. Making hydrogels using the

photocrosslinking method requires a photo-initiator. These compounds can form

good mechanical bonds, maintain hydrogel properties in the long term, obtain

uniform properties, and help form pores as a place for cell attachment (Qi et al., 2013). Irgacure® 2959 is

the most commonly used photo-initiator because of its low cytotoxicity and

possible immunogenicity, making it safe to make hydrogels as tissue sealants (Tomal et al., 2020). The added concentration of

Irgacure® 2959 affects the cross-linking between polymers and the

mechanical properties of the hydrogel as a tissue sealant. Therefore, this

study aims to determine the effect of the addition of Irgacure® 2959

on the characteristics of the chitosan-alginate hydrogel. Its parts will be

observed so that it can assess its potential as a tissue covering designed for

the large intestine.

2.1. Hydrogel Preparation

The chitosan comes from Bio

Chitosan Indonesia with a DD 98%, alginate from Leyoung Int, and Irgacure®

2959 from Jinan Huijinchuan Chemical Co., Ltd). The manufacture of the hydrogel

begins with the manufacture of a 2% chitosan solution, which refers to the

research of Baysal et al. (2013) with

modifications. 2 grams of powdered chitosan were dissolved in a 0.5% (v/v)

acetic acid solution. Stirred the solution using a hot plate stirrer (Arec Heating Magnetic Stirrer), at a

speed of 400 rpm for 1 hour at a temperature of 40-45?C. Furthermore, making a

2% alginate solution refers to the research of Bagher

et al. (2020) with modifications. 2 grams of powdered alginate were

dissolved in 100 ml of distilled water. Stirred the alginate solution using a

hot plate stirrer at a speed of 400 rpm for 1 hour at a temperature of 40-45?C.

The selection of alginate chitosan concentration was carried out through a

preliminary study by observing the viscosity of the solution visually. According to Sularsih (2013), when used as a wound healer in a

chitosan solution thick enough to facilitate application, its mucoadhesive

properties are expected to be better for wound healing and closure. The choice

of 2% alginate solution is because, according to Chandramouli

et al. (2004), the use of alginate concentrations of more than 2% is not

possible to obtain homogeneous results due to an increase in solution viscosity

and mass diffusivity, and higher alginate concentrations give heavier and

thicker membrane results. Still, the porosity, strength, and elongation are

decreasing.

2.2. Optimization of

Chitosan-Alginate Solution Mixing Method and Concentration of Irgacure®

2959

Mixing chitosan and alginate solutions refers to the research of Baysal et al. (2013) with modifications. Chitosan solution and alginate solution were mixed in a 1:1 ratio. The selection of hydrogel from the mixing method is chosen based on its homogeneity. At this stage, optimization is carried out with five different methods, namely as follows:

2% chitosan solution plus 2% alginate solution added dropwise at

room temperature

2% chitosan solution plus 2% alginate powder at 50oC

2% chitosan solution at 40?C plus 2% alginate solution at room

temperature directly

2% chitosan solution plus 1% alginate solution directly at a temperature

of 40-45oC

2% chitosan solution plus 2% alginate solution directly at a temperature

of 40-45oC

2.3. Method of

Mixing Irgacure® 2959 into Chitosan-Alginate Solution

Optimization of the

Irgacure® 2959 addition method was carried out in 2 ways: directly and added 30

minutes after the chitosan-alginate solution was mixed. Furthermore,

optimization of the concentration of Irgacure® 2959 was carried out

referring to the research by Qi et al. (2013)

and study by Han et al. (2020), used

concentrations of 0.5%, 0.75%, 1%, 1.25%, 2%, 3%, 4%, 5%, and 6%. The addition

of Irgacure® 2959 was added in powder form to the chitosan-alginate

solution. The choice of concentration used is based on the homogeneity of the

hydrogel and its suitability for application as a tissue sealant.

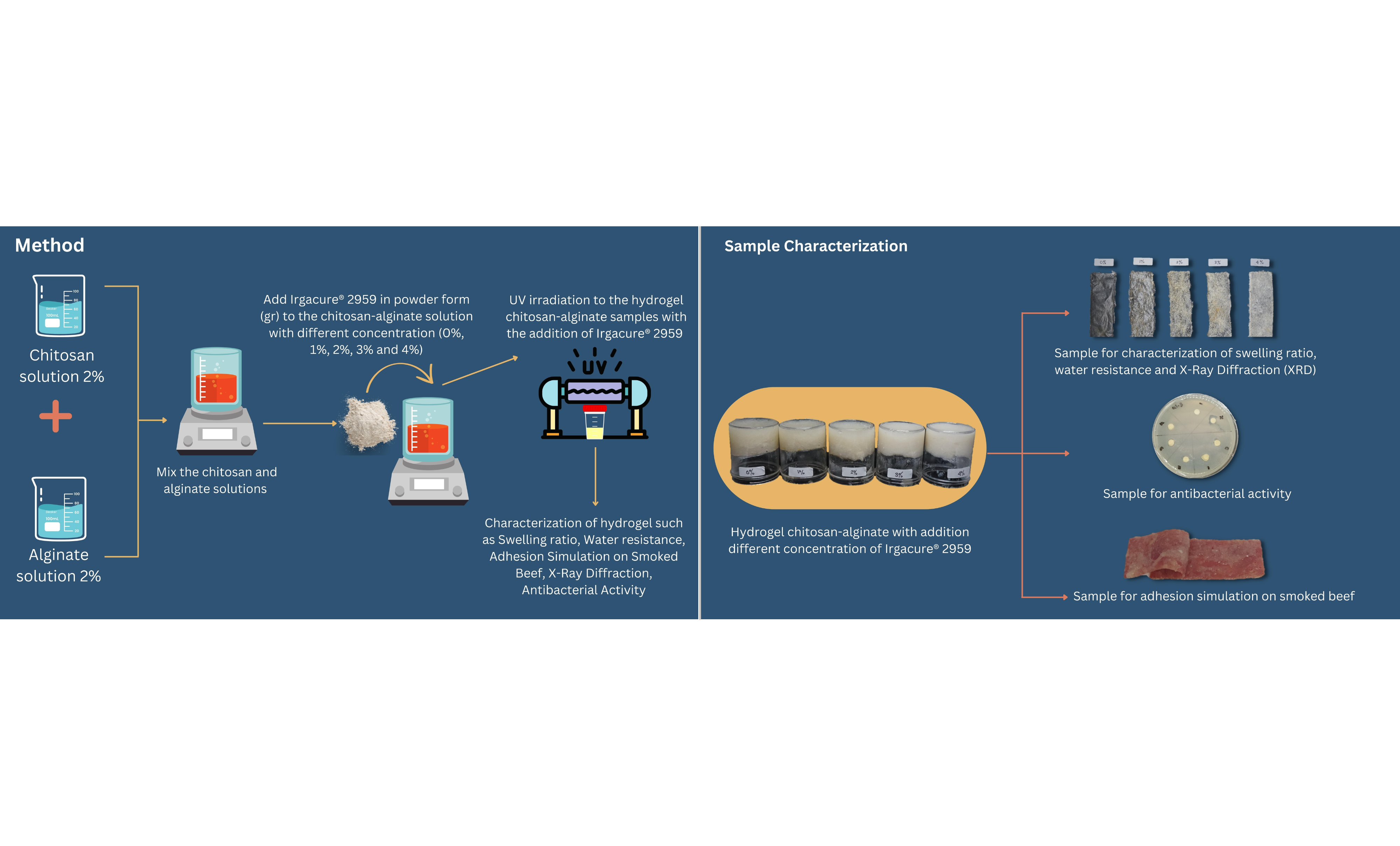

After doing all the optimization, the next step is to make chitosan-alginate hydrogel with the addition of Irgacure® 2959. The scheme for the illustration of the preparation of the composite can be seen in Figure 1.

Figure 1 Illustration of the preparation of the composite

2.4. Analysis and

Characterization of Hydrogels as Tissue Sealant

2.4.1. Swelling ratio

The swelling test refers to

the research of Khan et al. (2020), which

was modified. The swelling test was carried out using a 1x1 cm dried hydrogel

sample that was immersed in 10 ml of phosphate buffer saline (PBS) solution at

37?C at 130 rpm for 24 hours on a water bath shaker. The water still on the

surface of the hydrogel was removed using a tissue. The swelling ratio is

calculated as the difference between the final weight after immersion and the

initial weight, divided by the final weight of immersion, and multiplied by

100%.

Where Wd is the sample was weighed, and Ws is the initial weight

2.4.2. Water

resistance

The water resistance test

refers to the research of Sumarni et al. (2017).

The sample used is a dry hydrogel measuring 1 x 1 cm. Then, put the sample into

a beaker containing 10 ml of distilled water for 1 minute. After 1 minute,

remove the sample and wipe away any adhering water with a tissue. Then repeat

the process until you reach a constant weight. Then the percentage of water

resistance is calculated as 100% minus the difference in the final weight with

the initial weight divided by the initial weight multiplied by 100%.

Where W0 is the initial

weight of the sample, and W has finally weighed the sample

2.4.3. Adhesion

simulation on smoked beef

This test was conducted using smoked

beef media, which refers to the research of Ono et

al. (2000). The adhesive simulation test is done by preparing two pieces

of smoked beef measuring 2x5 cm with a thickness of 2mm. The created hydrogel

is then applied to one part of the smoked beef and glued together. After that,

the smoked beef is stored in the refrigerator for three days. The results are

observed by opening the two smoked beef that have been glued together and then

qualitatively observing whether the two smoked beef are glued together or not.

2.4.4. X-ray

Diffraction (XRD)

The test was carried out by cutting the

sample of 1.9x1.4 cm with a thickness of 1mm according to the size of the

sample holder. Sample pieces are placed on the sample holder. The sample holder

is then placed on the XRD tool for analysis. The analysis took six minutes

using an X-ray diffraction device. The results will appear on the monitor

screen with readings ranging from 5? to 40?. After obtaining the peak data, the

percentage of sample crystallinity was calculated by dividing the area of the

??crystalline fraction by the area of the ??crystalline fraction plus the area

of the ??amorphous fraction multiplied by 100. The formula for calculating the

percent crystallinity is as follows:

2.4.5. Antibacterial activity

The procedure for testing

film samples was modified using the paper disc diffusion method on escherichia

coli bacteria. Antibacterial testing using the disc method refers to the

research of Mahdavinia et al. (2019) with

modifications. Escherichia coli bacteria were grown on NB medium, and the

density was measured through OD testing using a spectrophotometer. The

bacterial suspension was taken in amounts as much as 0.1 ml and put into a

petri dish that already contained a solid NA medium. The paper dish that will

be used is immersed in the sample in each treatment for 5 minutes, then put

into a petri dish. After that, the media filled with bacterial suspension is

incubated for 24 hours at 37?C, then the inhibition zone formed is measured

using a ruler. The diameter of the inhibition zone included was calculated as

the difference from the diameter of the paper disk.

3.1. Optimization of The Method of Mixing

Chitosan Solution and Alginate Solution

Mixing chitosan and alginate solutions

was carried out to obtain a homogeneous solution. The mixing method's

optimization results are given in Table 1. Based on the optimization

results, the more plus signs indicate the thicker the solution obtained, and

the more lumps, precipitates, fibers formed, and smoother the texture, so the

method chosen for the next process is the one that has the fewest and most

homogeneous fibers, namely the method with code E using a 2% chitosan solution

plus a 2% alginate solution directly at a temperature of 40-45?C.

Table

1 Mixing Method of

Chitosan and Alginate

|

Code |

Method |

Physical Observation of Solution | ||||||

|

Chitosan (%) |

Alginate (%) |

Material condition |

Temperature |

Viscosity |

Lumps |

Fiber |

Texture | |

|

A |

2 |

2 |

S+S |

27oC |

++ |

+++ |

+++ |

+ |

|

B |

2 |

2 |

S+P |

50oC |

+ |

+++ |

+ |

+ |

|

C |

2 |

2 |

S+S |

40oC 27oC |

++ |

++ |

++ |

+ |

|

D |

2 |

1 |

S+S |

40oC-45oC |

++ |

++ |

++ |

++ |

|

E |

2 |

2 |

S+S |

40oC-45oC |

+++ |

+ |

+ |

+++ |

Information: +:

low; ++: medium; +++: high; S: Solution; P: Powder

3.2. Optimization of Mixing Method and

Concentration of Irgacure® 2959

Table 2 Irgacure® 2959 mixing

method

|

Method |

Physical

Observation of Solution |

|

Added directly |

The solution is not mixed, the

texture is rough, and there are clumps of fibre |

|

Added after the

chitosan-alginate solution was stirred for 30 minutes |

The solution is well mixed; the

texture is smooth and compact |

The method of mixing

Irgacure® 2959 into the chitosan-alginate hydrogel was carried out

in two ways: directly added and added 30 minutes after the chitosan-alginate

solution was stirred. The results of mixing are given in Table 2. Based on

these results, the method of adding Irgacure® 2959 was chosen by

adding it after the chitosan-alginate solution was stirred for 30 minutes. The

choice was based on the fact that when Irgacure® 2959 was directly

added together with chitosan-alginate, it could cause its bonding with alginate

and chitosan to become less regular, resulting in an inhomogeneous solution,

while the addition of Irgacure® 2959 30 minutes after the

chitosan-alginate was mixed could provide space for the chitosan and alginate

to be mixed beforehand, which made the bond between the chitosan-alginate and

the Irgacure® 2959 more regular and more homogeneous.

3.3 Chitosan-Alginate Hydrogel Analysis and Characterization

3.3.1. The effect of

variations in the concentration of Irgacure® 2959 on the swelling

ratio

Based on the study's results, the addition of Irgacure® 2959

caused a lower degree of development. This follows the research of Qi et al. (2013) that the addition of Irgacure®

2959 at higher concentrations causes the degree of swelling to be lower due to

an increase in cross-linking, which can cause the cross-linking to become

stronger so that the structure will be tighter, and less water will enter. The

percentage of development produced from chitosan-alginate hydrogel with the

addition of Irgacure® 2959 as a photo-initiator is given in Figure 2.

Based on these results, this composite has

potential as a tissue sealant because, Mukherjee et

al. (2018), in its application as a wound healer, state that low

swelling is needed to heal wounds because hydrogels with too high swelling can

inhibit the rate of healing, and too much fluid absorption that occurs can

cause dehydration in the wound, thereby slowing down the wound healing process.

And hydrogels with good hydrophilicity can provide soft physical properties

when applied to living tissue (Barleany et al.,

2019).

Figure 2 Swelling ratio of chitosan-alginate

hydrogel with the addition of Irgacure® 2959 at different concentrations

3.3.2. The

effect of variations in the concentration of Irgacure® 2959 on

hydrogel resistance to water

The adhesive's resistance to water makes the tissue sealant not easily crushable or detached when attached to surfaces with a lot of water content, such as intestines. The addition of Irgacure® 2959 with a higher concentration causes its ability to bind water to increase. These results indicate that the addition of Irgacure® 2959 significantly affects the water resistance of the chitosan-alginate hydrogel as a tissue sealant. According to Rudyardjo (2014), when there is no addition of Irgacure® 2959 as a photo-initiator, the O-H group possessed by chitosan will bind less, so that its water resistance will decrease. On the other hand, with the addition of Irgacure® 2959, the O-H group will bind more and more, so its ability to hold water will increase. The average value of hydrogel resistance to water are given in Figure 3.

Figure 3 Percentage of hydrogel

resistance to water

Based on the findings, this composite has the

potential to be used as a tissue sealant due to its high-water resistance

characteristics. This result is suitable as a tissue sealant. According to Briawan et al. (2011) the body contains 75% water

and 25% solid matter, so a tissue sealant that has an elevated level of water

resistance is needed so that when it is used as a tissue sealant in the

intestine, it is not easily brittle but can still help the process of

attachment and cell growth.

3.3.3. The

effect of variations in the concentration of Irgacure® 2959 on the

simulation results of adhesion to smoked beef

Adhesion simulation was carried out using

smoked beef media because its structure is like tissue. Adhesion simulation was

carried out to qualitatively determine the adhesive strength of

chitosan-alginate hydrogel with the addition of Irgacure® 2959. The

results of the simulation of adhesion can be seen in Table 3. The simulation

results indicate that the higher addition of Irgacure® 2959 means

that smoked beef can stick together. Based on Table 3, the more signs the

smoked beef has, the stronger the bond and the more difficult it is to

separate. In connection with these results, the addition of Irgacure®

2959 at a higher concentration can produce hydrogels with more potent adhesive

abilities.

Table 3

Simulation results of adhesion with variations of Irgacure® 2959

with qualitative methods

|

Concentration of Irgacure® 2959 |

Adhesive Strength Level |

Description |

|

0% |

+ |

Smoked

beef can stick to each other, but when you take it off, it's still easy to

separate |

|

1% |

++ |

Smoked

beef can stick to each other, but when you take it off, it's still easy to

separate |

|

2% |

+++ |

Smoked

beef can stick to each other, but when you take it off, it's getting a little

difficult to separate |

|

3% |

++++ |

Smoked

beef can stick to each other, but when you take it off, it's hard to separate |

|

4% |

+++++ |

Smoked

beef can stick to each other, but when you take it off, it's hard to separate |

Information: +: less sticky; ++: slightly

sticky; +++: a bit sticky; ++++: paste; +++++: very sticky

3.3.4. The effect of variations in the concentration of Irgacure®

2959 on the degree of crystallinity (XRD)

XRD

is used to identify crystallites in materials using X-ray diffraction radiation

to identify crystallite structures that appear as sharp or amorphous peaks (Hakim et al., 2019). The results of the XRD graph

can be seen in Figure 4. Based on Figure 4, the graphic pattern of

chitosan and alginate does not have a crystal peak, indicating that chitosan

and alginate are amorphous materials. Furthermore, the chitosan-alginate graph

pattern shows amorphous results with comprehensive graphs without clear crystal

peaks. In contrast, the Irgacure® 2959 graph pattern shows the

presence of crystallinity indicated by sharp peaks, and based on calculations,

Irgacure® 2959 has a crystallinity percent of 63.39%. The addition

of Irgacure® 2959 to chitosan-alginate showed a crystal peak seen at

a sharp peak, indicating that the presence of Irgacure® 2959 caused

cross-linking between chitosan and alginate. The percentage of crystallinity

obtained after the calculation is 26.21%.

This

value is lower than Irgacure® 2959 because of the cross-linking that

occurs with chitosan-alginate. The percent crystallinity was obtained by

calculating the area fraction of the crystalline material divided by the total

area of ??the amorphous and crystalline materials. The results of mixing

chitosan-alginate hydrogel with Irgacure® 2959 decreased

crystallinity, indicating that there had been an interaction between

chitosan-alginate and Irgacure® 2959, which was supported by the

research of Cervera et al. (2004), which

states that the decrease in intensity can indicate that there is an interaction

that occurs between chitosan-alginate. Based on the XRD results, the addition

of Irgacure® 2959 to the chitosan-alginate hydrogel causes

crystallinity to occur and indicates that there has been a bond between

chitosan-alginate and Irgacure® 2959.

Figure 4 Graph of Crystallinity Degree (XRD) Pattern (a) Alginate; (b) Chitosan; (c) Irgacure® 2959; (d) Chitosan-Alginate; (e) Chitosan-Alginate-Irgacure® 2959

3.3.5. Antibacterial

activity testing aims to determine the ability of the hydrogel to inhibit

bacterial growth.

Characteristics

of antibacterial activity were carried out only to find out whether the

hydrogel still had antibacterial properties derived from chitosan after being

mixed with alginate and Irgacure® 2959. According to Surjowardojo

et al. (2015), the diameter of the inhibition zone formed at 5mm falls

into the weak category. The results of the inhibition zone with the addition of

Irgacure® 2959 treatment ranged from 0% to 4%, were included in the

weak category because of < 5 mm. The mean value of the diameter of the

bacterial inhibition zone on the chitosan-alginate hydrogel with the addition

of Irgacure® 2959 is presented in Table 4.

Table 4 Average

zone of inhibition formed on Escherichia coli bacteria

|

The concentration of Irgacure®

2959 |

Inhibitor Zone (mm) |

|

Control negative |

0b |

|

Control positive |

4a |

|

0% |

1.7ab |

|

1% |

1.3ab |

|

2% |

1.3ab |

|

3% |

1.7ab |

|

4% |

1.7ab |

abcat each concentration, for different letters

showed statistically significant differences with a 95% confidence level

(p-value <0.05)

These results suggest that the addition of

Irgacure® 2959 influences the inhibitory ability of bacteria in

chitosan-alginate gel used as a tissue sealant. Still, between treatments,

Irgacure® 2959 with different concentrations did not produce a

significantly different effect. This happens because chitosan is bound to

alginate and Irgacure® 2959, so there is a reduction in the positive

charge on the chitosan group. Thus, the electrostatic interaction with the

negative amount on the bacterial cell wall decreases (Pasaribu,

2020). The NH3+ glucosamine content in chitosan,

which has a positive charge, will interact with the negative charge-forming

proteins on the bacterial cell membrane, which can cause damage to the outer

cell membrane and leakage of intracellular constituents of the bacteria so that

the bacteria will die (Nurainy et al., 2008).

The additional concentration of Irgacure®

2959 to the chitosan-alginate hydrogel can be used as a tissue sealant.

Increasing the concentration of Irgacure® 2959 results in a lower

swelling percentage and increases the hydrogel's resistance to water, so the

hydrogel is not easily brittle. Based on the characteristics, the best

concentration is Irgacure® 2959 4%.

This research is part of the thesis of

the first author. We would like to thank the

Faculty of Agriculture, Universitas Gadjah Mada for the funding that has been

provided through Lecturer Research Grant 2021.

Asadpour, S., Kargozar, S.,

Moradi, L., Ai, A., Nosrati, H., Ai, J., 2020. Natural Biomacromolecule Based Composite Scaffolds from Silk

Fibroin, Gelatin and Chitosan Toward Tissue Engineering Applications. International

Journal of Biological Macromolecules, Volume 154, pp. 1285–1394

Bagher, Z.I., Ehterami, A.,

Safdel, M.H., Khastar, H., Semiari, H., Asefnejad, A., Davachi, S.M., Mirzaii,

M., Salehi, M., 2020. Wound Healing with Alginate/Chitosan

Hydrogel Containing Hesperidin in Rat Model. Journal of Drug Delivery

Science and Technology, Volume 55, pp. 1–8

Bakshi, P.S., Selvakumar, D.,

Kadirvelu, K., Kumar, N.S., 2020. Chitosan as an

Environment Friendly Biomaterial – A Review on Recent Modi?cations and

Applications. International Journal of Biological Macromolecules, Volume

150, pp. 1072–1083

Barleany, D.R., Ananta, C.V., Maulina, F., Rochmat,

A., Alwan, H., Erizal, E., 2020. Controlled Release of Metformin Hydrogen

Chloride from Stimuli-responsive Hydrogel based on Poly (N-

Isopropylacrylamide)/Chitosan/Polyvinyl Alcohol Composite. International

Journal of Technology, Volume 11(3), pp. 511–521

Baysal. K., Aroguz, A.Z., Adiguzel,

Z., Baysal, B.M., 2013. Chitosan/alginate Cross-Linked

Hydrogels: Preparation, Characterization and Application for Cell Growth

Purposes. International journal of biological macromolecules, Volume 59,

pp. 342–348

Bektas, N., ?enel, B., Yenilmez,

E., Özatik, O., Arslan, R., 2020. Evaluation of Wound Healing Effect of

Chitosan-Based Gel Formulation Containing Vitexin. Saudi pharmaceutical

journal, Volume 28(1), pp. 87–94

Briawan, D., Sedayu, T.R., Ekayanti, I., 2011. Drinking Habits and

Fluid Intake of Adolescents in Urban Areas. Indonesian Journal of Clinical

Nutrition, Volume 8(1), pp. 36–41

Cervera, M.F., Heinämäki, J.,

Krogars, K., Jörgensen,

A.C., Karjalainen, M., Colarte, A.I., Yliruusi, J., 2004. Solid-state and Mechanical Properties of Aqueous

Chitosan-Amylose Starch Films Plasticized with Polyols. AAPS PharmSciTech, Volume

5(1), pp.109–114

Chandramouli, V., Kailasapathy, K.,

Peiris, P., Jones, M., 2004. An Improved Method

of Microencapsulation and Its Evaluation to Protect Lactobacillus Spp. in Simulated

Gastric Conditions. Journal of Microbiological Methods, Volume 56(1),

pp. 27–35

Dewi, A.H., Yulianto, D.K., Ana, I.D., Rochmadi,

Siswomihardjo, W., 2020. Effect of Cinnamaldehyde, an Anti-Inflammatory Agent,

on the Surface Characteristics of a Plaster of Paris – CaCO3 Hydrogel for Bone

Substitution in Biomedicine. International Journal of Technology, Volume

11(5), pp. 963–973

Hakim, L., Dirgantara, M., Nawir,

M., 2019. Characterization of The Material Structure of Group C Excavated Sand

Blocks Using X-Ray Diffraction (XRD) in The City of Palangkaraya. Jurnal

Jejaring Matematika dan Sains (Journal of Mathematics and Science Network),

Volume 1(1), pp 44–51

Han, W.T., Jang, T., Chen, S.,

Chong, L.S.H., Jung, H.D., Song, J., 2020. Improved Cell Viability for Large-Scale Biofabrication with

Photo-Crosslinkable Hydrogel Systems Through a Dual-Photo-Initiator Approach. Biomaterials

Science, Volume 8(1), pp. 450–461

Jarret, P, Coury, A., 2013.

Joining and Assembly of Medical Materrials and Devices. Woodhead publishing limited. USA, pp. 449–490

Khan, Y.A., Ozaltin, K.,

Bernal-Ballen, A., Di Martino, A., 2020. Chitosan-Alginate Hydrogels for Simultaneous and Sustained

Releases of Ciprofloxacin, Amoxicillin and Vancomycin for Combination Therapy. Journal

of Drug Delivery Science and Technology, Volume 61(5), pp 1–13

Lee, K.Y., Mooney, D.J., 2012.

Alginate: Properties and Biomedical Applications. Progress in polymer

science, Volume 37, pp. 106–126

Mahdavinia, G.R., Karimi,

M.H., Soltaniniya, M., Massoumi, B., 2019. In Vitro Evaluation of Sustaine

Ciproflfloxacin Release from ?-Carrageenan-Crosslinked Chitosan/Hydroxyapatite

Hydrogel Nanocomposites. International Journal of Biological Macromolecule, Volume

126, pp. 443–453

Mukherjee, D., Azamthulla, M.,

Santhosh, S., Dath, G., Ghosh, A., Natholia, R., Anbu, J., Teja, B.V.,

Muzammil, K.M., 2018. Development and Characterization

of Chitosan-Based Hydrogels as Wound Dressing Materials. Journal of Drug

Delivert Science and Technology, Volume 46, pp. 498–510

Nayeb, H.F., Salahshoor, K.S., Afshar, T.F.,

Shariatinia, Z., 2011. A Novel Topical

Biocompatible Tissue Adhesive Based on Chitosan-Modified Urethane Pre-Polymer. Irian

Polymer Journal, Volume 20(8), pp. 671–680

Nurainy, F., Rizal, S.,

Yudiantoro, 2008. Effect of Chitosan Concentration on Antibacterial Activity

Using the Agar Diffusion Method (Wells). Journal of Industrial Technology

and Agricultural Products, Volume 13(2), pp. 117–125

Ono, K., Saito, Y., Yura, H.,

Ishikawa, K., Kurita, A.,

Akaike, T., Ishihara, M., 2000. Photocrosslinkable Chitosan as a Biological Adhesive. Journal of

Biomedical Materials Research: An Official Journal of The Society for

Biomaterials and The Japanese Society for Biomaterials, Volume 49(2), pp. 289–295

Pasaribu, S.P., 2020. Synthesis of N-Maleoyl Chitosan Hydrogel - Dialdehyde Alginate for

Retentive Drug Delivery Systems. Disertation, Graduate Program, Faculty of Mathematics and Natural

Sciences, University of Northern Sumatra, Indonesia

Qi, Z., Xu, J., Wang, Z.,

Nie, J., Ma, G., 2013. Preparation and Properties of

Photo-Crosslinkable Hydrogel Based on Photopolymerizable Chitosan Derivative. International

Journal of Biological Macromolecules, Volume 53, pp. 144–149

Rudyardjo, D.I., 2014.

Effect of The Addition of Glycerol Plasticizer on The Characteristics of

Chitosan-Glutaraldehyde Hydrogel for Wound Dressing Applications. Jurnal

Ilmiah Sains (Scientific Journal of Science), Volume 14(2), pp.18–28

Sularsih. 2013. Effect of

The Viscosity of Chitosan Gel on Its Use in The Wound Healing Process. Journal

of Dentistry Materials, Volume 2(1), pp. 60–67

Sumarni, W., Prasetya, A.T.,

Rahayu, E.F., 2017. Effect of Glycerol Sumarni, W., A.T.

Prasetya, Dan E.F. Rahayu. 2017. Effect of Glycerol on Physical Properties of

Biofilms Gembili Starch (Dioscorea Esculenta)–Chitosan. In Proceeding

of Chemistry Conferences, Volume 2, pp. 56–65

Surjowardojo, P.,

Susilorini, T.E., Sitrait, G.R.B., 2015. Decoction Inhibition of Manalagi Apple

Skin (Malus Sylvestrs Mill.) on The Growth of Staphylococcus Aureus and Pseudomonas Sp. Causes of

Mastitis in Dairy Cows. Journal of Tropical Livestock, Volume 16(2), pp.

40–48

Tomal, W., Ortyl, J., 2020.

Water-soluble Photo-Initiators in Biomedical Applications. Polymers,

Volume 12(5), p. 1073

Wang, G., Wang, X., Huang,

L., 2017. Feasibility of Chitosan-Alginate (Chi-Alg) Hydrogel Used as Scaffold

for Neural Tissue Engineering: A Pilot Study in Vitro. Biotechnology &

Biotechnological Equipment, Volume 31(4), pp. 766–773