Development of the Sterilization Box for Medical Equipment with an Ozone Gas Leak Sensor Feature

Corresponding email: tomy.abuzairi@gmail.com

Published at : 30 Dec 2022

Volume : IJtech

Vol 13, No 8 (2022)

DOI : https://doi.org/10.14716/ijtech.v13i8.6156

Abuzairi, T., Sumantri, N.I., Putri, N.A., Andarini, M.V., Lampung, E.J., Sitinjak, D., 2022. Development of the Sterilization Box for Medical Equipment with an Ozone Gas Leak Sensor Feature. International Journal of Technology. Volume 13(8), pp. 1672-1680

| Tomy Abuzairi | 1. Electrical Engineering, Department of Electrical Engineering, Faculty of Engineering, Universitas Indonesia, Depok, West Java, 16424, Indonesia, 2. Research Center for Biomedical Engineering, Facul |

| Nur Imaniati Sumantri | Biomedical Engineering, Department of Electrical Engineering, Faculty of Engineering, Universitas Indonesia, Depok, West Java, 16424, Indonesia |

| Nadira Alya Putri | Biomedical Engineering, Department of Electrical Engineering, Faculty of Engineering, Universitas Indonesia, Depok, West Java, 16424, Indonesia |

| Mulya Viani Andarini | Biomedical Engineering, Department of Electrical Engineering, Faculty of Engineering, Universitas Indonesia, Depok, West Java, 16424, Indonesia |

| Ebenhaezar Jan Lampung | Biomedical Engineering, Department of Electrical Engineering, Faculty of Engineering, Universitas Indonesia, Depok, West Java, 16424, Indonesia |

| Defrianto Sitinjak | Biomedical Engineering, Department of Electrical Engineering, Faculty of Engineering, Universitas Indonesia, Depok, West Java, 16424, Indonesia |

One of the efforts to control the growth of

microorganisms is sterilization. The sterilization process can use ozone gas,

which is a triatomic form of the element oxygen. Ozone acts as an oxidizing

agent capable of destroying the structure of bacterial cell walls, and their

molecules are unstable and easily decomposed into oxygen, so that ozone can be

applied in sterilization technology for medical devices. In this work, a

sterilization box with an ozone generator has been designed with a MQ-131 ozone

sensor as an indicator if there is a leak in the box. The output voltage of the

ozone generator is 4 kV with a current of 30 mA. We developed an instrument

using an Arduino nano as a microcontroller for reading sensor values and

displaying sensor values on an LCD monitor. For testing the sterilization

effect of the ozone box, a Staphylococcus aureus bacterial sample was

used. For the sterilization object, we designated stethoscopes and thermometers

as medical equipment. The optimum time for sterilizing medical devices on the

sterilization ozone box was 20 minutes, which can reduce the colony of S.

aureus bacteria with an ozone concentration of 4.94 ppm.

Leak sensor; Microcontroller; Medical equipment; Ozone; Sterilization; Staphylococcus bacteria

Ozone (O3) is a strong oxidizing agent and a triatomic

compound of the element oxygen (O). Ozone is also an unstable compound that

quickly decomposes at ambient temperature (Ebbing & Gammon, 2017). The sterilization process

using ozone occurs through a direct oxidation process. Ozone oxidation has the

ability to destroy cell membranes and the outer walls of microorganism cells,

leading to cell dead (Takayama et

al., 2006). Ozone is often used as a sterilization method because it is

oxidative and easy to decompose, among others, to eliminate bacteria in the

soil/soil sterilization. It is applied in the agricultural field because ozone

can kill bacteria, viruses, and fungi in the soil as well as in irrigation

systems, and then ozone

will decompose into oxygen (O2) (Suryawan et al., 2021; Munarso

et al.,

Ozone production can be carried

out in various ways, such as through electrochemical reactions, UV irradiation

methods, and plasma technology. Plasma is the most abundant of these various methods (Suksri et al., 2009).

If the temperature continues to be raised, the atoms will decompose into

charged particles that move freely (electrons and positive ions) and enter the

plasma state (Bellan, 2008).

Plasma also be used as a sterilization method for medical devices using Plasma

Activated Water (PAW) with some modifications to its physicochemical

properties, such as pH, temperature, ORP, and nitrite concentration (Abuzairi et al., 2018).

Moreover,

UVC was employed for room sterilization and disinfection (Rusdinar et al., 2021). ?The authors claim that the UVC

can reduce and kill airborne bacteria; therefore, it can disinfect different

types of rooms (e.g., isolation, operating, and public rooms) contaminated with

hazardous bacteria, such as COVID-19 (Rusdinar et al., 2021; Berawi, 2021).

Recently, ozone has also been

applied in some hospitals as a method for sterilizing medical equipment and

other equipment in hospitals because it has been proven effective against

vegetative bacteria, fungi, mycobacteria, and bacterial spores (Dufresne et al., 2004). In the

food sector, ozone is produced in dielectric barrier discharge plasma (DBDP)

and then applied to maintain the quality of amino acids in fish (Sosiawati et

al., 2014). In addition, ozone could be a hand sanitizer using air

and tap water enriched by hydrogen peroxide (El Shaer et al., 2017). Ozone can be used to combat

coronaviruses both inside and outside the body (Manjunath et al., 2021).

Ozone is very

useful for sterilization; however, at high concentrations, it is also harmful

to humans. From previous studies on the design of sterilization instrumentation

using ozone gas, no study has developed sterilization instrumentation with an

ozone gas leak sensor. Therefore, in this study, we developed a sterilization

box for medical equipment with an ozone gas leak sensor feature.

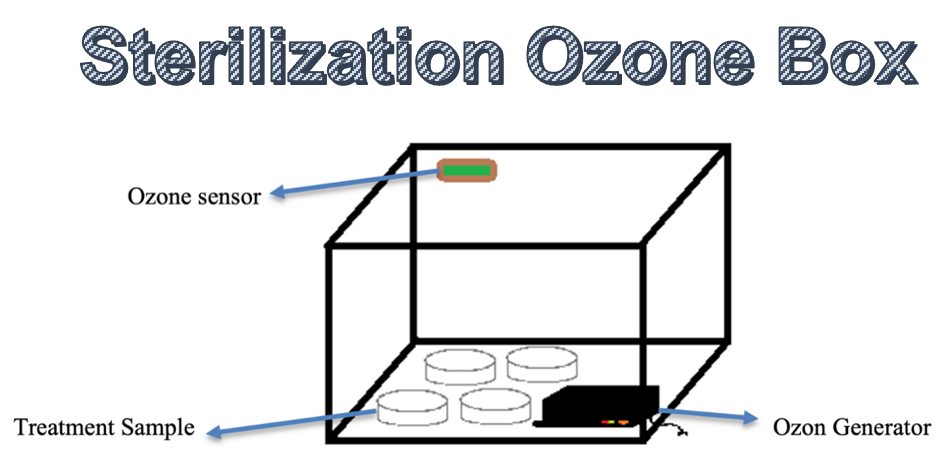

2.1. Ozone sterilization box

The sterilization box is shown in

Figure 1. The ozone generator uses a Dielectric Barrier Discharge (DBD)

configuration. The ozone generator will be put in a sterilization box, which

functions as a safety so that ozone is not inhaled or contaminates other objects.

The ozone

generator and samples will be put into the storage box, and then a hole will be

made as an outlet for the cable. This ozone sterilization box is also connected

to a timer relay and switch to make it easier for users to set the duration of

the ozone generator’s activation.

Figure 1 Sterilization box with ozone gas leak sensor feature

2.2. Ozone gas leak sensor circuit

The ozone sensor MQ-131 is

connected to the Arduino nano, as shown in the schematic in Figure 2. The sensitive

material of the MQ-131 ozone sensor is a metallic oxide semiconductor, which

has high conductivity in clean air. When ozone gas is present, the sensor’s

conductivity decreases as the gas concentration increases. Aside from sensitivity to specific ozone, the MQ-131

sensor also has a sensitivity to strong oxides, Cl2 and NO2.

In order to work optimally, it requires preheating for approximately 48 hours.

The MQ-131 sensor can be applied as a domestic or industrial ozone

concentration alarm and can also be used as a portable ozone concentration

detector. The MQ-131 ozone sensor has a long life, easy to apply and is

flexible enough to be connected to a microcontroller for various applications.

The MQ-131 ozone sensor circuit is added outside the sterilization box and then connected to the LCD to be able to monitor the level of ozone that comes out/leaks during the treatment process. This is done as a safety system when a leak occurs or the box is not tightly closed. This sensor was also used in other Covid-19 research for controlling ozone concentration (Dave et al., 2020).

Figure 2 Schematic of ozone gas leak sensor circuit

2.3. Ozone concentration measurement

A plasma

generator is connected to a high voltage generator at the DBD to see the glow discharge and

ozone produced. Ozone concentration is calculated quantitatively with an air

quality monitor the Zuidid DM502-O3 where there is one feature that can measure

ozone concentration in ppm units.

2.4. Validation of ozone sterilization

In this study, we used a Staphylococcus aureus bacterial sample to validate the sterilization effectiveness of ozone. S. aureus is a Gram-positive bacterium in the form of a coccus. When the ozone generator circuit has been designed, the next step is to test the effectiveness against staphylococcus bacteria on medical equipment, which is stethoscopes and thermometer guns (Abuzairi et al., 2021). Bacterial samples were taken from a stethoscope and thermometer, which were then swabbed and planted in Mannitol Salt Agar (MSA) and Plate Count Agar (PCA) media. Samples that have been planted are then treated using an ozone generator, which is designed with a treatment duration of 5 minutes, 10 minutes, and 20 minutes. Samples that have been treated will then be cultured for two days, and after counting the bacterial colonies formed, they will be counted and analyzed. In the treatment method, the device is put into a sterilization box to be treated according to the optimal time obtained in the first experiment, then cultured in the media for 2 days, and the bacterial colonies that form will be counted and analyzed. Figure 3 shows the stages of bacterial sterilization.

Figure 3 Stages of

bacterial sterilization with an ozone sterilization box. (a)-(b)

Medical equipment is swabbed, and the sample is stored in a transport medium.

(c) The sample is planted on a PCA/MSA plate. (d) the sample-containing plate

is treated with ozone. (e) The plate is incubated at 36°C for 48 hours. (f)-(g)

Colony counting and cell observation under the microscope

3.1. Ozone generator

Figure 4(a) shows the

device before it is electrified, and Figure 4(b) shows it after it is

electrified. When electrified, a glow discharge appears on the dielectric

barrier, indicating a plasma discharge process. This is in accordance with the

parameters for the ozone generator, which are indicated by the presence of a

glow discharge when electrified. In addition, there is a distinctive smell of

ozone. Based on the technical specifications in the circuit and the simulation

results, the output voltage is 4 kV with a current of 30 mA. This circuit will

be measured ozone concentration and designed for a sterilization box.

Figure 4 (a) Ozone generator not electrified. (b)

Ozone generator electrified

3.2. Ozone sensor

The ozone gas leak sensor circuit is attached to the upper of the sterilization box, as shown in Figure 5(a). The MQ-131 sensor could detect the ozone concentration up to 1000 ppm, with a sensitivity (ozone/air) is 2 in 50 ppm ozone (Zhengzhou Winsen Electronics Technology, 2021). The side of the storage is perforated for cable output, which will be connected to switches and timers to make it easier to turn off and turn on the device because it would be better if during the treatment process, there were no people in the treatment room and there is air circulation in the room to anticipate if something happened like an ozone gas leak. On the outside of the front sterilization box, a series of sensors MQ-131 are provided with an LCD Figure 5(b) to monitor during treatment if there is ozone leaking from inside the box, as shown in Figure 5(c). This is added because, according to WHO regulations and some countries limits, the ozone concentration in a room should not be more than 0.1 ppm. Human exposure to ozone is primarily by inhalation, but reactions on the skin are also reported (Salonen et al., 2018). Acute and chronic health effects and the contributions of ozone to morbidity and mortality are summarized in WHO documents (WHO, 2021).

Figure 5 (a) Inside of the sterilization box with the

generator. (b) Sensor MQ-131 outside the box. (c) Ozone sensor circuit MQ-131

3.3. Ozone concentration

Figure 6 shows ozone concentrations for (a) 5 minutes, (b) 10 minutes, and (c) 20 minutes in the sterilization ozone box. In Figure 6(a), the duration of the ozone generator is 5 minutes, the concentration of ozone formed reaches 1.65 ppm, and the duration of the decomposition of ozone into O2 takes 3 minutes. For Figure 6(b) with the generator running for 10 minutes, every minute the ozone concentration increases linearly until it reaches its maximum point for 10 minutes with an ozone concentration of 4.01 ppm after the ozone generator is turned off and it takes 4 minutes to decompose all the ozone. Furthermore, in Figure 6(c), when the ozone generator is turned on for 20 minutes, the ozone concentration gradually increases until it reaches a concentration of up to 4.92 ppm. Then, to be able to decompose as a whole it takes about 6 minutes. Previous research conducted by (Ma’ruf et al., 2017) and (Waluyo et al., 2015) also showed this trend, in which ozone concentration will increase with the duration of treatment.

Figure 6 Ozone Concentration for: (a)

5 minutes; (b) 10 minutes; and (c) 20 minutes

In

the three variations of duration, the increase in ozone concentration was

stable until it reached a concentration of 4 ppm and slowed down. The

concentration of ozone is known to be in line with duration and the increase of

voltage to produce ozone (Vezzu et al., 2009). On the other hand, the

concentration of ozone produced also refers to the oxygen around the generator.

A previous study said ozone generators with a dry air source and an oxygen

source directly experienced differences in the concentrations produced. Ozone

produced by oxygen sources is more and more concentrated, as much as 7–10% (Teke et al., 2014). In this

research, the source in the form of ambient air is not supplied with oxygen

directly, and when it reaches a concentration of 4 ppm and a duration of 17

minutes, the increase in ozone concentration slows down. This is because the

amount of oxygen that was in the sterilization box is decreasing, and because

the box is closed, there is no incoming oxygen supply, so the oxygen

concentration produced is stuck at four ppm.

3.4. Results of sterilization treatment of medical

equipment

The results of the treatment

process are presented in Table 1 that sterilizes several

medical equipment’s, namely a stethoscope and thermometer gun. The

results showed that when each of these devices was not treated, bacterial

colonies formed above 300 CFU, or it can be said to be Too Numerous to Count

(TNTC). After that, each medical device was treated and put into a

sterilization box for 20 minutes according to the optimal time in the previous

experiment, then planted in two different media (PCA and MSA) and cultured; the

number of bacterial colonies was reduced to below 50 CFU. It can be concluded

that within 20 minutes, with the concentration of ozone produced, ozone can

damage the walls of bacteria in each medical device and cause the bacteria to

lyse or die. Previous research by (Botelho-Almeida

et al., 2018), (Verma et

al., 2016), and (Fu et al., 2020) with ozone

treatment to reduce bacteria in medical devices was also successful.

Table 1 Results of sterilization

treatment of the medical equipment

|

Medical

equipment |

Duration

(minutes) |

Colonies

formed (CFU) | |

|

PCA |

MSA | ||

|

Stethoscope |

0 |

TNTC |

32 |

|

5 |

126 |

26 | |

|

10 |

64 |

18 | |

|

20 |

36 |

10 | |

|

Thermometer gun |

0 |

TNTC |

7 |

|

5 |

134 |

6 | |

|

10 |

76 |

4 | |

|

20 |

36 |

1 | |

Ozone is considered to be a disinfectant agent in the medical-related

field for its bactericidal activity (Botelho-Almeida et al., 2018; Giuliani et al., 2018). The way it kills the

bacteria is by disrupting the bacteria's cell membrane. Glycoprotein and

glycolipid components of the cell membrane are the target of ozone properties,

resulting in cell rupture. Protein and nucleotide disturbances are the other mechanism

that occurs due to ozone exposure. Cellular enzymatic activity is affected by

the ozone attack on the sulfhydryl groups of certain enzymes, leading to a loss

of function. Ozone also attacks nucleic acid bases,

resulting in DNA damage (Megahed et al., 2018). The previous study

revealed the effect of ozone on membrane cell disruption leading to cell lysis

in both Gram-positive and Gram-negative bacteria (Thanomsub et al., 2002).

Figures 7-8

show samples in PCA and MSA media after incubation. In PCA media, the

growth of general bacterial colonies can be seen, while MSA media show certain

bacterial colonies. MSA media is useful for growing bacterial colonies of S.

aureus (Sharp

& Searcy, 2006). There was a very significant decrease in colonies in the treatment

with a duration of 20 minutes, Petri dishes given treatment in 5 minutes had

the number of colonies TNTC (>300) on PCA media, while in MSA media colonies

ranged under 50 colonies, this is because MSA is a selective and differential

growth medium for Gram-positive bacteria, so that Gram-negative bacteria could

not grow. When the duration of exposure is increased to 10 minutes, the number

of colonies again decreases until only tens or dozens remain. At 20 minutes of

exposure, it can be seen that the number of colonies decreases to near zero.

|

|

|

|

Figure 7 Bacterial colonies on PCA media

after treatment for 5, 10, and 20 minutes (a,b,c)

|

|

|

|

Figure 8 Bacterial colonies on MSA media

after treatment for 5, 10, and 20 minutes (a,b,c)

The sterilization box for

medical equipment with an ozone gas leak sensor feature has been successfully

developed. The sterilization box with an ozone generator has been designed with a

MQ-131 ozone sensor as an indicator if there is a leak in the box. In testing the effectiveness of ozone treatment

against S. aureus,

the optimal duration was 20 minutes with an ozone concentration of 4.92 ppm,

which significantly reducing the number of colonies compared to a shorter

duration. Further testing was carried out on two medical equipment, namely a

stethoscope and a thermometer gun, with a duration of 20 minutes, and the

results showed very significant sterilization, with bacterial colonies formed

after the treatment process being below 50 CFU.

This research was supported by Kedaireka Grant

2022 from Ministry of Education, Culture, Research and Technology Republic of

Indonesia and Research Grant PUTI Q3 2020 (NKB-4567/UN2.RST/HKP.05.00/2020)

from the Directorate Research and Development Universitas Indonesia.

Abuzairi,

T., Ramadhanty, S., Puspohadiningrum, D.F., 2018. Investigation on

Physicochemical Properties of Plasma activated Water for The Application of

Medical Device. In AIP Conference Proceedings, Volume 1933, p. 040017

Abuzairi,

T., Sumantri, N.I., Irfan, A., Mohamad, R.M., 2021. Infrared Thermometer on the

Wall (Ithermowall): An Open Source and

3-D Print Infrared Thermometer for

Fever Screening. HardwareX, Volume 9, p. e00168

Bellan,

P.M., 2008. Fundamentals of Plasma Physics. Cambridge University Press,

Cambridge, England

Berawi,

M.A., 2021. World Agenda on Sustainable Recovery from the Covid-19 Pandemic:

Recover Together, Recover Stronger. International Journal of Technology,

Volume 12(4), pp. 671–675

Botelho-Almeida,

T.d.S., Lourenço, F.R., Kikuchi, I.S., Awasthi, R., Dua, K., Pinto, T.d.J.A.,

2018. Evaluating the Potential, Applicability, and Effectiveness of Ozone

Sterilization Process for Medical Devices. Journal of Pharmaceutical

Innovation, Volume 13, pp. 87–94

Dave,

N., Pascavis, K.S., Patterson, J., Kozicki, M., Wallace, D., Chowdhury,

A., Abbaszadegan, M., Alum, A., Herckes,

P., Zhang, Z., Chang, J., Ewell, C., Smith, T., Naufel, M., 2020.

Characterization of a Novel, Low-Cost, Scalable Ozone Gas System for

Sterilization of N95 Respirators and Other COVID-19 Related Use Cases. MedRxiv, https://doi.org/10.1101/2020.06.24.20139469

Dufresne,

S., Hewitt, A., Robitaille, a.S., 2004. Ozone Sterilization: Another Option for

Healthcare in the 21st Century. American Journal of Infection Control,

Volume 32(3), pp. 3–4

Ebbing,

D., Gammon, S. D., 2016. General Chemistry. Cengage Learning, Boston, USA

El

Shaer, M., Mobasher, M., Zaki, A., 2017. Low-Cost Dielectric Barrier Discharge

Plasma Hand Sanitizer Using Air and Tap Water Enriched by Hydrogen Peroxide. Plasma

Medicine, Volume 7(3), pp. 273–282

Fu,

L., Le, T., Liu, Z., Wang, L., Guo, H., Yang, J., Chen, Q., Hu, J., 2020.

Different Efficacies of Common Disinfection Methods Against Candida

Auris and Other Candida Species. Journal of

Infection and Public Health, Volume 13(5),

pp. 730–736

Giuliani,

G., Ricevuti, G., Galoforo, A.,

Franzini, M., 2018. Microbiological Aspects of Ozone: Bactericidal Activity and

Antibiotic/Antimicrobial Resistance in Bacterial Strains Treated with Ozone. Ozone

Therapy, Volume 3(3), p. 7971

Manjunath,

S.N., Sakar, M., Katapadi, M., Balakrishna, R.G., 2021. Recent Case Studies on

the Use of Ozone to

Combat Coronavirus: Problems and perspectives. Environmental Technology

& Innovation, Volume 21, p. 101313

Ma’ruf,

A., Dewi, S., Wardoyo, F., 2017. Time of Exposure to Ozone Gas on the Growth of

Escherichia Coli Bacteria. In: Seminar Nasional Pendidikan, Sains dan

Teknologi, pp. 1–5

Megahed,

A., Aldridge, B., Lowe, J., 2018. The Microbial Killing Capacity

of Aqueous and Gaseous Ozone on Different Surfaces Contaminated with Dairy

Cattle Manure. The Microbial Killing Capacity of Aqueous and Gaseous Ozone on

Different Surfaces Contaminated with Dairy Cattle Manure. PLoS One,

13(5), p. e0196555

Munarso,

S.J., Kailaku, S.I., Arif, A.B., Budiyanto, A., Mulyawanti, I., Sasmitaloka,

K.S., Setyawan, N., Dewandari, K.T., Widayanti, S.M., 2020. Quality Analysis of

Chili Treated with Aqueous Ozone Treatment and Improved Transportation and

Handling Technology. International Journal of Technology, Volume 11(1),

pp. 37–47

Paw?at,

J., Stryczewska, H.D., Ebihara, K., 2010. Sterilization Techniques for Soil

Remediation and Agriculture Based on Ozone and AOP. Journal of Advanced

Oxidation Technologies, Volume 13, pp. 138–145

Rusdinar,

A., Purnama, I., Fuadi, A.Z., Adiluhung, H., Wicaksono, M., Risnanda, N., 2021.

Automated Ultraviolet C Light Mobile Robot for Room Sterilization and

Disinfection. International Journal of Technology, Volume 12(4), pp. 854–864

Salonen,

H., Salthammer, T., Morawska, L., 2018. Human Exposure to Ozone in School and

Office Indoor Environments. Environment International, Volume 119, pp.

503–514

Sharp,

S.E., Searcy, C., 2006. Comparison of Mannitol Salt Agar and Blood Agar Plates for Identification and Susceptibility Testing of Staphylococcus Aureus in Specimens from

Cystic Fibrosis Patients. Journal of

Clinical Microbiology,

Volume 44(12), pp. 4545–4546

Suksri,

A., Karnchanalekha, K., Tonmitra, K.,

Apiratikul, P., 2009. A comparative study on suitable high voltage sources for

ozone generation. In: 2009 6th International Conference on

Electrical Engineering/Electronics, Computer, Telecommunications and

Information Technology, IEEE, Volume 1, pp. 296–299

Suryawan,

I.W.K., Septiariva, I.Y., Helmy, Q., Notodarmojo, S., Wulandari, M., Sari,

N.K., Sarwono, A., Pratiwi, R., Lim, J., 2021. Comparison of Ozone

Pre-Treatment and Post-Treatment Hybrid with Moving Bed Biofilm Reactor in

Removal of Remazol Black 5. International Journal of Technology, Volume 12(4),

pp. 728-738

Takayama,

M., Ebihara, K., Stryczewska, H., Ikegami, T., Gyoutoku, Y., Kubo, K.,

Tachibana, M., 2006. Ozone Generation by Dielectric Barrier Discharge for Soil Sterilization. Thin Solid Films,

Volume 506, pp. 396–399

Thanomsub,

B., Anupunpisit, V.,

Chanphetch, S., Watcharachaipong, T., Poonkhum, R., Srisukonth, C., 2002.

Effects of Ozone Treatment on

Cell Growth and Ultrastructural Changes in Bacteria. The Journal of General

and Applied Microbiology, 48(4), pp. 193–199

Teke,

S., Nur, M., Winarni, T., 2014. Ozone Generator by Using Dielectric Barrier

Discharge Plasma Technology with Spiral-Cylinder Configuration: Comparison

Between Oxygen and Air as Sources. Berkala Fisika, Volume 17, pp. 25–32

Verma,

K., Gupta, D., Gupta, A., 2016. Optimization of Ozone Disinfection and Its

Effect on Trihalomethanes. Journal of Environmental Chemical Engineering,

Volume 4(3), pp. 3021–3032

Vezzu,

G., Lopez, J., Freilich, A., Becker, K., 2009. Optimization of Large-Scale Ozone Generators. IEEE Transactions

on Plasma Science, Volume 37(6),

pp. 890–896

World Health Organization (WHO),

2021. WHO Global Air Quality Guidelines: Particulate Matter (?PM2.5 And PM10)?,

Ozone, Nitrogen Dioxide, Sulfur Dioxide and Carbon Monoxide. World Health Organization

Waluyo,

W., Permana, D.A., Saodah, S., 2015. Design and Realization of Ozone Generator

Using Alternating High Voltage Generation Method. Jurnal Teknik Energi

Elektrik, Teknik Telekomunikasi, & Teknik Elektronika, Volume 3, p. 38

Zhengzhou

Winsen Electronics Technology, 2021. MQ131 High Concentration Ozone Gas Sensor.

Avalaible Online at: https://www.winsen-sensor.com/sensors/o3-gas-sensor/mq131-h.html,

Accessed on 16 March 2022