Design of a Transforaminal Lumbar Interbody Fusion (TLIF) Spine Cage

Corresponding email: yudan.whulanza@ui.ac.id

Published at : 30 Dec 2022

Volume : IJtech

Vol 13, No 8 (2022)

DOI : https://doi.org/10.14716/ijtech.v13i8.6152

Faadhila, A., Rahman, S.F., Whulanza, Y., Supriadi, S., Tampubolon, J.Y., Wicaksana, S.I., Rahyussalim, A.J., Kurniawati, T., Abdullah, A.H., 2022. Design of a Transforaminal Lumbar Interbody Fusion (TLIF) Spine Cage. International Journal of Technology. Volume 13(8), pp. 1663-1671

| Afrah Faadhila | Biomedical Engineering Study Program, Department of Electric Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, West Java 16424, Indonesia |

| Siti Fauziyah Rahman | 1. Biomedical Engineering Study Program, Department of Electric Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, West Java 16424, Indonesia, 2. Research Center for Biomedic |

| Yudan Whulanza | 1. Research Center for Biomedical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, West Java 16424, Indonesia, 2. Department of Mechanical Engineering, Faculty of Engineer |

| Sugeng Supriadi | 1. Research Center for Biomedical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, West Java 16424, Indonesia, 2. Department of Mechanical Engineering, Faculty of Engineer |

| Joshua Yoshihiko Tampubolon | PT Trafas Dwi Medika, Jakarta 13920, Indonesia |

| Septian Indra Wicaksana | PT Trafas Dwi Medika, Jakarta 13920, Indonesia |

| Ahmad Jabir Rahyussalim | Department of Orthopaedic and Traumatology, Cipto Mangunkusumo National Central General Hospital and Faculty of Medicine, Universitas Indonesia, Jakarta 10430, Indonesia |

| Tri Kurniawati | Stem Cell and Tissue Engineering Cluster, Indonesian Medical Education and Research Institute, Faculty of Medicine, Universitas Indonesia, Jakarta 10430, Indonesia |

| Abdul Halim Abdullah | Biomechanical & Clinical Engineering Research Group, College of Engineering, Universiti Teknologi Mara, Malaysia |

Lumbar Interbody Fusion is a technique used to treat

various spinal disorders, which has many types, such as the Transforaminal

Lumbar Interbody Fusion (TLIF) Technique. With TLIF being one of the most

well-known techniques, which many spinal surgeons are trained and skilled at,

there are various types of TLIF Spine Cages available on the market. In this

paper, we designed a TLIF Cage and compared the simulation's analysis with the

prototype's experimental testing. The design was developed using the reverse

engineering method, and findings on the jaws profile and other design

considerations through literature review. The design was then analyzed through

a simulated compression test using Ansys Software. The simulation showed that

the designed TLIF spine cage in this paper can withstand the force usually

given to an implanted lumbar spinal cage.

3D Design; Interbody Fusion; Spine Cage; TLIF implant

Patients increasingly suffer spinal injuries due to accidents or incorrect movement positions in athletes. The loss or reduced function of the spinal disc to support the spine and maintain foraminal height is one of the most common injuries. This injury can cause the narrowing of the spinal canal, or degenerative lumbar spinal stenosis, which affects the patient’s movement (Lee et al., 2020). If not properly treated, this disease can lead to ischemia and chronic pain (Lee et al., 2020). Several types of treatment can be given to patients, ranging from therapeutic testing with injections for minor injuries, combining medications with physical therapy, for spine cage implant surgery using the lumbar interbody fusion technique (Hennemann & de Abreu, 2021; Mobbs et al., 2015). The Lumbar Interbody Fusion Technique treats various spinal disorders, including degenerative pathologies, trauma, infection, and neoplasia. This technique is done by inserting an implant, a cage, a spacer, or a structural graft, into the intervertebral space using various approaches (Mobbs et al., 2015).

There are

several spine cage implant options available that differ in their geometry

depending on the approach for insertion. First is Posterior Lumbar Interbody

Fusion (PLIF) which many spinal surgeons are well-trained to use. It provides

better nerve root visualization than other cages. But it also requires high

neural retraction. Then there is Anterior Lumbar Interbody Fusion (ALIF) as the

most efficacious and predominant treatment for discogenic low back pain which

can maximize implant size and surface area. But ALIF insertion surgery can

cause some complications, such as retrograde ejaculation, and visceral and

vascular injury. For sagittal and coronal deformity correction, lateral lumbar

interbody fusion (LLIF) and oblique lumbar interbody fusion (OLIF) are

suitable. Both cages can be performed with rapid postoperative mobilization and

aggressive deformity correction. These cages, unfortunately, can cause lumbar

plexus, psoas, bowel, and vascular injuries. The last cage type is

Transforaminal Lumbar Interbody Fusion (TLIF).

This technique is the best for stabilization and treatment of

degenerative lumbar disease following failed conservative treatment (Rahyussalim et al., 2017).

Despite the disadvantages, such as paraspinal iatrogenic injury from prolonged

muscle retraction, it can still perform direct and unilateral access to the

intervertebral foramen and preserve ligamentous structures. This access can

reduce direct dissection, the prior chance of damaging back muscles and the

thecal sac, minimize bleeding, and improve postoperative recovery (Hammad et al.,

2019; Mobbs et al., 2015).

The neural foramen is also opened on one side only, so damage to the nerves is

less compared to the other technique (Mobbs et al., 2015). With all

those advantages, TLIF has become one of the most commonly used techniques for

Disc Degeneration Disease treatment and is worth developing.

2.1.

Determining the Size and 3D model of the TLIF Spine Cage

where:

UVW : upper vertebral width

UVD : upper vertebral depth

DH : disc height

PH : pedicle height

PDW : pedicle width

The UVW, UVD, DH, PH and PDW will be acquired from

obtained data from previous research.

2.2.

Prototyping of the TLIF spine scage

In order to execute the 3D design of the spine cage, an

additive manufacturing technique commonly known as stereolithography (SLA) was

conducted. A Photon Mono X (Anycubic, Shenzhen, China) with LCD-based SLA

technology that has faster printing speeds and a larger volume was utilized. The previously determined solid model file in.stl

format was now ready to be transferred to the SLA machine. The Photon Mono-X

machine uses a

bio-photopolymer resin mixed with bio-poly lactic acid from eSUN (Shenzhen, China). The PLA-resin has a low viscosity and has

mechanical properties as detailed in Table 1.

Table 1 Mechanical Properties of

eResin-PLA at 25?C

2.3.

Numerical simulation of TLIF spine cage

A finite element analysis (FEA) was conducted using ANSYS

2022 workbench software (2022 R2 version, Canonsburg, Pennsylvania, USA). In

the FEA simulation, the spine cage was assumed to be isotropic (Ahmad et al.,

2020). The material that is being simulated for the spine cage is

polyetheretherketone (PEEK). The data shows that this material has a

compressive strength of 120-300 MPa (depending on the molecular weight) and

elongation of a break at around 1.6-43%.

The environmental simulation needed the mechanical properties

of the PLA-resin materials. Therefore, a compressive test was conducted to

acquire the mechanical parameters of the PLA-resin material. A 3D printed block

with the size of 20mm x 10mm x 10mm was prepared as the testing material. The

compression was conducted using the universal testing machine MCT-2150 from

A&D Company (Tokyo, Japan). The compression rate was set at 10 mm/min.

3.1. Size

Determination and 3D Model of the Spine Cage Implant

Figure

1 The image processing result of Indonesian Lumbar

dimension in sagittal plane (a) and axial plane (b)

Table 1 Lumbar Dimension Indonesian Lumbar dimension in sagittal plane (a)

and axial plane (b)

|

Parameters |

Spine Section- L4 |

Spine Section- L5 |

Units |

|

UVW |

46 |

48 |

mm |

|

UVD |

33 |

33 |

mm |

|

DH |

11 |

10 |

mm |

|

PH |

13 |

12 |

mm |

|

PDW |

10 |

13 |

mm |

Spine cage sizes were derived from the dimensions of the

above spine section. Note that the spine cage was not designed to cover all the

spine areas. The spine cage was designed to be as small as possible compared to

that spine section, but the cage must withstand the load from the human body.

Based on our study, we converted the dimension of TLIF spine cages to adapt a

minimum insertion size at around 8 mm. The formula to calculate the length (L),

Width (W), Height (H), and Lordosis Angle (LA) of the TLIF spine cages are

given in Equations 1, 2, 3, and 4 based on L4 sizes. The L was calculated to

adjust the length area of the cages that can cover the spine area. The W was

arranged from the PDW size as the insertion side of the cage. The LA was

formulated from the measure of the lordotic angle between two lumbar bodies.

Besides the dimension and angle of the

cage, it is known that several factors might influence the biomechanical stability of a lumbar

interbody spine cage construct, such as geometry, contact area, and integrated

fixation (Triwardono

et al., 2021). Therefore, in this paper, we designed a

banana-shaped spine cage with a slanted side to facilitate TLIF placement.

Based on the lumbar morphometry, formulas, and those biomechanical stability

factors, geometry, and sizes of the spine cage design are shown in Table 2.

Table 2 Design Fixture of Spine Cage

|

Fixture |

Metrics |

Units |

|

Length |

27.7 |

mm |

|

Width |

8 |

mm |

|

Height |

11 |

mm |

|

Lordosis Angle |

7 |

degree |

|

Jaws Shape |

Pyramid |

-- |

|

Slanted Side |

36.5 |

degree |

|

Window Holes |

3 |

pieces |

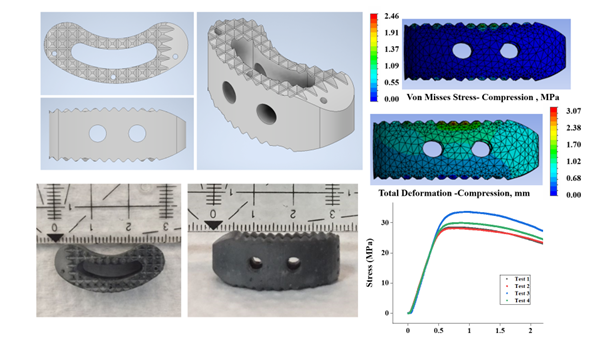

By following the lumbar morphometry and biomechanical stability factors in Table 2, the TLIF spine cage design is shown in Figure 2. The spine cage consists of a vertical middle hole and two horizontal holes to insert bone graft materials (Figure 2c). The banana-shaped facilitated the placement of the implant through the posterior side. The designed implant has slightly different measurements compare to those available on the market. The length of the designed implant was 27.7 mm and had an angle of 7.27 degrees.

Figure

2 The 3D design of spine cage considering the

adjustment of size and features of bone graft holes and pyramid jaws: a) top

view; b) side view and perspective view

The fixation for this implant is designed to use a pedicle screw

fixation, as an integrated screw fixation is usually not enough to give the

biomechanical stability needed for a spine cage implant. For the contact area,

the profile of the jaws was made to increase friction and limit the micromotion

of the spine cage. Increasing the surface roughness of the spine cage is suitable

for fixating the implant to the bone (Triwidodo et

al., 2021). Therefore, we designed the surface area equipped with a pyramid

jaws profile to gain a better osteogenic process. with bone graft than a simple one-type jaws

profile design. The pyramid jaws are depicted in Figure 2c.

3.2. Prototyping of the TLIF Spine Cage

The prototyping was conducted using additive manufacturing technology that involves stereolitography of liquid resin. The machine realized the structure as a predetermined design in the 3D model file. The fabrication result was depicted in Figure 3, with an accuracy of around less than 0.5 mm according to the technical specification. Moreover, the realized geometry indicated that the deviation was less than 1 mm compared to the design dimension. It can be concluded that this additive manufacturing technique can be used as a reference model or a prototype of the implant before its transfer to industrial scale. (Syuhada et al., 2018).

Figure

3 TLIF design printing with PLA Resin: a) top view

and b) side view

3.3.

Numerical Simulation of TLIF Spine Cage

The numerical simulation predicts that our design would withstand applied loading on the spine cage. The simulation calculates the peak of von Mises stress (PVMS) value as the failure criteria of the selected material of the spine cage (Izmin et al., 2020). Moreover, this study also ensures the safety design of the spine cage with our geometrical arrangement. The stress visualizations of the spine cage simulation are shown in Figure 4. Here, a force of 500 N was applied to the spine cage in an axial direction, following the highest possible loading of the human body (Alief et al., 2019).

Figure

4 Finite Element Analysis results for spine cage

implant: a) Total Deformation - Compression and b) Von Misses – Compression

The

simulation results were summarized further in Table 5 to include the maximum

point of the spine case during the loading scenario. As shown in Table 5, the

von misses results are far below the tensile strength of the simulated material,

i.e. PEEK. It suggested that the implant geometry and material successfully

support the spinal movement (figure 4a). Also, in torsion and shear simulations,

the result does not indicate the failure of the spine cage implant (table 5). A

relatively small deformation value from the results also indicate that the

implant will be able to function properly (figure 4b). Since compression,

tensile, shear, and torsion tests only indicate a simple vertical movement of

the spine.

Table 3 Differentiation of Lumbar

Interbody Fusion Implant

3.4. Validation of the

model

A comparison of numerical simulation and the experimental setup is

needed to validate the numerical study in our previous section. We simulate a

compressive test of the realized resin-PLA spine cage in the finite element environment.

This phenomenon was followed by compression using the universal testing

machine. Figure 5 shows the Finite

Element Analysis of the sample block in terms of its total deformation and

calculated von Misses Stress.

Figure

5 Finite Element Analysis results for PLA sample

block: a) Von Misses and b) total deformation in compression testing mode

The compressive test on a 3D printed acquire the young’s modulus value

at around 55.6 MPa. This value was confirmed by our previous study (Supriadi et al., 2021, Saseendran et al.,

2017). A 500 N vertical compression and tensile force were given from

the top surface to calculate Von Mises and deformation of the implant (He et al., 2021). Shear stress with 200 N and 25 Nm torsion was also evaluated in this

implant simulation (Krijnen

et al., 2006; Pitzen et al., 2000). Table 4 shows the mechanical parameters in the Ansys simulation

software.

Table 4 Parameters for Finite Element Analysis

|

Density (g/mm3) |

Young’s Modulus (MPa) |

Poisson’s Ratio |

Reference |

|

1.13 |

55.6 |

0.35 |

(Saseendran et

al., 2017) |

Figure

6 Compressive test result for PLA sample block

compare with the numerical calculation of elastic modulus

Figure 6 presents the experimental result of block test (with

four repetitions of samples). It showed its maximum strength at around 30 MPa.

The numerical simulation gives the dotted line in Figure 6. The line was

projected from the force-displacement relation from the environmental

simulation (Figure 5). It showed a deviation of 9% compared to the experimental

result. Consequently, it can be suggested that the simulation result of spine

cage has a 9% gap mostly in the elastic region (red line area in Figure 6).

A TLIF spine cage based on Indonesian morphometry with a 28 x 9 x

11 mm dimension was designed with a pyramid-shaped jaw profile, multiple holes

as a space for bone graft, and a thread hole for insertion of the implant into

the disc space. We performed a finite

element analysis simulation with the Ansys software, performing compression and

tensile tests to stimulate the stress impacted on the implant. Shear and

torsion test was also simulated in this research. This simulation was done to

test the strength of the design using PLA Resin material. The results showed

that the design is strong enough to withstand the force given. Our numerical

study also showed that a deviation around 9% between experimental loading and

numerical calculation might occurred. However, it is believed that this gap

between experimental and realization might give important information when the

candidate material, PEEK, will be used in the future application.

The authors would like to acknowledge the Matching

Fund Grant No.279/PKS/WRIII-DISTP/UI/2022 from Kementerian Pendidikan,

Kebudayaan, Riset, dan Teknologi.

Ahmad, M.A., Zulkifli, N.N.M.E., Shuib, S., Sulaiman, S.H., Abdullah,

A.H., 2020. Finite Element Analysis of Proximal Cement Fixation in Total Hip

Arthroplasty. International

Journal of Technology, Volume 11(5), pp. 1046–1055

Alief, N.A., Supriadi, S., Whulanza, Y., 2019. Modelling The Shape

Memory Properties of 4D Printed Polylactic Acid (PLA) for Application of Disk

Spacer in Minimally Invasive Spinal Fusion. In: AIP Conference

Proceedings, 2092, 020005

Burnard, J.L., Parr, W.C.H., Choy, W.J., Walsh, W.R., Mobbs, R.J., 2020.

3D-printed Spine Surgery Implants: A Systematic Review of The Efficacy and

Clinical Safety Profile of Patient-Specific and Off-The-Shelf Devices. European Spine

Journal,

Volume 29(6), pp. 1248–1260

Genisa, M., Shuib, S., Ahmad Rajion, Z.A., Mohamad, D., Arief, M.E.,

2020. Dental Implant Monitoring Using Resonance Frequency Analysis (RFA) and

Cone Beam Computed Tomography (CBCT) Measurement. International Journal of Technology, Volume 11(5), pp. 1015–1024

Hammad, A., Wirries, A., Ardeshiri, A., Nikiforov, O., Geiger, F., 2019.

Open Versus Minimally Invasive TLIF: Literature Review and Meta-Analysis. Journal of

Orthopaedic Surgery and Research, Volume 14(1), p. 229

He, L., Xiang, Q., Yang, Y., Tsai, T.Y., Yu, Y., Cheng, L., 2021. The Anterior

and Traverse Cage Can Provide Optimal Biomechanical Performance for Both

Traditional and Percutaneous Endoscopic Transforaminal Lumbar Interbody Fusion.

Computers in Biology and Medicine, Volume 131, p. 104291

Hennemann, S., de Abreu, M.R., 2021. Estenose Degenerativa Do Canal

Lombar (Degenerative Stenosis of The Lumbar Canal). Revista Brasileira de Ortopedia, Volume 56(01), pp. 009–017

Izmin, N.A.N., Hazwani, F., Todo, M., Abdullah, A.H., 2020. Risk of

Bone Fracture in Resurfacing Hip Arthroplasty at Varus and Valgus Implant

Placements. International Journal of Technology, Volume 11(5), pp. 1025–1035

Krijnen, M.R., Mensch, D., van Dieen, J.H., Wuisman, P.I., Smit, T.H., 2006.

Primary Spinal Segment Stability with a Stand-Alone Cage: In Vitro Evaluation of

a Successful Goat Model. Acta Orthopaedica, Volume 77(3), pp. 454–461

Lee, B.H., Moon, S.H., Suk, K.S., Kim, H.S., Yang, J.H., Lee, H.M., 2020.

Lumbar Spinal Stenosis: Pathophysiology and Treatment Principle: A Narrative

Review. Asian Spine Journal, Volume 14(5), pp. 682–693

Mobbs, R.J., Phan, K., Malham, G., Seex, K., Rao, P.J., 2015. Lumbar Interbody

Fusion: Techniques, Indications and Comparison of Interbody Fusion Options

Including PLIF, TLIF, MI-TLIF, OLIF/ATP, LLIF and ALIF. Journal of Spine

Surgery,

Volume 1(1), pp. 2–18

Peck, J.H., Kavlock, K.D., Showalter, B.L., Ferrell, B.M., Peck, D.G.,

Dmitriev, A.E., 2018. Mechanical Performance of Lumbar Intervertebral Body

Fusion Devices: An Analysis of Data Submitted to The Food and Drug

Administration. Journal of Biomechanics, Volume 78, pp. 87–93

Pitzen, T., Geisler, F.H., Matthis, D., Müller-Storz, H., Steudel, W.I.,

2000. Motion of Threaded Cages in Posterior Lumbar Interbody Fusion. European Spine

Journal,

Volume 9(6), pp. 571–576

Rahyussalim, A.J. Kurniawati, T., Aprilya, D., Anggraini, R., Ramahdita,

G., Whulanza, Y., 2017. Toxicity and Biocompatibility Profile of 3D Bone

Scaffold Developed by Universitas Indonesia: A Preliminary Study. AIP Conference

Proceedings, Volume 1817, p. 020004

Saseendran, S., Wysocki, M., Varna, J., 2017. Cure-state Dependent

Viscoelastic Poisson’s Ratio of LY5052 Epoxy Resin. Advanced Manufacturing:

Polymer & Composites Science, Volume 3(3), pp. 92–100

Supriadi, S., Rachman, P., Saragih, A.S., Whulanza, Y., Rahyussalim,

A.J., Triwidodo, A., 2021. Design, Development, and Finite Element Study on The

Novel Biomimetic Lumbosacroiliac Prosthesis. In: AIP Conference Proceedings, AIP Publishing LLC, Volume

2344(1), p. 050021

Syuhada, G., Ramahdita, G., Rahyussalim, A.J., Whulanza, Y.

Multi-material Poly (Lactic Acid) Scaffold Fabricated Via Fused Deposition

Modeling and Direct Hydroxyapatite Injection as Spacers in Laminoplasty. AIP Conference

Proceedings, Volume 1933, p. 020008

Triwidodo, A., Rahyussalim, A.J., Yulisa, N.D., Pandelaki, J., Huraiby,

L.S., Hadi, I.A.N., Liosha, F.Y., Dilogo, I.H., 2021. Sacrum Morphometry and

Spinopelvic Parameters Among The Indonesian Population Using Computed

Tomography Scans. Medicine, Volume 100(47)

Triwardono, J., Supriadi, S., Whulanza, Y., Saragih, A.S., Novalianita

D.A., Utomo, M.S., Kartika, I., 2021. Evaluation of The Contact Area in Total

Knee Arthroplasty Designed for Deep Knee Flexion. International Journal of Technology, Volume 12(6), pp.

1312–1322

Walter, C.,

Baumgärtner, T., Trappe, D., Frantz, S., Exner, L., Mederake, M., 2021.

Influence of Cage Design on Radiological and Clinical Outcomes in Dorsal Lumbar

Spinal Fusions: A Comparison of Lordotic and Non-Lordotic Cages. Orthopaedic Surgery, Volume 13(3), pp. 863–875