Surface Coating Effect on Corrosion Resistance of Titanium Alloy Bone Implants by Anodizing Method

Corresponding email: eva-oktavia@chem-eng.its.ac.id

Published at : 28 Jun 2023

Volume : IJtech

Vol 14, No 4 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i4.6146

Ningrum, E.O., Khoiroh, I., Nastiti, H.I., Affan, R.A., Karisma, A.D., Agustiani, E., Surono, A., Suroto, H., Suprapto, S., Taji, L.S., Widiyanto, S., 2023. Surface Coating Effect on Corrosion Resistance of Titanium Alloy Bone Implants by Anodizing Method. International Journal of Technology. Volume 14(4), pp. 749-760

| Eva Oktavia Ningrum | Department of Industrial Chemical Engineering, Faculty of Vocational Studies, Institut Teknologi Sepuluh Nopember, Kampus ITS Sukolilo, Surabaya 60111, Indonesia |

| Ianatul Khoiroh | Department of Chemical & Environmental Engineering, Faculty of Science and Engineering, University of Nottingham Malaysia, Jalan Broga 43500 Semenyih, Selangor, Malaysia |

| Hanifah Inas Nastiti | Department of Industrial Chemical Engineering, Faculty of Vocational Studies, Institut Teknologi Sepuluh Nopember, Kampus ITS Sukolilo, Surabaya 60111, Indonesia |

| Ryan Anindya Affan | Department of Industrial Chemical Engineering, Faculty of Vocational Studies, Institut Teknologi Sepuluh Nopember, Kampus ITS Sukolilo, Surabaya 60111, Indonesia |

| Achmad Dwitama Karisma | Department of Industrial Chemical Engineering, Faculty of Vocational Studies, Institut Teknologi Sepuluh Nopember, Kampus ITS Sukolilo, Surabaya 60111, Indonesia |

| Elly Agustiani | Department of Industrial Chemical Engineering, Faculty of Vocational Studies, Institut Teknologi Sepuluh Nopember, Kampus ITS Sukolilo, Surabaya 60111, Indonesia |

| Agus Surono | Department of Industrial Chemical Engineering, Faculty of Vocational Studies, Institut Teknologi Sepuluh Nopember, Kampus ITS Sukolilo, Surabaya 60111, Indonesia |

| Heri Suroto | Orthopedic and Traumatology Department, Faculty of Medicine, Airlangga University/Dr. Soetomo General Academic Hospital, Jl. Mayjen Prof. Dr. Moestopo No.47, Surabaya, Jawa Timur 60132, Indonesia |

| S. Suprapto | Department of Industrial Chemical Engineering, Faculty of Vocational Studies, Institut Teknologi Sepuluh Nopember, Kampus ITS Sukolilo, Surabaya 60111, Indonesia |

| Lulu Sekar Taji | Department of Industrial Chemical Engineering, Faculty of Vocational Studies, Institut Teknologi Sepuluh Nopember, Kampus ITS Sukolilo, Surabaya 60111, Indonesia |

| Sinung Widiyanto | Magister of Ocean Engineering, Faculty of Engineering and Marine Sciences, Hang Tuah University, Jl. Arief Rahman Hakim No.150, Keputih, Kec. Sukolilo, Surabaya 60111, Indonesi |

In the presented work, the

formation of anodic oxide film on Ti-6Al-4V ELI (Extra Low Interstitial) alloy

in 0.02 M trisodium phosphate (Na3PO4) electrolyte solution using various voltages were investigated. The color produced by the anodizing, the intensity of TiO2 content, the thickness of the oxide layer, and the corrosion rate were examined. It was obtained that the color appearance of Ti-6Al-4V ELI could be changed easily by altering the applied voltages. The higher the voltage applied in the anodizing process, the thicker the titanium oxide layer formed. The corrosion resistance analysis in a Simulated Body Fluid revealed that the non-anodized specimen showed a higher corrosion rate compared to the anodized specimen. The increase of oxide layer thickness leads to a significant decrease in corrosion rate and consequently increases the corrosion resistance. In addition, the anodized sample achieved the highest corrosion resistance at 15 V.

Anodizing; Corrosion resistance; Titanium oxide; Ti-6Al-4V alloy

A bone

implant is a medical device used to strengthen the existing bone

structure or supports an injured bone structure. In this case,

approximately 90% of implants in Indonesia imports. Therefore, given

the rising demand for implants, the development of bone implants is a crucial

debate issue. Based on the biomedical viewpoint, implant stability and the

osseointegration process, which has the potential for rehabilitation, are the

most important internal factors in the implantation of medical devices. Therefore,

it is essential to create bone implants that have high-quality and

effective when placed within the body (Dewi et

al., 2020; Genisa et al., 2020; Izmin et al., 2020). Orthopedic implants are now

made from various materials, including polymers, ceramics, metals, and

composites. The majority of metals are bio tolerant, although titanium and its

alloys have a bioinert nature under

specific circumstances (Koju, Niraula and Fotovvati, 2022).

Titanium Ti-6Al-4V ELI is a commonly used implant material in the

medical field due to its mechanical and corrosion resistance properties

Implant surface modification is necessary to obtain good implant

properties and performance for the body. This surface modification is important

to increase surface energy by providing surface roughness and chemical

composition. This will increase tissue adhesion and implant integration as well

as reduce bacterial reactions and inflammatory responses in the body

According to prior research, some inorganic

ions, such as molybdate and metavanadate, can passivate titanium in solutions

of sulfuric and hydrochloric acids

Research concerning the anodizing process of Ti-6Al-4V alloy has been

numerously conducted; however, it is only limited to the use of corrosion

resistance test solution, causing its inability to simulate the body's

physiological condition. Therefore, the current research used SBF solution. The

effect of various voltage on the implant color visual, the mass of the oxide

layer formed, oxide film thickness, and implant corrosion resistance were

investigated in this study. Moreover, the correlation between film thickness

and its corrosion resistance was also elucidated. In addition, the trisodium

phosphate electrolyte solution was chosen because it provides better corrosion

resistance compared to the acidic electrolyte solution (Karambakhsh et al., 2015).

2.1.

Materials

The main material used in this research was Ti-6Al-4V ELI metals act as

an anode that would be layered by TiO2 using an anodizing method. An

aluminum foil sheet was also used as a cathode. The electrolyte used was 2 g of

trisodium phosphate dodecahydrate purchased from Merck, which initially

dissolved in 1000 mL aquadest. Titanium wire 28 AWG 0.3 mm and alligator clip

were also employed as the supporter of both Ti-6Al-4V ELI metal and aluminum

foil during the anodizing process. The electrical power source was obtained

from DC Power Supply WANPTEK of NPS 1203W 120V/3A type. In addition, a SBF

solution was used as an electrolyte during the potentiodynamic polarization

analysis to investigate the corrosion rate of anodized Ti-6Al-4V ELI metal

material.

2.2. Methods

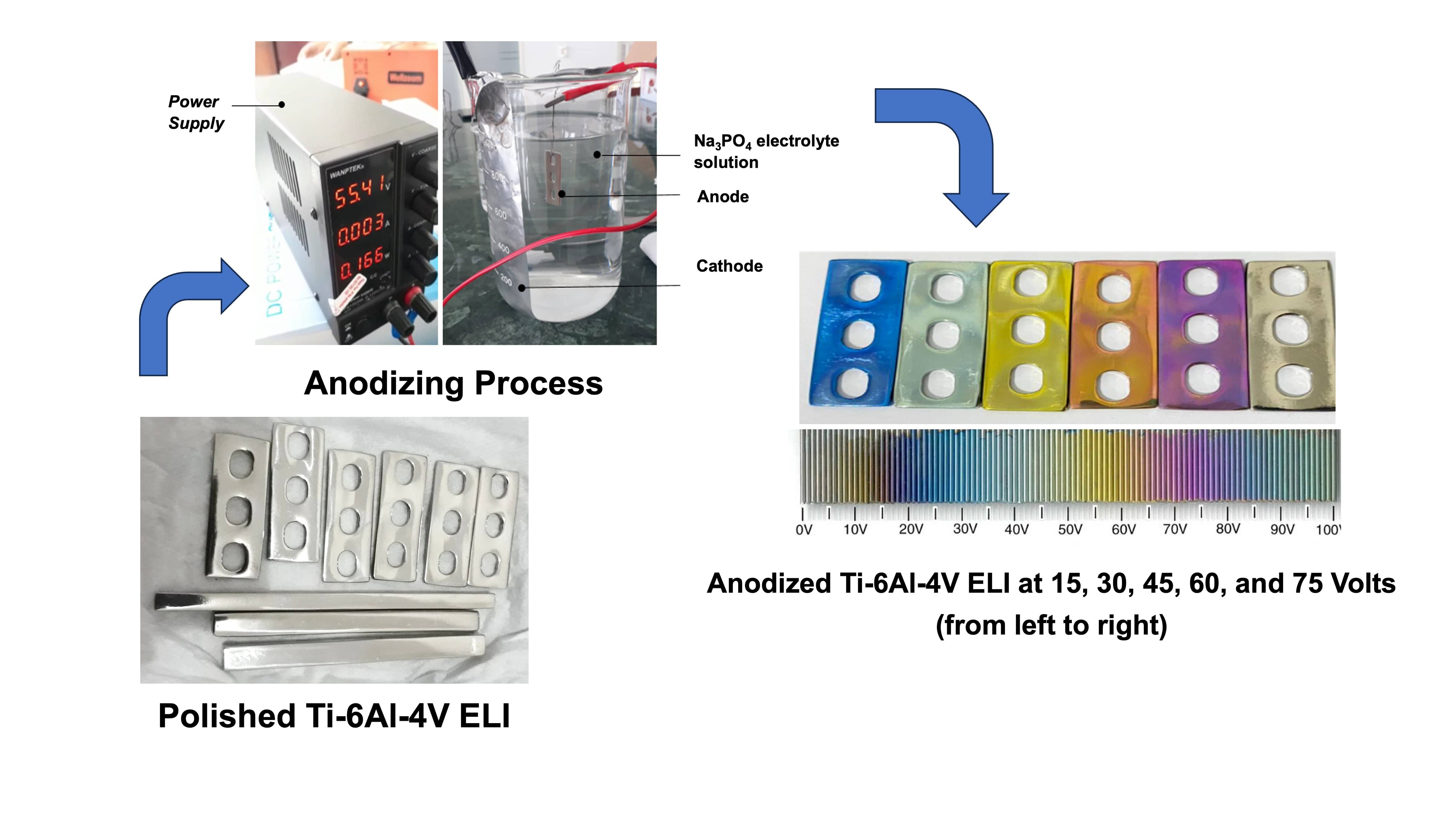

Anodizing method was done in Na3PO4

(base solution) electrolyte solution. In this case, the Ti-6Al-4V

specimen obtained pre-treatment to make the implant surface shiny so that the

anodizing color produced can be seen clearly. This pre-treatment process used

Ti-6Al-4V ELI metals, previously polished using langsol or green stone to obtain a mirror-like surface. The

solution used for anodizing was Trisodium Phosphate solution with a

concentration of 0.02 M of 250 mL volume. The cathode was aluminum foil, and

the anode was the Ti-6Al-4V specimens. Anodizing process was performed within

30 s for each sample, the variable parameter being the anodizing voltage.

Anodizing was performed in the 15-75 V voltage range, and with the steps of 15

V. The schematic apparatus for an anodizing process is shown in Figure 1.

2.2.1. XRD Analysis

XRD was

used to identify the titanium oxide crystal component formed after anodizing.

2.2.2. Spectrophotometry

Analysis

Spectrophotometry

Analysis was carried out to determine the quantitative parameters of the

specimen surface color (Konica Minolta CM-5 spectrophotometer). In order to

measure the color difference of each specimen, this tool would obtain data

values of L*, a*, and b*, where chromaticity was obtained using the CIELAB

color space method based by using Equation (1)

|

No |

Reagent |

Composition (g/L) |

|

1. |

NaCl |

8.00 |

|

2. |

KCl |

0.40 |

|

3. |

CaCl2 |

0.18 |

|

4. |

NaHCO3 |

0.35 |

|

5. |

Na2HPO4.2H2O |

0.48 |

|

6. |

MgCl2.6H2O |

0.10 |

|

7. |

KH2PO4 |

0.06 |

|

8. |

MgSO4.7H2O |

0.10 |

|

9. |

Glucose |

1.00 |

3.1. Analysis of Anodizing

Results in Trisodium Phosphate Electrolyte

3.1.2. Effect of Voltage on the Mass of Oxide Layer Formed

Based on Faraday’s Law I, the mass formed on the anode after the

anodizing process can be obtained using Equation (3)

As data comparison, in addition to using a theoretical equation, data

collection was also conducted by weighing the titanium specimen mass, both

before and after the anodizing process, to investigate the mass of the oxide

layer formed after the anodizing process. Figure 3 indicates the addition of

mass in each anodizing voltage variety based on Faraday’s Law I equation. In

this case, there was an increase in titanium oxide mass from 15 V voltage to 75

V voltage. Such results are in accordance with the previous literature that the

higher the voltage for the anodizing process, the thicker the titanium oxide

layer formed obtained from the experimental method using

an analytical scale that mass addition resulting from 15 V to 75 V voltage

shows an increasing trend. Hence, based on the comparison between these data,

the higher voltage given during anodizing process, the thicker the oxide layer

formed on the titanium specimen.

Based on the theoretical calculation conducted, the addition

anomaly occurred at 45 V to 60 V, indicating the most significant increase

compared to the other voltages. In this case, the

increase occurred was

more than 100% from 45 to 60 V. This occurred due to the current formed during

the anodizing process. Furthermore, it was known that from 45 V to 60 V the

increased current was quite high from 0.090 A to 0.48 A. This current increase

occurred due to the instability of electrode distance during the anodizing

process, where the closer the distance of the electrode, the higher the current

) obtained from both theoretical and experimental calculations.

Figure 3 Effect of Voltage on TiO2 Mass Formed

3.2. Analysis of XRD

The peak of

Figure 4 XRD Analysis spectrum of

Ti-6Al-4V specimen (a) Titanium Oxide Reference of ICDD Standard No.

98-009-9784 and XRD Analysis spectrum after Anodizing Process at (b) 75 Volt,

(c) 45 Volt, (d) 15 Volt

3.3. Analysis of Spectrophotometry Results

Table 2 L*, a*, b* Parameter and Chromaticity

|

No |

Variable |

L* |

a* |

b* |

Chromaticity |

|

1. |

15

Volt |

46.75 |

-0.47 |

-0.44 |

0.207 |

|

2. |

30 Volt |

49.25 |

-0.36 |

-7.51 |

28.264 |

|

3. |

45

Volt |

49.61 |

-1.03 |

-3.83 |

7.864 |

|

4. |

60 Volt |

50.67 |

-1.67 |

-2.04 |

3.475 |

|

5. |

75

Volt |

64.47 |

5.40 |

9.65 |

61.141 |

Table 2 above shows that the

highest lightness was obtained at a voltage of 75 Volt, which produced goldish

yellow. This lightness parameter would be further used to know the brightness

level of the color. Meanwhile, a high chromatic score was obtained at a voltage

of 30 V by 28.264 and at 75 V by 61.141. In this case, chromaticity is defined as the quality of light

characterized by a dominant wavelength. Based on this description, L*,

a*, and b* parameters on CIELAB color space were used to investigate color

quality produced by the anodizing process, which has no correlation with the

oxide layer thickness produced.

3.3.1. Effect of Voltage on Oxide

Film Thickness

Table 3 Film Thickness of Titanium Oxide

(TiO2)

|

No |

Voltage |

Wavelength (nm) |

Refractive index (n0) |

Thickness of Oxide Layer (nm) |

|

1. |

15 V |

380 |

1.448 |

65.596 |

|

2. |

30 V |

469 |

1.438 |

81.543 |

|

3. |

45 V |

535 |

1.429 |

93.626 |

|

4. |

60 V |

583 |

1.421 |

102.580 |

|

5. |

75 V |

608 |

1.416 |

107.307 |

Table 3 shows that the oxide layer

thickness is directly related to anodizing voltage. As shown above, the thickness of the oxide layer

increased by increasing voltage from 15-75 V. In this case, the highest oxide

layer was obtained at 75 V by 107.307 nm, while the lowest was at 15 V by

65.596 nm. This is in accordance with the report by (Karambakhsh et al., 2011) that the addition of voltage in the anodizing process produces an

increase in the oxide layer, which leads to an increase in

mass produced. This

difference further provides different interference color visuals as well, according to the voltage variety.

The increase in TiO2 film thickness was caused by the greater the

applied voltage, so the greater the current delivered. This causes more TiO2

to be deposited at the Ti-6Al-4V anode.

3.4. Effect of Voltage on Implant

Corrosion Resistance

Table 4 Corrosion Resistance of non-anodized and anodized specimens

|

No |

Variable |

Ecorr |

Icorr |

Corrosion Rate | |

|

(Volts) |

(Amps/cm2) |

(mmpy) | |||

|

1 |

Non-anodized |

-1.31E-01 |

1.21E-06 |

9.27E-02 | |

|

2 |

15 V |

1.97E-03 |

4.38E-08 |

3.35E-03 | |

|

3 |

30 V |

-1.76E-02 |

4.46E-08 |

3.42E-03 | |

|

4 |

45 V |

-6.61E-02 |

1.04E-07 |

7.94E-03 | |

|

5 |

60 V |

1.83E-01 |

1.13E-07 |

8.68E-03 | |

|

6 |

75 V |

1.87E-01 |

1.25E-07 |

9.56E-03 | |

Based on the potentiodynamic

analysis obtained, the Tafel curve is shown in Figure 5. From this Tafel curve,

it can be seen the effect of Ecorr and Icorr on the corrosion rate. The higher

the I corr, the higher the corrosion rate. It was also

found that the higher the voltage or the current, the greater the corrosion

rate, according to Equation 4.

where

CR =

corrosion rate (mm/yr) for icorr

K1 =

0.1288 (mpy.g/A.cm2)

Icorr = exchange current

density

=

density (g/cm3)

EW =

equivalent weight

The corrosion rate is directly

proportional to its Icorr. Even though anodizing may reduce the corrosion rate

when compared to without anodizing, there still be a percentage increase in

corrosion rate as the anodizing voltage increases.

Figure 5 Tafel Curve in Each Voltage

Variety (a) 15V, (b) 30V, (c) 45V, (d) 60V, (e) 75V, and (f) non-anodized

specimen

Table 5

shows that the effect of voltage on corrosion rate was not quite

significant, where there was an increased corrosion rate by 2% at 15 V to 30 V,

9% at 45 V to 60 V, and 10% 60 V to 75 V. This indicates that voltage in a

fixed anodizing time variable was not quite significant in affecting the

corrosion rate, where the corrosion rate tends to be constant at 15-30 V and at

45-75 V. However, an anomaly occurred in the corrosion rate increase from 30V

to 45V by 57%. Based on the testing on the anodized titanium specimen, there

was an insignificant increase in corrosion rate in each voltage variable. This

occurred because TiO2 layer thickness had not yet been complete during the anodizing process

at 45-75 V in 30 seconds because the higher the voltage, the higher the current

given. When the current provided during the anodizing process is higher, the

time spent on the anodizing process also increases. In this case, the anodizing

process is considered complete when the current value (A-COARSE) on the power

supply shows a decrease approaching zero. In addition, this increase can

also cause higher porosity than the surface layer as the voltage increases,

hence increasing the corrosion rate

Table 5 Layer Thickness and Corrosion

Rate for anodized and non-anodized Ti-6Al-4V specimen

The

anodizing process using Na3PO4 electrolyte solution

produces different colors in various voltages by the interference color

phenomenon. Based on spectrophotometry analysis revealed that a high chromatic

score was obtained at a voltage of 75 V. From the refractive index indicates

that the higher the voltage, the longer the wavelength obtained. Higher voltage

in the anodizing process produces an increase in the oxide layer, which leads

to an increase in mass produced. Moreover, based on the potentiodynamic

analysis obtained that increasing the voltage or the current result in a higher

corrosion rate. The XRD analysis indicates the presence of TiO2

based on the ICDD standard in all voltages employed. Increasing the anodizing

voltage increased the oxide film thickness, consequently increasing the TiO2

content in the specimen. Furthermore, the corrosion resistance analysis

in a Simulated Body Fluid revealed the non-anodized specimen showed a higher

corrosion rate compared to the anodized specimen. The increase of oxide layer

thickness leads to a significant decrease in corrosion rate and consequently

increases the corrosion resistance. Therefore, in future work, the anodized

implant of Ti-6Al-4V ELI in this work will be further evaluated by comparing it

with other electrolytes such as hydroxide, organic acid, sulfuric acid, and

friendly inorganic salt electrolytes in various concentrations.

The current study was supported by a Research Grant of “Penelitian Produk Vokasi Unggulan

Perguruan Tinggi 2022” from The Ministry

of Education, Culture, Research, and Technology (KEMENDIKBUDRISTEK

TAHUN 2022 (1919/PKS/ITS/2022).

Al-Mobarak,

N.A., Al-Swayih, A.A., 2014. Development of Titanium Surgery Implants for

Improving Osseointegration Through Formation of a Titanium Nanotube Layer. International

Journal of Electrochemical Science, Volume 9(1), pp. 32–45

Alphanoda, A.F.,

2016. Effect of Anode-Cathode Distance and Coating

Duration on Corrosion Rate on Hard Chrome Electroplating Results (Pengaruh Jarak Anoda-Katoda dan Durasi Pelapisan Terhadap Laju Korosi

pada Hasil Electroplating Hard Chrome). Jurnal Teknologi Rekayasa, Volume 1(1),

pp. 1–6

Atmani, D.,

Saoula, Nadia., Abdi, A., Azzaz, M., Wang, Y., Mohamedi, M., 2018.

Structural, Morphological, and Electrochemical Corrosion Properties of TiO2

Formed on Ti6Al4V Alloysby Anodization. Crystal Research and Technology,

Volume 53(12), pp. 1–7

Bakr, M.,

Thabet, H., Ghandour, N., Farrag, A, Mohamed, R.E., 2021. Histological and

Ultrastructural Changes of White Blood Cells in Vitro Storage of Human Blood at

Different Time Intervals. Egyptian Journal of Histology, Volume 45(3),

pp. 849–862

Bhola, R.,

Bhola, M., Mishra, B., Ayers, R.A., Olson, D.L., Ohno, T., 2011.

Surface Characterization of Anodically Treated - Titanium Alloy for

Biomedical Applications.

Volume 47(4),

pp. 75–82

Dewi, A.H., Yulianto, D.K.,

Ana, I.D., Rochmadi, Siswomihardjo, W., 2020. Effect of Cinnamaldehyde, an

Anti-Inflammatory Agent, on the Surface Characteristics of a Plaster of Paris –

CaCO3 Hydrogel for Bone Substitution in Biomedicine. International

Journal of Technology, Volume 11(5), pp. 963–973

Fadl-allah,

S.A., Quahtany, M., El-Shenawy, N.S., 2013. Surface Modification of Titanium

Plate with Anodic Oxidation and Its Application in Bone Growth. Journal of Biomaterials and

Nanobiotechnology. Volume 4(1), pp. 74–83

Gabor, R.,

Doubkove, M., Gorosova, S., Malanik, K., Vandrovcoca, M., Cvrcek, L.,

Drobikova, K., Kutlakova, K.M., Bacakova, L., 2020. Preparation of Highly

Wettable Coatings on Ti–6Al–4V ELI Alloy for Traumatological Implants Using

Micro-Arc Oxidation in An Alkaline Electrolyte. Scientific Reports,

Volume 10(1), pp. 1–16

Genisa, M., Shuib, S., Ahmad

Rajion, Z.A., Mohamad, D., Arief, M.E., 2020. Dental Implant Monitoring Using

Resonance Frequency Analysis (RFA) and Cone Beam Computed Tomography (CBCT)

Measurement. International Journal of Technology, Volume 11(5), pp. 1015–1024

Indira, K.,

Mudali, K.U., Rajendran, N., 2013. Corrosion Behavior of Electrochemically

Assembled Nanoporous Titania for Biomedical Applications. Ceramics

International. Volume 39(2), pp. 959–967

Izmin, N.A.N., Hazwani, F., Abdullah, A.H., Todo,

M., 2020. Risk of Bone Fracture in Resurfacing Hip Arthroplasty at Varus

and Valgus Implant Placements. International Journal of Technology.

Volume 11(5), pp. 1025-1035

Izmir,

M., Ercan, B., 2019. Anodization of Titanium Alloys for Orthopedic

Applications. Frontiers of Chemical Science and Engineering, Volume

13(1), pp. 28–45

Jaafar, A.,

Hecker, C., Arki, P., Joseph, Y., 2020. Sol-Gel Derived Hydroxyapatite

Coatings for Titanium Implants: A Review. Bioengineering, Volume 7(4),

p. 127

Kahar, S., Singh,

A., Patel, V., Kanetkar, U., 2020. Anodizing of Ti and Ti Alloys for Different

Applications: A Review. International Journal for Scientific Research &

Development, Volume 8(5), pp. 272–276

Karambakhsh,

A., Afshar, A., Ghahramani, S., Malekinejad, P., 2011. Pure Commercial

Titanium Color Anodizing and Corrosion Resistance. Journal of Materials

Engineering and Performance, Volume 20(9), pp. 1690–1696

Karambakhsh,

A., Afshar, A., Malekinejad, P., 2012. Corrosion Resistance and Color

Properties of Anodized Ti-6Al-4V. Journal of Materials Engineering and

Performance, Volume 21(1), pp. 121–127

Karambakhsh,

A., Ghahramani, S., Afshar, A., Malekinejad, P., 2015. Comparison of the

Corrosion Resistance of Alkaline- and Acid Anodized Titanium. Materials

Performance, Volume 54(1), pp. 51–55

Kashyap, N.,

Rashid, R.A., Khanna, N., 2022. Carbon Emissions, Techno-Economic and

Machinability Assessments to Achieve Sustainability in Drilling Ti6Al4V ELI for

Medical Industry Applications. Sustainable Materials and Technologies,

Volume 33, pp. 175–194

Kiel-Jamrozik,

M., Szewczenko, J., Basiagi, M., Nowinska, K., 2015. Technological Capabilities of Surface Layers

Formation on Implant Made of Ti-6Al-4V ELI Alloy. Acta of Bioengineering and

Biomechanics, Volume 17(1), pp. 31–37

Koju, N.,

Niraula, S., Fotovvati, B., 2022. Additively Manufactured Porous Ti6Al4V for Bone

Implants: A Review, Metals, 12(4), p. 687

Lestari, F.P.,

Sari, Y.R., Rokhmanto, F., Asmaria, T., Pramono, A.W., 2020. Surface

Modification of Ti-6Al-4V Alloy By Anodization Technique at Low Potential to

Produce Oxide Layer. Journal of Electronics, Volume 2(3), pp. 93–102

Martinez, A.L.,

Flamini, D.O., Saidman, S.B., 2022. Corrosion Resistance Improvement of

Ti-6Al-4V Alloy by Anodization In The Presence of Inhibitor Ions. Transactions

of Nonferrous Metals Society of China, Volume 32(6), pp. 1896–1909

Mogoda, A.S.,

Ahmad, Y.H., Badawy, W.A., 2004. Corrosion Inhibition of Ti-6Al-4V Alloy in

Sulfuric and Hydrochloric Acid Solutions Using Inorganic Passivators. Materials

and Corrosion, Volume 55(6), pp. 449–456

Nagy, P.M., Ferencz, B.,

Kálmán, B., Djuricic, B., Sonnleitner, R., 2005.

Morphological Evolution of Ti Surfaces During Oxidation Treatment. Materials

and Manufacturing Processes, Volume 20(1), pp. 105–114

Napoli, G.,

Paura, M., Vela, T., Schino, A.D., 2018. Colouring Titanium

Alloys By Anodic Oxidation. Metalurgija, Volume 57(1–2), pp. 111–113

Narayanan,

R., Seshadri, S.K., 2007. Phosphoric Acid Anodization of Ti-6Al-4V - Structural

and Corrosion Aspects. Corrosion Science, Volume 49(2), pp. 542–558

Rani, S.,

Jatolia, S.N., 2018. Electrodeposited Hap Coatings on Titanium Alloys: A

Review. International Journal of Research and Analytical Reviews, Volume

847(4), pp. 847–853

Roessler,

S., Zimmermann, R., Scharnweber, D., Werner, D., Worch, H., 2002.

Characterization of Oxide Layers on Ti6Al4V and Titanium by Streaming Potential

and Streaming Current Measurements. Colloids and Surfaces B: Biointerfaces,

Volume 26(4), pp. 387–395

Saraswati,

W.C., Anawati, A., Jujur, I.N., Gumelar, M.D., 2020. Effect of Coloring by

Anodizing on the Corrosion Behavior of Ti-6Al-4V Alloy. In: AIP

Conference Proceedings, Volume 2232(1). pp. 1–5

Swain, S.,

Misra, R.D.K., You, C.K., Rautray, T.R., 2021. TiO2 Nanotubes

Synthesised on Ti-6Al-4VELI Exhibits Enhanced Osteogenic Activity: A potential

Next-Generation Material to Be Used as Medical Implants. Materials

Technology, Volume 36(7), pp. 393–399

Szewczenko,

J., Basiaga, M., Kiel-Jamrozik, M., Kaczmarek, M., Grygiel, M., 2015. Corrosion

Resistance of Ti6Al7Nb Alloy After Various Surface

Modifications. Solid State Phenomena, Volume 227, pp. 483–486

Szewczenko,

J., Walke, W., Nowinska, K., Marciniak, J., 2010. Corrosion Resistance of

Ti-6Al-4V Alloy After Diverse Surface Treatments. Materialwissenschaft und

Werkstofftechnik, Volume 41(5), pp.

360–371

Szymczyk-Ziolkowska,

P., Hoppe, V., Gasiorek, J., Rusinska,

M., Keszycki,

D., Szczepanski, L., Dudek-Wicher, R., Detyna,

J., 2021. Corrosion Resistance Characteristics

of a Ti-6Al-4V ELI Alloy Fabricated by Electron Beam Melting After the Applied

Post-Process Treatment Methods. Biocybernetics and Biomedical Engineering,

Volume 41(4), pp. 1575–1588

Szymczyk-Ziolkowska,

P., Ziolkowski, G., Hoppe, V., Rusinska, M., Kobiela, K., Madeja, M.,Dziedzic, R., Junka, A., Detyna, J., 2022.

Improved Quality and Functional Properties of Ti 6Al-4V ELI Alloy for

Personalized Orthopedic Implants Fabrication with EBM Process. Journal of Manufacturing Processes, Volume

76(1), pp. 175–194

Tamilselvi,

S., Raman, V., Rajendran, N., 2006. Corrosion Behaviour of Ti-6Al-7Nb and

Ti-6Al-4V ELI Alloys in the Simulated Body Fluid Solution by Electrochemical

Impedance Spectroscopy. Electrochimica Acta, Volume 52(3), pp. 839–846

Van-Gils, S.,

Mast, P., Stijins, E., Terryn, H., 2004. Colour Properties of Barrier

Anodic Oxide Films on Aluminium and Titanium Studied with Total Reflectance and

Spectroscopic Ellipsometry. Surface and Coatings Technology, Volume 185(2–3), pp. 303–310

Wadhwani,

C., Brindis, M., Kattadiyil, M., O'Brien, R., Chung, K.H., 2018. Colorizing

Titanium 6Aluminum-4Vanadium Alloy Using Electrochemical Anodization:

Developing a Color Chart. Journal of Prosthetic Dentistry, Volume

119(1), pp. 26–28

Ziebowicz,

A., Ziebowicz, B., Baczkowski, B., 2015. Electrochemical Behavior of Materials

Used in Dental Implantological Systems. Solid State Phenomena, Volume

227, pp. 447–450