Integrated Electrochemical Dopamine Sensing with Finger Priming Pump on a Chip

Corresponding email: yudan.whulanza@ui.ac.id

Published at : 30 Dec 2022

Volume : IJtech

Vol 13, No 8 (2022)

DOI : https://doi.org/10.14716/ijtech.v13i8.6140

Whulanza, Y., Antory, A.D., Warjito, W., Rahman, S.F., Gozan M., Utomo, M.S., Kassegne, S., 2022. Integrated Electrochemical Dopamine Sensing with Finger Priming Pump on Chip. International Journal of Technology. Volume 13(8), pp. 1735-1744

| Yudan Whulanza | 1. Department of Mechanical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, West Java 16424 Indonesia, 2. Research Center for Biomedical Engineering, Faculty of Engineerin |

| Abram Dion Antory | Department of Mechanical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, West Java 16424 Indonesia |

| Warjito Warjito | Department of Mechanical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, West Java 16424 Indonesia |

| Siti Fauziyah Rahman | Research Center for Biomedical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, West Java 16424 Indonesia 3Biomedical Engineering Study Program, Department of Electric Eng |

| Misri Gozan | 1. Research Center for Biomedical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, West Java 16424 Indonesia, 2. Department of Chemical Engineering, Faculty of Engineering, |

| Muhammad Satrio Utomo | National Research and Innovation Agency (BRIN), Tangerang Selatan, 15314, Indonesia |

| Samuel Kassegne | Department of Mechanical Engineering, College of Engineering, San Diego State University, San Diego 5500, USA |

Development in microfluidic technology has

contributed to increased understanding in neural tissue engineering through the

in vitro observation of cell-on-chip (CoC) systems. This has been further

helped by the integration with the broader MEMS (micro mechanical and

electromechanical systems) technology that offers external devices such as

detectors or biosensors to show the characteristics of the observed object. An

on-chip microsystem microfluidic platform for dopamine detection is presented

here. The microfluidic platform integrates electrochemical detection with

finger pumping and a valve system as means to control the fluid flow. This

microenvironment offers a quicker result in observing the phenomena related to

the neural cell activities with a relatively small specimen volume of 50-100

µL, eases the handling of movement, and consequently reduces the cost of

consumable items. The microfluidic platform presented here showed that the pump module that also serves

as a mixing point was able to deliver at maximum of 121.36 µL with 2-3 strokes

of normal finger pressure priming. A series of valves aids in the termination

or isolation of fluid flow in a specific zone for further processing.

Ultimately, the microfluidic platform is also equipped with a portable

electrochemical detection module that allows us to measure the dopamine

concentration up to 1 mM. This development showed that the on-chip testing of

dopamine could be conducted easier and be more portable to handle.

Cell-on-chip; Dopamine; MEMS; Neural tissue engineering; On-chip testing

The use of conductive carbon matrix to culture

neuronal cells has been demonstrated recently (Whulanza et al., 2022; Sagita

et al., 2018). To optimize neuron growth across the matrix, a

scaffold was used as a substrate to enhance nerve cell interaction in vitro.

The substrate, together with the in-vitro platform was analyzed for cellular

viability and electrically controlled and release of neuromodulators

(Nimbalkar et al., 2019; Vomero et al., 2018). The characterization of

neuromodulator, i.e., dopamine ions, in release and uptake studies on the

conducting substrate for neural application is ultimately the main interest of

this research. Successful optimization of these characteristics will be

important for treating injuries to the nervous system. Interactions between

neuron cells and extracellular matrix are key factors in studying cell

migration, proliferation, differentiation, and apoptosis, all of which are

critical functions for a neural-engineered construct (Pavesi et al., 2015; Kotwal &

Schmidt, 2001). These requirements are not fully understood by

researchers; therefore, study of the complete set of biological requirements

must be employed.

The availability of commercial

microfluidic devices such as microreactor systems is growing rapidly to carry

out various industrial and laboratory processes (Nadhif

et al., 2019; Nadhif et al., 2017; Whulanza et al., 2017). The system

typically integrates input processes, chemical reactions, outputs, and analyses

on a laboratory scale that are carried out continuously. Early developments in

microreactor technology mainly focused on the design of microreactor chips with

silicon, glass, or polymer materials such as PDMS (polydimethylsiloxane). The

design aims to add a small amount of reagent to the reaction zone in a volume

of microliters under controlled conditions. Such flows can be clearly observed

through the precise control of reaction parameters (Nunut

et al., 2020; Whulanza et al., 2019; Whulanza et al., 2014). This recent

advancement demonstrates the incorporation of significant microfluidic device

work into a functional Lab-on-Chip that addresses the required result in a

portable device with minimal laborious work.

The process of developing microfluidic systems

has resulted in successful product commercialization. However, some challenges

still lie ahead for a Lab-on-Chip (LoC). The most basic thing is in the concept

of end-to-end integration. But currently, off-device development research will

soon be grafted into a full LoC system. LoC has the same problem in the chip

world, namely the interface problem. A Micro-Electro-Mechanical-System (MEMS)

sensor package is needed in such a way that it can provide accurate

readings. Therefore, this preparation

system requires additional systems such as microscopes, pumps, computers, and

spectrometers (Charmet et al., 2020; Whulanza et al., 2015; Suwandi et al., 2014).

Finger-powered micropump has been widely

developed for variety of application, including operational of finger-actuated,

one-way, positive micropump for pathogens detection system (Qi et al., 2022; Jo et al., 2020),

finger-actuated, negative pressure chamber for electrochemical detection of

ascorbic acid (Liu et al., 2022) and

microreactor (Lee et al., 2022; Park et al., 2019; Whulanza et al., 2019). The

lab-on-a-chip that is being developed in this study is the integration of

microreactor processes such as cell culture or adsorption with the microfluidic

component, i.e., finger priming pump and manual valve. Ultimately, the dopamine

sensing package is also coupled with the portable electrochemical detection

module.

2.1. Design Consideration

The process of designing this lab-on-a-chip

device is based on previously introduced lab-on-a-chip devices, which miniaturized the space of a laboratory onto a single

75 mm x 25 mm x 6 mm chip. This current platform is designed to have a channel

width of 1 mm, with its larger contact surface area facilitating the mixing

process. To improve the practicality and flow conditions of our previously

designed 200 ?m

x 200 ?m

channel, the current channel is designed to have a width and height of 1 mm x 1

mm. There

are three main working divisions of this chip, which are the preparation

region, the pumping and mixing region, and the detection region.

The preparation

region contains two inlets and one intersection merging the inlets. The inlets

have a diameter of 1.68 mm to accommodate the Microfluidic Chipshop GmbH. Luer

connection, which is used to transfer fluid samples from a syringe pump or

micropipette onto the channel of the chip. Two inlets are designed to allow

simultaneous insertion of two samples, if necessary.

The pumping and mixing regions contain the

liquid sample reservoir, which serves also as the micropump, the meander

channel section, and a pneumatic valving mechanism. The reservoir pumping

section is a cylindrical space with 6.51 mm in diameter and 1.5 mm high. It is

also designed to accommodate the pushing of fingers. Since the microfluidic

chip is designed to be 2 mm thick, the ratio of thickness and diameter of

pumping reservoir is expected to be capable of pumping operation. The meander

section is designed to allow two liquid samples to interact and mix by means of

diffusion. Two pneumatic valve points are used to control fluid entering and

exiting the pumping and mixing region.

A reservoir covers the

area of three electrodes used in the electro-chemical detecting process in the

detection region. It has an 8.00 mm in diameter to accommodate the 3 working

electrodes designed for electro-chemical detection (Christian

et al 2022). On top of it lies the sample outlet twice the size of the

inlet.

2.2. Fabrication

There are four important steps to fabricate the lab-on-a-chip device:

mold building, polydimethylsiloxane (PDMS) casting and curing, silicone rubber

casting and curing, and product assembly. Mold is designed by using Solidworks

2016® software. To minimize the cost of production of the mold, FDM/FFF (fused

deposition modeling/fused filament fabrication) was the first method that was adopted,

but results show that DLP-SLA (digital light processing stereolithography) is a

better fit for the final prototype.

After

the mold was completed, PDMS substrate was added to the mold, which is PDMS

casting, along with a curing agent equal to 10% of the PDMS weight. The mold will

then be put into a vacuum chamber, as air is not wanted in the PDMS mix, which

may cause gas bubble formation for 45 minutes, Due to the mold's poor heat resistance, it will then be heated in a

heating bed for about 6 hours at 50°C before peeling. On the other hand,

similar steps were performed on silicone rubber casting, but it needs about 4%

of the curing agent. Also, silicone rubber casting uses a blank aluminum mold,

so heating it to 120? would not be a problem, thereby, speeding up the curing

process to about 1-2 hours.

The last step for lab-on-a-chip fabrication is assembling PDMS and

silicone rubber to become a single integrated chip. This process requires a

plasma bonder from Blackhole Lab., which will be used to stick two different

layers, so that they will become one piece of a device.

2.3. Flow Testing

This chip will be tested by its ability to contain and displace fluids, as

well as create space to be able to work side by side with the electro-chemical

detector. Three tests and three measurements will be conducted to see if the

chip is doing its designated job. A flow test will be done by inserting fluid into

the chip all the way from the inlet to the outlet to see how well those two

layers are attached together so that there will be no leakage. A valve test, on

the other hand, is needed to see how well the valves, are inspired by a water

gate- work by stopping fluid flow. A mixing test will be conducted to see if the

two fluids are mixed consistently.

Finger-pumping force measurement is done as a complementary to see how

much force human fingers exerted on the PDMS chip, which will be useful for the

next measurement. It is also done because of the fluctuation level on the force

gauge meter; hence, measurement will be done 100 times to see the average value

of a human finger's force. Force vs. volume measurement is the main thing to do

in this research because it shows the characteristics of the finger-pump that

is used to displace fluid. It is done by inserting a certain controlled amount

of fluid by using a 10-100 ?l micropipette, pumping that fluid, and extracting

the fluid on the electro-chemical detector section by using a syringe. The

fluid will then be put into micro-tubes to be weighed down, where the

difference between a liquid-inside-micro-tube and an empty micro-tube is the

weight of the water, and hence from its density, the volume of the water can be

found.

2.3.1. Measurement

of Dopamine Ions Using Electrochemical Detection

The dopamine concentration was monitored in situ by measuring the electrochemical detection of the specimen right after the pumping process. Here, the electrodes were connected to an open-source potentiostat (Rodeostat, Pasadena, USA) with a cyclic voltameter (CV) mode. The detection chamber included three electrodes that were screen printed together with the carbon matrix (Arafat et al., 2021; Istiyanto et al., 2019). During the CV tests, the working electrode potential alternated between ?1.0 and 1.0 V with a scan rate of 100 mV/s.

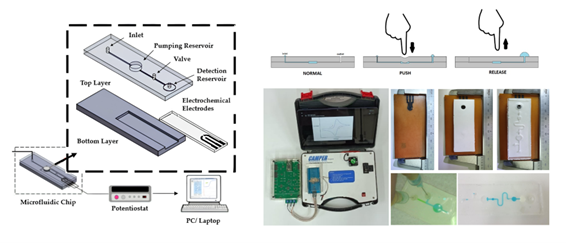

Figure

1 Experiment set-up and apparatus

Figure 2 a) Integration of an electrochemical biosensor, a

microfluidic platform, and a processor; (b) arrangement of carbon-based

electrodes on a PCB substrate in three steps; (c) the silicone rubber as base

layer for microfluidic platform as the inlet (d) top layer of microfluidic

platform from PDMS as pump priming with a stop valve.

3.1. Flow Test

The

flow test is a part of complementary tests to ensure that the chip does what it

is supposed to do, especially the most important one as it should not produce

any fluid leakage. The test uses a syringe pump,

which is set to 7.2 mL/h (a similar value to the peristaltic pump used on the mixing test

later). Strength-wise, the bonding of these two layers is excellent, and no

leakage is present as the fluid flows until the electro-chemical detector

section.

3.2. Valve Test

A

valve test is also included in complementary tests to ensure that two valves

work properly at the designated valve points. These valve points only exist on

the Trial 4 mold and are designed to be a perfect match dimension-wise to the

Microfluidic Chipshop Gmbh. Luer, whose original function is to insert a

syringe tip onto the chip. While using the Luer in place on the valve point, a

syringe pump begins to insert fluid at a normal rate of 7.2 mL/h.

3.3. Finger Pumping Measurement

Figure 3 a) Pressure measurement of finger pumping (n=100)

and b) the liquid delivered into the sensing zone

3.4. Force vs. Volume Measurement

The

characteristic of the finger pump used on this lab-on-a-chip device will be

shown here by how much volume of water is displaced from the mixing point to

the electro-chemical detector region to be extracted using a syringe., But

before any of that, there is one effect that is vital to the pump’s usage, which

is the flow’s velocity difference. Below is the different velocity caused by

pumping the mixing point region of the chip while fluid is constantly flowing.

The

velocity generated by a 7.2 mL/h flow from the syringe pump is 1.11 mm/s; it is measured by

measuring a certain linear distance on the chip and how much time is needed for

the water to reach out that distance. The next step is to measure the linear

channel after the mixing point region and determine how much time is needed for

it to cover that distance. After 4 measurements, the velocity generated by

pumping is 24.00 mm/s with a standard deviation of 2.79. On average, the

velocity rise made from this measurement is about 22.89 mm/s.

Figure

4a shows the mapping of points along the pumping region, which corresponds, to

the x-axis of Figure 4b. Point 5 and 6 are the points where pumping is

happening, and after that, the velocity rises as in Figure 4b. Moving on to the

next task, which is to see how much pressure, is needed to displace a certain amount

of fluid, Pumping it once will not get the job done, so on average, based on

this measurement, it took about 4-5 pumps to displace fluid to the

electro-chemical detector region. 30 measurements are taken to determine how

the data differs from one another in order to generate a linear graph on its

own. Another thing to consider is how well the micropipette works, which in

this case is not so precise. Its 100 ?L of liquid reading is equivalent to an average of 121.36 ?L of liquid by 4 measurements with

a standard deviation of 2.46. It is critical to compare the percentage of

liquid extracted to the percentage of liquid inserted.

From

Figure 3b, the total volume delivered by the pump is extracted when the fluid

is in the electro-chemical detector zone and is extracted by a syringe. The

maximum average volume delivered is 102.31 ?L in class 130 – 135 N, and the

minimum average volume delivered is 83.75 ?L in 90 – 95 N class. This

represents a directly proportional relationship force and volume.

Figure

3b shows a histogram of displaced volume distribution based on the experimental

data. As much as 36.67% out of 30 measurements are in the 90 – 95 class. The

second highest frequency of displaced volume is in the 85 – 90

and 95 – 100

class with 20% each, as it is combined for 76.67% of the total in the 85 –

100

range.

Figure 4 a) The position of measuring point in the pumping

zone and b) measurement of velocity in the pumping zone

3.5. Dopamine Detection Using in Situ Measurement

Figure 5 Electrochemical detection plot result

Figure 5(b) shows that the peak dopamine concentration

was linearly dependent on the concentration that was prepared (from 0.05 mM to

1 mM). Figure 5(b) also shows the regression plot of the

dopamine solution, which is expressed as I (µA) = 2.7752*Concentration

Dopamine (µM) + 0.0742 with a Pearson correlation of 0.986. The sensitivity and

linear detection range of the dopamine solution were specifically calculated

at 0–1 mM. It can be estimated that the limit of detection was around 0.20 mM.

The linear model is used since the most

suitable model for measurement or detection is when the parameters are linearly

related. The linearity analysis suggested that the measurement using this setup

has a plausible result provided by the calculated detection limit. The margin

error compared to the linear model showed a lowest value of 0.3% at a

concentration of 1 mM, whereas at a concentration of less than 0.1 mM showed an

error of 24%. his high

error was consistent with the calculated limit detection at 0.2 mM. Hence, this

finding showed that our setup enables us to work with a dopamine detection

range of 0.2 – 1.0 mM.

It can be concluded from this research that the appropriate rapid

prototyping method for the current chip mold is DLP-SLA. Although its

production cost is more expensive than FFF, the result is much better. DLP-SLA

shows a little deviation among the design, the mold, and the product. Moreover,

combining PDMS and silicone rubber is a perfect match to create one whole

lab-on-a-chip. For the channel size, a 1 mm x 1 mm channel produces a good

mixing with two simultaneous flows. For the finger pump, it creates a rise of

around 22.89 mm/s to the fluid flow velocity. Overall fluid displacement can be

concluded by an average of 75.43% of liquid being displaced from the mixing

point region.

Authors gratefully thanks for the

funding from Kementerian Pendidikan, Kebudayaan, Riset, dan Teknologi through

Penelitian Dasar Unggulan Perguruan Tinggi (PDUPT) 2022 No.

NKB-860/UN2.RST/HKP.05.00/2022.

Arafat, Y.B.,

Whulanza, Y., 2021. Realizing Textured Electrode for Electrochemical Biosensor

Using Homemade CNC Desktop. In: AIP Conference Proceedings, Volume 2344(1),

p. 050019

Ahmed, I.,

Sullivan, K., Priye, A., 2022. Multi-Resin Masked Stereolithography (MSLA) 3D

Printing for Rapid and Inexpensive Prototyping of Microfluidic Chips with

Integrated Functional Components. Biosensors, Volume 12, pp. 1–17

Charmet, J.,

Rodrigues, R., Yildirim, E., Dallmann, R., Whulanza, Y., 2020. Low-Cost Microfabrication

Toolbox. Micromachines, Volume 11(2), p. 135

Christian,

E.T.H., Basari, B., Rahman, S.F., Whulanza, Y., 2022.

Electrochemical Detection and Spectrophotometry of Dopamine using Commercial

Screen-Printed Electrodes. Journal of Biomedical Science and Bioengineering, Volume 2(1), pp. 1–9

Feng, Q.M., Cai, M., Shi, C.G., Bao, N.,

Gu, H.Y., 2015. Integrated Paper-Based Electroanalytical Devices for

Determination of Dopamine

Extracted from Striatum of Rat. Sensors & Actuators: B. Chemical,

Volume 209, pp. 870–876

Istiyanto, J.,

Lubis, H.F., Adhitama, G., Fadhilah, S., Whulanza, Y., Kassegne, S.M., 2019. Beehive Texturing of Carbon Electrode Biosensor Using Screen Printing

Method. In: AIP

Conference Proceedings, Volume 2092,

p.

020010

Jo, Y., Park,

J., Park, J.K., 2020. Colorimetric Detection of Escherichia coli O157:H7 with

Signal Enhancement Using Size-Based Filtration on a Finger-Powered Microfluidic

Device. Sensors, Volume 20, pp. 1–10

Kotwal, A., Schmidt, C., 2001. Electrical Stimulation Alters Protein Adsoption and

Nerve Cell Interactions with Electrically Conducting Biomaterials. Biomaterials, Volume 22(10), pp. 1055–1064

Hardi, G.W.,

Rahman, S.F.,

2020. Amperometric Detection of Dopamine based on a Graphene Oxide/PEDOT: PSS

Composite Electrode. International Journal of Technology, Volume 11(5), pp.

974–983

Lee, Y.S., Lu,

Y.T., Chang, C.M., Liu, C.H., 2022. Finger-powered Cell-Sorting Microsystem

Chip for Cancer-Study Applications. Sensors & Actuators: B. Chemical,

Volume 370, pp. 1–9

Liu, C., Gomez, F.A., Miao, Y., Cui, P.,

Lee, W., 2019. A Colorimetric Assay System for Dopamine Using Microfluidic

Paper-Based Analytical Devices. Talanta, Volume 194, pp. 171–176

Liu, X., Li, M.,

Zheng, J., Zhang, X., Zeng, J., Liao, Y., Chen, J., Yang, J., Zheng, X., Hu,

N., 2022. Electrochemical Detection of Ascorbic Acid in Finger-Actuated

Microfluidic Chip. Micromachines, Volume 13, pp. 1–13

Liu, Z., Jin, M., Cao, J., Niu, R., Li,

P., Zhou, G., Yu, Y., van den Berg, A., Shui, L., 2018. Electrochemical Sensor

Integrated Microfluidic Device for Sensitive and Simultaneous Quantification of

Dopamine and 5-Hydroxytryptamine. Sensors & Actuators: B. Chemical,

Volume 273, pp. 873–883

Maminski, M., Olejniczak, M., Chudy, M.,

Dybko, A., Brzozka, Z., 2005. Spectrophotometric Determination of Dopamine in

Microliter Scale Using Microfluidic System Based on Polymeric Technology. Analytica

Chimica Acta, Volume 540, pp. 153–157

Manbohi, A., Ahmadi, S.H., 2019. Sensitive and Selective Detection of

Dopamine Using Electrochemical Microfluidic Paper-Based Analytical Nanosensor. Sensing

and Bio-Sensing Research, Volume 23, pp. 1–7

Nadhif, M.H., Whulanza, Y., Istiyanto,

J., Bachtiar, B.M., 2017. Delivery

of Amphotericin B to Candida albicans by using biomachined lab-on-A-chip. Journal of Biomimetics, Biomaterials

and Biomedical Engineering, Volume 30, pp.

24–30

Nadhif, M.H., Hadiputra, A.P., Utomo,

M.S., Whulanza, Y., 2019.

Fabrication and Characterization of an Affordable Conditioned Bio-Specimen

Transporter (Conbiport) for Urban Areas. International Journal of Technology, Volume 10(8), pp. 1626–1634

Nimbalkar, S., Castagnola, E.,

Balasubramani, A., Scarpellini, A., Samejima, S., Khorasani, A., Boissenin, A.,

Thongpang, S., Moritz, C., Kassegne, S., 2018. Ultra-capacitive Carbon Neural

Probe Allows Simultaneous Long-Term Electrical Stimulations and High-Resolution

Neurotransmitter Detection. Scientific Reports, Volume

8(1), p. 6958

Nunut, I., Whulanza, Y., Kassegne, S.,

2020. Testing of Beeswax Printing Technology in the Design of a Paper-Based

Microfluidic System. International Journal of

Technology, Volume 11(5), pp. 1036–104

Park, J., Roh,

H., Park, J.K., 2019. Finger-Actuated Microfluidic

Concentration Gradient Generator Compatible with a Microplate. Micromachines, Volume 10(174), pp. 1–10

Pavesi, A., Adriani, G., Rasponi,

M., Zervantonakis, I.K., Fiore, G.B., Kamm, R.D., 2015. Controlled Electromechanical Cell Stimulation On-A-Chip. Scientific

Reports,

Volume 5(1), p. 11800

Rahman, S.F.,

Min, K., Park, S.H., Yoo, J.C., Park, D.H., 2016. Selective Determination of Dopamine with

an Amperometric Biosensor Using Electrochemically Pretreated and Activated

Carbon/Tyrosinase/Nafion®-Modified Glassy Carbon Electrode. Biotechnology and

Bioprocess Engineering, Volume 21(5), pp. 627–633

Qi, W., Zheng,

L., Hou, Y., Duan, H., Wang, L., Wang, S., Liu, Y., Li, Y., Liao, M., Lin, J.,

2022. A Finger-Actuated Microfluidic Biosensor for

Colorimetric Detection of Foodborne

Pathogens. Food Chemistry,

Volume 381, pp. 1–9

Sagita, I.D.,

Whulanza, Y., Dhelika, R., Nurhadi, I., 2018.

Designing Electrical Stimulated Bioreactors for Nerve Tissue Engineering. In: AIP

Conference Proceedings, Volume 1933, p. 040019

Vomero, M.,

Oliveira, A., Ashouri, D., Eickenscheidt, M., Stieglitz, T., 2018. Graphitic Carbon

Electrodes on Flexible Substrate for Neural Applications Entirely Fabricated

Using Infrared Nanosecond Laser Technology. Scientific Reports, Volume 8, p. 14749

Whulanza, Y.,

Aditya, R., Arvialido, R., Utomo, M. S., Bachtiar, B. M., 2017. Ease Fabrication of PCR Modular Chip for

Portable DNA Detection Kit. In: AIP Conference Proceeding 1817, pp. 040006.

Whulanza Y., Arafat, Y.B., Rahman, S.F., Utomo, M.S., Kassegne, S.K., 2022. On-chip

Testing of a Carbon-based Platform for Electro-adsorption of Glutamate. Heliyon, Volume

8(5), pp. 1–10

Whulanza, Y.,

Hakim, T.A., Utomo, M.S., Irwansyah, R., Charmet, J., 2019.

Design and Characterization of Finger-Controlled Micropump for Lab-on-a-Chip

Devices. Evergreen, Volume 6(2), pp. 108–113

Whulanza, Y.,

Sitanggang, T., Istiyanto, J., Supriadi, S, 2015. Seedless-Electroplating Process

Development for Micro-Features Realization. International Journal of

Technology,

Volume 6(6), pp. 1050–1056

Suwandi, D., Whulanza, Y., Istiyanto, J., 2014. Visible Light Maskless

Photolithography for Biomachining Application. Applied Mechanics and Materials, Volume 493, pp. 552–557

Whulanza, Y.,

Utomo, M.S. Hilman, A., 2018. Realization of a passive micromixer using

herringbone structure. In: AIP Conference

Proceedings 1933, pp. 040003

Whulanza, Y.,

Widyaratih, D.S., Istiyanto, J., Kiswanto, G., 2014. Realization and testing of lab-on-chip

for human lung replication. ARPN Journal of Engineering and Applied Sciences,

2014, 9(11), pp. 2064–2067

Yu, Y., Shamsi, M.H., Krastev, D.L.,

Dryden, M.D.M., Leung, Y., Wheeler, A.R., 2016. A Microfluidic Method for

Dopamine Uptake Measurements in Dopaminergic Neurons. Lab on a Chip,

Volume 16, pp. 543–552

Yue, Y., de Campos, R.P.S., Hong, S.,

Krastev, D.L., Sadanand, S., Leung, Y., Wheeler, A.R., 2019. a Microfluidic

Platform for Continuous Monitoring of Dopamine Homeostasis in Dopaminergic

Cells. Microsystems & Nanoengineering, Volume 5(10), pp. 1–13