Techno-Economic Evaluation of Novel SARS-CoV-2 Vaccine Manufacturing in the Insect Cell Baculovirus Platform

Corresponding email: kanya.alifia@gmail.com

Published at : 30 Dec 2022

Volume : IJtech

Vol 13, No 8 (2022)

DOI : https://doi.org/10.14716/ijtech.v13i8.6139

Alifia, K.C.H., Kontoravdi, C.Kis, Z., Ismail, D., 2022. Techno-Economic Evaluation of Novel SARS-CoV-2 Vaccine Manufacturing in the Insect Cell Baculovirus Platform. International Journal of Technology. Volume 13(8), pp. 1630-1639

| Kanya Citta Hani Alifia | 1. Department of Chemical Engineering, ACE Extension, Faculty of Engineering, Imperial College London, South Kensington Campus, London SW7 2AZ, United Kingdom, 2. Department of Chemical Engineering, |

| Cleo Kontoravdi | Department of Chemical Engineering, ACE Extension, Faculty of Engineering, Imperial College London, South Kensington Campus, London SW7 2AZ, United Kingdom |

| Zoltán Kis | Department of Chemical and Biological Engineering, Sir Robert Hadfield Building, The University of Sheffield, Mappin Street, Sheffield, S1 3JD, United Kingdom |

| Dianursanti Ismail | Department of Chemical Engineering, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, West Java 16424 Indonesia |

The need to increase the COVID-19 vaccine

manufacturing capacity at low to middle-income countries (LMIC) led to a

growing focus on Novavax (NVX-CoV2373), a thermostable protein subunit vaccine

manufactured using a baculovirus and insect cell system (BICS) platform. This

study aimed to conduct a techno-economic analysis to assess the BICS platform

of vaccine manufacturing and compare it to the mRNA and the saRNA platform. The

data from the Novavax patent for the COVID-19 vaccine formulation and the

manufacturing steps were used to simulate the BICS vaccine production in

SuperPro Designer. From the techno-economic analysis, the productivity of all

platforms was compared in terms of doses/day per L production scale. The saRNA

platform’s productivity is about 1,000-fold of the BICS platform and 20-fold of

the mRNA platform. BICS is a feasible option for LMIC to produce vaccines

because the cost per dose is like the saRNA platform, while the mRNA platform’s

cost per dose is 7 times higher than the BICS and saRNA platforms. However,

further optimization is necessary to improve the productivity of the BICS

platform to match saRNA’s platform.

Baculovirus; COVID-19; Insect cell; Techno-economic analysis; Vaccine

The

advancement of modern

technology enabled researchers to predict the properties of the COVID-19 virus

and apply this knowledge to rapidly develop vaccines that successfully lessened the impact of the COVID-19

pandemic globally as posited by Berawi et al.

(2020a, 2020b). As of 2nd August 2022, 5.3 billion people had

received at least one dose of vaccine, which accounts for 67% of the world

population. In total, 12.36 billion vaccine doses have been administered

worldwide (Ritchie et al., 2021). However,

there is a clear gap in vaccination rates among countries. High-income

countries can administer 100 doses per 100 people on average whereas low-income

countries had not even reached a 20% vaccination rate by August 2022 (Ritchie et al., 2021; Irwin, 2021). The

manufacturing capacity of COVID-19 vaccines in 2021 was around 8 billion doses

a year; a combined capacity of AstraZeneca, Pfizer, Sinovac, Sinopharm, and

Moderna (AstraZeneca, 2021; Pfizer, 2021; Shumei, 2021; Steenhuysen &

O'Donnell, 2021). Although global herd immunity was achieved due to

vaccinations, some low-income countries failed to achieve this (Ritchie et al., 2021). As COVID-19 virus rapidly

mutated into different variants throughout the years, this highlights the

importance of annual booster shots in the future, which adds to the vaccine

demands (O'Neill, 2021). Thus, it is

necessary to increase the vaccine manufacturing capacity mainly aimed for low

to middle-income countries (LMIC).

RNA vaccines such as Pfizer

and Moderna require ultra-cold storage at -70°C and -20°C, respectively (Gerhardt et al., 2021). The distribution of these

vaccines is challenging in warmer areas where access to an ultra-cold supply

chain is insufficient. Other vaccine types such as inactivated whole virus,

viral vector, and protein subunit only require 2-8°C temperature for storage in

a refrigerator, with Novavax (2021a, 2021b) as

the leading example. Novavax (NVX-CoV2373) is a protein subunit vaccine with

89.3% efficacy against multiple variants in its phase 3 trial conducted in the

UK (Novavax, 2021a). It is manufactured

using a baculovirus and insect cell system (BICS) platform. A platform

technology can be used to manufacture various vaccines simply by modifying the

genetic sequence of the cloned baculovirus. Adopting a platform technology will

improve the resilience capacity of biopharmaceutical industries to be prepared

against future pandemics. Vaccine production using platform technology have

more robust and rapid productivity. Moreover, a platform technology is

adjustable to produce different vaccines (Sofyan et al., 2021).

BICS is a well-established

platform for vaccine manufacturing using recombinant DNA technology, it can

produce three different vaccine types: recombinant proteins as subunit

vaccines, virus-like particles (VLPs) as subunit vaccines, and recombinant

baculovirus as vaccine vectors. The vaccine development process starts with

modifying the recombinant baculovirus to contain the gene of interest from the

native virus. This gene can either encode the formation of protein subunits,

the construction of VLPs, or produce antigens to be carried by the baculovirus

vectors (Mena & Kamen, 2011). The insect

cells act as the host, which contains the necessary organelles for heterologous

protein production and can rapidly construct the desired component (Sari et al., 2016). Insect cells have a higher

reproduction rate than mammalian cells and contain a protein folding mechanism

that bacteria lack, highlighting the advantage of the BICS platform (Mena & Kamen, 2011).

To make Novavax vaccines,

the genetic sequence of SARS-CoV-2 spike protein is cloned into baculovirus

culture to infect Sf9 insect cells for the protein folding process. The

expressed antigen protein is then purified as multimeric nanoparticles and

configured with saponin-based Matrix-M™ adjuvant to enhance neutralizing

antibodies and increase long-lasting B-cell and T-cell immunity (Novavax, 2021b). This vaccine is thermostable,

adaptable to new COVID-19 variants, feasible for rapid large-scale production,

and can be produced with standard equipment (Novavax,

2016 & 2021c). Novavax released its patent for SARS-CoV-2 vaccine

formulation in March 2021, showing the manufacturing steps and the trials that

were taken to determine the optimum formulation of antigen substance and

adjuvant (Novavax, 2021c). This patent was

used to build the vaccine production flowsheet with SuperPro Designer software;

a process

simulator that facilitates the modelling, evaluation, and optimization of

integrated biological and chemical processes. Meanwhile the mass

balances in the bioreactors are calculated by accounting for the insect cells

metabolic fluxes to estimate the stoichiometric reaction equation (Carinhas et al., 2011; Gioria et al., 2006).

It is beneficial to compare

Novavax’s insect cell vaccine with the mRNA (messenger RNA) vaccine and novel

saRNA (self-amplifying RNA) vaccine, to find out which platform can achieve the

target vaccine cost per dose of 1 USD (Kis et al.,

2020a). A comparative study of

various vaccine platforms had been commenced with the indicators such as

technology readiness, complexity, ease of scale-up, flexibility, vaccine

thermostability, and speed of response. These indicators show that RNA and BICS

platforms are nearly up to par, but a more detailed feasibility study must be

done with techno-economic analysis (Kis et al.,

2019). Moreover, Kis et

al. also conducted a techno-economic simulation of the mRNA and saRNA vaccine

platform, which will be the benchmark for BICS platform performance (Kis et al., 2020b). This study aimed to

conduct a techno-economic analysis to assess the BICS platform for COVID-19

vaccine manufacturing using SuperPro Designer software and compare it with

previous findings.

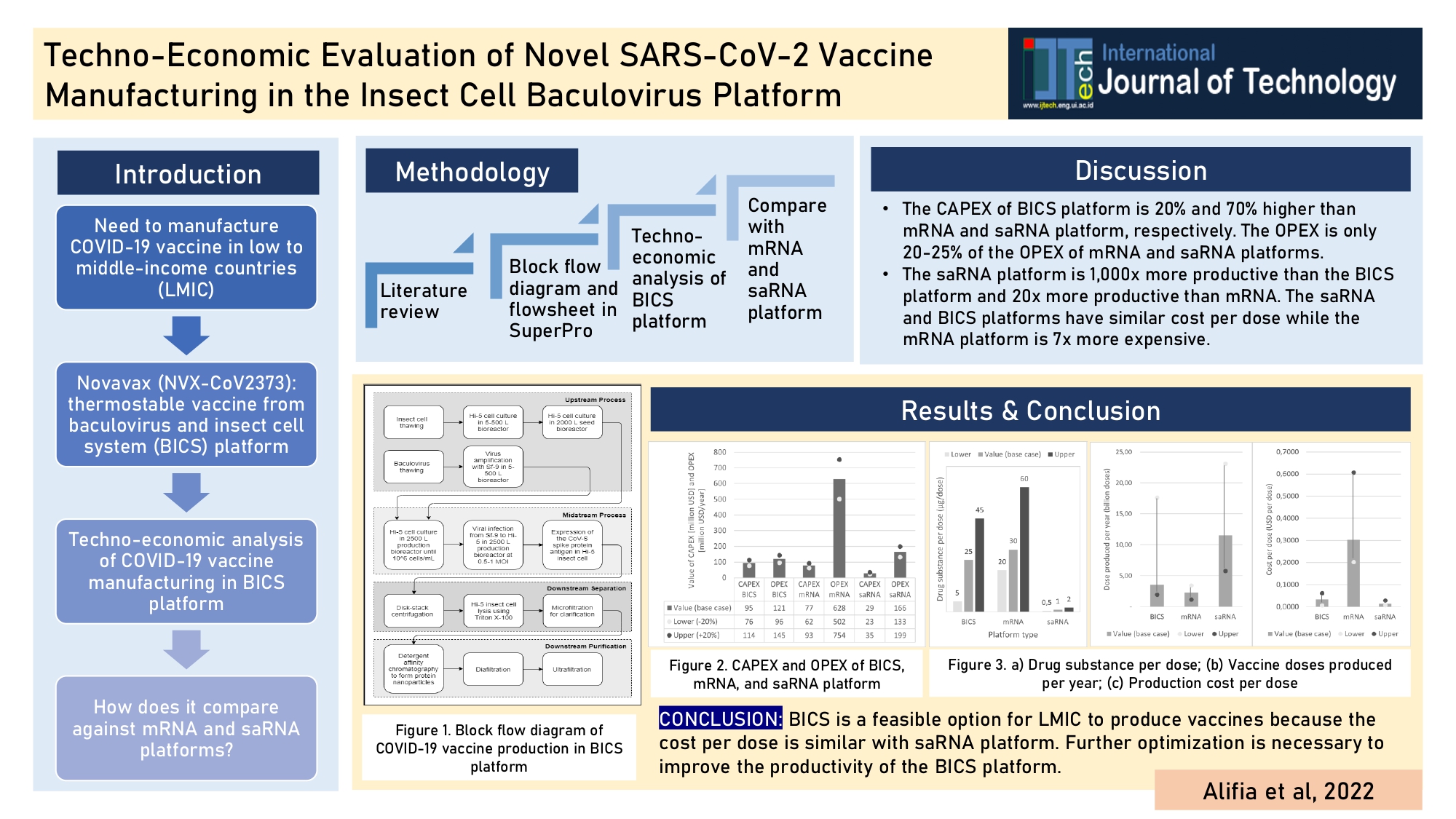

A literature review was conducted to

gather information regarding COVID-19 vaccine production processes in the BICS

platform. The step-by-step production process and the costs are taken from Novavax patents (2016, 2021c), scientific

literature (Kis et al., 2020a; Kis et al., 2019; Sari et al., 2016; Mena & Kamen,

2011), and trusted suppliers such as ThermoFisher, Sigma Aldrich, Cytiva

Life Sciences, and GE Life Sciences. The production flowsheet was designed

according to the block flow diagram of CoV-S protein vaccine production in BICS

from the Novavax patent, especially for the parameters of the bioreactor and

downstream processes (Novavax, 2021c; Kis et al.,

2019). Additional data was obtained from the SuperPro Designer

equipment, materials, utilities, and cost databases. The demand for BICS

vaccines was estimated at 3 billion doses, considering by 2021 that 8 out of 11

billion doses had been met by existing manufacturers.

2.1. Simulation of COVID-19 Vaccine Production

in BICS Platform

The vaccine production

process was modeled using SuperPro Designer version 12 from Intelligen, Inc

starting from the upstream, midstream, until downstream assuming fed-batch

operation mode. The formulation and the fill-to-finish line were not simulated

in SuperPro Designer since it is usually done in a separate facility. This

bioprocess simulation tool can calculate the material and energy balances,

equipment sizes, labor requirements, and optimal scheduling of operations and

procedures. SuperPro Designer version 12 can also procure an economic

evaluation using its built-in database, user-specified costs, and selling

prices (Canizales et al., 2020).

For the

upstream and midstream processes, the cultivation of Hi-5 insect cells is done

using a 5-500 L disposable bioreactor and then scaled up into a 2000 L seed

bioreactor, while the virus amplification is done in a separate line with Sf-9

insect cells in 5-500 L disposable bioreactors. In the next step, the

baculovirus transfects the insect cells in a 2500 L bioreactor to instruct the

cells to express the spike protein antigen of the SARS-CoV-2 virus (Novavax, 2021c; Kis et al., 2019). The duration of cell culture in the main production bioreactor

lasts 48-96 hours (Novavax, 2021c). The

stoichiometric reaction equation for the Sf9 insect cell growth phase, the Hi5

insect cell growth phase, and the baculovirus infection phase are modelled

according to the metabolic fluxes of the cells (Carinhas

et al., 2011; Gioria et al., 2006). This equation is necessary to model

the mass balances inside the bioreactors.

The downstream

separation step starts with centrifugation to separate the cells from the

liquid medium, then mixed with Triton X-100 for cell lysis. Then the mixture is

passed through the microfiltration step to separate the antigen polypeptides

from cell debris. Polypeptide nanoparticles are formed using a detergent

exchange method in a sequence of affinity chromatography, where the first

column uses NP9 detergent, and the second column uses PS80 detergent. The

result will be trimers of polypeptides or glycoproteins attached to a detergent

core. For the downstream purification, the mixture undergoes dialysis of CoV-S

polypeptide in a solution of sodium phosphate, NaCl, and PS80, as well as

ultrafiltration. The mixture is frozen until it is ready for the formulation

step in another facility, to be mixed with excipients and Matrix-M™ adjuvant.

The CoV-S polypeptide drug substance per vaccine ranges between 5-45 µg/dose

based on the clinical trial (Novavax, 2021c).

The block flow diagram of COVID-19 vaccine production in the BICS platform is

shown below (Figure 1). This diagram only shows the production of the CoV-S

spike protein antigen, which is the active ingredient in COVID-19 vaccines.

Further processing, such as formulation and packaging, are typically conducted

in a different plant, which are not accounted for in this simulation flowsheet.

Figure 1 Block flow diagram of

COVID-19 vaccine production in baculovirus-incest cell system (BICS)

2.2. Simulation of

COVID-19 Vaccine Production in mRNA and saRNA Platform

The

simulation for both platforms was done in a previous study by Kis et al. (2020b). In the upstream process, the

DNA template is generated, amplified in E. coli culture, purified, and

linearized. In the midstream process, the RNA is synthesized with in vitro

transcription reaction and 5’ cap analogs are used for the 5’ capping of the

RNA to ensure antigen expression. It is then purified and formulated in lipid

nanoparticles or polycationic formulations to maintain its stability. The

operation runs as a batch process that lasts 11 hours from start to finish. For

self-amplifying RNA (saRNA) vaccines, each dose contains 0.1-10 µg drug

substance while for mRNA vaccines each dose contains 25-250 µg drug substance (Kis et

al., 2019). The result from this study was compared to the techno-economic

analysis results of the BICS platform.

3.1. Techno-Economic Analysis

of BICS, mRNA, and saRNA Platform

A comparison of

techno-economic analysis between BICS and mRNA platforms is conducted to assess

which platform can fulfill global vaccine demands at the lowest cost possible.

The novel saRNA platform is also compared against these two platforms due to its

rapid production rate with less than 10 L reactor size (Kis

et al., 2019), showing potential for high-level productivity. The Phase

I clinical trial showed 87% effectiveness in 192 people aged 18-45, thus more

studies are needed to assess the safety and immunogenicity of saRNA vaccine in

other age groups and with a higher number of test subjects (Pollock et al., 2022).

The base case was calculated

at the median value of all process input parameters (process scale, process

failure rate, production titer, basic labor rate, CoV-S protein amount per

dose, and cost of lab/QC/QA) which then resulted in a particular production titer,

while the lower and upper case were calculated using ± 20% margin of the

production titer differences from the 10.5 g/L base case. The upper-case

scenario is when the process produces +20% production titer or 12.6 g/L, while

the lower-case scenario is when the process makes -20% production titer or 8.4

g/L (Kis et al., 2020b). The

summary of process input parameter values for the BICS simulation is shown in

Table 1.

Table 1 Input parameters and their respective ranges,

central values, and distribution

|

Parameter name and unit |

Value of input parameter |

Reference |

|

Process scale [L] |

2,500 |

(Novavax, 2021c) |

|

Process failure rate [%] |

2,500 |

(Novavax, 2021c) |

|

Production titre [g L-1] |

10.5 |

(Novavax, 2021c) |

|

Basic labor rate [USD hour 1] |

20 |

(Petrides, 2021) |

|

CoV-S protein amount per dose [µg dose-1] |

25 |

(Novavax, 2021c) |

|

Cost of Lab/QC/QA [% of total labor costs] |

40 |

(Petrides, 2021) |

3.1.1 Comparison

of CAPEX and OPEX

The capital expenditure

(CAPEX) and annual operating expenditure (OPEX) were calculated by SuperPro

Designer and then compared between BICS, mRNA, and saRNA platforms (Figure 2).

Figure 2 CAPEX and OPEX of vaccine production in BICS, mRNA,

and saRNA platform

The BICS platform has the

highest value of capital expnditure (CAPEX) at 76-114 million USD, followed by

the mRNA platform at 62-93 million USD, then the saRNA platform at 23-35 million

USD. The high CAPEX in the BICS platform is due to the significantly higher

production scale. The process also involves an upstream process of the Hi-5

insect cell culture line and virus amplification line in the Sf-9 insect cell,

which does not exist in RNA-based vaccine production. The main contributors to

the CAPEX in the BICS platform are equipment purchase, installation,

engineering, and construction fees.

The CAPEX of the mRNA

platform is 20% lower than the CAPEX of the BICS platform, while the CAPEX of

the saRNA platform is 70% lower than the CAPEX of the BICS platform. The

smaller production scale of RNA platforms reduced the cost of equipment

purchase and installation costs, engineering fees, and construction fees. The

CAPEX of the mRNA platform mainly consists of the buildings and construction costs

because the downstream process for mRNA vaccine drug substance requires

multiple steps such as tangential flow filtration (TFF), chromatography,

microfiltration, and dialysis, thus still needing enough space in the plant

layout (Petrides, 2021). The equipment cost

and installation cost are still lower because of the reduced scale compared to

the BICS platform. The main contributor of CAPEX in the saRNA platform is the

same as the mRNA platform due to the high similarity of the production process

in both platforms.

The annual operational

expenditure (OPEX) of mRNA platform is at 502-754 million USD. That is about 4

times larger than the OPEX of the saRNA platform at 133-199 million USD and

even 5 times larger than the OPEX of the BICS platform at 96-145 million USD.

The main reason the OPEX of the mRNA platform is very high is the raw material

cost, mainly the CleanCapAU priced at 340,000 USD per kg and the UTP priced at

230,000 USD per kg, which contribute to 35% and 24% of the total raw material

costs, respectively. With a price this high, it will be helpful to research any

substitute material or find ways to produce these at a lower cost. Using

single-use equipment for storage, mixing, and production of drug substances

also adds to the consumable costs. Overall, the raw materials and consumables

costs are 74% and 24% of the total OPEX, respectively.

3.1.2.

Comparison of cost per dose and productivity

The amount of drug substance

per dose varied based on the clinical trials of each vaccine type as shown in

Figure 3a (Novavax, 2021c; Kis et al., 2020b). The variations of scenarios would affect the

number of doses produced per year and correspond to the lower case, base case,

and upper case. The cost per dose is calculated by dividing the annual OPEX by

the annual doses produced. The yearly doses produced and the cost per dose are

presented in Figure 3b and Figure 3c. The production scale of BICS, mRNA, and

saRNA platforms are set at 2500 L, 30 L, and 7 L, respectively (Novavax, 2021c; Kis et al., 2020b). The prices for adjuvants (Matrix M and saponin) are considered

additional costs that increase the cost per dose (SigmaAldrich,

2021).

Figure 3 a) Drug substance per

dose; (b) Vaccine doses produced per year; (c) Production cost per dose

The productivity of each platform was obtained by dividing the doses

produced per year by the working days (assumed to be 330 days), then dividing

it again with the production scale volume. This calculation used the base

values from the range of inputs and the practical working days to obtain the

productivity value. The saRNA platform’s productivity is about 1,000-fold of

the BICS platform and 20-fold of the mRNA platform. The saRNA and BICS

platforms are economically up to par according to the cost per dose, while the

mRNA platform’s cost per dose is 7 times higher than the BICS and saRNA

platforms. These are shown in Table 2.

Table 2 Productivity of BICS, mRNA, and saRNA vaccine

production platform presented as doses per day per L bioreactor

|

Platform |

Doses/year |

Doses/day |

Production scale (L) |

Productivity (Doses/day per L) |

|

BICS |

±3,500,000,000 |

±11,000,000 |

2,500 |

±4,000 |

|

mRNA |

±2,300,000,000 |

±7,000,000 |

30 |

±200,000 |

|

saRNA |

±11,500,000,000 |

±35,000,000 |

7 |

±5,000,000 |

The smaller production scale of saRNA

compared to the mRNA platform significantly reduced the volume of CleanCapAU

needed thus reducing its OPEX. The mRNA platform has a higher throughput per

year at 69.04 kg of the drug substance while the saRNA platform only produced

11.55 kg of the drug substance. Comparing the production cost per kilogram

product shows the value for the saRNA platform at 14.4 million USD per kg

and the mRNA platform at 10.1 million

USD per kg. BICS platform remained the most economically feasible option at 1.3

million USD per kg product and 92.66 kg of the drug substance annual

throughput.

The OPEX of the BICS platform

is mainly dominated by the cost of baculovirus and insect cells (both Hi-5 and

Sf-9) as well as the consumables cost such as the disposable bioreactor and

Capto Lentil Lectin column (3400 GBP for 5 x 5 mL set) for the chromatography

process (SigmaAldrich, 2022; ThermoFisher, 2022; SigmaAldrich, 2021; Cytiva, 2020).

With the reproductive nature of insect cell culture, the cell line and scaling

up process do not require a lot of new cells and are only necessary to maintain

the insect cell culture in an optimum reactor condition and medium content. The

large production scale provides a higher annual throughput of 23 kg than the

mRNA platform. The base case for drug substance per dose for BICS and mRNA is

quite similar, thus their annual dose produced is only 1 billion doses apart.

With a significantly lower OPEX per kilogram drug substance than mRNA and

saRNA, the BICS platform can manufacture vaccines as rapidly as mRNA with an

almost 90% cheaper production cost per dose. Although saRNA has the highest

production cost per kilogram product at 14.4 million USD per kg, the ultra-low

dosage at 1 µg/dose enables the platform to produce 11.5 billion doses

annually. This drives the cost per dose even lower than the BICS platform.

The

smaller productivity (doses/day per L production scale) in the BICS platform is

due to the vast difference in production scale between the BICS platform and

both RNA-based platforms. The substantially lower amount of RNA drug substance

per dose for the saRNA vaccine also contributed to more rapid production of

vaccine doses compared to mRNA and BICS. When investing in a vaccine

manufacturing platform, there will be a trade-off to consider between platform

productivity and the cost per dose (Kis et al.,

2020b). When saRNA is ready for large-scale manufacturing after multiple

phases of clinical trials and assessment of current Good Manufacturing

Practices (cGMP), it will be fair to consider this platform for vaccine

production. Overall, the BICS platform shows a significant advantage over the

mRNA platform both technologically (annual production of vaccine doses) and

economically (cost per dose). The lower productivity will be a challenge for

further research on optimizing the production scale and productivity.

Baculovirus and insect cell system (BICS),

mRNA, and saRNA platforms were evaluated for their techno-economic feasibility

to manufacture the SARS-CoV-2 vaccine rapidly using SuperPro Designer. From the

techno-economic analysis, the saRNA

platform’s productivity is about 1,000-fold of the BICS platform and 20-fold of

the mRNA platform. The saRNA and BICS platforms are economically up to

par, as shown by their similar cost per dose, while the mRNA platform’s cost

per dose is 7 times higher than BICS and saRNA platforms. However, it is best

to focus on developing the BICS platform for SARS-CoV-2 vaccine manufacturing

in LMICs because it is more clinically developed than saRNA, which by 2021 had

not reached the clinical trials step while BICS had passed its third clinical

trial. Further research is needed to consider other costs in the

techno-economic analysis and optimization study of the BICS platform to improve

its productivity and lower its capital cost.

The

authors would like to acknowledge the Department of Chemical Engineering in

Imperial College London for facilitating this research in 2021. The authors

would like to thank the Research Center for Biomedical Engineering at the

University of Indonesia for conducting the joint conference of ACB-ISBE which

allowed the authors to present and publish this research. The authors are

thankful for the research Matching Fund scheme of “Hibah PUTI Q2” under the

Agreement Letter number: NKB-1470/UN2.RST/HKP.05.00/2022.

AstraZeneca,

2021. Pushing Boundaries to Deliver COVID-19 Vaccine Across

the Globe. Available Online at:

https://www.astrazeneca.com/what-science-can-do/topics/technologies/pushing-boundaries-to-deliver-covid-19-vaccine-accross-the-globe.html,

Accessed on December 20, 2021

Berawi, M.A.,

2020. Empowering Healthcare, Economic, and Social Resilience during Global

Pandemic Covid-19. International

Journal of Technology, Volume 11(3),

pp. 436–439

Berawi, M.A., Suwartha, N., Kusrini, E.,

Yuwono, A.H., Harwahyu, R., Setiawan, E.A., Yatmo, Y.A., Atmodiwirjo, P.,

Zagloel, Y.T., Suryanegara, M., Putra, N., Budiyanto, M.A., Whulanza, Y., 2020.

Tackling the COVID-19 Pandemic: Managing the Cause, Spread, and Impact. International

Journal of Technology, Volume 11(2), pp. 209–214

Canizales, L., Rojas, F., Pizarro, C.A., Caicedo-Ortega, N.H.,

Villegas-Torres, M.F., 2020. SuperPro Designer®, User-Oriented

Software Used for Analyzing the Techno-Economic Feasibility of Electrical

Energy Generation from Sugarcane Vinasse in Colombia. Processes,

Volume 8(9), p. 1180

Carinhas, N., Bernal, V., Teixeira,

A.P., Carrondo, M.J., Alves, P.M., Oliveira, R., 2011. Hybrid Metabolic Flux

Analysis: Combining Stoichiometric and Statistical Constraints to Model the

Formation of Complex Recombinant Products. In: BMC systems biology, Volume 5(1), pp.1–13

Cytiva, 2020.

Capto Lentil Lectin Affinity Chromatography Resin. Available Online at:

https://www.cytivalifesciences.com/en/us/shop/chromatography/resins/affinity-specific-groups/capto-lentil-lectin-affinity-chromatography-resin-p-05955,

Accessed on January 3, 2022

Gerhardt, A., Voigt, E., Archer, M.,

Reed, S., Larson, E., Van Hoeven, N., Kramer, R., Fox, C., Casper, C., 2021. A Thermostable,

Flexible RNA Vaccine Delivery Platform for Pandemic Response. In: bioRxiv.

DOI: https://doi.org/10.1101/2021.02.01.429283

Gioria, V.V., Jäger, V., Claus, J.D.,

2006. Growth, Metabolism and Baculovirus Production in Suspension Cultures of an

Anticarsia Gemmatalis Cell Line. In: Cytotechnology, Volume 52(2), pp.113–124

Irwin, A., 2021.

What It Will Take to Vaccinate The World Against COVID-19.

Available Online at: https://www.nature.com/articles/d41586-021-00727-3,

Accessed on December 20, 2021

Kis, Z.,

Kontoravdi, C., Dey, A., Shattock, R., Shah, N., 2020. Rapid Development and

Deployment of High?Volume Vaccines for Pandemic Response. Journal of Advanced Manufacturing and

Processing, Volume 2(3), p.e10060

Kis, Z., Kontoravdi, C., Shattock, R., Shah,

N., 2020. Resources, Production Scales and Time Required for Producing RNA Vaccines

for The Global Pandemic Demand. Vaccines, Volume 9(1), p. 3

Kis, Z., Shattock, R., Shah, N., Kontoravdi,

C., 2019. Emerging Technologies for Low?Cost, Rapid Vaccine Manufacture.

Biotechnology journal, Volume 14(1), p.1800376

Mena, J.A., Kamen,

A., 2011. Insect Cell Technology is a Versatile and Robust

Vaccine Manufacturing Platform. Expert Review of Vaccines, Volume 10(7), pp. 1063–1081

Novavax, 2016. Immunogenic

Middle East Respiratory Syndrome Coronavirus (MERS-CoV) Compositions and

Methods. US Patent, No. 0206729 A1, July 21, 2016

Novavax, 2021a. Coronavirus

Vaccine Formulations. US Patent, No. 10953089 B1, March 23, 2021.

Novavax, 2021b. Novavax

COVID-19 Vaccine Demonstrates 89.3% Efficacy in UK Phase 3 Trial. Available

Online at: https://ir.novavax.com/2021-01-28-Novavax-COVID-19-Vaccine-Demonstrates-89-3-Efficacy-in-UK-Phase-3-Trial#:~:text=(Nasdaq%3A%20NVAX)%2C%20a,the%20United%20Kingdom%20(%20UK%20),

Accessed on December 24, 2021

Novavax, 2021c. Our Recombinant

Protein-Based Nanoparticle Vaccine Technology. Available Online at:

https://www.novavax.com/science-technology/recombinant-protein-based-nanoparticle-vaccine-technology#recombinant-%20nanoparticle-vaccine-technology,

Accessed on December 24, 2021

O'Neill, L.,

2021. Coronavirus: Will Immunity Rapidly Fade Or Last

A Lifetime?. Available Online at:

https://theconversation.com/coronavirus-will-immunity-rapidly-fade-or-last-a-lifetime-155905,

Accessed on January 12, 2022

Petrides, D.,

2021. SuperPro Designer User Guide - A Comprehensive

Simulation Tool for the Design, Retrofit & Evaluation of Specialty

Chemical, Biochemical, Pharmaceutical, Consumer Product, Food, Agricultural,

Mineral Processing, Packaging and Water Purification, Wastewater. Available

Online at:

http://www.intelligen.com/downloads/SuperPro_ManualForPrinting_v10.pdf, Accessed

on January 1, 2022

Pfizer, 2021. Manufacturing

and Distributing the COVID-19 Vaccine. Available Online at:

https://www.pfizer.com/science/coronavirus/vaccine/manufacturing-and-distribution,

Accessed on December 22,

2021

Pollock, K.M., Cheeseman, H.M., Szubert,

A.J., Libri, V., Boffito, M., Owen, D., Bern, H., O'Hara, J., McFarlane, L.R.,

Lemm, N.M., McKay, P.F., 2022. Safety and Immunogenicity of a Self-Amplifying RNA

Vaccine Against COVID-19: COVAC1, A Phase I, Dose-Ranging Trial. EClinicalMedicine, Volume 44, p.101262

Ritchie, H., Mathieu, E., Rodés-Guirao,

L., Appel, C., Giattino, C., Ortiz-Ospina, E., Hasell, J., Macdonald, B.,

Beltekian, D., Roser, M., 2021. A Global Database of COVID-19 Vaccinations. Nature

Human Behaviour, Volume 5, pp. 947–953

Sari, D., Gupta, K., Raj, D.B.T.G.,

Aubert, A., Drncová, P., Garzoni, F., Fitzgerald, D., Berger, I., 2016. The

MultiBac Baculovirus/Insect Cell Expression Vector System for Producing Complex

Protein Biologics. Advanced Technologies for Protein Complex

Production and Characterization, pp.

199–215

Shumei, L., 2021.

Sinovac to Lift Yearly Production Capacity to 2 Billion

Doses by June as China Expands Vaccination Program. Available Online at:

https://www.globaltimes.cn/page/202103/1217214.shtml, Accessed on January 5,

2022

SigmaAldrich,

2021. Matrix M and Saponin Adjuvant Price. Available Online at:

https://www.sigmaaldrich.com/GB/en/product/sigma/47036?gclid=Cj0KCQjwssyJBhDXARIsAK98ITRNziWVEv_51eil5Y9cwNQx6W8r8eCFdGww7Dq2uMmsvro7n7naXYaAryjEALw_wcB,

Accessed on January 10, 2022

SigmaAldrich,

2022. Sf9 Insect Cell Price. Available Online at:

https://www.sigmaaldrich.com/GB/en/product/mm/71104m?context=product, Accessed

on January 4, 2022

Sofyan, N.,

Yuwono, A.H., Harjanto, S., Budiyanto, M.A., Wulanza, Y., Putra, N.,

Kartohardjono, S., Kusrini, E., Berawi, M.A., Suwartha, N., Maknun, I.J.,

Yatmo, Y.A., Atmodiwirjo, P., Asvial, M., Harwahyu, R., Suryanegara, M.,

Setiawan, E.A., Zagloel, T.Y.M., Surjandari, I., 2021. Resilience and

Adaptability for a Post-Pandemic World: Exploring Technology to Enhance

Environmental Sustainability. International

Journal of Technology, Volume 12(6),

pp. 1091–1100

Steenhuysen, J.,

O'Donnell, C., 2021. Moderna Boosting COVID-19 Vaccine Capacity,

Targets Up to 3 Billion Shots in 2022.

Available Online at:

https://www.reuters.com/business/healthcare-pharmaceuticals/moderna-boosting-covid-19-vaccine-making-capacity-targets-up-3-billion-shots-2021-04-29/,

Accessed on January 9, 2022

ThermoFisher,

2022. Hi5 Insect Cell Price. Available Online at:

https://www.thermofisher.com/order/catalog/product/10486025#/10486025, Accessed

on January 4, 2022