An Experimental Study on the Performance of Check Valve-Aided Savonius Wind Rotors with Semi-Circular Blade

Published at : 24 Dec 2024

Volume : IJtech

Vol 15, No 6 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i6.6110

Farozan, I., Indartono, Y.S., 2024. An Experimental Study on the Performance of Check Valve-Aided Savonius Wind Rotors with Semi-Circular Blade. International Journal of Technology. Volume 15(6), pp. 1923-1935

| Ivan Farozan | Faculty of Mechanical and Aerospace Engineering, Institut Teknologi Bandung, Bandung 40132, Indonesia |

| Yuli Setyo Indartono | 1. Faculty of Mechanical and Aerospace Engineering, Institut Teknologi Bandung, Bandung 40132, Indonesia. 2. Research Center for New and Renewable Energy, Institut Teknologi Bandung, Bandung 40132, I |

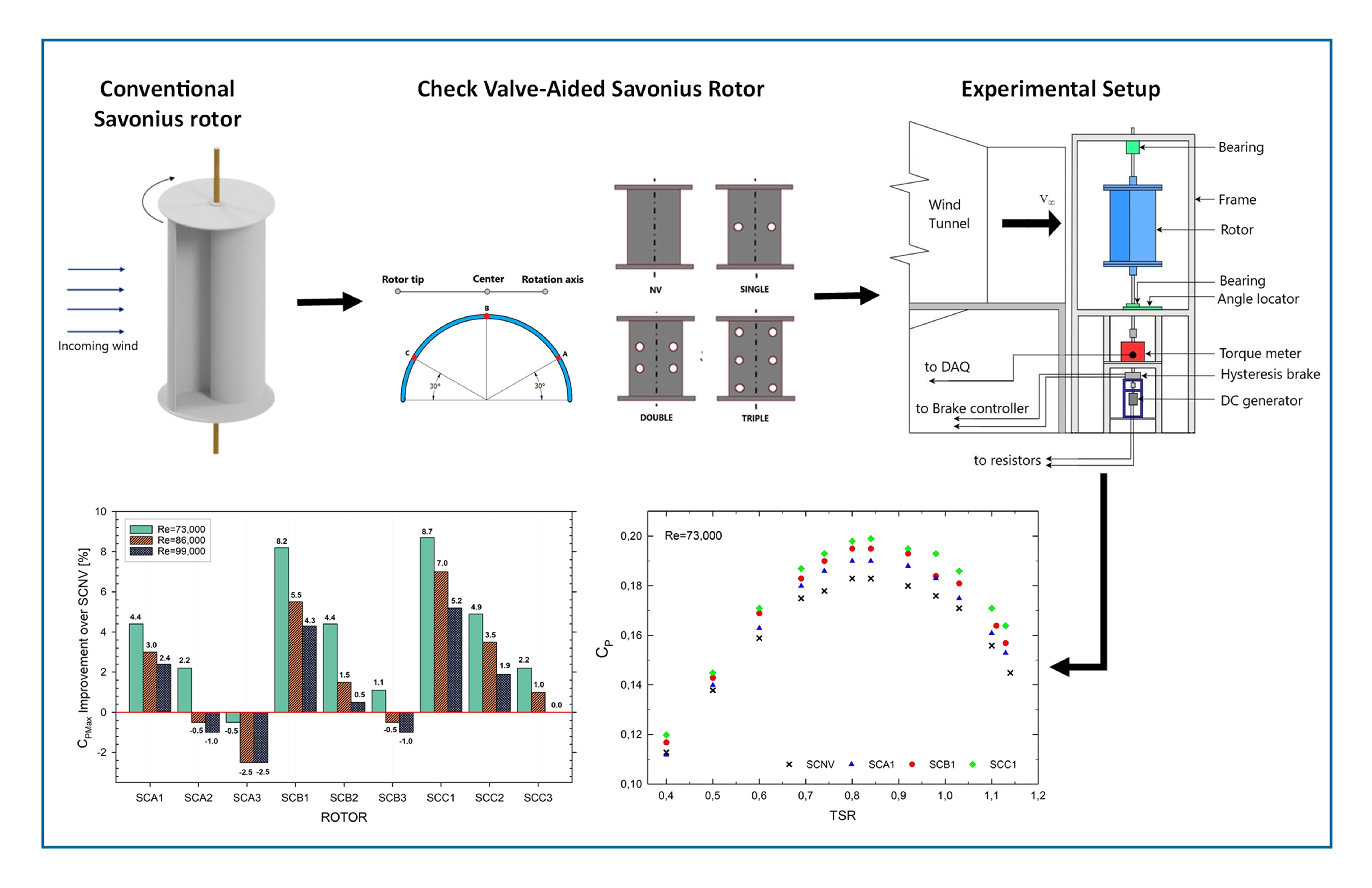

The Savonius wind turbine is perceived favorable for a small-scale application because it is simple, relatively inexpensive, insensitive to wind directions, and has a good self-starting ability. However, it has a low power coefficient caused by the negative torque from the returning blade. This study aimed to investigate the effect of valve addition on the semi-circular Savonius rotor's performance. The experiments for this study were conducted on an open jet wind tunnel, with the valve located near the rotation axis, blade center, and rotor tip. The valve opening area ratio used was 0.02, 0.04, and 0.06, with Reynolds numbers 73,000, 86,000, and 99,000. The results showed that rotors with a valve placed near the tip performed better than those at the blade center and near the rotation axis. The performance decreased with an increase in the valve opening area ratio. Furthermore, the performance-improvement magnitude decreased with an increase in the Reynolds number. The rotor with a single valve near the tip performed the highest at a Reynolds number of 73,000. It achieved a maximum power coefficient of 0.199 compared to 0.183 obtained by a conventional Savonius rotor.

Augmentation; Check valve; Renewable energy; Savonius wind-rotor; Wind turbine

The Intergovernmental Panel on

Climate Change (IPCC) warned that the world would reach 1.5 oC of

warming by 2040, and only swift and drastic cuts in carbon emissions would help

prevent an environmental disaster (IPCC, 2022). One way to reduce carbon emissions is reduced by

using renewable energy sources such as wind energy to decarbonize the global

electricity generation systems. In 2019, global wind power capacity reached 651

GW, contributing approximately 5.9% of global electricity generation (REN21, 2019). With wind energy

costs expected to drop significantly in the future, this contribution is

expected to increase (Wiser et al., 2021).

Savonius rotor is a vertical axis wind turbine (VAWT) comprising two semi-circular buckets arranged asymmetrically to resemble an 'S' shape. It works based on drag force with a slight contribution from the lift force (Alom, Borah, and Saha, 2018). The positive torque generated by an advancing blade moving with the wind is higher than the negative torque generated by the returning blade moving against the wind. The difference between the two torques causes the rotor to spin. The Savonius rotor power coefficient (CP) is much lower than the horizontal axis wind turbine (HAWT) due to the negative torque produced. However, it has several intrinsic advantages over the HAWT, such as simpler design, good starting ability, omnidirectional, lower noise, and easier to maintain (Kumar, Raahemifar, and Fung, 2018). These advantages make the rotor more suitable for harnessing wind power in urban sites, building rooftops, and remote areas (Cho, Jeong, and Sari, 2011; Ishugah et al., 2014; Mao et al., 2020). In addition to energy generation, wind turbines installed in an urban area allow direct use of energy which eliminates energy transmission losses (Krasniqi, Dimitrieska, and Lajqi, 2022). When combined with a suitable and improved generator design, such as a reduced cogging-torque permanent magnet generator (Nur and Siregar, 2020), the Savonius rotor may provide an interesting method for small-scale wind power generation. The basic geometry of a conventional Savonius rotor is illustrated in Figure 1.

Figure 1 Basic

geometry of a conventional Savonius rotor

The performance of a Savonius

rotor highly depends on its geometric parameters. Saad et

al. (2020) found that the rotor

with end plates performed better, with the optimum value for end plate diameter

(De) at 1.1 of the rotor diameter (D). Mahmoud

et al. (2012) investigated

the aspect ratio (AR), a non-dimensional parameter resulting from dividing the

rotor height (H) by its diameter. The study found that the maximum CP

(CPMax) was improved as the AR increased. Saad, Ookawara,

and Ahmed (2022) observed a similar finding on multi-stage rotors. This

CP improvement for a higher AR reduces loss at the tip, similar to

adding end plates (Akwa, Vielmo, and Petry, 2012). Studies on the overlap ratio (?) of the distance

between rotor blades (e) and the blade chord length (d) found that the optimum

value ranges from 0.15 to 0.2 (Alom and Saha, 2017;

Cuevas-Carvajal et al., 2022; Roy and Saha, 2013). Additionally, Kamoji,

Kedare, and Prabhu (2009) investigated the effect of the Reynolds number on a

conventional and modified Savonius rotor. The study found that the CPMax

improved by 19% as the Reynolds number increased from 80,000 to 150,000.

The modification f the

conventional Savonius rotor blade shape can also improve its performance. Abdelaziz et al. (2022) numerically

studied the performance of a conventional Savonius rotor with various outer and

inner arc angles and gap ratios. They managed to improve the CPMax

by 4.5% and 12.9% with a 160O outer angle and 20O inner

angle, respectively. A novel Savonius rotor with a modified-bach blade was

proposed by Elmekawy, Saeed, and Kassab (2021). They found a 32.2% CPMax improvement over

a conventional Savonius rotor through numerical study. The blade shape was also

modified to improve the Savonius performance at a higher TSR range (above 0.8).

Savonius rotor with a combination of the semi-circular and elliptical profile

was found to have CPMax at TSR=1.4, double that of a conventional

rotor's TSR=0.7 (Le et al., 2022). Based on the result, Dinh

Le, Minh, and Trinh (2022) further

modified the previous rotor into a combination of multi-curve and auxiliary

blades. The new rotor combination not only possessed a higher CPMax

at a higher TSR, but it also exhibited a 6.9% higher CP than the

conventional rotor in the lower TSR range.

Several studies have suggested

different methods to enhance the performance of the Savonius rotor. For

instance, Mohamed et al. (2010) improved the CP by 27.3% by placing a deflector upstream to prevent the

wind from hitting the returning blade. Nimvari,

Fatahian, and Fatahian (2020) used a porous deflector and achieved a 10% increase

in CPMax. El-Askary et al.

(2015) proposed a design that

incorporated a Savonius rotor inside curved guide plates, which achieved a CPMax

of 0.52 at a TSR of 1.1. However, this design produced large wakes behind

the rotor, which could affect the operation of other turbines in a wind farm.

Although these methods significantly improve performance, they compromise the

simplicity and omnidirectional nature of the Savonius rotor.

Ideal augmentation methods can

improve rotor performance while keeping all the Savonius advantages intact. One

of the methods is the addition of a check valve to the rotor blades. This

method allows a portion of wind freestream to pass through the returning-blade

convex side, reducing the drag force and lowering the negative torque.

Furthermore, valve addition can be a complementary method with the potential to

further enhance an already high-performance Savonius rotor with a modified

blade.

Rajkumar and Saha (2006) first investigated the valve-addition method by placing slot-shaped

aluminum hinged-type valves on a conventional and twisted Savonius rotor. Saha Thotla, and Maity (2008) later used a thin fabric called Rexine as the valve

material instead of aluminum and conducted experiments using an open jet wind

tunnel. The findings showed that the two-stage, valve-aided Savonius rotor had

a 19% higher CPMax than a conventional rotor. Both of the

aforementioned studies used a fixed-size valve placed at the center of the

blade. Amiri and Anbarsooz (2019) investigated the effect of valve location on a conventional Savonius

rotor's performance. The study used a rectangular pivot-type valve made from

the same material as the rotor. The valve's opening area ratio (OAR), which is

the ratio between the area of the valves and the rotor's frontal area (D.H),

was fixed at 0.33. This pivotal valve was placed near the rotation axis as well

as in the middle and at the tip of the rotor. The results showed that the valve

at the tip location yielded a 20.8% performance improvement. Furthermore, Borzuei, Moosavian, and Farajollahi (2021) performed a numerical experiment on the effect of

adding a rectangular pivot-type valve to the static torque coefficient of a

Savonius rotor with three blades. The results showed a 14.5% improvement in the

static torque coefficient. This was indicated by the large pivot valve with an

unlimited opening angle and counter-clockwise opening direction placed at the

center of the rotor blade.

Previous studies have shown that using a part of the rotor blade as a pivot-type valve can have a positive effect (Borzuei, Moosavian, and Farajollahi, 2021; Amiri and Anbarsooz, 2019). However, a large OAR can have a negative impact on the structural integrity and manufacturability of the rotor. The slot-shaped hinge-type valve proposed by Saha, Thotla, and Maity (2008) has better structural integrity and manufacturability. However, previous studies on Savonius rotors with hinge-type valves did not investigate the effect of valve locations and OAR on the rotor's performance under different wind speeds. This study aims to fill this gap. Moreover, in contrast to the slot-shaped valve used in by Saha, Thotla, and Maity (2008) this study employs a circular valve to improve the manufacturability of the rotor blade.

2.1.

Studied Rotor Design and

Manufacturing

This study investigated a

single-stage Savonius with two semi-circular rotor blades. All the studied

rotors have the same design and dimension. The valves were placed near the

rotor rotation axis (A), at the center of the rotor blade (B), and near the rotor

tip (C). Moreover, the study used three increasing OAR for each location to

study ten rotors, including the non-valve-aided rotor. Tables 1 and 2 show the

geometrical dimension and rotor specifications, while the valve location and

arrangements are depicted in Figure 2a.

The rotors were manufactured using 3D printers and

PLA+ material with a thickness of 2.5mm. Each rotor was divided into lower and

top plates and rotor blades, a design chosen to reduce manufacturing time and

material use while allowing for quick reconfiguration. The valve body was made

from synthetic leather pasted onto the rotor blade. Figure 2b shows the

manufactured rotors.

Table 1 Geometrical

dimension of the studied Savonius semi-circular rotor

|

Chord length (d) |

Rotor diameter (D) |

End plate diameter (De) |

Rotor Height (H) |

Rotor Aspect ratio (AR) |

Overlap ratio (?) |

|

100 mm |

180 mm |

198 mm |

360 mm |

2 |

0.2 |

Table 2 Studied

rotors identification and specification

|

Parameter |

Rotor Identification | ||||||||||

|

SCNV |

SCA1 |

SCA2 |

SCA3 |

SCB1 |

SCB2 |

SCB3 |

SCC1 |

SCC2 |

SCC3 |

| |

|

Valve Location |

N/A |

Near the rotation axis |

At the blade center |

Near rotor tip | |||||||

|

Valve Qty |

0 |

1 |

2 |

3 |

1 |

2 |

3 |

1 |

2 |

3 |

|

|

OAR |

0 |

0.02 |

0.04 |

0.06 |

0.02 |

0.04 |

0.06 |

0.02 |

0.04 |

0.06 |

|

Figure 2 (a) Valve locations and arrangement on the rotor; (b)

3D printed rotors

2.2.

Experimental Setup

The experiments were performed

using the low-speed open jet wind tunnel at the Institut Teknologi Bandung. The

wind velocity at the tunnel exit () could be adjusted up to

10 m/s using a variable speed drive. The averaged wind velocity at the tunnel

exit was measured using a calibrated hotwire anemometer. The experiments were

conducted at a Reynolds number of 73,000, 86,000, and 99,000. The rotor axis was positioned 300 mm away from the

wind tunnel exit. The open test section in which the rotor was situated

measured 1,000 mm x 600 mm, resulting in a blockage ratio of 12%. This value is

low for an open-type wind tunnel test and does not require a blockage

correction factor (Gonçalves, Pereira, and Sousa, 2022; Van Bussel et al., 2004). The overall setup of the experimental study is

depicted in Figure 3a.

The study used a DYN-200 rotary torque

meter to measure the torque (T) and the rotor's rotation speed (N).

The torque meters measurement was calibrated using known torques, while the

rotation speed was checked against a calibrated optical tachometer. The meter

accuracy was specified as ±0.1% and ±1 rpm for the torque and rotation speed,

respectively. Furthermore, the torque meter output was connected to a laptop

via a Labjack U6 data acquisition module. A hysteresis brake and a DC generator

were combined to simulate a dynamic load. At each test point, measurements were

taken at a sampling rate of 4 Hz for 15

seconds. Figure 3b shows the instrumental setup.

Figure 3 (a) Overall experimental setup; (b) Instrumentation

setup

2.3.

Data Reduction

The study measured the freestream wind velocity

(), rotor torque (T), and rotor rotational

speed (N). The rotor was operated under a steady wind velocity and

constant load during a dynamic test. The torque and rotation speeds were

measured for a fixed time and then averaged. The load was then varied to obtain

the rotor's performance characteristics. The torque loss due to bearing

frictions cannot be ignored at higher rotational speeds. Therefore, a separate

experiment was conducted to obtain the frictional power loss characteristic.

The dimensionless rotor tip speed ratio (TSR) was then calculated using

Equation 1:

where D is the rotor diameter (m), is the

wind velocity (m/s), and

is the

rotor angular velocity (rad/s) calculated using Equation 2:

where N is the measured rotor rotation speed (rpm). The dimensionless rotor power coefficient CP is expressed using Equation 3:

where TSR is the tip speed ratio given by

Equation 1, and ![]() is the

dimensionless rotor torque coefficient calculated using Equation 4:

is the

dimensionless rotor torque coefficient calculated using Equation 4:

where T is the measured torque (N.m), H

is the rotor height (m), and is the

air density in (kg/m3).

The uncertainty related to the

measurement is calculated using the root-sum-square method (Wheeler and Ganji, 2009). The

total uncertainties for the measured quantities (T, N, and

) are

calculated using Equation 5:

where is the systematic uncertainty taken from the

instrument's accuracy specification, and

is the random uncertainty based on the standard

deviation of the mean. The uncertainties for derived quantities

are then calculated using the propagation of

error method shown in Equation 6:

where is the total uncertainty for the derived

quantities, and

is the sensitivity coefficient of derived

quantities R with respect to variable

The confidence level associated with the

uncertainties was chosen at 95%. The total uncertainties for the TSR,

are 2.3%,

4.0%, and 6.3% respectively.

3.1.

Conventional (Non-Valve-Aided) Savonius

Rotor Performance

Figure 4 The effect of Reynolds number on the Savonius rotor

(a) coefficient of power; and (b) coefficient of torque

The results suggest that the power

coefficient increased as the Reynolds number increased. The CPMax

value increased by 14.6% as the Reynolds number increased from 73,000 to

99,000, which is consistent with the findings of Kamoji,

Kedare, and Prabhu (2009). The increase in CPMax

was attributed to the delayed separations at the rotor blades at higher

Reynolds numbers or wind velocities (Kamoji, Kedare, and Prabhu, 2009). Similarly, the CTMax also increased

with the Reynolds number. The CTMax values for Reynolds numbers

73,000, 86,000, and 99,000 were 0.284, 0.304, and 0.323, respectively. The CT

peaked at a tip speed ratio of 0.4 and decreased almost linearly as the tip

speed ratio increased, which was observed for all three Reynolds numbers.

3.2.

Effect of Valve Locations on the Rotor

Performance

Figure 5 The effect of valve locations on SCNV, SCA1, SCB1, and SCC1 rotor (a) CP vs TSR at Re=73,000; (b) CP vs TSR at Re=86,000; (c) CP vs TSR at Re=99,000; (d) CT vs TSR at Re=73,000; (e) CT vs TSR at Re=86,000; and (f) CT vs TSR at Re=99,000

The

rotors with a single valve performed better than the non-valve-aided (SCNV)

rotors in all three locations and for all Reynolds numbers. However, the

magnitude of CPMax improvement decreased as the Reynolds number

increased. For instance, the SCC1 rotor yielded an 8.7%, 7.0%, and 5.2% CPMax

improvement when tested at Reynolds numbers 73,000, 86,000, and 99,000,

respectively. This condition may be caused by the valve's presence on the blade

surface disrupting the flow-separation delay that normally occurs when the

Reynolds number increases. Adding a single valve did not significantly affect

the tip speed ratio corresponding with the CPMax. The tip speed

ratio range related to the CPMax is 0.85 to 0.87 compared to SCNVs

0.84 to 0.86. A similar observation was made by Amiri and Anbarsooz (2019).

The

rotor with a valve near the rotor tip (SCC1) consistently showed higher CPMax

than the other two for the three Reynolds numbers. This result is consistent

with Amiri and Anbarsooz (2019) that the negative torque

reduction by the valve at the tip has a greater impact because the air flows

through the valve at a higher rate. In contrast, the rotor with a valve placed

near the rotation axis (SCA1) produced the least improvement. A valve at this

location is too close to the moment axis, resulting in the lowest negative

torque reduction. Placing a valve near the rotation axis also disturbs the

overlapping-gap flow that is supposed to energize the returning blade (Nakajima, Iio, and Ikeda, 2008). The overlapping-gap flow

disturbance further reduces the effectiveness of the valve placed near the

rotation axis. This finding shows a tradeoff between the positive and negative

effects on each valve location.

Adding

a single valve to the rotor did not change the trend of rotor CT.

Similar to the non-valve-aided rotor (SCNV), the CTMax occurred at

TSR=0.4 and decreased as the TSR increased. This applied to all three

valve-aided rotors (SCA1, SCB1, and SCC1). The value of the CTMax

for SCC1 and SCB1 rotors increased, while the SCA1 rotor CTMax

remained close to the SCNV. Similar to the CP result, the magnitude

of CTMax improvement decreased as the Reynolds number increased. A

comparison of the result between the present study and the works of Amiri and Anbarsooz (2019) and Saha, Thotla,

and Maity (2008) can be found in Table 3.

Table 3 Result comparison

for studies on Savonius rotor aided with a single valve

|

Author |

Valve shape |

Valve location |

Valve OAR |

Reynolds Number |

CPMax |

TSR for CTMax |

|

Saha, Thotla, and Maity (2008) |

Slot |

Center |

Not specified |

148,000 (estimated) |

0.310 |

Not specified |

|

Amiri and Anbarsooz (2019) |

Rectangular |

Center |

0.33 |

138,000 (estimated) |

0.116 |

0.55 |

|

The present study |

Circular |

Center |

0.02 |

73,000 |

0.199 |

0.87 |

3.3.

Effect of Valve Opening Area Ratio on the

Rotor Performance

The

valve opening area ratio was varied between 0.02 and 0.06 by increasing the

number of valves with the same diameter. A total of six multi-valve rotors

(SCA2, SCA3, SCB2, SCB3, SCC2, and SCC3) were made and tested in this study.

The results showed a similar trend for the three-valve locations. Therefore,

the study discussed the results mainly from SCC1, SCC2, and SCC3, with the

valve at the tip. Figures 6a and 6b illustrate the effect of OAR on the SCC

rotor CP and CT at the same Reynolds number of 73,000,

while Table 4 summarizes the overall experiment result.

Figures 6a and 6b show that the rotors' performance coefficient decreases as the valve OAR increases. The CPMax at Re=73,000 for SCC1, SCC2, and SCC3 is 0.199, 0192, and 0.187, respectively. The CTMax for SCC1, SCC2, and SCC3 is 0.302, 0.291, and 0.284, respectively. Table 4 shows that these CPMax and CTMax downward trends can be observed in all three valve locations and for all Reynolds numbers. This result indicates that the amplification of positive effects from increasing OAR, such as negative torque reduction, is weaker than that of negative effects. The design and working mechanism of the hinge-type valve may contribute to the reduced performance. The thin synthetic-leather fabric used as the valve material could be affected by the airflow condition and lifted open when unexpected.

Figure 6 The

effect of valve locations on SCNV, SCC1, SCC2, and SCC3 rotor (a) CP vs

TSR at Re=73,000; (b) CT vs TSR at Re=73,000

Figure

7 shows the opening of all valves at returning and advancing blade side for the

SCC3 rotor at 150O relative to the incoming wind. Opening the valves

at the advancing side reduces the blade surface pushed by the wind, lowering

the net torque value. This phenomenon is also observed with SCC1 and SCC2.

Furthermore, increasing the OAR (number of valves) near the rotation axis has

further disturbed the overlapping-gap flow, which cannot be compensated by the

negative torque reduction effect. Figure 8 shows the plot for valve-aided

rotors' CPmax improvement over the SCNV.

Figure 8 Summary of valve-aided rotors CPmax

improvement over the SCNV rotor

The study aimed to compare the performance of

conventional and valve-aided Savonius wind rotors with semi-circular blades by

varying valve locations, OAR, and Reynolds numbers. Results indicated that

rotor power and torque coefficient increased with Reynolds numbers. For all

Reynolds numbers and OAR values, rotors with valves at the rotor tip

outperformed those in other locations. Additionally, rotor performance

decreased as valve OAR increased due to coexisting adverse effects like flow

disruption alongside the beneficial effect of negative torque reduction. The

highest CPMax improvement of 8.7% was shown by the rotor with a

single valve at the tip, with a CPMax of 0.199 at a tip speed ratio

of 0.87. The augmentation of the Savonius rotor with valve addition improved

the rotor performance while keeping all the intrinsic advantages intact.

Therefore, a valve-assisted Savonius wind rotor can potentially enhance wind

power generation in urban areas and sites with a low average wind speed.

The authors

thank the Faculty of Mechanical and Aerospace Engineering (FTMD) ITB for their financial support

through the Penelitian, Pengabdian Masyarakat, dan Inovasi (P2MI) 2021~2022 grant

scheme. The authors

would also like to extend their gratitude to the Research Center for New and

Renewable Energy ITB for their support so that this study could be conducted.

| Filename | Description |

|---|---|

| R1-ME-6110-20221203071122.png | Figure 1 |

| R1-ME-6110-20221203071249.png | Figure 2a |

| R1-ME-6110-20221203071327.JPG | Figure 2b |

| R1-ME-6110-20221203071548.jpg | Figure 3a Revised |

| R1-ME-6110-20221203071613.jpg | Figure 3b |

| R1-ME-6110-20221203072609.png | Figure 4a |

| R1-ME-6110-20221203072630.png | Figure 4b |

| R1-ME-6110-20221203072652.jpg | Figure 5a revised |

| R1-ME-6110-20221203072742.jpg | Figure 5b revised |

| R1-ME-6110-20221203072816.jpg | Figure 5c revised |

| R1-ME-6110-20221203072836.jpg | Figure 5d |

| R1-ME-6110-20221203072855.jpg | Figure 5e |

| R1-ME-6110-20221203072915.jpg | Figure 5f |

| R1-ME-6110-20221203073018.jpg | Figure 6b |

| R1-ME-6110-20221203073050.jpg | Figure 7 |

| R1-ME-6110-20221203073125.JPG | Figure 8 |

| R1-ME-6110-20221203073604.jpg | Figure 6a revised |

Abdelaziz, K.R., Nawar, M.A.A., Ramadan, A., Attai, Y.A., Mohamed, M.H.,

2022. Performance Investigation of a Savonius Rotor by Varying the Blade Arc

Angles. Ocean Engineering, Volume 260, p. 112054. https://doi.org/10.1016/j.oceaneng.2022.112054

Akwa, J.V., Vielmo, H.A., Petry, A.P., 2012. A Review on the Performance

of Savonius wind Turbines. Renewable and Sustainable Energy Reviews,

Volume 16(5), pp. 3054–3064. https://doi.org/10.1016/J.RSER.2012.02.056

Alom, N., Borah, B., Saha, U.K., 2018. An

Insight into the Drag and Lift Characteristics of Modified Bach and Benesh

Profiles of Savonius Rotor. Energy Procedia, Volume 144, pp. 50–56. https://doi.org/10.1016/j.egypro.2018.06.007

Alom, N., Saha, U.K., 2017. Arriving at the optimum overlap ratio for an

elliptical-bladed savonius rotor. Proceedings of the ASME Turbo Expo,

Volume 9, pp. 1–10. https://doi.org/10.1115/GT2017-64137

Amiri, M., Anbarsooz, M., 2019. Improving the Energy Conversion

Efficiency of a Savonius Rotor Using Automatic Valves. Journal of Solar

Energy Engineering, Volume 141(3), p. 031017. https://doi.org/10.1115/1.4042828

Banerjee, A., 2019. Performance and flow analysis of an elliptic bladed

Savonius-style wind turbine. Journal of Renewable and Sustainable Energy,

Volume 11(3), p. 033307. https://doi.org/10.1063/1.5097571

Borzuei, D., Moosavian, S.F., Farajollahi, M., 2021. On the Performance Enhancement of the Three-Blade

Savonius Wind Turbine Implementing Opening Valve. Journal of Energy

Resources Technology, Volume 143(5), p. 051301. https://doi.org/10.1115/1.4049460

Cho, K.-P., Jeong, S.-H., Sari, D.P., 2011. Harvesting Wind Energy from

Aerodynamic Design for Building Integrated Wind Turbines. International

Journal of Technology, Volume 2(3), pp. 189–198. https://doi.org/10.14716/ijtech.v2i3.65

Cuevas-Carvajal, N., Cortes-Ramirez, J.S., Norato, J.A., Hernandez, C.,

Montoya-Vallejo, M.F., 2022. Effect of Geometrical Parameters on the

Performance of Conventional Savonius VAWT: A Review. Renewable and

Sustainable Energy Reviews, Volume 161, p. 112314. https://doi.org/10.1016/J.RSER.2022.112314

Dinh Le, A., Minh, B.D., Trinh, C.D., 2022. High Efficiency Energy

Harvesting Using a Savonius Turbine with Multicurve and Auxiliary Blade. Journal

of Fluids Engineering, Volume 144(11), p. 111207. https://doi.org/10.1115/1.4054705

El-Askary, W.A., Nasef, M.H., AbdEL-hamid, A.A., Gad, H.E., 2015.

Harvesting Wind Energy for Improving Performance of Savonius Rotor. Journal

of Wind Engineering and Industrial Aerodynamics, Volume 139, pp. 8–15. https://doi.org/10.1016/j.jweia.2015.01.003

Elmekawy, A.M.N., Saeed, H.A.H., Kassab, S. Z., 2021. Performance

Enhancement of Savonius Wind Turbine by Blade Shape and Twisted Angle

Modifications. In: Proceedings of the Institution of Mechanical

Engineers, Part A: Journal of Power and Energy, Volume 235(6), pp. 1487–1500. https://doi.org/10.1177/0957650920987942

Ferrari, G., Federici, D., Schito, P., Inzoli, F., Mereu, R., 2017. CFD

study of Savonius wind turbine: 3D model validation and parametric analysis. Renewable

Energy, Volume 105, pp. 722–734. https://doi.org/10.1016/j.renene.2016.12.077

Gonçalves, A.N.C., Pereira, J.M.C., Sousa, J.M.M., 2022. Passive Control

of Dynamic Stall in a H-Darrieus Vertical Axis Wind Turbine using Blade

Leading-Edge Protuberances. Applied Energy, Volume 324, p. 119700. https://doi.org/10.1016/j.apenergy.2022.119700

Intergovernmental Panel on Climate Change (IPCC), 2022. Summary for

Policymakers. Report in Climate Change 2022: Impacts, Adaptation and

Vulnerability, Contribution of Working Group II to the Sixth Assessment Report

of the Intergovernmental Panel on Climate Change, IPCC, New York, USA. https://doi.org/10.1017/9781009325844.001

Ishugah, T.F., Li, Y., Wang, R.Z., Kiplagat, J.K., 2014. Advances in

Wind Energy Resource Exploitation in Urban Environment: A Review. Renewable

and Sustainable Energy Reviews, Volume 37, pp. 613–626. https://doi.org/10.1016/j.rser.2014.05.053

Kamoji, M.A., Kedare, S.B., Prabhu, S.V., 2009. Experimental

Investigations on Single Stage Modified Savonius Rotor. Applied Energy,

Volume 86(7–8), pp. 1064–1073. https://doi.org/10.1016/J.APENERGY.2008.09.019

Krasniqi, G., Dimitrieska, C., Lajqi, S., 2022. Wind Energy Potential in

Urban Area: Case Study Prishtina. International Journal of Technology,

Volume 13(3), pp. 458–472. https://doi.org/10.14716/ijtech.v13i3.5323

Kumar, R., Raahemifar, K., Fung, A.S., 2018. A Critical Review of

Vertical Axis Wind Turbines for Urban Applications. Renewable and

Sustainable Energy Reviews, Volume 89, pp. 281–291. https://doi.org/10.1016/j.rser.2018.03.033

Le, A.D., Minh Duc, B., van Hoang, T., The Tran, H., 2022. Modified

Savonius Wind Turbine for Wind Energy Harvesting in Urban Environments. Journal

of Fluids Engineering, Volume 144(8), p. 081501. https://doi.org/10.1115/1.4053619

Mahmoud, N.H., El-Haroun, A.A., Wahba, E., Nasef, M.H., 2012. An

Experimental Study on Improvement of Savonius Rotor Performance. Alexandria

Engineering Journal, Volume 51(1), pp. 19–25. https://doi.org/10.1016/J.AEJ.2012.07.003

Mao, Z., Yang, G., Zhang, T., Tian, W., 2020. Aerodynamic performance

analysis of a building-integrated Savonius turbine. Energies, Volume

13(10), p. 2636. https://doi.org/10.3390/en13102636

Mohamed, M.H., Janiga, G., Pap, E., Thèvenin, D., 2010. Optimization of

Savonius Turbines using an Obstacle Shielding the Returning Blade. Renewable

Energy, Volume 35(11), pp. 2618–2626. https://doi.org/10.1016/j.renene.2010.04.007

Nakajima, M., Iio, S., Ikeda, T., 2008. Performance of Double-step

Savonius Rotor for Environmentally Friendly Hydraulic Turbine. Journal of

Fluid Science and Technology, Volume 3(3), pp. 410–419. https://doi.org/10.1299/jfst.3.410

Nimvari, M.E., Fatahian, H., Fatahian, E., 2020. Performance Improvement

of a Savonius Vertical Axis Wind Turbine using a Porous Deflector. Energy

Conversion and Management, Volume 220, p. 113062. https://doi.org/10.1016/j.enconman.2020.113062

Nur, T., Siregar, M., 2020. Two-Steps Slotting Method in Magnet Edge of

PMG for Wind Energy Harvesting. International Journal of Technology, Volume

11(7), pp. 1442–1450. https://doi.org/10.14716/ijtech.v11i7.4554

Rajkumar, M.J., Saha, U.K., 2006. Valve-Aided

Twisted Savonius Rotor. Wind Engineering, Volume 30(3), pp. 243–254. https://doi.org/10.1260/030952406778606269

Renewable Energy Policy Network for the 21st Century (REN21), 2019. Renewables

2019 Global Status Report. Renewable

Energy Policy Network for the 21st Century, REN21 Secretariat, Paris, France

Roy, S., Saha, U.K., 2013. Computational

Study to Assess the Influence of Overlap Ratio on Static Torque Characteristics

of a Vertical Axis Wind Turbine. Procedia Engineering, Volume 51, pp.

694–702. https://doi.org/10.1016/J.PROENG.2013.01.099

Roy, S., Saha, U.K., 2015. Wind tunnel experiments of a newly developed

two-bladed Savonius-style wind turbine. Applied Energy, Volume 137, pp.

117–125. https://doi.org/10.1016/j.apenergy.2014.10.022

Saad, A.S., El-Sharkawy, I.I., Ookawara, S., Ahmed, M., 2020.

Performance Enhancement of Twisted-Bladed Savonius Vertical Axis Wind Turbines.

Energy Conversion and Management, Volume 209, p. 112673. https://doi.org/10.1016/j.enconman.2020.112673

Saad, A.S., Ookawara, S., Ahmed, M., 2022. Influence of Varying the

Stage Aspect Ratio on the Performance of Multi-Stage Savonius Wind Rotors.

Journal of Energy Resources Technology, Volume 144(1), p. 011301. https://doi.org/10.1115/1.4050876/1107060.

Saha, U.K., Thotla, S., Maity, D., 2008. Optimum Design Configuration of Savonius Rotor Through Wind Tunnel

Experiments. Journal of Wind Engineering and Industrial Aerodynamics, Volume

96(8–9), pp. 1359–1375. https://doi.org/10.1016/J.JWEIA.2008.03.005

Torresi, M., de Benedittis, F.A., Fortunato, B., Camporeale, S.M., 2014.

Performance and Flow Field Evaluation of a Savonius Rotor Tested in a Wind

Tunnel. Energy Procedia, Volume 45, pp. 207–216. https://doi.org/10.1016/J.EGYPRO.2014.01.023

Van Bussel, G.J.W., Mertens, S., Polinder, H., Sidler, H.F.A., 2004. The

Development of Turby, A Small Vawt for the Built Environment. In:

Proceedings of the Global Windpower 2004 Conference and Exhibition, pp. 1–10

Wheeler, A., Ganji, A., 2009. Introduction to Engineering

Experimentation. 3rd Edition. USA: Pearson

Wiser, R., Rand, J., Seel, J., Beiter, P., Baker, E., Lantz, E., Gilman,

P., 2021. Expert Elicitation Survey Predicts 37% to 49% Declines in Wind Energy

Costs by 2050. Nature Energy, Volume 6(5), pp. 555–565. https://doi.org/10.1038/s41560-021-00810-z