The Bibliometric Analysis of 3D Printer Research Development and Opportunities in Indonesia

Corresponding email: herianto@ugm.ac.id

Published at : 28 May 2025

Volume : IJtech

Vol 16, No 3 (2025)

DOI : https://doi.org/10.14716/ijtech.v16i3.6059

Mastrisiswadi, H, Herliansyah, MK, Sari, WP, Tontowi, AE & Herianto 2025, ’The bibliometric analysis of 3D printer research development and opportunities in Indonesia’, International Journal of Technology, vol. 16, no. 3, pp. 865-881

| Hasan Mastrisiswadi | 1. Department of Mechanical and Industrial Engineering, Universitas Gadjah Mada, Indonesia 2. Department of Industrial Engineering, Universitas Pembangunan Nasional Veteran Yogyakarta, Indonesia |

| Muhammad Kusumawan Herliansyah | Department of Mechanical and Industrial Engineering, Universitas Gadjah Mada, Indonesia |

| Wangi Pandan Sari | Department of Mechanical and Industrial Engineering, Universitas Gadjah Mada, Indonesia |

| Alva Edy Tontowi | Department of Mechanical and Industrial Engineering, Universitas Gadjah Mada, Indonesia |

| Herianto | Department of Mechanical and Industrial Engineering, Universitas Gadjah Mada, Indonesia |

Indonesia is a large country in the ASEAN region with great potential to apply 3D printing technology. However, due to the archipelagic nature of the territory, the distribution process between islands is time consuming and expensive. The problems were promoted by the government to move the National Capital to other islands to improve efficiency and affordability of distribution channels. With respect to this analysis, 3D printers is a solution to the logistical challenges because it presented an opportunity for technology development in the 4.0 era. The finished products have numerous advantages such as low cost, fast process, creation of complex shapes with simple processes, and enabled the use of various materials. Therefore, this research aimed to determine how the opportunities associated with the use of 3D printers will be determined in the future. The bibliometric analysis method was used to quantitatively overview the research. The results showed that the growth of 3D printers in Indonesia increased annually by 14.6% in various fields of science. Additionally, it explored Indonesia global position, frequently targeted publications, institutions with the highest contribution, collaborating countries, prevalent topics, and future prospects.

3D printer; Bibliometric analysis; Indonesia; Literature review

Indonesia is the country with the most significant manufacturing value added in ASEAN in 2017 (Innovation, 2019). The country has a massive landmass, which is even larger than the total area of 11 Western European countries. Meanwhile, as an archipelagic country, most economic activities are centered on Java Island. This concentration resulted in lower product prices on this island compared to the others, due to distance constraints and expensive sea or air transportation. The government is currently working towards building a more affordable and faster route to connect the islands, aiming for a more evenly distributed economy. Additionally, the plan of the Indonesian government to move the National Capital to Kalimantan, also served as a catalyst for the development of this distribution channel.The developmental process was supported by industry 4.0, a revolution used to transformed human life through advanced technologies connected to cloud services. The evolution era facilitated the rapid and straight forward integration of various systems, which is widely developed and widely adopted technologies in industrial 4.0 era known as 3D printing. This printing process can be carried out in a relatively faster time, used to make products with complex geometries, have easier operations, uses various materials, and lower production costs (Ambrus et al., 2019; Skawi?ski and Goetzendorf-Grabowski, 2019; Vilardell et al., 2019; Boyard et al., 2018; Tofail et al., 2018; Aremu et al., 2017). These advantages attracted multiple industries, including aerospace, military, food, manufacturing, automotive, electronics, etc (Herianto et al., 2020). Initially, 3D printing technology was used for rapid prototyping, creating product prototypes in a short period and produce finished products. However, due to the nature of adding material sequentially, this technology is also called layered manufacturing (Esslinger and Gadow, 2020; Fountas et al., 2020; Honarvar and Varvani-Farahani, 2020; Khosravani and Reinicke, 2020; Matos and Jacinto, 2019; Ngo et al., 2018; Rinaldi et al., 2018; Song et al., 2018).

The evolution of 3D

printing technology helped to address the economic distribution challenges

faced by Indonesia, and supports the relocation of the National Capital to

another island. The technology prevents the need for expensive sea or air

transportation costs.

The literature review method

served as a valuable tool for summarizing and synthesizing technological

advancements (Donthu et al., 2021). Technology, has been applied in

various fields such as logistics (Cano et al., 2021), lean manufacturing (Driouach et al., 2019), Digital employee experience (Moganadas and Goh, 2022), and Labor Force (Mudzar and Chew, 2022). The literature review method

was also used to assess the development of additive manufacturing technology.

However, complexities were experienced because the number of publications were

too large with broad topics. Meanwhile, to address these challenges,

bibliometric analysis, offered a solution to effectively present current

research development within a specific topic (Donthu et al., 2021).

Bibliometric analysis had been

widely applied in several research fields. Ahmed et al. (2021), conducted a bibliometric review focusing on

3D printing research during the Covid-19 pandemic. Similarly, bibliometric analyses had been used to explore 3D printing

applications in the health sector (Lin et al., 2023; Yang et al., 2023; Jin et al., 2022), food (Fasogbon and Adebo, 2022), and robotics (Aghimien et al., 2020). Presently, the

research on 3D printing technology in Indonesia is lower compared to other

nations such as China, America, Germany, Australia, and Japan. The present

investigation addresses this disparity by discussing the current and potential

future directives of 3D printing research in Indonesia. It serves as a valuable

guide for several research conducted globally and offers insights that

facilitate the collaboration of other countries, and individual cooperations.

Research

Question

The research questions and

objectives were used to identify, collect and analyze data. The bibliographic

review was used to address the following questions and objectives, namely

Q1: What is the comparative

position of 3D printing research in Indonesia on a global scale?

O1: The answer to this question

aims to determine the position of 3D printing research globally, providing

insights into the necessary efforts, and technological readiness required for

competitiveness in Industry 4.0.

Q2: How does the development of

publication numbers and citations in 3D printing research relate to Indonesia?

O2: The answer to this question

aims to explain the history of 3D printing research in Indonesia and the

concurrent efforts to advance additive manufacturing technology, through

research development.

Q3: How does the characteristic

of the published manuscript relate to 3D printing in Indonesia?

O3: The answer to this question

aims to analyze the distribution of publications and identify potential target

journals for further research. Additionally, it seeks to evaluate the quality

of these publications in order to identify areas for improvement.

Q4: Which institution contributes

significantly to the number of documents related to the theme of 3D Printing in

Indonesia?

O4: The answer to this question

aims to map the distribution of institutions that have conducted 3D printing

research, providing valuable data for potential collaborations in research,

patents, or manufacturing endeavors.

Q5: Which countries collaborate

with Indonesia regarding the theme of 3D printing?

O5: The answer to this question

aims to identify existing collaborative research relationships related to 3D

printing as well as assess the strength. Furthermore, it seeks to explore

potential collaborative opportunities that have not yet been established but

show promise.

Q6: What are the frequent topics

covered in 3D printing-themed publications in Indonesia?

O6: The answer to this question aims to identify prevalent research themes within 3D printing analyses carried out in Indonesia. The aim is to strengthen existing research areas and uncover unexploited potentials, thereby enhancing the novelty and increasing the number of publications in the country.

Method

The bibliometric analysis method was used to address the research questions, as well as analyze the literature to obtain a comprehensive understanding of the topic being studied. In addition, several research have adopted this method with data collected from articles indexed by Scopus (Ahmad et al., 2020; Huang et al., 2020; Martínez-López et al., 2018; Merigó and Yang, 2017; Rey-Martí et al., 2016). The objective of the bibliometric analysis was to examine reports on 3D Printing, discovering the history, development, opportunities, and future directions for research. A search query was used twice to ascertain the global research position on 3D printing, and ascertain the position of ss Indonesia. These searches were conducted on Monday, August 29, 2022, at 4:22 p.m.

First search query: TITLE-ABS-KEY ("3d print" OR "3d printing" OR "additive manufacturing" OR "additive manufacture" OR "Layered manufacture" OR "Layered manufacturing" OR "3d-print" OR "3D-printing" OR "Selective Laser Sintering" OR "Stereolithography" OR "Digital Light Processing" OR "Electronic Beam Melting" OR "Selective Laser Melting" OR "Fused Deposition Modelling" OR "Laminated object manufacturing" OR "Photopolymer jet" OR "Ployjet" OR "Direct ink writing" OR "Fused filament fabrication").

Second search query: TITLE-ABS-KEY ("3d print" OR "3d printing" OR "additive manufacturing" OR "additive manufacture" OR "Layered manufacture" OR "Layered manufacturing" OR "3d-print" OR "3D-printing" OR "Selective Laser Sintering" OR "Stereolithography" OR "Digital Light Processing" OR "Electronic Beam Melting" OR "Selective Laser Melting" OR "Fused Deposition Modelling" OR "Laminated object manufacturing" OR "Photopolymer jet" OR "Ployjet" OR "Direct ink writing" OR "Fused filament fabrication") AND ( LIMIT-TO ( AFFILCOUNTRY , "Indonesia") ). The first query was used to find publication data worldwide, while the second was for Indonesia, accomplished by adding a limitation query using LIMIT-TO (AFFILCOUNTRY, “Indonesia”).

The query was based on both common keywords and specific methods related to 3D printing, intended to capture more relevant articles. This method ensured that even articles using less common terminology were included. In addition, data processing was carried out using vosviewer (Van Eck and Waltman, 2010) and biblioshiny software (Aria and Cuccurullo, 2017).

4.1. The

position of 3D printing research in Indonesia compared to the world

Indonesia lags

significantly in 3D printing research, ranking 45th in the number of

publications compared to other countries such as America, China, Australia and

Russia as shown in Table 1. Additionally, there is an annual increase in the

global interest in 3D printing continues with 86 publications already expected

in 2023, as shown in Figure 1, which means Indonesia need to intensify the

research efforts in this field.

3D printing technology is a major part of the industrial revolution 4.0. As the world continues to advance, the application of sophisticated 3D printing would become more widespread. When Indonesia fails to bridge this gap, it risks falling significantly behind other countries in the future. Furthermore, research can be conducted independently or in collaboration with other countries, and such selection would be based on the number of publications made, as shown in Table 1.

Figure 1 The development of publications (1970-2023)

Table 1 Top 50 countries by number of publications related to 3D print topics

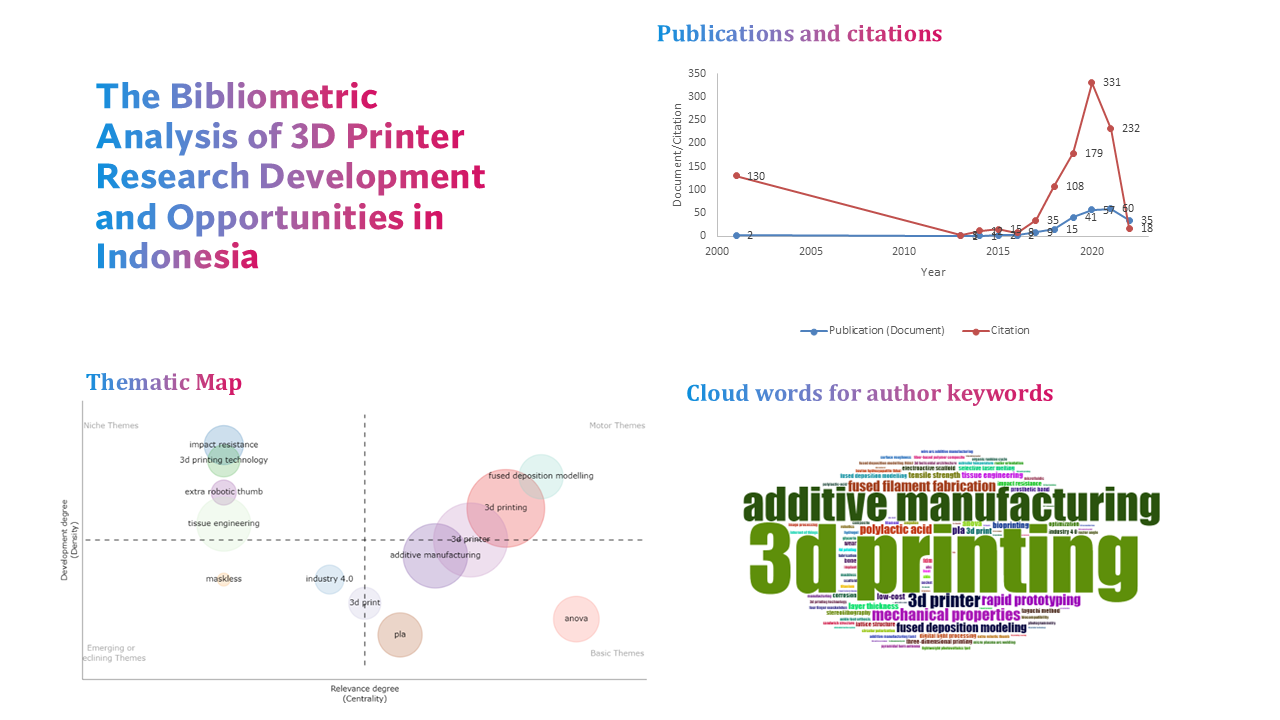

4.2. The

Publications in Indonesia

In Indonesia, 3D printing publications started in 2001, with only two

research that have been cited 130 times. After the initial research, there was

a gap till 2013, when the number continued to grow until 2021. In mid-2022, the

number of manuscripts was greater than 50% of the total in the previous year as

shown in Figure 2. The number of citations also increased rapidly,

outperforming the growth in publications. The annual growth rate of documents

is approximately 14.6%, and the most cited manuscript being Tontowi A. E. in

2001, with a total of 114 citations in the Rapid Prototyping Journal (Tontowi and

Childs, 2001) as shown in Table 2.

Figure 2 Publications and citations in Indonesia

Table 2 Most cited document in Indonesia

|

Paper |

Total

Citations |

|

Tontowi Ae,

2001, Rapid Prototyping J |

114 |

|

Arif Mf,

2020, Compos Part B: Eng |

70 |

|

Ilyas Ra,

2021, Polym |

67 |

|

Shie M-Y,

2019, Polym |

54 |

|

Wibowo A,

2020, Mater |

43 |

|

Das Ak, 2020,

S Afr J Bot |

39 |

|

Kristiawan

Rb, 2021, Open Eng |

37 |

|

Rosli Na,

2021, J Mater Res Technol |

31 |

|

Gojzewski H,

2020, Acs Appl Mater Interfaces |

30 |

|

Zadi-Maad A,

2018, Iop Conf Ser Mater Sci Eng |

23 |

|

Gudjónsdóttir

M, 2019, Magn Reson Chem |

18 |

|

Wahyudi Ah,

2018, Ieee Int Workshop Antenna Technol, Iwat - Proc |

18 |

|

Nasrullah

Aih, 2020, Structures |

16 |

|

Suteja Tj,

2020, J Phys Conf Ser |

16 |

|

Hsiao Cc,

2001, Adv Space Res |

16 |

|

Nurhudan Ai,

2021, J Manuf Processes |

15 |

|

Marbelia L,

2020, J Membr Sci |

15 |

|

Triyono J,

2020, Open Eng |

15 |

|

Rismalia M,

2019, J Phys Conf Ser |

15 |

|

Tanoto Yy,

2017, Aip Conf Proc |

15 |

|

Dwiyati St,

2019, J Phys Conf Ser |

13 |

|

Nugroho A,

2018, J Phys Conf Ser |

13 |

|

Syuhada G,

2018, Aip Conf Proc |

12 |

|

Arifin M,

2015, Energy Procedia |

12 |

|

Suwandi D,

2014, Appl Mech Mater |

12 |

The 3D printing technology developed in 2001 was a selective laser

sintering method. The expensive cost of tools and materials posed a significant

challenge to further research. Regardless of the database and parameters used,

the research on 3D printing did not completely stop between 2001 and 2013. Instead, it was not detected in the search queries due to several

factors such as unindexed journals, language barriers, or the use of more

specific keywords related to material development, machine features, etc. For

example, the research on laser sintering had been carried out since 1997, but

these investigations were published in Bahasa and were not indexed in the

Scopus database.

The number of research increased rapidly after 2013, coinciding with the development of fused deposition modeling technology (FDM) in Indonesia. This method shown in Figure 3, gained popularity due to the affordability and ease of use compared to selective laser sintering in terms of machinery and materials. In addition, advanced technological development made FDM more accessible, leading to an increase in research on 3D printing across various scientific fields. Engineering accounted for 27 percent of the research, followed by physics and astronomy, materials and computer sciences at 14%, 13%, and 10%, respectively. Other fields, such as environmental, chemistry, mathematics, earth sciences, business, etc also had significant contribution as shown in Figure 4(a).

Figure 3 Publication Timeline based on the top 20 authors with

the most publications

Figure 4 (a) Subject of research, and (b) Document types

4.3. Publication

characteristics

Based on the data obtained, majority of the 3D printing

research in Indonesia was dominated by conference papers (51%), followed by

articles (41%). While the review papers constituted only 7% and the book

chapter represented only 1% as shown in Figure 4(b). The highest number of

publications were found in the AIP Conference, totaling 23 articles, followed

by the IOP Conference Series materials, science, engineering and the Journal of

physics, each with 17 articles. In accordance with this data, it was observed

that the most publications were conference papers centered on these three

sources, mainly due to extensive collaboration between international seminars

in Indonesia and the publishers. It led to an opportunity for other publishers

to cooperate with the organizers of international seminar in Indonesia

considering the enormous market potential of the country.

The journals hosting research publications on 3D printing

were mainly of high quality, with a prevalence of Q1 and Q2 journals as shown

in Table 3. This indicated that the research conducted in Indonesia was of

outstanding quality, regardless of the minimal quantity. Based on the data

obtained, Polymers was the most cited journal with 140 citations, followed by

the rapid prototyping journal with 125.

Table 3 The top sources based on citations per document (excluding proceeding)

4.4. Institutions contributing

to 3D printer research in Indonesia

Indonesia has thousands of universities spread across all parts of the

archipelago. From the data obtained, research related to 3D printing also

collaborated with other universities abroad. Furthermore, Universitas Gadjah

Mada leads in the number of publications on this topic, followed by Universitas

Indonesia and the Institut Teknologi Bandung as shown in Table 4. These top

three ranking institutions are located in different regions, namely Yogyakarta,

Jakarta, and Bandung.

Table 4 The number of publications by affiliation

Despite this geographic diversity, the research on 3D printing is

mainly centered on the island of Java. Regarding the number of documents

published, Whulanza (Nurhudan et al.,

2021; Varian and Whulanza, 2021; Charmet et al., 2020; Nunut et al., 2020;

Alief et al., 2019a; 2019b; Istiyanto et al., 2019; Syuhada et al., 2018;

Whulanza et al.,2018; Damayanti et al., 2017; Suwandi et al., 2014) from the Universitas

Indonesia ranked first with 11 papers, followed by Ariyanto et al. (2019, 2018), Taqriban et

al., 2019, and Ismail (2022; 2020; 2017) from Universitas Diponegoro,

Herawan (Che Mat et al., 2022; Mat et al., 2022; Rosli et al., 2022;

2021; Alkahari et al., 2021; Damanhuri et al., 2021; Ramli et al., 2020) from Universitas Bina

Nusantara, and J. Triyono (Sukanto et al., 2020;

Triyono et

al., 2020a; 2020b; 2019; Achdianto et al., 2019; Solechan et al., 2019; Tontowi et al,

2015) from Universitas Sebelas Maret with seven documents each as shown in

Table 5. The collaboration network between institutions on the theme of 3d

printing in Figure 5(a), showed that some affiliates even cooperated with the

counterparts abroad.

Figure 5(b), illustrated that

the keywords for research at Universitas Gadjah Mada focused on FDM technology,

measurement of mechanical properties or surface roughness, and the use of PLA

as the primary material. However, recent research

indicated an interest in the following keywords metal printing, composite, and

framework. Figure 5(c) showed that the direction of research conducted by

Universitas Indonesia was oriented towards the medical field with keywords such

as clinical applications, treatment planning, penetrating cost,

biocompatibility, binders, and ankle foot orthosis prominently featured.

Meanwhile, Figure 5(d), illustrated the broad application of 3D printing

technology. The research conducted at Institut Teknologi Bandung focused on the

health sector, particularly bone tissue engineering, anti-infection scaffold,

the generation of absorbable, and biodegradable implants. Additionally, there

was a reappearance of research on horn antennas in 2021. The absence of

significant representation of medical-related research topics in Figure 4(a)

suggested that the direction of development gained prominence only in 2021.

There are numerous opportunities for furthering the application of this technology. Meanwhile, Universitas Gadjah Mada had adopted a slightly different step with the following keywords metal printing and composite. The opportunities for developing these two materials are also huge, considering that weaknesses in FDM technology are often limited to mechanical properties or surface roughness.

Table 5 Top 3D print researchers in Indonesia

|

AUTHOR NAME |

Affiliation |

Publication (Documents) |

H-index |

|

Whulanza, Y. |

Universitas Indonesia |

11 |

11 |

|

Ariyanto, M. |

Universitas Diponegoro |

7 |

9 |

|

Herawan, S.G. |

Universitas Bina Nusantara |

7 |

6 |

|

Ismail, R. |

Universitas

Diponegoro |

7 |

10 |

|

Triyono, J. |

Universitas Sebelas Maret |

7 |

6 |

|

Arifvianto, B. |

Universitas

Gadjah Mada |

6 |

10 |

|

Herianto |

Universitas Gadjah Mada |

6 |

11 |

|

Mahardika, M. |

Universitas

Gadjah Mada |

6 |

14 |

|

Muflikhun, M.A. |

Universitas Gadjah Mada |

6 |

8 |

|

Munir, A. |

Institut

Teknologi Bandung |

6 |

15 |

4.5. Countries

Collaborating with Indonesia

In respect to 3D printing research, 37 countries collaborated with

Indonesia as shown in Figure 5 (e). Based on the results of the analysis

carried out using VOS viewer software, seven clusters were obtained, and

divided as follows

Cluster 1:

Bangladesh, Brazil, India, Nepal, Sweden, Thailand, Vietnam

Cluster 2: Argentina,

Bolivia, Italy, Japan, South Korea, Turkey, United Kingdom

Cluster 3: Bulgaria,

Iraq, Malaysia, Pakistan, Slovakia, Tanzania

Cluster 4: Australia,

Brunei Darussalam, Netherlands, Poland, Saudi Arabia, Singapore

Cluster 5: Germany,

Hungary, New Zealand, Taiwan, United Arab Emirates, United States

Cluster 6: Iceland,

Indonesia, Portugal, Russian Federation

Cluster 7: Belgium,

Philippines

Examining the visualization results of cooperation between countries as showed in Figure 6, illustrated the extent of the relationship in conducting 3D printing in Indonesia. However, China, a major contributor to research related to this topic, has not collaborated with Indonesia or several African countries.

Figure 5 (a) Collaboration between institutions; Research's keyword visualization conducted by (b) Universitas Gadjah Mada; (c) Universitas Indonesia; (d) Institut Teknologi Bandung; (e) Collaboration between countries; (f) VOS viewer visualization for author's keyword; (g) Cloud word for author keywords

Figure

6 Collaboration map between countries

4.6. Frequently

occurring topics

The prevalence of topics are measured by the number of appearances in

keywords from the author, which are connected in Figure 5(f). Lighter or yellow

color indicates a new topic in 2022, while darker shades denotes a pre-existing

issue.

Figure 5(g) showed the most frequently appearing words, namely 3D

printing, additive manufacturing, fused filament fabrication, 3d printer, rapid

prototyping, mechanical properties, fused deposition modeling, polylactic acid,

PLA, etc. The frequently used methods were FDM and FFF, which both require

extrusion materials. While these methods offer cost-effectiveness and

flexibility, challenges persist in achieving precision and smoothness in the

final product. Keywords such as PLA or polylactic acid, were commonly used in

FDM, with options including ABS, conductive, and flexible materials. The

prominence of mechanical properties in the results indicated that 3D printing

research in Indonesia is still in the early stages of testing the strength

quality, with fewer explorations into broader applicable themes.

3D printing technology is increasingly considered as a substitute for manufacturing products or components made of various materials, including metals. However, challenges persist, particularly related to the mechanical properties. Several factors such as speed, nozzle, bed temperatures, nozzle size, printing direction and patternsignificantly influence these properties during the manufacturing process. Therefore, the continuous development of mechanical properties is critical for the advancement of this technology.

Figure

7 Thematic Map

The research on 3D printing focused on both technological advancements

and the development of suitable materials. Although not directly connected to

the keywords used, the research on materials is essential for advancing this

technology in the country. Furthermore, the exploration of various application

of 3D printing technology in the medical, culinary, and electronic sectors is

in progress. The support from the government, companies, society, and all

parties is crucial for fostering the development of this technology.

Figure

8 Relationship between cited

source, author, and keyword author

The thematic map based on the author keywords describes four quadrants

representing the positioning of 3d printing research in Figure 7. The niche

themes comprised impact resistance, 3d printing technology, extra robotic

thumb, and tissue engineering. Motor themes, consisted of the following

keywords fused deposition modeling, 3d printing, and printer. The evolving or

disappearing themes include maskless and industry 4.0, while the basic themes

were PLA and ANOVA. Figure 8 shows the relationship between the cited sources

on the left, authors in the middle, and author keywords on the right. In

addition, the relationship illustrated how cited sources inspired authors in

producing various keywords.

4.7. Discussion

The results of the

bibliometric analysis showed that research on 3D printing in Indonesia mainly

focused on mechanical properties. Meanwhile, several research opportunities can

be carried out, such as 3D printing research in food (Enfield et al.,

2022; Tejada-Ortigoza and Cuan-Urquizo, 2022; Zhang et al., 2022), health (Paradowska-Stolarz et al., 2022; Punia et al., 2022; Asriyanti

et al., 2022), jewelry (Abisuga et al.,

2022; Gaber Al-Khulaqi et al., 2022; Soares, 2022), robotics (Crowley et al.,

2022; Shorthose et al., 2022; Zhou et al., 2022), etc.

Based on in-depth observations, it was discovered

that the main research focus of the three most influential universities in 3D

printing included metals, composites, antennas, and medical applications. In

the future, these areas would undoubtedly become the axis of research in

Indonesia, considering the enormous opportunities. Effective collaboration

among the institutions led to the formation of particular research clusters,

synergizing without redundancy. However, this division must be carefully

analyzed to ensure consistency. The proactive participation of the government

and relevant associations was crucial to realize research development in the

desired direction.

Publicization was widely carried out in proceedings,

indicating ongoing advancements in 3D printing technology. The proceedings

served as markers, signifying pioneering research in the field. It provided the

fastest media for disseminating research when compared to journals. Moreover,

future research opportunities in 3D printing would be significantly developed.

Publications in the form of articles, turned out to be able to penetrate

high-quality journals. Meanwhile, Universitas Gadjah Mada, Universitas Indonesia,

and the Institut Teknologi Bandung significantly contributed to the number of

documents related to research in this field.

There were at least 37 countries that collaborated

with Indonesia in the development of this technology. However, this number

could still be increased further to promote more publications in the country.

Certain countries, such as China and several African nations were yet to engage

in collaboration efforts.

Indonesia mainly focused on FDM and FFF methods in

3D printing, overlooking other available options that could address the needs

of the nation. Despite the cost-effectiveness, and accessibility of these

methods, its usage posed challenges related to mechanical properties influenced

by various factors. Therefore, investigating the influence of factors on

mechanical properties and quality dimensions was essential. The research in

this field was extensive, which led to the need for further exploration.

The material used also focused on PLA with the theme

of mechanical properties, due to the widespread availability, affordability,

and versatility in terms of texture and color. Indonesia had barely explored

the potential of other materials and the industrial applications. Despite the

growing demand for specific materials, such as those used for edible products,

biomaterials for prosthetic limbs, conductive materials for electronics, as

well as magnetic materials for various industrial purposes, further research

and development were needed. As the application of 3D printing continued to

expand, the need for specialized materials increased, driving a surge in

research activities in this field. PLA is also the keyword

that appeared most often in 3D printing research in Indonesia. This affordable

and easy to obtain filament is commonly used in melt deposition modeling

methods. However, various materials with unique characteristics are available

and being sold freely to provide new research potential. These include

conductive (Pejak Simunec and

Sola, 2022; Stefano et al., 2022), magnetic (Amirov et al.,

2022), and flexible materials (Herianto et al.,

2019).

Preliminary research conducted in Indonesia showed

promising quality and potentials for collaboration with counterparts from other

affiliates and countries. Additionally, these research though in the early

stages had the potential for further development, particularly in obtaining the

final product and societal applications. Various themes such as perceptions,

consumer needs, business implications, reciprocity, etc were open for

exploration. The versatility of 3D printing technology enabled the generation of

complex and artistic shapes, offering opportunities across diverse industrial

sectors such as food, medicine, military weapons, sensors, electronics,

automotive, medical devices, prosthetics, etc. Indonesia presented a

substantial market for both research endeavors and practical applications of 3D

print technology outcomes.

In conclusion, 3D printing research in Indonesia was

still minimal compared to global standards. The research on this topic

increased at an annual rate of 14.6 percent and continued. Despite the

relatively few numbers of publications, the quality was commendable. The

research on 3D printing was centered on Java Island, which made the development

on other islands a significant challenge. Assuming this technology could be

acquired later, distributing manufacturing products between islands, which

required a lot of cost and time, would be resolved. Indonesia had already

collaborated with 37 other countries and was expected to increase it even

further. The bibliometric analysis provided a complete overview of the 3D

printing research map as well as identified future research opportunities.

However, it failed to focus deeply on the specific development of this

technology in the country. Therefore, the results obtained were supplemented

with a literature review focused on a particular research theme in the field of

3D printing. This method contributed to the advancement of additive

manufacturing technology in Indonesia.

We would like to thank the Indonesian Education Scholarship (BPI), the Center for Higher Education Funding and Assessment Ministry of Higher Education, Science, and Technology of the Republic of Indonesia, and the Indonesia Endowment Fund for Education (LPDP) for supporting this research.

Author

Contributions

H. Mastrisiswadi: conceptualization, data collection, analysis, writing-review & editing; M.K. Herliansyah: conceptualization, analysis, and supervision; W.P. Sari: conceptualization, review & editing, and supervision; A.E. Tontowi: supervision; and Herianto: conceptualization and supervision.

Conflict of Interest

The

authors declare no conflict of interest.

Abisuga, OA,

Doran, K & de Beer, D 2022, 'Study of investment casting process for 3D

printed jewellery design', In: MATEC Web of Conferences, vol. 370,

article 04002, https://doi.org/10.1051/matecconf/202237004002

Achdianto,

Cahyati, S, Triyono, & Saifudin 2019, 'Integrated CAD customization system

for fused deposition models in additive manufacture with 3D printing machine',

In: IOP Conference Series: Materials Science and Engineering, vol. 694,

no. 1, article 012008, https://doi.org/10.1088/1757-899X/694/1/012008

Aghimien, DO,

Aigbavboa, CO, Oke, AE & Thwala, WD 2020, 'Mapping out research focus for

robotics and automation research in construction-related studies: A

bibliometric approach', Journal of Engineering, Design and Technology,

vol. 18, no. 5, pp. 1063-1079, https://doi.org/10.1108/JEDT-09-2019-0237

Ahmad, P, Asif,

JA, Alam, MK, & Slots, J 2020, 'A bibliometric analysis of Periodontology

2000', Periodontology 2000, vol. 82, no. 1, pp. 286-297, https://doi.org/10.1111/prd.12328

Ahmed, A, Azam,

A, Bhutta, MMA, Khan, FA, Aslam, R, & Tahir, Z 2021, 'Discovering the

technology evolution pathways for 3D printing (3DP) using bibliometric

investigation and emerging applications of 3DP during COVID-19', Cleaner

Environmental Systems, vol. 3, article 100042, https://doi.org/10.1016/j.cesys.2021.100042

Alief, NA,

Supriadi, S & Whulanza, Y 2019a, 'Modelling the shape memory properties of

4D printed polylactic acid (PLA) for application of disk spacer in minimally

invasive spinal fusion', In: AIP Conference Proceedings, vol. 2092, no.

1, article 020005, https://doi.org/10.1063/1.5096673

Alief, NA,

Utomo, MS, Kartika, I, & Whulanza, Y 2019b, 'Geometrical and mechanical

performance of multi-material fused deposition modelling', In: IOP

Conference Series: Materials Science and Engineering, vol. 557, no. 1,

article 012022, https://doi.org/10.1088/1757-899X/557/1/012022

Alkahari, MR,

Rosli, NA, Majid, SNA, Maidin, S, Herawan, SG, & Ramli, FR 2021,

'Properties of 3D printed structure manufactured with integrated pressing

mechanism in FDM', Journal of Mechanical Engineering Research and

Developments, vol. 44, no. 2, pp. 122-131

Ambrus, R, Alshweiat, A, Csóka, I, Ovari, G, Esmail, A, & Radacsi, N

2019, '3D-printed electrospinning setup for the

preparation of loratadine nanofibers with enhanced physicochemical properties',

International Journal of Pharmaceutics, vol. 567, article 118455, https://doi.org/10.1016/j.ijpharm.2019.118455

Amirov, A,

Omelyanchik, A, Murzin, D, Kolesnikova, V, Vorontsov, S, Musov, I, Musov, K,

Khashirova, S, & Rodionova, V 2022, '3D printing of PLA/magnetic ferrite

composites: effect of filler particles on magnetic properties of filament', Processes,

vol. 10, no. 11, article 2412, https://doi.org/10.3390/pr10112412

Aremu, AO,

Brennan-Craddock, J, Panesar, A, Ashcroft, IA, Hague, RJM, Wildman, RD &

Tuck, CJ 2017, 'A voxel-based method of constructing and skinning conformal and

functionally graded lattice structures suitable for additive manufacturing', Additive

Manufacturing, vol. 13, pp. 1-13, https://doi.org/10.1016/j.addma.2016.10.006

Aria, M &

Cuccurullo, C 2017, 'Bibliometrix: An R-tool for comprehensive science mapping

analysis', Journal of Informetrics, vol. 11, no. 4, pp. 959-975, https://doi.org/10.1016/j.joi.2017.08.007

Ariyanto, M,

Ismail, R, Setiawan, JD, & Yuandi, EP 2019, 'Anthropomorphic transradial

myoelectric hand using tendon-spring mechanism', Telkomnika

(Telecommunication Computing Electronics and Control), vol. 17, no. 1, pp.

537-548, https://doi.org/10.12928/TELKOMNIKA.v17i1.11600

Ariyanto, M,

Setiawan, JD, Ismail, R, Haryanto, I, Febrina, T, & Saksono, DR 2018,

'Design and characterization of low-cost soft pneumatic bending actuator for

hand rehabilitation', In: Proceedings of the 5th International Conference on

Information Technology, Computer and Electrical Engineering (ICITACEE), pp.

45-50, https://doi.org/10.1109/ICITACEE.2018.8576909

Asriyanti, Saptaji, K, Khoiriyah, N, Utomo, MS, Dwijaya,

MS, Nadhif, MH, Triawan, F 2022, 'Fabrication of rigid polyurethane foam lumbar

spine model for surgical training using indirect additive manufacturing', International Journal of Technology,

vol. 13, no. 8, pp. 1612-1621, https://doi.org/10.14716/ijtech.v13i8.6125

Boyard, N, Christmann, O, Rivette, M, Kerbrat, O, &

Richir, S 2018, 'Support optimization for additive manufacturing: Application

to FDM', Rapid Prototyping

Journal, vol. 24, no. 1, pp. 69-79, https://doi.org/10.1108/RPJ-04-2016-0055

Cano, JA,

Gómez-Montoya, RA, Salazar, F & Cortés, P 2021, 'Disruptive and

conventional technologies for the support of logistics processes: A literature

review', International Journal

of Technology, vol. 12, no. 3, pp. 448-460, https://doi.org/10.14716/ijtech.v12i3.4280

Charmet, J,

Rodrigues, R, Yildirim, E, Challa, PK, Roberts, B, Dallmann, R, & Whulanza,

Y 2020, 'Low-cost microfabrication toolbox', Micromachines,

vol. 11, no. 2, article 135, https://doi.org/10.3390/mi11020135

Che Mat, MA,

Ramli, FR, Sudin, MN, Herawan, SG, Mat, MS, & Alkahari, MR 2022, 'The

effects of varying oxygen concentrations on tensile strength and surface

roughness of 3D printer', In: Proceedings

of the 7th International Conference and Exhibition on Sustainable

Energy and Advanced Materials, pp. 52-56, https://doi.org/10.1007/978-981-19-3179-6_11

Crowley, GB,

Zeng, X & Su, HJ 2022, 'A 3D printed soft robotic gripper with a variable

stiffness enabled by a novel positive pressure layer jamming technology', IEEE Robotics and Automation Letters,

vol. 7, no. 2, pp. 5477-5482, https://doi.org/10.1109/LRA.2022.3157448

Damanhuri, AAM,

Hariri, A, Ghani, SA, Mustafa, MSS, Herawan, SG, & Paiman, NA 2021, 'The

effects of virgin and recycled PA12 powders in SLS processes on occupational

exposures', International

Journal of Environmental Science and Development, vol. 12, no. 11,

pp. 339-345, https://doi.org/10.18178/IJESD.2021.12.11.1359

Damayanti, I,

Lilies, L & Latief, BS 2017, 'Three-dimensional (3-D) model utilization for

fracture reconstruction in oral and maxillofacial surgery: A case report', In: AIP Conference Proceedings,

vol. 1817, p. 040005, https://doi.org/10.1063/1.4976790

Donthu, N,

Kumar, S, Mukherjee, D, Pandey, N & Lim, WM 2021, 'How to conduct a

bibliometric analysis: An overview and guidelines', Journal of Business Research, vol. 133, pp. 285-296,

https://doi.org/10.1016/j.jbusres.2021.04.070

Driouach, L,

Zarbane, K & Beidouri, Z 2019, 'Literature review of lean manufacturing in

small and medium-sized enterprises', International

Journal of Technology, vol. 10, no. 5, pp. 930-941, https://doi.org/10.14716/ijtech.v10i5.2718

Enfield, RE,

Pandya, JK, Lu, J, McClements, DJ, & Kinchla, AJ 2022, 'The future of 3D

food printing: Opportunities for space applications', Critical Reviews in Food Science and

Nutrition, vol. 63, no. 29, pp. 10079-10092, https://doi.org/10.1080/10408398.2022.2077299

Esslinger, S

& Gadow, R 2020, 'Additive manufacturing of bioceramic scaffolds by

combination of FDM and slip casting', Journal

of the European Ceramic Society, vol. 40, no. 11, pp. 3707-3713, https://doi.org/10.1016/j.jeurceramsoc.2019.10.029

Fasogbon, BM

& Adebo, OA 2022, 'A bibliometric analysis of 3D food printing research: A

global and African perspective', Future

Foods, vol. 5, article 100175, https://doi.org/10.1016/j.fufo.2022.100175

Fountas, NA,

Kechagias, JD, Manolakos, DE, & Vaxevanidis, NM 2020, 'Single and

multi-objective optimization of FDM-based additive manufacturing using

metaheuristic algorithms', Procedia

Manufacturing, vol. 51, pp. 740-747, https://doi.org/10.1016/j.promfg.2020.10.104

Gaber Al-Khulaqi, AA, Siran, Z & Khong, CW 2022, 'A

comparative study on the jewellery making process between traditional and 3D

printing methods for Islamic geometric patterns design (IGPs)', In: Proceedings of the International Symposium

on Humanities, Science and Sustainable Engineering (ISHuSSE), http://shdl.mmu.edu.my/id/eprint/10764

Herianto, H,

Atsani, S & Mastrisiswadi, H 2020, 'Recycled polypropylene filament for 3D

printer: Extrusion process parameter optimization', In: IOP Conference Series: Materials Science

and Engineering, vol. 852, article

012022, https://doi.org/10.1088/1757-899X/722/1/012022

Herianto,

Irawan, W, Ritonga, AS, & Prastowo, A 2019, 'Design and fabrication in the

loop of soft pneumatic actuators using fused deposition modelling', Sensors and Actuators A: Physical,

vol. 298, article 111556, https://doi.org/10.1016/j.sna.2019.111556

Honarvar, F

& Varvani-Farahani, A 2020, 'A review of ultrasonic testing applications in

additive manufacturing: Defect evaluation, material characterization, and

process control', Ultrasonics,

vol. 108, article 106227, https://doi.org/10.1016/j.ultras.2020.106227

Huang, Z, Chen,

H & Liu, Z 2020, 'The 100 top-cited systematic reviews/meta-analyses in

central venous catheter research: A PRISMA-compliant systematic literature

review and bibliometric analysis', Intensive

and Critical Care Nursing, vol. 57, article 102803, https://doi.org/10.1016/j.iccn.2020.102803

Innovation, T

2019, Additive manufacturing:

Adding up growth opportunities for ASEAN, Thyssenkrupp, Singapore

Ismail, R,

Ariyanto, M, Pambudi, KA, Syafei, JW, & Ananto, GP 2017, 'Extra robotic

thumb and exoskeleton robotic fingers for patient with hand function

disability', In: Proceedings of

the 4th International Conference on Electrical Engineering, Computer Science

and Informatics (EECSI), https://doi.org/10.1109/EECSI.2017.8239166

Ismail, R,

Ariyanto, M, Wicaksono, LR, Ispramuditya, A & Putri, FT 2022, 'The design

and analysis of low-cost myoelectric hand using six-bar linkage mechanism', Asia-Pacific Journal of Science and

Technology, vol. 27, no. 1, https://doi.org/10.14456/apst.2022.4

Ismail, R,

Taqriban, RB, Ariyanto, M, Atmaja, AT, Sugiyanto, Caesarendra, W, Glowacz, A,

Irfan, M, & Glowacz, W 2020, 'Affordable and faster transradial prosthetic

socket production using photogrammetry and 3D printing', Electronics, vol. 9, no. 9,

article 1456, https://doi.org/10.3390/electronics9091456

Istiyanto, J,

Adhitama, G, Zulkarnaen, BA, & Whulanza, Y 2019, 'Profile characteristics

of biomachined zinc', Journal of

Physics: Conference Series, vol. 1376, article 012032, https://doi.org/10.1088/1742-6596/1376/1/012032

Jin, B, Liu, Y, Du, S, Sang, X, Yang, H, & Mao, Y

2022, 'Current trends and research topics regarding liver 3D bioprinting: A

bibliometric analysis research', Frontiers

in Cell and Developmental Biology, vol. 10, article 1047524, https://doi.org/10.3389/fcell.2022.1047524

Khosravani, MR

& Reinicke, T 2020, '3D-printed sensors: Current progress and future

challenges', Sensors and

Actuators A: Physical, vol. 305, article 111916, https://doi.org/10.1016/j.sna.2020.111916

Lin, GX, Chen,

CM, Rui, G, & Hu, BS 2023, 'Research relating to three-dimensional (3D)

printing in spine surgery: A bibliometric analysis', European Spine Journal, vol.

32, no. 2, pp. 395-407, https://doi.org/10.1007/s00586-022-07409-2

Martínez-López,

FJ, Merigó, JM, Valenzuela-Fernández, L & Nicolás, C 2018, 'Fifty years of

the European Journal of Marketing: A bibliometric analysis', European Journal of Marketing,

vol. 52, no. 1/2, pp. 439-468, http://dx.doi.org/10.1108/EJM-11-2017-0853

Mat, MAC, Jamil,

N, Khalid, M, Hussin, MW, Kamaruddin, N & Kadir, A 2022, 'The effect of

tensile strength and surface roughness by varying oxygen level in 3D printer

chamber', Jurnal Tribologi,

vol. 33, pp. 80-96

Matos, F &

Jacinto, C 2019, 'Additive manufacturing technology: Mapping social impacts', Journal of Manufacturing Technology

Management, vol. 30, no. 1, pp. 70-97, https://doi.org/10.1108/JMTM-12-2017-0263

Merigó, JM &

Yang, JB 2017, 'A bibliometric analysis of operations research and management

science', Omega,

vol. 73, pp. 37-48, https://doi.org/10.1016/j.omega.2016.12.004

Moganadas, SR

& Goh, GGG 2022, 'Digital employee experience constructs and measurement

framework: A review and synthesis', International

Journal of Technology, vol. 13, no. 5, pp. 999-1012, https://doi.org/10.14716/ijtech.v13i5.5830

Mudzar, NMBM,

& Chew, KW 2022, 'Change in labour force skillset for the Fourth Industrial

Revolution: A literature review', International

Journal of Technology, vol. 13, no. 5, pp. 969-978, https://doi.org/10.14716/ijtech.v13i5.5875

Ngo, TD,

Kashani, A, Imbalzano, G, Nguyen, KTQ & Hui, D 2018, 'Additive

manufacturing (3D printing): A review of materials, methods, applications and

challenges', Composites Part B:

Engineering, vol. 143, pp. 172-196, https://doi.org/10.1016/j.compositesb.2018.02.012

Nunut, I, Whulanza, Y & Kassegne, S 2020, 'Testing of

beeswax printing technology in the design of a paper-based microfluidic

system', International Journal

of Technology, vol. 11, no. 5, pp. 1036-1045, https://doi.org/10.14716/ijtech.v11i5.4336

Nurhudan, AI,

Supriadi, S, Whulanza, Y & Saragih, AS 2021, 'Additive manufacturing of

metallic based on extrusion process: A review', Journal of Manufacturing Processes, vol. 66, pp.

228-237, https://doi.org/10.1016/j.jmapro.2021.04.018

Paradowska-Stolarz,

A, Malysa, A & Mikulewicz, M 2022, 'Comparison of the compression and

tensile modulus of two chosen resins used in dentistry for 3D printing', Materials, vol. 15, no. 24,

article 8956, https://doi.org/10.3390/ma15248956

Pejak Simunec, D

& Sola, A 2022, 'Emerging research in conductive materials for fused

filament fabrication: A critical review', Advanced

Engineering Materials, vol. 24, no. 7, article 2101476, https://doi.org/10.1002/adem.202101476

Punia, U,

Kaushik, A, Garg, RK, Chhabra, D, & Sharma, A 2022, '3D printable

biomaterials for dental restoration: A systematic review', Materials Today: Proceedings,

vol. 63, pp. 566-572, https://doi.org/10.1016/j.matpr.2022.04.018

Ramli, FR,

Nazan, MA, Alkahari, MR, Abdullah, MA, Sudin, MN, & Herawan, SG 2020,

'Dimensional accuracy of fused filament fabrication by cassava adhesion on

printing platform', Journal of

Advanced Manufacturing Technology, vol. 14, no. 2-1, pp. 149-158,

Rey-Martí, A,

Ribeiro-Soriano, D & Palacios-Marqués, D 2016, 'A bibliometric analysis of

social entrepreneurship', Journal

of Business Research, vol. 69, no. 5, pp. 1651-1655, https://doi.org/10.1016/j.jbusres.2015.10.033

Rinaldi, M,

Ghidini, T, Cecchini, F, Brandao, A, & Nanni, F 2018, 'Additive layer

manufacturing of poly(ether ether ketone) via FDM', Composites Part B: Engineering, vol. 145, pp. 162-172,

https://doi.org/10.1016/j.compositesb.2018.03.029

Rosli, NA,

Alkahari, MR, bin Abdollah, MF, Maidin, S, Ramli, FR, & Herawan, SG 2021,

'Review on effect of heat input for wire arc additive manufacturing process', Journal of Materials Research and

Technology, vol. 11, pp. 2127-2145, https://doi.org/10.1016/j.jmrt.2021.02.002

Rosli, NA,

Alkahari, MR, Ramli, FR, Abdollah, MFb, Kudus, SIA, & Herawan, SG 2022,

'Parametric optimisation of micro plasma welding for wire arc additive

manufacturing by response surface methodology', Manufacturing Technology, vol. 22, no. 1, pp. 59-70,

https://doi.org/10.21062/mft.2022.001

Shorthose, O,

Albini, A, He, L, & Maiolino, P 2022, 'Design of a 3D-printed soft robotic

hand with integrated distributed tactile sensing', IEEE Robotics and Automation Letters, vol. 7, no.

2, pp. 3945-3952, https://doi.org/10.1109/LRA.2022.3149037

Skawinnski, I

& Goetzendorf-Grabowski, T 2019, 'FDM 3D printing method utility assessment

in small RC aircraft design', Aircraft

Engineering and Aerospace Technology, vol. 91, no. 6, pp. 865-872, https://doi.org/10.1108/AEAT-07-2018-0189

Soares, ADLA

2022, 3D-printed jewelry: A new

era for online jewelry customization: Exploring consumer perceptions,

consumption drivers and barriers for the Portuguese online market,

PhD thesis, Universidade Catolica Portuguesa, Portugal

Solechan,

Rubijanto, JP, Triyono, J, & Pujiyanto, E 2019, 'Study of making implant

plate and screen of femur bone internal fixation from hydroxyapatite bovine and

polymer biodegradation material using 3D printers on mechanical strength', In: IOP Conference Series: Materials Science

and Engineering, vol. 494, no. 1, article 012070, https://doi.org/10.1088/1757-899X/494/1/012070

Song, Y, Yang,

Z, Liu, Y, & Deng, J 2018, 'Function representation based slicer for 3D

printing', Computer Aided

Geometric Design, vol. 62, pp. 276-293, https://doi.org/10.1016/j.cagd.2018.03.012

Stefano, JS, e

Silva, LRG, Rocha, RG, Brazaca, LC, Richter, EM, Muñoz, RAA, & Janegitz, BC

2022, 'New conductive filament ready-to-use for 3D-printing electrochemical

(bio)sensors: Towards the detection of SARS-CoV-2', Analytica Chimica Acta, vol. 1191, article

339372, https://doi.org/10.1016/j.aca.2021.339372

Sukanto, H,

Smaradhana, DF, Triyono, J, & Wicaksono, P 2020, 'Investigating the effect

of layer thickness on the product quality of PLA manufactured by 3D printing

technique', Lecture Notes in

Mechanical Engineering, pp. 811-818, https://doi.org/10.1007/978-981-15-4481-1_77

Suwandi, D, Whulanza, Y & Istiyanto, J 2014, 'Visible

light maskless photolithography for biomachining application', Applied Mechanics and Materials,

vol. 493, pp. 552-557, https://doi.org/10.4028/www.scientific.net/AMM.493.552

Syuhada, G,

Ramahdita, G, Rahyussalim, AJ, & Whulanza, Y 2018, 'Multi-material

poly(lactic acid) scaffold fabricated via fused deposition modeling and direct

hydroxyapatite injection as spacers in laminoplasty', In: AIP Conference Proceedings,

vol. 1933, article 020008, https://doi.org/10.1063/1.5023942

Taqriban, RB,

Ismail, R, Ariyanto, M, & Putra, AFYS 2019, '3D model of photogrammetry

technique for transtibial prosthetic socket design development', In: Proceedings of the 2nd International

Seminar on Research of Information Technology and Intelligent Systems (ISRITI),

pp. 456-461, https://doi.org/10.1109/ISRITI48646.2019.9034670

Tejada-Ortigoza,

V & Cuan-Urquizo, E 2022, 'Towards the development of 3D-printed food: A

rheological and mechanical approach', Foods,

vol. 11, no. 9, article 1191, https://doi.org/10.3390/foods11091191

Tofail, SA,

Koumoulos, EP, Bandyopadhyay, A, Bose, S, O'Donoghue, L & Charitidis, CA

2018, 'Additive manufacturing: scientific and technological challenges, market

uptake and opportunities', Materials

Today, vol. 21, no. 1, pp. 22-37, https://doi.org/10.1016/j.mattod.2017.07.001

Tontowi, AE

& Childs, THC 2001, 'Density prediction of crystalline polymer sintered

parts at various powder bed temperatures', Rapid

Prototyping Journal, vol. 7, no. 3, pp. 180-184, https://doi.org/10.1108/13552540110395637

Tontowi, AE,

Dwi, IS & Triyono, J 2015, 'Study on a layered photo composite of

hydroxyapatite-bioplastic-camphorquinone composed by response surface method', International Journal of Applied

Engineering Research, vol. 10, no. 13, pp. 32951-32958

Triyono, J,

Alfiansyah, R, Sukanto, H, Ariawan, D, & Nugroho, Y 2020a, 'Fabrication and

characterization of porous bone scaffold of bovine hydroxyapatite-glycerin by

3D printing technology', Bioprinting,

vol. 18, article e00078, https://doi.org/10.1016/j.bprint.2020.e00078

Triyono, J,

Mahdiyah, U, Putri, AA, Tontowi, AE & Deni, M 2019, 'The effect of extruder

pressure of 3D bioprinter on hardness and compressive of scaffold bovine

hydroxyapatite', Cogent

Engineering, vol. 6, no. 1, article 1586812, https://doi.org/10.1080/23311916.2019.1586812

Triyono, J,

Sukanto, H, Saputra, RM, & Smaradhana, DF 2020b, 'The effect of nozzle hole

diameter of 3D printing on porosity and tensile strength parts using polylactic

acid material', Open Engineering,

vol. 10, no. 1, pp. 762-768, https://doi.org/10.1515/eng-2020-0083

Van Eck, N &

Waltman, L 2010, 'Software survey: VOSviewer, a computer program for

bibliometric mapping', Scientometrics,

vol. 84, no. 2, pp. 523-538, https://doi.org/10.1007/s11192-009-0146-3

Varian, M &

Whulanza, Y 2021, 'Hydrogel-based bioprinter design with support bath as

printing environment', In: AIP

Conference Proceedings, vol. 2323, article 020020, https://doi.org/10.1063/5.0047166

Vilardell, AM,

Takezawa, A, du Plessis, A, Takata, N, Krakhmalev, P, Kobashi, M, Yadroitsava, I & Yadroitsev, I 2019,

'Topology optimization and characterization of Ti6Al4V ELI cellular lattice

structures by laser powder bed fusion for biomedical applications', Materials Science and Engineering: A,

vol. 766, article 138330, https://doi.org/10.1016/j.msea.2019.138330

Whulanza, Y,

Arsyan, R & Saragih, AS 2018, 'Characterization of hydrogel printer for

direct cell-laden scaffolds', In: AIP

Conference Proceedings, vol. 1933, article 040002, https://doi.org/10.1063/1.5023972

Yang, Z, Li, H,

Lin, J, Xing, D, Li, JJ, Cribbin, EM, Kim, AM, He, Z, Li, H, Guo, W, Zhang L,

& Lin, J 2023, 'Research landscape of 3D printing in bone regeneration and

bone repair: A bibliometric and visualized analysis from 2012 to 2022', International Journal of Bioprinting,

vol. 9, no. 4, article 737, https://doi.org/10.18063/ijb.737

Zhang, Y, Lee,

AY, Pojchanun, K, Lee, CP, Zhou, A, An, J, Hashimoto M, Tan, U-X, Leo, CH,

Wang, G, Chua, CK & Pant, A 2022, 'Systematic engineering approach for

optimization of multi-component alternative protein-fortified 3D printing food

ink', Food Hydrocolloids,

vol. 131, article 107803, https://doi.org/10.1016/j.foodhyd.2022.107803

Zhou, H, Tawk, C & Alici, G 2022, 'A 3D printed soft robotic hand with embedded soft sensors for direct transition between hand gestures and improved grasping quality and diversity', IEEE Transactions on Neural Systems and Rehabilitation Engineering, vol. 30, pp. 550-558, https://doi.org/10.1109/TNSRE.2022.3156116