Microstructure and Mechanical Properties of Magnesium ZRE1 (Mg-Zn-Zr) Alloy with Rare Earth Element (Samarium) Addition

Corresponding email: nurkamilah@uthm.edu.my

Published at : 25 Jan 2024

Volume : IJtech

Vol 15, No 1 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i1.6057

Tukiat, I.S.T., Yusuf, N.K., Khaireez, H., Al-Alimi, S., Lajis, M.A., Shamsudin, S., Ruhaizat, N.E., 2024. Microstructure and Mechanical Properties of Magnesium ZRE1 (Mg-Zn-Zr) Alloy with Rare Earth Element (Samarium) Addition. International Journal of Technology. Volume 15(1), pp. 49-62

| Ikhwan Shah Tisadi Tukiat | Sustainable Manufacturing and Recycling Technology (SMART), Advanced Manufacturing & Materials Center (AMMC), Faculty of Mechanical and Manufacturing Engineering, Universiti Tun Hussein Onn Malaysia, |

| Nur Kamilah Yusuf | Sustainable Manufacturing and Recycling Technology (SMART), Advanced Manufacturing & Materials Center (AMMC), Faculty of Mechanical and Manufacturing Engineering, Universiti Tun Hussein Onn Malaysia, |

| Haikal Khaireez | Sustainable Manufacturing and Recycling Technology (SMART), Advanced Manufacturing & Materials Center (AMMC), Faculty of Mechanical and Manufacturing Engineering, Universiti Tun Hussein Onn Malaysia, |

| Sami Al-Alimi | Sustainable Manufacturing and Recycling Technology (SMART), Advanced Manufacturing & Materials Center (AMMC), Faculty of Mechanical and Manufacturing Engineering, Universiti Tun Hussein Onn Malaysia, |

| Mohd Amri Lajis | Sustainable Manufacturing and Recycling Technology (SMART), Advanced Manufacturing & Materials Center (AMMC), Faculty of Mechanical and Manufacturing Engineering, Universiti Tun Hussein Onn Malaysia, |

| Shazarel Shamsudin | Sustainable Manufacturing and Recycling Technology (SMART), Advanced Manufacturing & Materials Center (AMMC), Faculty of Mechanical and Manufacturing Engineering, Universiti Tun Hussein Onn Malaysia, |

| Nasha Emieza Ruhaizat | Sustainable Manufacturing and Recycling Technology (SMART), Advanced Manufacturing & Materials Center (AMMC), Faculty of Mechanical and Manufacturing Engineering, Universiti Tun Hussein Onn Malaysia, |

The

influences of rare earth (RE) samarium (Sm) added contents to ZRE1 (Mg-Zn-Zr)

magnesium (Mg) cast alloy over strength properties to be investigated. Sm at

0.5, 1.0, 1.5, and 2.0 wt.% were added separately as an alloying element to

ZRE1 alloy. Optical Microscope (OM), X-ray powder diffraction (XRD), and

scanning electron microscope Energy-dispersive X-ray (SEM/EDS) were used to

investigate the microstructure of alloy, while mechanical properties

investigated include Ultimate Tensile Strength (UTS)and Micro-Hardness (MH)

tests. The result revealed that as the Sm level reached 1.5 wt.%, the grain

size decreased by 20.9 %. Additionally, UTS and Yield Strength (YS) showed

improvements of 8.5 % and 7.9 %, respectively, with the addition of 1.5 wt.% of

Sm. In addition, elongation and hardness have been improved by 32.3 % and 10.9 %

respectively at 1.5 wt.% Sm addition. Mg-Zn-Ce-Sm was formed as a new phase

upon the addition of Sm and was detected via XRD analysis. The addition of Sm

to the ZRE1 alloy had significant effects on the refinement of the material's

microstructure, leading to an increase in its mechanical and physical

properties. Therefore, the new ZRE1-RE magnesium alloy was developed.

Magnesium ZRE1 alloy; Microstructure and mechanical properties; Metal forming and materials refinement

Magnesium (Mg) alloys have great potential as engineering materials

because of their high specific strength, low density, high stiffness, excellent

electromagnetic shielding characteristics, superior damping capacity, and good

machinability (Kristanto, Gusniani, and Ratna, 2015;

Rzychon, Kielbus, and Szala, 2008). Mg alloys have sparked

enormous interest in aerospace, defense, electronics, and automotive industries

in recent years. However, Mg application in engineering is still limited due to

high material cost, poor corrosion resistance as well as low strength,

durability, fatigue life, ductility, toughness, and creep resistance (Purnama et al., 2020; Kiani et al., 2017;

Adrian, 2012). The addition of RE metal to Mg alloy could overcome its weakness

and further improve its properties.

According to (Jahedi, McWilliams, and Knezevic, 2018), the rare-earth elements containing Mg alloys could (i) increase ductility and strength while reducing the anisotropy and tension/compression asymmetry, (ii) higher resistance to creep and corrosion, (iii) improve biodegradability, (iv) reduce flammability, (v) retain high-temperature strength, (vi) improve elongation to fracture, (vii) grain boundary strengthening and (viii) improve fatigue resistance and fracture toughness. Zinc (Zn) is the second most effective and common alloying material to produce Mg alloy after aluminum (Al). The addition of zinc in Mg alloy increases room-temperature strength, increases alloy fluidity in casting, and improves corrosion resistance (Moosbrugger, 2017). In addition, recent research shows that adding RE elements to Mg-Zn alloy can further improve various mechanical and chemical properties. The most common RE metal additions in Mg-Zn alloy are Cerium, Lanthanum, Gadolinium, Neodymium, and Yttrium (Al-Alimi et al., 2021; Materialstechnology, 2019).

ZRE1 is one of

many Mg alloys available in the market nowadays. ZRE1 is an Mg alloy containing

RE metal with the addition of zinc and zirconium, forming Mg-RE-Zn-Zr (Ahmad et al., 2017a). The detailed

chemical composition of the ZRE1 alloy is shown in Table 1. ZRE1 exhibits

superior high-temperature creep resistance (Ferro,

Saccone, and Delfino, 2013) and resistance to stress relaxation compared

to that of benchmark alloy AE42 (Rzychon, Kielbus, and Szala, 2008). The presence of RE in ZRE1 makes the alloy free

of microporosity and holds up to hot cracking, which at the same time offers

good weldability (Ferro, Saccone, and Delfino, 2013).

Currently, ZRE1 is used in the aerospace industry for intermediate casings on

Tay engines, gearboxes of RB211 engines, and gearboxes of Tay engines (Materialstechnology, 2019).

Table 1 Chemical composition of the ZRE1 alloy in wt.% (Rzychon, Kielbus, and Szala, 2008)

|

Zn |

RE |

Zr |

Ni |

Si |

Cu |

Mn |

Fe |

Mg |

|

2.7 |

3.18 |

0.53 |

<0.001 |

<0.01 |

<0.01 |

0.02 |

0.002 |

balance |

Research by (Ahmad et al., 2017a)

explored the effect of Praseodymium (Pr) addition on the microstructure and

hardness of cast ZRE1 Mg alloy. They reported that 1 wt.% Pr addition on ZRE1

cast alloy reduces the grain size of ZRE1 alloy by around 37%. Meanwhile, the

addition of Pr improves the hardness value of ZRE1 by 24 %. This is due to the

effect of grain refinement and the effect of the second phase (Mg-Zn)12 RE and

intermetallic compound (Mg-Zn-Ce-Pr). In their study, Ahmad

et al. (2016) extended their research to examine the effects of

Gadolinium on the microstructure and hardness of ZRE1 cast alloy. They found

out that the addition of 3 wt.% heavy RE Gadolinium (Gd) reduce grain size by

28% and increased the volume fraction of eutectic secondary phase while at the

same time improving the hardness by 34%.

Samarium (Sm) is one of the RE elements with

huge potential to form Mg alloy. Researchers have been applied Sm as an

alloying element for various Mg alloys for a long time (Guan

et al., 2018). The addition of Sm to Mg alloy could reduce grain

size, improve corrosion resistance, enhance yield strength and ultimate tensile

strength, improve toughness, and at the same time, better elongation to Mg

alloys, as shown in Table 2. However, to the best of our knowledge, researchers

still have not given any attention to the influence of Sm addition on

microstructures and mechanical properties of as-cast ZRE1 alloy. Sm is an

orthorhombic structure with good solid-solution and precipitation strengthening

in Mg alloys (Li, Xu, and Tong, 2019).

Additionally, Sm costs are lower compared to Nd, Y, and Gd in the market (Lucas et al., 2014). Based on the Rare

Earth Metal price, Sm is the cheapest RE of all, only beaten by Ce and La in

price (Institute of Rare Earths and Strategic

Metals eV, 2020). Additionally, Sm is the seventh most abundant RE in

earth’s crust, with 7.1 ppm. Among all earth’s elements, Sm is the 40th most

abundant and widely available than silver, tin, and gold (Enghag, 2004).

Hence, researchers have conducted studies on the

effect of Sm addition to various magnesium systems such as Mg-6.0Zn-0.5Zr alloy

(ZK60) (Guan et al., 2018),

Mg-11Gd-2Y-0.6Al (Chen et al., 2019),

Mg-Al-Zn (AZ61) (Anawati, Asoh, and Ono, 2018; Chen

et al., 2015) Al-Zr-Ce (Kirman, Zulfia, and

Suharno, 2016) and Mg-5Y-2Nd-0.5Zr (Yunwei et

al., 2018). It is found the application of 1.5 wt.% Sm additive in

Mg- 6.0Zn-0.5Zr alloy (ZK60) refined the grains of the as-cast sample, while

the extruded sample shows even finer (Guan et

al., 2018). At the same time, Sm addition further improves the

strength of ZK60 alloy due to fine grain strengthening and precipitation

strengthening. This outcome is consistent with Chen

et al. (2019) findings, where they demonstrated a refined grain

structure and improved tensile strength in the microstructure and mechanical

properties of the Mg-Gd-Y-Sm-Al alloy. This corresponds to a study on the

effects of samarium addition to the AZ61 (Mg-Al-Zn) magnesium alloy, resulting

not only in a refined microstructure but also in improved ultimate tensile

strength and elongation. However, excessive Sm addition could cause the

coarsening of grain, leading to the decline of strength and plasticity (Rady et al., 2019; Al-Alimi, Lajis, and

Shamsudin, 2017).

Table 2 Previous study on RE addition to Mg alloy

|

Researcher |

Mg alloy |

RE addition |

Result |

|

Liu et al. (2016) |

Mg-Zn-Zr |

Ce, Y |

Improve YS,

UTS |

|

Rogal et al. (2019) |

E21 Mg-Gd-Nd-Zn-Zr |

Nd-Y |

Improve YS, plasticity, hardness |

|

Ahmad et al. (2017a) |

ZRE1

Mg-RE-Zn-Zr |

Pr |

Reduces grain

size, improves hardness |

|

Ahmad et al. (2016) |

ZRE1 Mg-RE-Zn-Zr |

Gd |

Increased volume fraction, improved

hardness |

|

Guan et al. (2018) |

ZK60 Mg-Zn-Zr |

Sm |

Improves

strength |

|

Chen et al. (2019) |

Mg-Gd-Y-Sm-Al |

Sm |

Improved TS, microstructure |

|

Chen et al. (2015) |

AZ61

Mg-Al-Zn-Mn |

Sm |

Refined

microstructure, improved UTS, EL |

|

Yunwei et al. (2018) |

Mg-Y-Nd-Zr |

Sm |

Improve UTS, YS and hardness |

|

Liu et al. (2021) |

AZ41

Mg-Al-Zn-Mn |

Sm |

Improve UTS,

YS and EL |

|

Rokhlin et al. (2021) |

Mg-Gd |

Sm |

Increase strength |

Samarium also has unique properties that make it useful for various

applications other than as an alloying element in metals. Chauhan, Lohra, and Langyan (2020) found that

ternary samarium (III) complexes exhibit fascinating optical properties, making

them potentially useful in bio-assays, electroluminescent devices, and liquid

lasers. Luo et al. (2019) synthesized

a novel samarium complex that emits red light and has potential as a red light

emitting material for LEDs. Meanwhile Hashmi et

al. (2019) studied the effects of samarium incorporation in ZnO thin

films and found that it affected the optical and electrical characteristics of

the films, making them suitable for use in optical devices for UV and blue

emission. Marzouk and Hammad (2020) found that samarium oxide affects the structural and optical properties

of bismuth glass, making it suitable for photonic applications. Sadeq and Morshidy (2020) showed that samarium

oxide influences the structural, optical, and electrical properties of

alumino-borate glasses, making them good optical filters. Overall, the papers

suggest that samarium has unique properties that make it useful for various

applications in optics, electronics, and materials science.

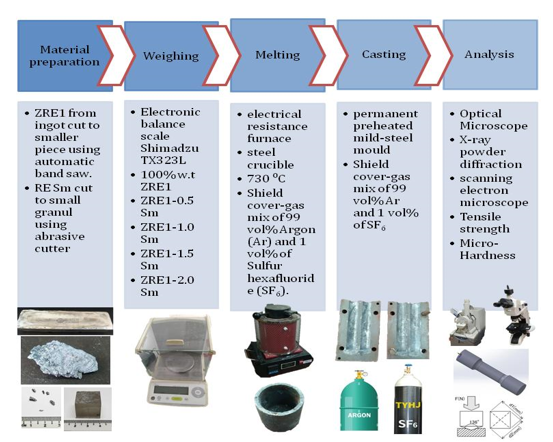

An Mg base alloy (ZRE1 Mg cast) was supplied

by ILM Ventures Ltd., Kuala Lumpur, Malaysia in ingot cast. The base alloy was

melted in an electrical resistance furnace with a steel crucible under a

cover-gas mixture of 99 vol% Argon (Ar) and 1 vol% of Sulfur hexafluoride

(SF6), both from Linde and supplied by Linde Malaysia Sdn Bhd, Kuala Lumpur,

Malaysia. Sm from Merck, Kuala Lumpur, Malaysia was added in contents of 0.5 wt.%,

1.0 wt.%, 1.5 wt.% and 2.0 wt.% separately as small pieces after the base alloy

melted at approximately 730°C. After the addition, the melt was stirred for

approximately 30 minutes to ensure stabilization, homogeneous composition, and

dissolution of the alloying elements. The molten metal was then poured into a

permanent steel mold preheated to 400°C. The cast was then left to cool down to

room temperature before being removed from the mold. The graphical abstract of

the research methodology and the melt-stir casting setup are shown in Figure 1

and Figure 2, respectively.

Figure 1

All microstructure analysis samples were cut from the center of the cast alloy. The sample was then prepared using the ASTM Standard Guide for Preparation of Metallographic Specimens (ASTM, 2011; Geels et al., 2007) grinding/polishing procedures before final etching with 4 vol% picric acid in ethanol solution. An optical microscope (Nikon Eclipse LV150NL) and image analysis software (IMT i-Solution DT v12.0) was used to measure the grain size and volume fraction. In addition, the specimens were examined using a scanning electron microscope (SEM) equipped with an energy-dispersive X-ray spectrometer (EDS) (Hitachi SU1510) and X-ray powder diffraction (XRD) (Bruker D8 Advance) for microstructure study and phase formed in the Mg alloy. A permanent preheated mild-steel mold was used to produce cylindrical tensile test specimens. The melt was neatly poured at 730 ± 5 °C into the preheated permanent steel mold after being skimmed and stirred. The castings were machined using CNC turning to achieve precise specimen dimensions based on the requirement of ASTM B557M (ASTM International, 2015).

Figure 2 Melt-stir casting setup with Argon and SF6 gas shield

XRD analysis was performed on Figure 3 and

the selected specimens to identify the phases present in the ZRE1-xSm alloys;

the results are shown in 1. It can be seen that the base alloy consisted of phase and Mg-Zn-Ce secondary intermetallic phase. The

phase was found

in a hexagonal structure, while the secondary phase was a tetragonal structure.

The position of peaks originating from Mg are exactly equivalent to Mg standard

peaks as reported by (Sheggaf et al., 2017;

Wang et al., 2014).

phase was found to possess a hexagonal

structure with crystallographic parameters of (a = 3.20936; b = 3.20936;

c = 5.21120)

while the Mg-Zn-Ce phase was tetragonal with (a = 3.83100;

b = 3.83100; c = 3.83100)

crystallographic parameters. Similar

phases were obtained by other Mg-Zn-Zr with RE addition alloys (Sheggaf et al., 2017; Liu et al., 2016).

Figure 3 XRD pattern of ZRE1-xSM

alloys

Furthermore, the XRD pattern also detected other phases in

the base ZRE1 alloy, which is MgZn2 and Zn2Zr3.

These phases form in small amounts and dissolve inside the Mg matrix of the

base alloy (Sheggaf et al., 2017; Liu et al., 2016). MgZn2 has a

hexagonal crystal structure with crystallographic parameters (a = 5.22250;

b = 5.22250; c = 8.56840) while Zn2Zr3

has a tetragonal crystal structure and (a = 7.63300; b = 7.63300;

c = 6.96500)

crystallographic parameters. The addition of the rare

earth element Sm to the ZRE1 base alloy resulted in the detection of the

MgZn(Ce,Sm) phase within the sensitivity limits of XRD, manifesting at the same

peaks as the secondary phase of the ZRE1 base alloy. The emergence of this

MgZn(Ce,Sm) phase indicates the transformation of a new phase from the

secondary phase of the ZRE1 base alloy (Sheggaf et

al., 2017). The new MgZn (Ce, Sm) intermetallic phase has a hexagonal

crystal structure with (a = 14.61900; b = 14.61900; c = 8.70800)

crystallographic parameters. Additionally, the Mg-Zn-Sm intermetallic phase

was detected at ZRE1-2.0 Sm alloy at the same peak of MgZn(Ce, Sm). This phase

shows that both phases were crystallized and combined at the alloy grain

boundaries (Sheggaf et al., 2017; Liu et al., 2016). Previous studies also

found the same result, where the MgZnRE phase was formed as a secondary

intermetallic phase (Sheggaf et al., 2017).

The addition of Sm does not change the crystalline size and

shape of before and after adding Sm. Both samples have a hexagonal

structure with crystallographic parameters of (a = 3.20936; b = 3.20936;

c = 5.21120)

and structure angle alpha 90o - beta 90o

- gamma 120o. However, there are slight changes in the crystalline

size of the MgZn2 crystal structure. Even though both samples

possess MgZn2 in a hexagonal structure, the size decreases from (a

= 5.22250; b = 5.22250; c = 8.56840)

for base ZRE1 alloy to (a

= 5.22100; b = 5.22100; c = 8.56700)

. Small changes in the c value

may be due to the addition of Sm, which has a large-sized atom in comparison to

a small atom of Mg, pushing the MgZn2 crystal compound to squeeze

slightly and squish its hexagonal structure size. According to one theory by Ke-Jie et al. (2009), when a solid

solidifies, Sm atoms are squeezed through the solid-liquid barrier, causing

constitutional supercooling and assisting in the development of a nucleus.

Furthermore, the mechanical properties of the material are

mainly caused by the type, distribution, amount, and morphology of the

intermetallic phase (Sheggaf et al., 2017).

The MgZnRE intermetallic phase has a long periodic piling ordered structure and

is coherent with the phase matrix. In Figure 4, the property-making MgZnRE

phase becomes a strengthening mechanism of MgZn alloys, thus improving

mechanical properties (Liu et al., 2016).

The strengthening of Mg alloys is due to the solid solution of the RE atoms in

borderline sizes together with secondary phase hardening of the MgZnRE

intermetallic compound (Yang et al., 2008).

The RE addition to Mg-Zn alloys formed intermetallic phases that improved the

strength of the Mg alloy. This improvement was caused by grain boundary

strengthening of the MgZnRE phase and MgZn (Ce, Sm) phase crystallized along the

grain boundaries. At the same time, the matrix phase and intermetallic phase

form a rigid atomic bonding by obstructing slip dislocation of MG-Zn-RE alloy

planes, thus strengthening the material further (Tekumalla

et al., 2014). Furthermore, both secondary phases, MgZn2

and Zn2Zr3 from ZRE1 base alloy, disappear completely

with the addition of Sm. This may be due to the addition of RE, which reduces

the solubility of Zn in the Mg matrix. As a result, the phases may not develop

or may form in small quantities, potentially beyond the detection limit of the

XRD spectrum (Huang et al., 2009).

Figure

4 shows optical microscopes taken from the ZRE1 base alloy and alloy with Sm

addition. The alloy microstructure consists of matrix (marked A) and

secondary phase crystalline along the grain boundary (marked B). The secondary

intermetallic phase forms in location B are known from XRD data as Mg-Zn-Ce,

MgZn2, and Zn2Zr3. The secondary phase at the

microstructure grain boundary shows massive morphology in a dark contrast

color. The Sm addition to the alloy changes the microstructure of the ZRE1 base

alloy. Similarly, research by (Sheggaf et al.,

2017) and (Kusrini et al., 2021)

showed that ZRE1 base alloys microstructure changes with the addition of Pr.

Figure 4 Microstructure image (a) ZRE1 base alloy and

(b-e) ZRE1 with Sm addition using optical microscope

The addition of

Sm shows a significant effect on ZRE1 grain size in Figure 5, where the

addition of 0.5 wt.% Sm reduces the grain size significantly by about 13% due

to an increase in the coherency time of the alloy (Ahmad

et

al., 2017b). Previous study shows that the dendrite

impingement rate occurs at a low pace while occurs at a higher speed for small

grain sizes (StJohn et al., 2005). The increase

of Sm content shows a reduction in the grain size of the alloy, which obtains

33.33 µm grain size of 0.5 wt.%, 31.53 µm for 1.0 wt.%, 30.43 µm for 1.5 wt.%

and 32.41 µm for 2.0 wt.% Sm. The trend is parallel to the outcome of another

similar Mg-RE research. It also has been reported by (Guan

et

al., 2018) that the addition of Sm is effective for grain

refinement of ZK60 alloy (Mg-6.0Zn-0.5Zr) due to the secondary phase containing

Sm that restricts grain growth. The mechanism behind the grain refinement

effect of rare earth on magnesium alloy is that RE acts as nucleation sites for

recrystallization and grain refinement (Ding-qian,

2008). Additionally, the formation of high melting-point Mg-RE phases

can act as the heterogeneous nucleation cores of the matrix and refine the

grain size (Zhang, Wang, and Li, 2017).

Figure 5 Effect of Sm addition on the average grain size of

ZRE1 magnesium alloy

The effect of Sm addition on the volume fraction of ZRE1 alloy has been

shown in Figure 6, where the addition of Sm shows a significant effect on ZRE1

volume fraction. The addition of Sm increased the volume fraction of Mg alloy

from 14.30 % for the base alloy to 17.64 % for 0.5 wt. % Sm addition, 19.28 %

for 1.0 wt. % Sm, 20.59 % for 1.5 wt. % Sm and 22.77 % for 2.0 wt. % Sm

addition. The trend is parallel to the outcome of other similar Mg-RE research (Ahmad et al., 2017b; Wang et al., 2014).

The study conducted by Ryou et al. (2018) examines

the correlation between grain size and grain boundary volume fraction. The

findings of the investigation indicate that a reduction in grain size leads to

an increase in the proportion of grain boundaries, owing to alterations in the

structure, including a rise in the volume fraction of triple junctions.

Figure 6 Effect of Sm addition on the volume fraction of ZRE1 magnesium alloy

Figure 6 shows the volume

fraction of the intermetallic compounds growing as a result of the addition of

Sm to the ZRE1 alloy. At the same time, the continuous networks of eutectic

compounds surround the primary grains where have a tendency to become

separated from the grains when it's refined (Sheggaf

et

al., 2017). Furthermore, the grain boundary width becomes

thicker as the content of Sm increases because Sm has a tendency to combine

with the secondary phases. It is supported by the research of (Guan et al., 2018) that the addition of Sm

increases the volume fraction of secondary intermetallic phases of ZK60 alloy.

Figure 7 (a) shows SEM

micrograph and EDS microanalyses of ZRE1 base alloy and ZRE1 alloy with 2.0

wt.% Sm addition shown in (b). SEM observations for base alloy microstructure

in (a-i) consist of grains, marked A, while surrounded by a secondary phase

crystallized along the grain boundaries like a vast morphology marked B. The

EDS spectrum of base alloy shown in (a-ii) is indicated by points consistently

showing the composition of the

matrix at region marked A and the secondary

phase of the base alloy at region B. The base alloy matrix phase comprises

magnesium, zinc, and a small amount of zirconium, while the secondary

intermetallic phase contains magnesium, zinc, and cerium.

SEM image of

ZRE1 with 2.0 wt.% Sm alloy shown in (b-i) exposed a composition of the matrix at region marked A, and two types of intermetallic phases (marked B and

C) crystallized along the grain boundaries. The EDS result in (b-ii) shows that

the intermetallic phase at point B was Mg-Zn-Ce-Sm while Mg-Zn-Sm formed at

point C. The addition of more than 2.0 wt.% Sm to base alloy shows new Mg-Zn-Sm

intermetallic compound formed at the grain boundary, where Sm forms its own

intermetallic compound out of Mg-Zn-Ce-Sm due to lack of Ce compound to form as

all intermetallic Mg-Zn-Ce-Sm (Sheggaf et al.,

2017). A previous study by (Li et al.,

2007) confirms the formation of the Mg-Zn-RE phase, where two types of RE

combined with Mg and Zn to form the Mg-Zn-RE phase. Their research adding Nd

and Y into Mg-Zn-Zr base alloy and forming Mg–Zn–Nd–Y–Zr alloys improved the

ultimate strength and elongation, as shown in Figure 8. The Mg-Zn-RE phase is

coherent with the ?-Mg matrix phase and makes the Mg-Zn-RE compound the

strengthening phase of the alloys. Incorporating rare earth elements into

magnesium alloy can lead to the creation of primary phases with high melting

points. These phases serve as nucleation cores for the

matrix and

effectively reduce the grain size through refinement. The presence of refined

grain boundaries has been observed to promote atom mobility and facilitate the

emergence of secondary metallic phases situated at the grain boundary (Zhang, Wang, and Li, 2019). Region B is where the

grain boundary is located, where the secondary intermetallic phaseforms the

Mg-Zn-Ce-Sm composition.

Figure 7 SEM micrograph and EDS microanalyses of (a)

ZRE1 base alloy and (b) ZRE1 - 2.0 wt.% Sm

The effect of Sm content addition on the tensile

properties of ZRE1Mg alloy is shown in Figure 8. The tensile test results

include the ultimate tensile strength (UTS), yield strength (YS), and

elongation (El) for the ZRE1 base alloy and the Sm-treated alloys. UTS result

shows that the addition of 0.5 wt.% Sm has a small effect on the UTS of the

alloy. The UTS only increased 3.2% from 150.3 MPa to 155.2 MPa compared to base

alloy. However, a significant increase in UTS value for 1.0 wt.% Sm at 161.7

MPa (7.5%) and 163.2 MPa (8.5%) for 1.5 wt.% Sm. This increases due to

refinement in grain size and an increase in the volume fraction of the

secondary intermetallic phase (Sheggaf et al., 2017;

Zhang et

al., 2017). While at 2.0 wt.% Sm, UTS value only slightly

increased to 156.2 MPa (3.9%) compared to base alloy due to there a decreasing

trend in grain size value (Sheggaf et al.,

2017; Zhang et al., 2017).

Figure 8 Effect of Sm content on the tensile properties of ZRE1Mg alloy

YS result shows that the

addition of 0.5 wt.% Sm has a small effect on the YS of the alloy. The YS only

increased 3.0% from 121.2 MPa to 124.9 MPa compared to base alloy. However, a

significant increase in UTS value for 1.0 wt.% Sm at 129.7 MPa (7.0%) and 130.9

MPa (7.9%) for 1.5 wt.% Sm. This increase is due to refinement in grain size

and an increase in the volume fraction of the secondary intermetallic phase (Sheggaf et al., 2017; Zhang et al.,

2017). While at 2.0 wt.% Sm, UTS value only slightly increased to 125.6 MPa

(3.6%) compared to base alloy due to there a decreasing trend in grain size

value (Sheggaf et al., 2017;

Zhang et

al., 2017). The elongation result shows that the addition

of 0.5 wt.% Sm has a small effect on the elongation of the alloy. The alloy

elongation only adds 8.1% from 4.9% elongation to 5.3% elongation compared to

the base alloy. However, significant improvement in elongation value for 1.0

wt.% Sm at 6.2% (25.9%) and 6.5% (32.3%) for 1.5 wt.% Sm. This increase is due

to refinement in grain size and an increase in the volume fraction of the

secondary intermetallic phase (Zhang et al.,

2017). While at 2.0 wt.% Sm, elongation value only slightly increased to

5.1% elongation (3.6%) compared to base alloy, due to there a decreasing trend

in grain size value (Zhang et al.,

2017).

The outcome of UTS, YS, and

elongation of this study is in line with previous research by (Zhang et al., 2017). They study the effects of

samarium addition on the microstructure and mechanical properties of

Mg-6Zn-0.4Zr magnesium alloy. They found considerable improvement in UTS and

elongation by adding 2.0 wt.% Sm. However, when the content of Sm increased

more, the UTS and elongation show declining possibly due to the MgZnSm phase

and the morphology of eutectic phases. The finding of the current study is also

consistent with those of (Li et al.,

2007) in the study on the effect of Nd and Y addition of as-cast Mg–Zn–Zr

alloy. They found out that the addition of two types of RE (Nd and Y) improved

the mechanical properties of the Mg alloy due to dendritic size refinement.

However, an increase in the amount of rare earth (RE) also resulted in a rise

in the quantity of interdimeric eutectic compounds. This formation deteriorates

the mechanical properties of Mg alloys due to their coarseness and their

location on grain boundaries. The strengthening of Mg alloys is due to a solid

solution of RE atom with borderline size and also caused by secondary phase

hardening (Sheggaf et al., 2017).

A study by Júnior et al. (2022) investigating the impact of

copper and nickel on alloys' microhardness and modulus of elasticity revealed

that the inclusion of copper resulted in a more granular microstructure,

thereby promoting a decrease in the mean value of modulus of elasticity. As per

the study mentioned earlier, the inclusion of copper led to the development of

a rougher microstructure, which consequently reduced the mean value of the

elasticity modulus. Likewise, the incorporation of samarium into the magnesium

ZRE1 alloy in the present investigation is expected to elicit analogous impacts

on the microstructural characteristics, thereby influencing the modulus of

elasticity. The observed correlation implies that the inclusion of samarium

could potentially lead to a decrease in the mean modulus of elasticity, thereby

corroborating the present study's findings.

Additionally,

the secondary intermetallic phase containing RE can deter the dislocation

movement, therefore improving the mechanical properties. However, after the

alloy achieves its peak hardness at 1.5 wt.% Sm, the hardness value trend

decreased. Where the ZRE1 alloy with 2.0 wt.% Sm shows a 57.0 HV value, a

reduction compared to the previous sample. This drop happens due to the

increase of grain size, which starts to occur when the Sm addition reaches 1.5

wt.% Sm thus reflected a reduction trend in hardness value. Previous research

by (Wang et al., 2018) also shows the same

hardness value trend. Their study on the effects of RE yttrium (Y) on Mg-Al-Zn

alloy shows that the harness value increases with the increase in Y addition,

though the trend starts moving downward after the alloy reaches its peak hardness

value. This trend is due to (i) an increase of secondary intermetallic phase

containing RE, leading to solid solution hardening effect, and (ii) grain size

coarsening of ?-Mg matrix. According to Pereira et

al. (2017), smaller grain sizes were obtained, affecting microhardness

and elongation in the alloy. Furthermore, smaller grain boundaries hinder the

movement of dislocations, resulting in enhanced resistance to deformation and

elevated microhardness values of the alloy.

The Addition of Sm

led to the formation of a new phase of MgZn(CeSm) where Ce and Sm combined to

form a secondary intermetallic phase surrounding the primary grain. The

formation of the intermetallic phase plays a major role in the improvement of

the mechanical properties of the alloy. While the identification of these

phases helped understand the strengthening mechanism of alloying treatment, Sm

addition is effective for the UTS and YS improvement. The addition of Sm leads

to intensive solution strengthening and increased dispersion strengthening of

the secondary phase, thus resulting in mechanical strength improvement. The

study shows that there is a strong relation between the microstructure and

mechanical properties of the Sm-treated ZRE1 alloy. Coarser average grain size

results in lower values of UTS, YS, elongation, and hardness. While finer

average grain size produces alloys with better UTS, YS, elongation, and

hardness. This is due to the secondary intermetallic phase containing RE, which

can deter the dislocation movement, therefore improving the mechanical

properties.

This research was supported by Universiti Tun

Hussein Onn Malaysia (UTHM) through Research Enhancement-Graduate Grant (RE-GG) (vot Q203). Communication

of this research is made possible through monetary assistance by UTHM

Publisher's Office via Publication Fund E15216. Additional support in terms of

facilities was also provided by Sustainable Manufacturing and Recycling Technology,

Advanced Manufacturing and Material Center (SMART-AMMC), Universiti Tun Hussein

Onn Malaysia (UTHM).

Adrian, M., 2012. Titanium Alloys for Aerospace Structures

and Engines A2. Introduction to Aerospace Materials, Woodhead Publishing,

pp. 202–223

Ahmad, R., Elaswad, A.M.M., Asmael, M.B.A., Shahizan,

N.R., 2017a. Effect of Yttrium Addition on Microstructure and Hardness of Cast

EV31A Magnesium Alloy. Key Engineering Materials, Volume 740, pp. 81–85

Ahmad, R., Hamzah, M.Z., Asmael, M.B.A., Sheggaf,

Z.M., 2016. Effects of Gadolinium on Microstructure and Hardness of Mg-Zn-Ce-Zr

cast alloy. ARPN Journal of Engineering and Applied Sciences, Volume 11(14),

pp. 8592–8597

Ahmad, R., Sheggaf, Z.M., Asmael, M.B.A., Hamzah,

M.Z., 2017b. Effect of Rare Earth Addition on Solidification Characteristics

and Microstructure of ZRE1 Magnesium Cast Alloy. Advances in Materials and

Processing Technologies, Volume 3(3), pp. 418–427

Al-Alimi, S., Lajis,

M.A., Shamsudin, S., 2017. Solid-State Recycling of Light Metal Reinforced

Inclusions by Equal Channel Angular Pressing: A Review. In: MATEC Web of

Conferences, Volume 135, p. 00013

Al-Alimi, S., Lajis, M.A., Shamsudin, S., Yusuf,

N.K., Chan, B.L., Didane, D.H., Rady, M.H., Sabbar, H.M., Msebawi, M.S., 2021.

Development of Hot Equal Channel Angular Processing (ECAP) Consolidation

Technique in the Production of Boron Carbide(B4C)- Reinforced Aluminium Chip

(AA6061)-Based Composite. International Journal of Renewable Energy Development,

Volume 10(3), pp. 607–621

American Society for Testing and Materials (ASTM).,

2011. Standard Guide for Preparation of Metallographic Specimens. In: American

Society for Testing and Materials (ASTM) Book of Standards

Anawati, A., Asoh, H., Ono, S., 2018. Degradation

Behavior of Coatings Formed by the Plasma Electrolytic Oxidation Technique on

AZ61 Magnesium Alloys Containing 0, 1 and 2 wt% Ca . International Journal

of Technology, Volume 9(3), pp. 622–630

American Society for Testing and Materials (ASTM)

International., 2015. Tension Testing Wrought and Cast Aluminum- and

Magnesium-Alloy Products (Metric). In: American Society for Testing and

Materials (ASTM) Book of Standards

Chauhan, A., Lohra, S., Langyan, R., 2020.

Synthesis and characterization of three ternary samarium(III) complexes and

their optical properties. Spectroscopy Letters, Volume 53, pp. 595–606

Chen, X., Li, Q., Chen, J., Zhu, L., 2019.

Microstructure and Mechanical Properties of Mg- Gd-Y-Sm-Al Alloy and Analysis

of Grain Refinement and Strengthening Mechanism. Journal of Rare Earths,

Volume 37(12), pp. 1351–1358

Chen, Y., Jin, L., Fang, D., Song, Y., Ye, R.,

2015. Effects of Calcium, Samarium Addition on Microstructure and Mechanical Properties

of AZ61 Magnesium Alloy. Journal of Rare Earths, Volume 33(1), pp. 86–92

Ding-qian, D., 2008. Effect of Rare-earth La on Microstructure

of Mg-4.5%Zn as-cast Magnesium Alloy. Light Alloy Fabrication Technology,

Volume 36(10), pp. 11–13

Enghag, P., 2004. Encyclopedia of the Elements?: Technical

Data, History, Processing, Applications. In: Wiley-VCH

Ferro, R., Saccone, A., Delfino, S., 2013.

Magnesium Alloys of the Rare Earth Metals: Systematics and Properties. Metallurgical

Science and Tecnology, Volume 16(1)

Geels, K., Fowler, D.B., Kopp, W.U., Rückert, M.,

2007. Metallographic and Materialographic Specimen Preparation, Light

Microscopy, Image Analysis and Hardness Testing. In: West Conshohocken: ASTM

international

Guan, K., Li, B., Yang, Q., Qiu, X., Tian, Z.,

Zhang, D., Zhang, D., Niu, X., Sun, W., Liu, X., Meng, J., 2018. Effects of 1.5

wt% samarium (Sm) addition on microstructures and tensile properties of a

Mg?6.0Zn?0.5Zr alloy. Journal of Alloys and Compounds, Volume 735, pp. 1737–1749

Hashmi, J.Z., Siraj, K., Latif, A., Naseem, S.,

Murray, M., Jose, G., 2019. The Role of Samarium Incorporated Structural Defects

in ZnO Thin Films Prepared by Femtosecond Pulsed Laser Deposition. Journal

of Alloys and Compounds, Volume 800, pp. 191–197

Huang, Z.H., Liang, S.M., Chen, R.S., Han, E.H.,

2009. Solidification Pathways and Constituent Phases of Mg-Zn-Y-Zr Alloys. Journal

of Alloys and Compounds, Volume 468(1–2), pp. 170–178

Institute of Rare Earths and Strategic Metals eV.,

2020. Rare Earth Prices | Institute of Rare Earths and Strategic Metals eV. Available

Online at: https://en.institut-seltene-erden.de/our-service-2/Metal-prices/rare-earth-prices/,

Accessed on 01/14/2020)

Jahedi, M., McWilliams, B.A., Knezevic, M., 2018.

Deformation and Fracture Mechanisms in WE43 Magnesium-rare Earth Alloy Fabricated

by Direct-chill Casting and Rolling. Materials Science and Engineering A,

Volume 726(March), pp. 194–207

Júnior, P. F., De Olivé Ferreira, L., Garcao, W.

J. L., De Paula Almeida, R., Melo, C. M., & Ferreira, A. F. (2022).

Heat-flow parameters affecting microstructure and mechanical properties of

Al-Cu and Al-Ni alloys in directional solidification: An experimental

comparative study. International Journal of Materials Research, 113(3),

181–193

Ke-jie, L., Quan-an, L., Xiao-tian, J., Jun, C.,

Xing-yuan, Z., Qing, Z., 2009. Effects of Sm Addition on Microstructure and Mechanical

Properties of Mg-6Al-0.6Zn Alloy. Scripta Materialia, Volume 60(12), pp.

1101–1104

Kiani, M., Gandikota, I., Rais-rohani, M., Motoyama,

K., 2017. Design of Lightweight Magnesium Car Body Structure Under Crash and Vibration

Constraints. Journal of Magnesium and Alloys, Volume 2(2), pp. 99–108

Kirman, Zulfia, A., Suharno, B., 2016. Effects of

Magnesium on Properties of AlZrCe-Mg-Al2O3 Nanocomposites. International

Journal of Technology, Volume 7(3), pp. 447–455

Kristanto, G.A., Gusniani, I., Ratna, A., 2015.

The performance of municipal solid waste recycling program in Depok, Indonesia.

International Journal of Technology, Volume 6(2), pp. 264–272

Kusrini, E., Ayuningtyas, K., Mawarni, D.P.,

Wilson, L.D., Sufyan, M., Rahman, A., Prasetyanto, Y.E.A., Usman, A., 2021.

Micro-structured Materials for the Removal of Heavy Metals using a Natural

Polymer Composite. International Journal of Technology, Volume 12(2), pp.

275–286

Li, Q., Wang, Q., Wang, Y., Zeng, X., Ding, W.,

2007. Effect of Nd and Y Addition on Microstructure and Mechanical Properties

of as-cast Mg-Zn-Zr alloy. Journal of Alloys and Compounds, Volume 427(1–2),

pp. 115–123

Li, K., Xu, H., Tong, Z., 2019. Effects of Sm on

Microstructure of Mg-12Gd-2Y-0.5Zr Alloy. In: IOP Conference Series:

Materials Science and Engineering, Volume 569(2), p. 022017

Liu, L., Chen, X., Pan, F., Gao, S., Zhao, C.,

2016. A New High-strength Mg-Zn-Ce-Y-Zr Magnesium Alloy. Journal of Alloys

and Compounds, Volume 688, pp. 537–541

Liu, B.S., Wang, H.H., Zhang, Y.Z., Yang, Y.X.,

Ren, X.X., Du, H.Y., Hou, L.F., Wei, Y.H., Song, G.L., 2021. The influence of Adding

Samarium on the Microstructure, Mechanical Performance and Corrosion Behavior

of as-extruded AZ41 Alloys. Journal of Physics and Chemistry of Solids, Volume

150, p. 109851.

Lucas, J., Lucas, P., Le-Mercier, T., Rollat, A.,

Davenport, W., 2014. Rare Earths Rare Earths Production and Use. In: Elsevier

B.V.

Luo, Q.Y., Luo, H., Kuang, H.M., Chen, W.T., Wen,

Y.X., 2019. A novel samarium material: Synthesis, structure, photophysical

properties and photoluminescence energy transfer mechanism. Journal of Solid

State Chemistry, Volume 270, pp. 200–204

Marzouk, S.Y., Hammad, A.H., 2020. Influence of Samarium

Ions on the Structural, and Optical Properties of Unconventional Bismuth Glass Analyzed

using the Judd–Ofelt Theory. Journal of Luminescence, Volume 231, p.

117772

Materialstechnology., 2019. Weblinks : Magnesium

Applications. TMS. Available Online at: www.materialstechnology.org, Accessed

on 03/03/2021

Moosbrugger, C., 2017. Engineering Properties of

Magnesium Alloys. In: ASM International (Issue M)

Pereira, P.H.R., Huang, Y., Langdon,

T.G., 2017. Thermal Stability and Superplastic

Behaviour Of An Al-Mg-Sc Alloy Processed by ECAP And HPT At Different

Temperatures. In: IOP Conference Series: Materials Science and

Engineering

Purnama, D., Winarto, W., Sofyan, N., Prihastomo,

A., Ito, K., 2020. Microstructure and Mechanical Properties of Ah-36 Steel

Weldment Welded using Magnesium Modified E6013 Electrode. International

Journal of Technology. Volume 11(1), pp. 48–59

Rady, M.H., Mahdi, A.S., Mustapa, M.S.,

Shamsudin, S., Lajis, M.A., Msebawi, M.S., Siswanto, W.A., Al Alimi, S., 2019.

Effect of Heat Treatment on Tensile Strength of Direct Recycled Aluminium Alloy

(AA6061). Materials Science Forum, Volume 961, pp. 80–87

Rogal, L., Kania, A., Berent, K., Janus, K.,

Litynska-Dobrzynska, L., 2019. Microstructure and Mechanical Properties of

Mg-Zn-RE-Zr Alloy After Thixoforming. Journal of Materials Research and

Technology, Volume 8(1), pp. 1121–1131

Rokhlin, L.L., Dobatkina, T.V., Tarytina, I.E.,

Luk’yanova, E.A., Temralieva, D.R., 2021. Effect of Samarium on the Recovery in

Gadolinium-Containing Magnesium Alloys. Russian Metallurgy (Metally), Volume

2021(7), pp. 816–820

Ryou, H., Drazin, J.W., Wahl, K.J., Qadri, S.B.,

Gorzkowski, E.P., Feigelson, B.N., Wollmershauser, J.A., 2018. Below the

Hall–petch Limit In Nanocrystalline Ceramics. American Chemical Society (ACS ) Nano,

Volume 4(12), pp. 3083–3094

Rzychon, T., Kie?bus, A., Szala, J., 2008.

Quantitative Description of Microstructure of ZRE1 Magnesium Alloy. Inzynieria

Materialowa, Volume 29(May), pp. 299–303

Sadeq, M.S., Morshidy, H., 2020. Effect of Samarium

Oxide on Structural, Optical and Electrical Properties of Some Alumino-borate Glasses

with Constant Copper Chloride. Journal of Rare Earths, Volume 38, pp. 770–775

Sheggaf, Z.M., Ahmad, R., Asmael, M.B.A., Elaswad,

A.M.M., 2017. Solidification, microstructure, and mechanical properties of the

as-cast ZRE1 magnesium alloy with different praseodymium contents. International

Journal of Minerals, Metallurgy and Materials, Volume 24, pp. 1306–1320

StJohn, D.H., Qian, M., Easton, MA., Cao, P., Hildebrand,

Z., 2005. Grain refinement of magnesium alloys. Metallurgical and Materials

Transactions A, Volume 36(7), 1669–1679

Tekumalla, S., Seetharaman, S., Almajid, A.,

Gupta, M., 2014. Mechanical Properties of Magnesium-rare Earth Alloy Systems: A

Review. Metals, Volume 5(1), pp. 1–39

Wang, M.F., Xiao, D.H., Zhou, P.F., Liu, W.S.,

Ma, Y.Z., Sun, B.R., 2018. Effects of rare earth yttrium on microstructure and

properties of Mg–Al–Zn alloy. Journal of Alloys and Compounds, Volume 742,

pp. 232–239

Wang, Y., Wu, G., Liu, W., Pang, S., Zhang, Y.,

Ding, W., 2014. Effects of Chemical Composition on the Microstructure and Mechanical

Properties of Gravity Cast Mg-xZn- yRE-Zr alloy. Materials Science and

Engineering A, Volume 594, pp. 52–61

Yang, Z., Li, J.P., Zhang, J.X., Lorimer, G.W.,

Robson, J., 2008. Review on Research and Development of Magnesium Alloys. Acta

Metallurgica Sinica, Volume 21(5), pp. 313–328

Yunwei, G., Quanan, L., Xiaoya, C., Zhitao, L.,

2018. As-cast Microstructures and Mechanical Properties of Mg-5Y-2Nd-xSm-0.5Zr

(x = 0, 1, 3, 5). Magnesium Alloys, Volume 7(2), p. 58

Zhang, Q., Wang, Y., Li, P., 2019. Grain-refinement Strengthening Effect of Y and Sm on Magnesium Alloy AZ81. In: IOP Conference Series: Materials Science and Engineering, Volume 592(1), p. 012027

Zhang, Y., Huang, X., Li, Y., Ma, Z., Ma, Y., Hao, Y., 2017. Effects of Samarium Addition on as-cast Microstructure, Grain Refinement and Mechanical Properties of Mg-6Zn- 0.4Zr Magnesium Alloy. Journal of Rare Earths, Volume 35(5), pp. 494–502