The Effect of Alumina Nanoparticles Impregnated Kevlar on Ballistic Resistance of Aluminum Alloy 7075 Hybrid Laminate Composite for Armor Application

Corresponding email: anne.zulfia@ui.ac.id

Published at : 25 Jan 2024

Volume : IJtech

Vol 15, No 1 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i1.6050

Syifa, S., Ariaty, M., Syahrial, A.Z., Pramono, A., 2024. The Effect of Alumina Nanoparticles Impregnated Kevlar on Ballistic Resistance of Aluminum Alloy 7075 Hybrid Laminate Composite for Armor Application. International Journal of Technology. Volume 15(1), pp. 39-48

| Salsabila Syifa | Composites Laboratory, Department of Metallurgical and Materials Engineering, Faculty of Engineering, Universitas Indonesia, Kampus Baru UI, Depok 16424, Indonesia |

| Myrna Ariaty | Composites Laboratory, Department of Metallurgical and Materials Engineering, Faculty of Engineering, Universitas Indonesia, Kampus Baru UI, Depok 16424, Indonesia |

| Anne Zulfia Syahrial | Composites Laboratory, Department of Metallurgical and Materials Engineering, Faculty of Engineering, Universitas Indonesia, Kampus Baru UI, Depok 16424, Indonesia |

| Agus Pramono | Department of Metallurgical Engineering, Faculty of Engineering, Universitas Sultan Ageng Tirtayasa Jl. Jenderal Sudirman Km 3, Kotabumi, Cilegon, Banten 42435 Indonesia |

Military equipment

development, especially means of transportation, currently revolves around

material selection, which includes hybrid laminate composite as a prominent

material choice due to its strength-to-weight ratio. The hybrid laminate

composite was fabricated by involving aluminum alloy

7075-T6 sheets and Kevlar fabrics

that were introduced to shear thickening fluid (STF). STF was made by mixing

PEG-400, alumina nanoparticles, and ethanol in a certain ratio. The composites were fabricated using variations

of Kevlar layers of 8, 16, and 24 layers. Ballistic impact resistance of the hybrid laminate

composite was observed through a ballistic test that was performed according to

the National Institute of Justice (NIJ) 1080.01 level II standard. The energy

absorption of the composites was evaluated by analyzing the diameter of the

perforation. Additionally, the failure mode of the Al7075 matrix and Kevlar

fabric are discussed. The findings from ballistic testing indicated that the

addition of alumina nanoparticles into three variations of Kevlar layers in

hybrid laminate composite yielded the improvement of ballistic performance and

impact energy of the composites.

Alumina; Ballistic performance; Hybrid laminate composite; Shear thickening fluid

The

latest trend in the improvement of military equipment is focusing on the

development of material selection for ballistic protection, especially for

vehicles such as tanks. However, to produce an ideal tank, fuel consumption and

vehicle agility must be taken into consideration. In order to be used as an

armor material, the composite should have ballistic performance. The typical

steel used for armor material can be replaced by the aluminum alloy 7075-T6,

which has major applications in the military industry (Senthil et al., 2017). Studies prove that AA 7075-T6 has better ballistic performance compared

to AA 2024 and AA 6061(Yeter, 2018). To

further enhance the energy absorption ability, Kevlar, which is well-known for

its high strength and other mechanical properties that are comparable with

steel, was involved. A study demonstrates that a hybrid laminate composite

treated with nanoparticles increases energy absorption based on a ballistic test (Haro, Szpunar, and Odeshi, 2016a). Nanoparticles are used as the constituent of shear thickening fluid, which has a

special microstructural change that leads to an improvement in energy

absorption.

Shear

thickening fluid (STF) is a type of non-Newtonian fluid consisting of oxide

particles suspended in liquid polymers that respond to stress by increasing the

viscosity, which is widely known as a hydro clustering mechanism (Haro, Szpunar, and Odeshi, 2016a). This mechanism explains that upon exposure to a high

shear rate, nanoparticles cause repulsive loading by hydro clustering formation

that packs together temporarily, forming a chain-like shape (Kim et al., 2018).

Furthermore, this mechanism explains that particles are pushed together by

shear, and to move away from each other, and they must overcome the viscous

drag forces from small lubrication gaps between neighboring particles (Brown and Jaeger, 2014). The

principle implies that above a certain shear rate, the particles will grow into

clusters, and the clustering mechanism results in a rise in viscosity which in

turn acts like a solid (Hasanzadeh and

Mottaghitalab, 2014). The previous study

conducted by Agustha and Anne (2022) revealed that the impregnated

Kevlar in STF mixed with TiC consistently demonstrated a higher impact value

compared to composites with plain Kevlar due to the TiC nano-powder filling the

space between the impregnated Kevlar fibers. Thus, the presence of TiC boosted

the Kevlar’s ability to absorb energy. Also, TiC nano-powder also strengthened

the Kevlar’s structure so its fibers would be unlikely to undergo shear stress,

considering it would cost more energy to create fiber pull-out. Reinforcements

with about 20 to 50 layers of woven aramid fibers are required to produce a

high ballistic performance with respect to protection and energy absorption, in

which STF can be incorporated into the composite system to reduce the number of

layers of Kevlar fabric (Haro, Szpunar, and Odeshi, 2016b). Thus, the main objective of this research is to

observe the energy absorption behavior of hybrid laminate composite impregnated

with alumina, as a component of STF, with different thicknesses under both high

velocity and low-velocity impact along with the type of deformation both on the

aluminum surface and Kevlar fabric.

The method conducted in this research

consists of sample fabrication and experimental testing.

2.1. Sample

Fabrication

The process of fabricating hybrid laminate composites

started with the preparation of materials. Aluminum alloy 7075-T6 sheet and Kevlar-29

were cut into the size of 7.5 x 15 cm for ballistic test samples and 55 x 10 mm

dimensions for impact test samples. The chemical composition of aluminum alloy

was 90.5% Al, 5.1-6 .1% % Zn, 2.1-2.9% Mg, 1.2-2% % Cu, and max. 0.5% Fe. The

aluminum sheets’ surfaces were cleaned by using sandpaper and ethanol to remove

the impurities. The process was followed by the impregnation of Kevlar with

shear thickening fluid (STF) consisting of alumina with 99.9% purity and 50 nm

size supplied by Shanghai

Xinglu Chemical Tech Co, LTD and PEG-400 with a

1:2 ratio following (Haro, Szpunar, and Odeshi, 2016a). The formulation is shown in Tables 1 and 2.

Table 1 Shear Thickening Fluid Formulation for Ballistic Test Sample

|

Kevlar Layers |

Alumina

(g) |

PEG-400

(ml) |

Ethanol (ml) |

|

8 |

- |

- |

- |

|

16 |

- |

- |

- |

|

24 |

- |

- |

- |

|

8 |

10 |

20 |

20 |

|

16 |

20 |

40 |

40 |

|

24 |

30 |

60 |

60 |

STF was

produced by mixing an appropriate amount of alumina nanoparticles with

polyethylene glycol (PEG-400) by using a magnetic stirrer for 1 hour at the

speed of 1200 RPM. The process was continued by adding ethanol to the mixture

and stirring again for another 1 hour. Kevlar fabrics that had been cut into

desired dimensions were impregnated with STF. This step was followed by drying

for 72 hours at room temperature to let the ethanol dry up (Haro, Szpunar, and Odeshi, 2016a). The composite assembly was done with the

configuration shown in Figure 1. The hand lay-up method was used in the process

of composite assembly. The adhesive used was a mixture of epoxy resin

(Bisphenol A) and hardener with a ratio of 2:1. Pressure of 1600 Pa was given

to the composite for 24 hours at room temperature (Haro, Szpunar, and Odeshi, 2016a).

Table 2 Shear

Thickening Fluid Formulation for Impact Test Sample

|

Kevlar Layers |

Alumina

(g) |

PEG-400

(ml) |

Ethanol (ml) |

|

8 |

- |

- |

- |

|

16 |

- |

- |

- |

|

24 |

- |

- |

- |

|

8 |

1.47 |

2.94 |

2.94 |

|

16 |

2.94 |

5.88 |

5.88 |

|

24 |

4.41 |

8.82 |

8.82 |

Figure 1 Configuration of AA7075/Kevlar-Al2O3 Hybrid

Laminate Composite

2.2. Experimental Texting

2.2.1.

Microstructural Analysis and Fourier Transform Infrared (FTIR) Spectrometry

Microstructural analysis was carried out

on both impregnated and non-impregnated Kevlar samples to observe the

dispersion of alumina nanoparticles using a scanning electron microscope (SEM).

FTIR analysis was also performed on both samples to observe their respective

functional groups. Both SEM imaging and FTIR analysis were conducted at the

Center for Material Processing and Failure Analysis at Universitas Indonesia.

2.2.2.

Ballistic Test

A

ballistic impact test is categorized as a high-speed impact test that causes

local response on targets due to insufficient time to distribute the energy.

The test was performed by using a gun and projectile according to the NIJ

1080.01 standard level II, which are handgun (P1) and 9 x 19 mm projectile,

named Parabellum, weighed 8 grams with a hemispherical tip. The initial

velocity was 380 m/s with a 10 m distance. The energy absorbed by targets can

be calculated by Equation 1 and 2 from the difference

between the initial kinetic energy and the final kinetic energy as follows:

2.2.3. Impact Test

The

impact test is categorized as low-velocity impact test leading to the global

response. The test was performed by using the Charpy method according to ASTM

E23. The maximum energy exerted by the pendulum was 300 J.

3.1. Analysis of Nanoparticles Presence and

Dispersion

FTIR

spectra of non-impregnated samples show several major absorption bands at

wavelengths 3310.73, 1638.48, 1538.25, and 1303.33 cm-1, presented

in Figure 2. The wavelength of 3310.73 cm-1 corresponds to the

presence of the N-H group, followed by the wavelength of 1638.48 cm-1,

which indicates the presence of the amide carbonyl functional group (Ibrahim, Habib, and Jabrah, 2020). The wavelength of 1538.25 cm-1 is

assigned as an N-H bond, while the peak at 1303.33 cm-1 represents

the bonds of C-N and C-H bending (Ibrahim, Habib, and Jabrah, 2020).

As

compared to non-impregnated Kevlar, the impregnated sample show peaks at

3393.36, 2876.31, 1643.14, 1092.12, and 511.31 cm-1, shown in Figure

2. The peak at 3393.36 cm-1 is assigned as the terminal hydroxyl

group of PEG since the impregnated Kevlar contains PEG as the constituent of

STF (Gebregergs, 2018). The peaks at 2876.31, 1643.14, and 1092.17 cm-1 are

responsible for the presence of C-H bands, C=O stretching, and C-O-C (Gebregergs,

2018; Chieng et al., 2014; Polu and Kumar, 2011). The other prominent peak is at 511.31 cm-1, which is

assigned to the Al-O bond, indicating the presence of alumina (Nila

and Radha, 2018; Afruz and Tafreshi, 2014).

The dispersion of nanoparticles was observed

under a scanning electron microscope, and the results are shown in Figure 3.

Figures 3a and 3b demonstrate that individual Kevlar strands are arranged

neatly, but some vacancies are present between them. These vacancies can lead

to lower strength at a macroscopic scale. On the other hand, Figures 3c and 3d

illustrate the presence of alumina nanoparticles that have agglomerated with a

size of 350 nm, filling in the vacancies and covering some areas on the surface

of Kevlar fibers due to their nanoscale size.

The

effect of alumina nanoparticles' presence resulted in less amount of void,

which increased the strength and energy absorption ability. This also

facilitated stronger bonding of Kevlar fiber layers leading to stronger

structure (Haro, Szpunar, and Odeshi, 2016a). The impregnation can

strengthen fiber/matrix bonding and serve as a barrier to crack propagation,

which in turn increases the penetration resistance (Haro, Szpunar, and Odeshi, 2016a).

It

is apparent from Figure 3 that there are some agglomerated alumina

nanoparticles surrounding Kevlar fibers. Nanoparticles have high surface area

due to their smaller size, which leads to the increase in the Van der Waal

attractive force on the particle surface, which attracts other particles to

form a cluster that is referred to as the agglomeration process (Ilyas, Pendyala,

and Marneni, 2016). The small size of nanoparticles brings both advantages and disadvantages,

which is correlated to the high surface area. The disadvantage that can be seen

in Figure 3 is the attractive interaction between the particles, resulting in

agglomeration (Ashraf et al., 2018). Another study explains that nanoparticles

have an extremely high specific surface area, which makes them easy to

agglomerate (Zhu and Ou, 2014).

3.2. Analysis of

Kevlar Layer Amount and STF Impregnation to Ballistic Resistance

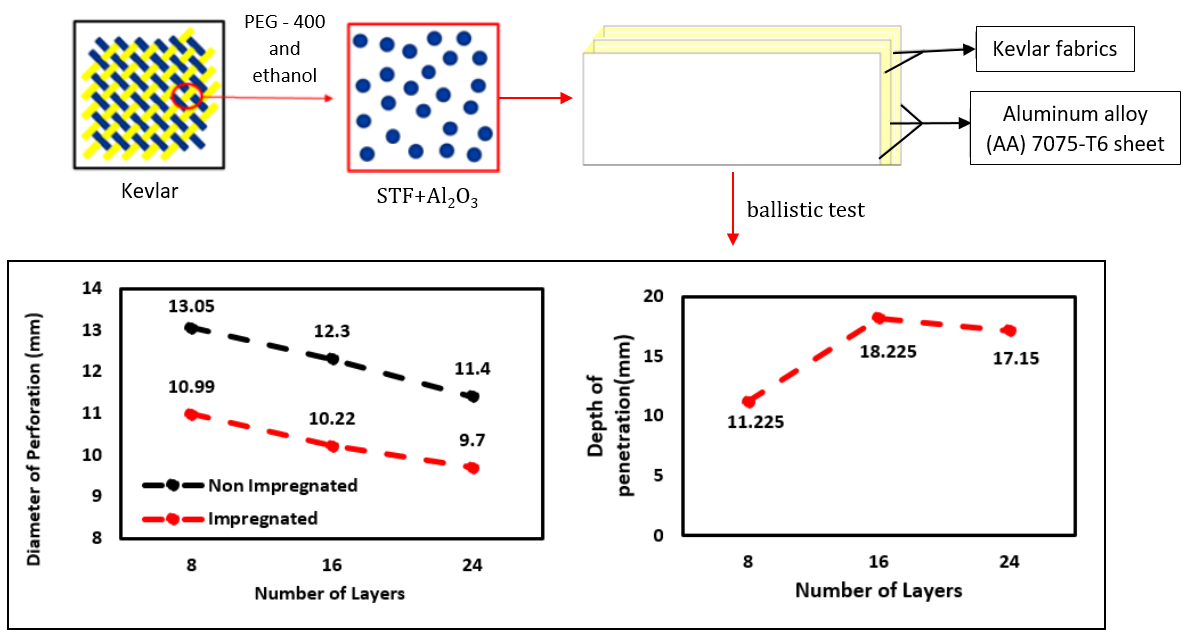

Figure 4a shows that the addition of Kevlar by 8 layers decreases the diameter of perforation by 5-7.3% within the category of non-impregnated and impregnated composite. In addition, the presence of alumina nanoparticles due to the impregnation process decreased the diameter of perforation by 14.9-16.9% for the same amount of Kevlar layers compared to non-impregnated ones. It can be explained that the increase in thickness increased the energy absorption since more fibers need to be broken, which leads to higher accumulative energy absorption from each layer (Liu et al., 2018).

Figure 2 FTIR Spectra of

Non-Impregnated and Impregnated Sample

Research shows that the increase in thickness leads to an increase in

energy absorption ability (Talib et al., 2012). The

presence of STF that contained alumina nanoparticles also contributed to the

perforation diameter. STF has such a mechanism that can resist the perforation

when it is subjected to the projectile. Owing to the mechanism of hydro cluster

formation, the viscosity of STF increases significantly in an instant. Hence,

the high-viscosity fluid, in which the clusters enhance the hydrodynamic

stress, is able to resist the energy to perforate the target (Haro, Szpunar, and Odeshi, 2016b).

The other parameter that can evaluate the ballistic performance is the

depth of penetration, presented in Figure 4b. The measurement of penetration

depth could only be done for impregnated samples as the non-impregnated samples

were not penetrated well. The general trend for depth of penetration is

increasing with the increase of Kevlar layers.

The low depth of penetration implies that the sample has less resistance

to projectile penetration (Haro, Szpunar, and Odeshi, 2016a). In principle, as the number of layers increases, the composite is able

to withstand energy exerted by projectiles. The energy received by the

composite will be distributed within the composite. As a result, the energy

absorption, which in this case is indicated by the depth of penetration, will

be higher.

The depth of penetration is proportional to the energy absorbed, meaning

that higher energy absorption can be observed by the high depth of penetration (Haro, Szpunar, and Odeshi, 2016a).

However, the depth of penetration increases significantly for the 16-layers

sample due to the presence of severely deformed parts. The deformed part was

also included in the measurement as it occurred in the site where the depth of

penetration could be measured. Meanwhile, the deformation in a 24-layers sample

was not so severe. The difference in the severity of deformation can explain by

the fact that although it had a lower depth of penetration than that of a

16-layers sample, the 24-layers sample had better resistance to a projectile,

which will be further discussed in the next section. This shows that the energy

absorption in a 24-layers sample was better as compared to a 16-layers sample.

3.3. Analysis of

Deformation Behavior of Ballistic Targets

It can be

compared that severe delamination took place in non-impregnated samples, while

impregnated samples experienced less severe delamination, which mostly occurs

at the front layers only. Delamination, which is shown in Figure 5a, b has such

a characteristic where the constituent layers of composites are detached after

being imposed to load. Delamination is assumed as an effect of interlaminar

stress, and other theories state that delamination is a type of failure that

occurs following the cracking of the matrix. The crack produces stress at the

interface between the layers, which leads to delamination (Stefan et al., 2020).

Delamination has such a mechanism in which a fraction of compressive stress is

reflected and becomes tensile stress, and the tensile wave causes crack

initiation (Mohotti et al., 2013).

Figure 3 SEM Observation Images of Non-Impregnated

Kevlar (a,b) and impregnated Kevlar (c,d)

Figure 4 Graphs of ballistic test: Diameter of Perforation (a); and Depth of

Penetration (b)

However, impregnated samples with 24 layers of Kevlar did not experience

delamination, as shown in Figure 5c. In impregnated samples, the clusters work

to enhance hydrodynamic stress by increasing the viscosity in the suspension

during impacts which contribute to the increase in delamination resistance as

well as resistance to posterior crack propagation through load distribution

between aluminum, resin, and the Kevlar fiber (Haro, Szpunar, and Odeshi, 2016b). In this

case, the major delamination mode is a combination of adhesion and cohesion

failure in which the adhesive layer remains on both surfaces of the Kevlar and

aluminum sheet. As seen in Figure 5, the adhesion/cohesion delamination was

dominated by adhesive failure. Furthermore, a study explains that delamination

in impregnated samples is less intense since the targets have better adhesion

with the aluminum sheet, resulting in more ductility and better resistance

against projectile penetration.

Macroscopical

photography was performed to better understand the phenomenon that cannot be

seen from the outside part of the impregnated samples. Petalling can be seen in

Figures 6a, b, and c, where the frontmost aluminum sheet created an open petal

shape. This shape was formed due to the compressive load of the projectile that

pushed the aluminum sheet to allow it to pass. The other type of deformation is

plugging which can be seen in Figures 6b and c. It occurred in the second sheet

of aluminum, which means that a fraction of the energy has been absorbed by the

front layer. Normally, plugging results in the detachment of the metal part,

but there is no evidence of such a failure in the sample. Instead, the sheet

was pushed back by the projectile as a mechanism of energy absorption.

Deformation due to compressive load from the projectile also took place at the

back surface of the samples, known as bulging. Bulging occurs due to the

remaining energy of the projectile that was absorbed by the backmost aluminum

sheet. However, the energy was not sufficient to penetrate through it and only

created a protruding spot in the sheet. Bulging can be seen clearly in Figure

6a. It is observed that bulging occurred in 8 and 16-layers composites. Figure

7 presents the back part of impregnated samples to better observe bulging.

Figure 5 Delamination

in 8-layers Non-Impregnated (a); Impregnated (b); 24-layers impregnated

Another thing that can be taken into consideration is the shape of the

projectile nose. Research shows that a hemispherical nose shape tends to

stretch the Kevlar fabric to failure instead of cutting through it by slipping

through the fabric and pushing it against the other layer (Khodadadi et al., 2019). The

stretching of Kevlar in the ballistic sample is shown in Figure 8. Due to its

high tensile strength, Kevlar is able to withstand the stretching effect from

the projectile.

Figure 7 Kevlar Stretching upon perforation (a); Bulging in impregnated 8-layers (b); and 16-layers configurations

3.4. Analysis of Charpy Impact Test Result

The average impact energy data for composite impact samples are shown in Figure 8. Impact energy is the absorbed energy by each sample. The addition of a Kevlar layer leads to an increase in impact energy. Additionally, impregnated samples have a higher impact energy than that non-impregnated samples. Due to impregnation, there was an increase in impact energy by 18.2%, 17.4%, and 15.3% for 8-layers,16-layers, and 24-layers configurations, respectively. The highest energy absorption is seen in the 24-layers impregnated sample. The increase in energy absorption is caused by the presence of alumina nanoparticles, which contribute to the energy absorption mechanism.

Figure 8 Graph of Average Impact Energy Absorption

for Non-Impregnated and Impregnated Samples

All impact samples showed bending in the middle since the

spots were hit by the pendulum, which can be seen in Figure 9. Non-impregnated

sample with 8 layers of Kevlar experienced less deformation as it has a less

delaminated part, and there is no sign of fracture or cracks on the aluminum

sheet. On the other hand, the non-impregnated sample with 16 Kevlar layers

delaminated more severely and experienced fracture in the frontmost aluminum

sheet. Meanwhile, 24-layers non-impregnated samples show slight delamination,

and there was no fracture.

The 8-layers and 16-layers configurations of impregnated

samples show bending and delamination. Lastly, the 24-layers sample shows

delamination, bending, and fracture. In impregnated samples, delamination may

also occur due to the agglomeration of nanoparticles that block a part of the

Kevlar area so that adhesive cannot completely reach Kevlar layers to hold it

together with the aluminum alloy sheet. Since the size of the impact test

sample is much smaller than that of ballistic samples, agglomeration has a

serious adverse effect. Besides, delamination is majorly generated by

interlaminar shear stresses, which are enhanced by the matrix cracks that

induce stress at the ply interface (Stefan et al., 2020). This condition is also supported by the global

response due to low-velocity impact.

Figure 9 Macro

photograph of Impact Test Results: 8 layers (a); 16 layers (b);

and 24 layers (c)

The effects of STF impregnation on Kevlar were observed in hybrid

laminate composites consisting of aluminum alloy 7075-T6, Kevlar, and epoxy

resin with three variations of Kevlar layers amount. Microstructural analysis

shows that alumina nanoparticles, as a constituent of STF, reduce the vacancies

in between Kevlar fibers which translates to higher energy absorption ability.

Some parameters that were investigated are perforation diameter, depth of

penetration, and impact energy. The results show that impregnation with STF

increases ballistic resistance and impact energy due to the hydro clustering

mechanism, which facilitates the ability to resist perforation in ballistic

test, which is categorized as high-velocity impact test. In addition, the

presence of STF and its hydro clustering mechanism also generate higher energy

absorption in impact test, which is categorized as low-velocity impact test.

Besides, the increasing amount of Kevlar layers also contribute to ballistic

resistance and energy absorption. The least severity of deformation mode from

the ballistic test is observed on the 24-layers impregnated ballistic sample.

The authors would like to thank

The Ministry of Research and Technology/National Research and Innovation Agency

for financial support under PDUPT Grant with contract number:

NKB-189/UN2.RST/HKP.05.00/2021.

Afruz, F.B., Tafreshi, M.J., 2014.

Synthesis of ?-Al2O3 Nano Particles by Different Combustion Modes using

Ammonium Carbonate. Indian Journal of Pure and Applied Physics, Volume

52(6), pp. 378–385

Agustha, F., Anne, Z.S., 2022, The Effect of

Nano TiC Impregnation on Kevlars and The Number of Layers on Ballistic

Properties of Laminate Hybrid Composite. Suranaree Journal of Science &

Technology, Volume 29(2), p. 010123

Ashraf, M.A., Peng, W., Zare, Y., Rhee, K.Y.,

2018. Effects of Size and Aggregation/Agglomeration of Nanoparticles on the

Interfacial/Interphase Properties and Tensile Strength of Polymer

Nanocomposites. Nanoscale Research Letters, Volume 13, pp. 1–7

Brown, E., Jaeger, H.M., 2014. Shear

Thickening in Concentrated Suspensions: Phenomenology, Mechanisms and Relations

to Jamming. Reports on Progress in Physics, Volume 77(4), p. 046602

Chieng, B.W., Ibrahim, N.A., Yunus, W.M.Z.W.,

Hussein, M.Z., 2014. Poly(lactic acid)/Poly(ethylene glycol) Polymer

Nanocomposites: Effects of Graphene Nanoplatelets. Polymers, Volume

6(1), pp. 93–104

Gebregergs, A., 2018. Synthesis and

Characterization of Cellulose-Based Hydrogels Using Citric Acid as a

Crosslinker. Addis Ababa University Addis, Ethiopia

Haro, E.E., Szpunar, J.A., Odeshi, A.G., 2016a.

The Energy Absorption Behavior of Hybrid Composite Laminates Containing

Nano-Fillers Under Ballistic Impact. International Journal of Impact

Engineering, Volume 96, pp. 11–22

Haro, E.E., Szpunar, J.A., Odeshi, A.G., 2016b.

Ballistic Impact Response of Laminated Hybrid Materials Made of 5086-H32

Aluminium Alloy, Epoxy and Kevlar® Fabrics Impregnated with Shear Thickening

Fluid. Composites Part A: Applied Science and Manufacturing, Volume 87, pp.

54–65

Hasanzadeh, M., Mottaghitalab, V., 2014. The

Role of Shear-Thickening Fluids (STFs) in Ballistic and Stab-Resistance

Improvement of Flexible Armor. Journal of Materials Engineering and

Performance, Volume 23(4), pp. 1182–1196

Ibrahim, M.B., Habib, H.Y., Jabrah, R.M.,

2020. Preparation of Kevlar-49 Fabric/E-Glass Fabric/Epoxy Composite Materials

and Characterization of Their Mechanical Properties. Revue Des Composites et

Des Materiaux Avances, Volume 30(3–4), pp. 133–141

Ilyas, S.U.,

Pendyala, R., Marneni, N., 2016. Stability and Agglomeration of Alumina

Nanoparticles in Ethanol-Water Mixtures. Procedia Engineering, Volume

148, pp. 290–297

Khodadadi, A.,

Liaghat, G., Bahramian, A.R., Ahmadi, H., Anani, Y., Asemani, S., Razmkhah, O.,

2019. High

Velocity Impact Behavior of Kevlar/Rubber and Kevlar/Epoxy Composites: A

Comparative Study. Composite Structures, Volume 216, pp. 159–167

Kim, Y.H., Park, Y., Cha, J.H., Ankem, V.A.,

Kim, C.G., 2018. Behavior of Shear Thickening Fluid (STF) Impregnated Fabric

Composite Rear Wall Under Hypervelocity Impact. Composite Structures,

Volume 204, pp. 52–62

Liu, L., Zhao, Z., Chen, W., Luo, G., 2018.

Influence of Pre-Tension on Ballistic Impact Performance of Multi-Layer Kevlar

49 Woven Fabrics for Gas Turbine Engine Containment Systems. Chinese Journal

of Aeronautics, Volume 31(6), pp. 1273–1286

Mohotti, D., Ngo, T., Mendis, P., Raman,

S.N., 2013. Polyurea Coated Composite Aluminium Plates Subjected to High

Velocity Projectile Impact. Materials & Design, Volume 52, pp. 1–16

Nila, A.S.S., Radha,

K., 2018. Synthesis

and XRD, FTIR Studies of Alumina Nanoparticle using Co-precipitation Method. International

Journal for Research in Applied Science and Engineering Technology, Volume

6(3), pp. 2493–2496

Polu, A.R., Kumar,

R., 2011. Impedance

Spectroscopy and FTIR Studies of PEG - Based Polymer Electrolytes. E-Journal

of Chemistry, Volume 8(1), pp. 347–353

Senthil, K., Iqbal, M.A., Chandel, P.S.,

Gupta, N.K., 2017. Study of The Constitutive Behavior Of 7075-T651 Aluminum

Alloy. International Journal of Impact Engineering, Volume 108, pp.

171–190

Stefan, A., Pelin, G., Dragomirescu, A.,

Petre, A., Ilina, S., 2020. Delamination Mechanisms in Fiber-Reinforced

Composites Structures Tested at Different Loadings. INCAS Bulletin,

Volume 12(1), pp. 175–182

Talib, A.R.A., Abbud,

L.H., Ali, A., Mustapha, F., 2012. Ballistic Impact Performance of Kevlar-29 and

Al2O3 Powder/Epoxy Targets under High Velocity Impact. Materials and Design,

Volume 35, pp. 12–19

Yeter, E., 2018. Investigation of Ballistic

Impact Response of Aluminum Alloys Hybridized with Kevlar/Epoxy Composites. Politeknik

Dergisi, Volume 22(1), pp. 219–227

Zhu, Q. W., Ou, M.G., 2014. The Function of

PEG in The Synthesis of Nanomaterials. Applied Mechanics and Materials, Volume

670, pp. 3–9