Coating Material Development by Pulsed Laser Deposition for JIS SKD61 Steel Insert Pins Used in Aluminum Casting Industry

Corresponding email: rusmankosasihsoehi@gmail.com

Published at : 28 Jun 2023

Volume : IJtech

Vol 14, No 4 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i4.6046

Kosasih, R., Priadi, D., Suliyanti, M.M., 2023. Coating Material Development by Pulsed Laser Deposition for JIS SKD61 Steel Insert Pins Used in Aluminum Casting Industry. International Journal of Technology. Volume 14(4), pp. 833-842

| Rusman Kosasih | Material and Metallurgical Engineering Department, Faculty of Engineering, University of Indonesia, Depok, 16424, Indonesia |

| Dedi Priadi | Material and Metallurgical Engineering Department, Faculty of Engineering, University of Indonesia, Depok, 16424, Indonesia |

| Maria Margaretha Suliyanti | Research Center for Photonics, National Research and Innovation Agency, South Tangerang, 15314, Indonesia |

A Pulsed Laser Deposition (PLD) technique is a

type of physical vapor deposition (PVD) technology. This research is one of a

series of PVD studies aimed at determining the best PLD coating that can

minimize the damage of steel pins made of SKD61 with a hardness of 48±1 HRc.

The study began with the dummy blocks from SKD61 as research samples, followed

by PVD-PLD with three coating materials as alternatives: Al/Cr (70:30), Al/Ti1

(50:50), and Al/Ti2 (63:37), all without active gases (N and C). The procedures

used to test the research findings were FESEM, SEM, XRF, EDS, Vickers, and

Rockwell Microhardness. The experiments were conducted at the BRIN Fotonic

Research Center and the PT AHM Laboratory. The PLD process lasted for 10

minutes and employed an Nd: YAG laser with a wavelength of 1064 nm, a Q-switch

with a time delay of 180 s, a pulse energy of 70 mJ, and a vacuum pressure of

1.161.35 Torr.Based on the results of the coating study, an AlTi1 coating was

found to be the most effective material coating. The coating consisted of

amorphous particles with a size range of 10 nm to 20 nm The coating had a

thickness of 23 µm, and the surface hardness was measured to be 474-523 mHv for

the single-layer coating and 477-501 mHv for the multilayer coating. The

materials in both single-layer and multilayer coating samples have the same

hardness in ascending order: AlCr, AlTi2, AlTi1, with a Ti concentration rise

from 0.7% to 3.7%. The impact of the Ti element is also crucial in increasing

hardness, wear resistance, and roughness.

Coating material; Minimize damage; Pin SKD 61; PLD process

Physical Vapour Deposition – Pulse Laser Deposition

( PVD-PLD ) is a coating process that has been widely used since 1987 to

generate superconductive thin films with high-temperature resistance, which are

employed in superconductors, medical applications, and electric, magnetic, and

protective layers (Bruncko et al., 2019; Duta and Popescu, 2019; Lorusso et al., 2015; Krebs et al.,

2003). It is sensitive to the target condition, pulse

energy, wavelength, vacuum process, target lens focus distance, and gas

condition (Subramaniam, 2015). A typical PLD process

experimental setup includes five key elements: target, substrate, laser, plasma

plume, and vacuum condition (Masood, 2014).

PLD has been developed in the last 10 years to manufacture crystalline layers

for ceramic oxide, nitride films, and metallic multilayers, as well as to

synthesize nanotubes, nanopowder, and quantum dots.

Pulse Laser Deposition – Neodymium-doped

yttrium aluminum garnet (PLD-NdYAG) uses a laser beam to ionize the target

material, which is then dispersed through a plasma arc generated during the

laser irradiation process. The released ions are then deposited on a substrate

as a thin layer made of 10-9 m nanosized particles, together with reactive

gases (Katase et al., 2012; Eason, 2007). Some physical and chemical material characteristics can

change dramatically on the nanoscale from those of bulk-structured materials

with the same composition. For example, the theoretical strength of

nanomaterials can be achieved, or quantum effects can appear; nanosized

crystals have a low melting point (up to a 1000°C difference with bulk

structures) and reduced lattice constants because surface atoms or ions form a

significant fraction of the total number of atoms or ions, and surface energy

plays a significant role in thermal stability (Balaskas et al., 2012; Katase et al., 2012; Pokropivny et

al., 2007). Laser irradiance, Pulse Repetition Rate,

and Liquid or Gas media also have important role for the deposition process (Khumaeni, Sutanto

and Budi, 2019).

Scholars have been intrigued by current

research and uses of superconductive materials, prompting them to investigate

their potential usage for protective coatings (Yang et al., 2018; Willmann et al., 2008). Furthermore, the aluminum casting industry has seen an increase in the

demand for protective layers to deal with die soldering. Die soldering occurs

when aluminum welds to the dies or mold surface, leading to die damage and

component defects and thereby halting production. Repairs are expensive and add

more than an hour to production time. Die soldering is scientifically described

as a chemical reaction that occurs during die casting between molten aluminum

and the die surface. This reaction happens due to the washout or removal of a

protective layer, such as a coating or lubricant, on the die. At sufficiently

high temperatures and pressures, a protective layer is broken when liquid

aluminum comes into contact with the die surface (Han, 2015). There are several alternatives method to minimize die

soldering. Researchers have been studying to use of alloying material (Kohlhepp et al., 2021), dies treatment method (Mochtar and Aldila, 2020), and coating method (Serekpayeva

et al., 2022; Kukuruzovic et al., 2021).

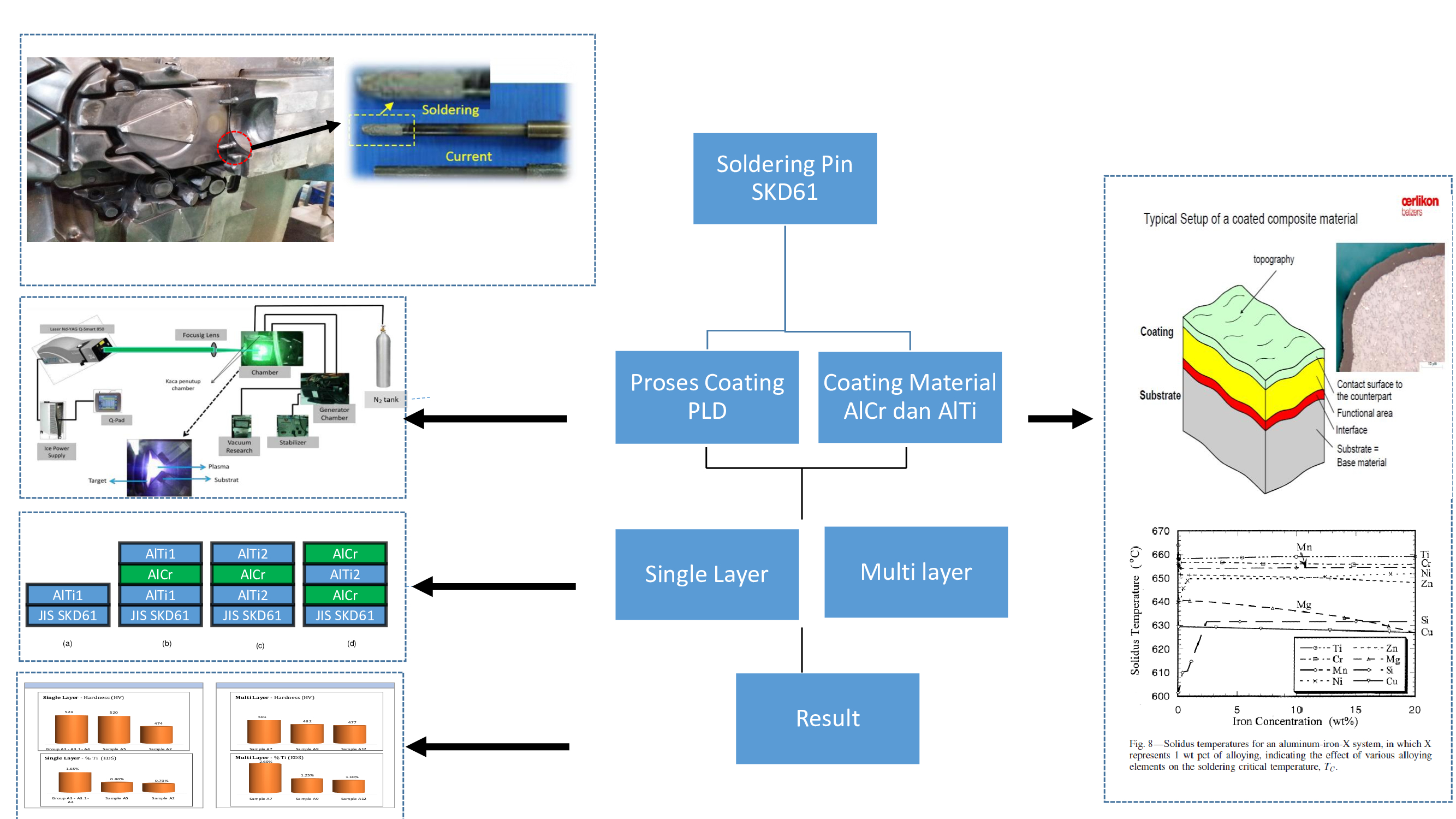

Figure 2

Samples of the two coating materials: AlCr and AlTi. a) single layer AlTi, b)

multi-layer AlTi 50:50/ AlCr/ AlTi 50:50, c) multi-layer AlTi 63:37/ AlCr/ AlTi

63:37, (d) multi-layer AlCr/ AlTi 63:37/ AlCr

2.3. PLD Preparation

The

PLD-NdYAG experiment was carried out at a wavelength of 1064nm, with a pulse

energy of 70mJ, Q-switch after a time delay of 180s, a vacuum pressure

of 1.16~1.35Torr, and a lens focusing distance of 15cm (Figure 3).

These settings are determined through experiments to get the optimum setup

outcomes as shown by plasma production in the target coating material. The good

plasma is the one which has a 2-3mm flame dia, solid, and silent sound. To

investigate the impacts, the materials were categorized such as A1–A6 for

single layer and A7–A12 for multilayer. The experiments were conducted in a

vacuum chamber with dimensions of 9cm x 9cm x 12cm, using a 15cm focus lens

to enhance the strength of the laser strike. A rotary motor was used to

maintain a target rotation speed of 3rpm, while the target-substrate distance

was set at approximately 1-1.5cm.

The samples were divided into groups to investigate

the impacts of Al, Ti, and Cr and compare their alloy compositions with

mechanical properties, i.e. the hardness of the coating layer (Figure 4). They

were also divided into two groups based on coating processes (single-layer and

multilayer) to see how the number of layers affected the same mechanical

qualities. Table 1 shows the classification.

Figure 4 Visual examination of the SKD61

plates after PLD

Table 1

Sample grouping by coating materials and techniques

|

Coating

Materials |

Samples |

Coating

Techniques |

|

Al/Cr (70:30) |

A1, A2 |

Single-layer |

|

Al/Ti1 (50:50) |

A3, A4 |

Single-layer |

|

Al/Ti2 (70:30) |

A5, A6 |

Single-layer |

|

Al/Ti1, Al/Cr, Al/Ti1 |

A7, A8 |

Multilayer |

|

Al/Ti2, Al/Cr, Al/Ti2 |

A9, A10 |

Multilayer |

|

Al/Cr, Al/Ti1, Al/Cr |

A11, A12 |

Multilayer |

3.1. FESEM test results

Field

emission scanning electron microscopy (FESEM, FEI Helios Dual Beam) was used to

study the microstructures of the PLD coatings at 10,000x, 20,000x, and 60,000x

magnifications. FESEM images (Figure 5 and 6) reveal the presence of extremely

tiny particles, 10-20nm in size, with a thickness of 23µm~30µm.

This particle size is predicted to open up several opportunities to discover mechanical

characteristics that differ from castings containing Al-Si particles with

normal diameters of around 110µm (Ishak et al., 2017; Pokropivny

et al., 2007). In general, smaller sizes can have a bigger ratio

of surface area vs volume than the normal size. In the end, it will bring more

reaction at the surface of the nanoparticles (Ramahdita, 2011). Therefore, PLD may be used

to create thin films, multilayers, nanotubes, nanofilaments, and nanosized

particles (Christen and Eres, 2008).

Furthermore, as shown in the cross-section of the coating, the coating film is

23µm~30µm thick, defining it as a thin film.

Figure 6 FESEM images showing the

cross-section and thickness of the coating (250x and 1,000x magnifications)

3.2. XRF test results

The Oxford X-MET 3000TX was used for the X-ray

fluorescence (XRF) test, and the findings were seen using the NIKON Epiphot 300

metallographic microscope. As shown in the Table 2. With an average weight of

91%, 10Fe (basic metal) is discovered to be the main element. Similarly, Cr is

the leading element in all of the investigated samples, although accounting for

just 4.99% to 5% of the basic metal. Because of the lack of equipment

capabilities and thickness of the coating film, Ti cannot be identified.

Because the coating created is too thin, this composition is conceivable (Katase et al., 2012); as a

result, the detection process can penetrate the basic metal.

Table 2

Chemical compositions of the PLD coating samples, as identified in the XRF test

|

No |

Sample |

Composition (weight %) | |||

|

Fe |

Cr |

Ti |

Al | ||

|

1 |

Sample A2 |

91.1 |

4.9 |

0 |

Not Defined |

|

2 |

Sample A3 |

91.6 |

5.1 |

0 |

Not Defined |

|

3 |

Sample A3.1 |

91 |

5 |

0 |

Not Defined |

|

4 |

Sample A4 |

91.1 |

5.1 |

0.1 |

Not Defined |

|

5 |

Sample A5 |

91 |

5 |

0.1 |

Not Defined |

|

6 |

Sample A7 |

91.1 |

5 |

0.2 |

Not Defined |

|

7 |

Sample A9 |

90.9 |

5.3 |

0 |

Not Defined |

|

8 |

Sample A12 |

90.9 |

5 |

0.1 |

Not Defined |

3.3. SEM-EDS test results

Analytical scanning electron microscope (SEM, JEOL

JSM 6360 LA) observations reveal noticeable dark and bright lines on the

coating. According to the EDAX Elect Plus energy dispersive spectroscopy (EDS)

test, the bright lines (001) contain more Fe than their dark counterparts (002)

(Figure 7). Both Cr and Ti content may be identified using the EDS and EDAX

methods. Cr content is 0.9% and 5.4% by weight. While the Ti content is 0.7%

and 3.7% by weight (Table 3).

Figure 7 A noticeable dark and bright

lines of the PLD coating samples, as identified in the SEM-EDS test

The titanium (Ti)

content of the coated surface has a significant impact on its hardness, as

shown in Figure 8 and Table 4. For the single layer type, the sample with the

highest Ti concentration (1.65%, sample A3) exhibited a hardness value of 523

mHv, while the sample with the lowest Ti content (0.7%, sample A2) had a

hardness of 474 mHv. In the case of the multi-layer type, the highest Ti

concentration (2.6%, sample A7) resulted in a hardness value of 501mHv, while

the lowest Ti content (1.1%, sample A12) produced a hardness of 477mHv. These

results indicate that the greater the Ti percentage, the higher the hardness

value of the coated layer (Comakli et

al., 2018). According to the hardness test findings, the

ex-single-layer coating is harder than the ex-multilayer coating. In the

meanwhile, another study revealed that multilayer coatings of varying

thicknesses can increase performance (Vereschaka et al.,

2018).

Table 3

Chemical compositions of the PLD coating samples, as identified in the EDS test

(EDAX Elect Plus)

|

No |

Insert Pin |

Chemical Composition By SEM-EDS (wt%) | ||||

|

Fe |

Al |

Ti |

Cr | |||

|

1 |

Sample A2 |

001 |

29.6 |

4.4 |

1.2 |

5.4 |

|

002 |

3.1 |

10.9 |

0.7 |

3.2 | ||

|

2 |

Sample A3 |

001 |

39.6 |

2.2 |

1.1 |

4.7 |

|

002 |

8.5 |

1.3 |

0.6 |

1.6 | ||

|

3 |

Sample A3.1 |

001 |

30.3 |

2.9 |

1.2 |

4 |

|

002 |

3.2 |

5.5 |

3.7 |

1 | ||

|

4 |

Sample A4 |

001 |

32.3 |

3 |

1.5 |

4.7 |

|

002 |

2.8 |

5.7 |

3.6 |

0.9 | ||

|

5 |

Sample A5 |

001 |

31.3 |

3.6 |

0.7 |

4 |

|

002 |

16 |

2.4 |

0.9 |

2,3 | ||

|

6 |

Sample A7 |

001 |

39.3 |

4.5 |

2.2 |

4,2 |

|

002 |

3.5 |

6.8 |

3 |

1.6 | ||

|

7 |

Sample A9 |

001 |

45.4 |

2.4 |

1.2 |

5 |

|

002 |

2.4 |

5.6 |

1.3 |

1 | ||

|

8 |

Sample A12 |

001 |

14 |

4.6 |

1.1 |

3.1 |

|

002 |

1.5 |

7.1 |

1.9 |

1.7 |

||

Table 4 Hardness,

materials, and compositions of coating samples with different coating

techniques

|

Ti (%) |

mHv |

Materials |

Compositions | |

|

Single-layer | ||||

|

A3, A3.1, A4 |

1.65 |

523 |

Al/Ti1 |

50:50 |

|

A5 |

0.80 |

520 |

Al/Ti2 |

63:37 |

|

A2 |

0.70 |

474 |

Al/Cr |

50:50 |

|

Multilayer | ||||

|

A7 |

2.60 |

501 |

Al/Ti1 |

Ti1/Cr/Ti1 |

|

A9 |

1.25 |

482 |

Al/Ti2 |

Ti2/Cr/Ti2 |

|

A12 |

1.10 |

477 |

Al/Cr |

Cr/Ti/Cr |

Figure 8 Vickers hardness test results

of the single-layer and multilayer groups

3.4. VDI adhesion and

roughness test results

The single-layer group's Rockwell hardness (FUTURE

Tech FR-3EL) and SEM test results (Figure 9) revealed that Al/Ti1 (50:50) has

higher adhesion performance and roughness than Al/Cr (70:30). Wear resistance

shifts from HF1 (AlCr) to HF2 (AlTi), and roughness shifts from 0.051m (AlCr)

to 0.050m. ( AlTi ). Adhesive level starts from good HF1–HF4, up to bad HF5–HF6. According to the findings of the adhesion and roughness tests, there is

a close relationship between hardness, adhesiveness, and roughness, with Ti

playing a substantial influence. Ti produces a tougher layer, which improves

adhesive performance and roughness.

Figure

9 Adhesion performance and

roughness of (a) AlCr 70/30 and (b) AlTi 50/50

Table 5

Adhesion Performance and roughness of AlCr 70/30 and AlTi 50/50

(a) (b)

|

AlCr 70/30 : 180 mJ/20’ |

AlTi 50/50 : 180 mJ/20’ | |||||

|

Work |

: |

Roughness |

Work |

: |

Roughness | |

|

Wavelenght |

: |

1064nm |

Wavelenght |

: |

1064nm | |

|

Date |

: |

04.Mar.20 |

Date |

: |

04.Mar.20 | |

|

Time |

: |

13:38:27 |

Time |

: |

13:44:18 | |

|

Adhesion |

: |

HF 1 |

Adhesion |

: |

HF 2 | |

|

Roughness |

: |

0.051 |

Roughness |

: |

0.05 | |

With the parameter settings utilized in this work,

the PLD-NdYAG method has been shown to be capable of creating a coating layer

with nanosized particles, i.e. 10-20nm.

In this experiment, the former reached a maximum hardness of 523mHv,

while the latter had a maximum hardness of 501mHv. Furthermore, the presence

of Ti in the target material increases the hardness of the coating, in contrast

to Cr. Ti has a hardness of up to 520mHv in single-layer coating samples with

a somewhat comparable composition, Al/X (65:35), whereas Cr has a hardness of

474mHv. Material composition differences suggest that greater Ti

concentrations in the coating are related to enhanced hardness. The coating

materials in the single-layer samples are hardened in the following order: Al/Cr

(70:30, 474mHv), Al/Ti2 (63:37, 520mHv), Al/Ti1 (50:50, 523mHv). The metal

surface adhesion and roughness test findings support the conclusion that Ti

produces better-performing coatings than Cr. Al/Ti1 (50:50) has HF2 wear

resistance and a Ra roughness of 0.050m, whereas Al/Cr (70:30) has HF1 wear

resistance and a Ra roughness of 0.051m. As a result, further studies in the

PVD research series are expected to meet the primary goal: the optimum coating

to avoid die soldering of SKD61 insert pins.

The authors would like to express their

appreciation to the University of Indonesia's Material and Metallurgical

Engineering Department (postgraduate programme), the BRIN Fotonic Research

Center, and PT AHM Laboratory for providing research opportunities and

assistance during the experiment and characterization.

Balaskas, A.C., Kartsonakis, I.A., Tziveleka, L.-A. Kordas,

G.C., 2012. Improvement of Anti-Corrosive Properties of Epoxy-Coated AA 2024-T3

with TiO2 Nanocontainers Loaded With 8-Hydroxyquinoline. Progress

in Organic Coatings, Volume 74(3), pp. 418–426

Bruncko, J., Sutta, P., Netrvalová, M., Michalka, M., Vincze,

A., 2019. Pulsed Laser Deposition of Ga doped ZnO Films-Influence of Deposition

Temperature and Laser Pulse Frequency on Structural, Optical and Electrical

Properties. Vacuum, Volume 159, pp. 134–140

Christen, H.M., Eres, G., 2008. Recent Advances in

Pulsed-Laser Deposition of Complex Oxides. Journal of Physics: Condensed

Matter, Volume 20(26), p. 264005

Comakli, O., Yazici, M., Yetim, T., Yetim, A., Çelik,

A., 2018. Effect of Ti Amount on Wear and Corrosion Properties of Ti-doped Al2O3

Nanocomposite Ceramic Coated CP Titanium Implant Material. Ceramics

International, Volume 44(7), pp 7421–7428

Dennis, R.V., Patil, V., Andrews, J.L., Aldinger,

J.P., Yadav, G.D., Banarjee, S., 2015. Hybrid Nanostructured Coatings for

Corrosion Protection of Base Metals: A Sustainability Perspective, Materials

Research Express, Volume 2(3), p. 032001

Duta, L., Popescu, A.C., 2019. Current Status on

Pulsed Laser Deposition of Coatings from Animal-Origin Calcium Phosphate

Sources, Coatings, Volume 9(5), p. 335

Eason, R., 2007. Pulsed Laser Deposition of Thin

Films: Applications-Led Growth of Functional Materials. John Wiley &

Sons

Han, Q., Viswanathan, S., 2003. Analysis of The

Mechanism of Die Soldering in Aluminum Die Casting. Metallurgical and

Materials Transactions A, Volume 34(1), pp 139–146

Han, Q.Y., 2015. Mechanism of Die Soldering During

Aluminum Die Casting. China Foundry, Volume 12(2), pp. 136–143

Ishak, N.N.M., Salleh, M.S., Yahaya, S.H., Mohamad, E.,

Sulaiman, M.A., 2017. The Effect of Equal Channel Angular Pressing (ECAP) on

The Microstructure and Hardness of A356 Aluminium Alloy. Journal of Advanced

Manufacturing Technology, Volume 11, pp 47–58

Katase, T., Hiramatsu, H., Kamiya, T., Hosono, H., 2012. Thin Film Growth by Pulsed Laser Deposition and Properties of 122-Type Iron-Based Superconductor AE (Fe1–xCox) 2As2 (AE= alkaline earth). Superconductor Science and Technology, Volume 25(8), p. 084015

Khumaeni, A.,

Sutanto, H., Budi, W.S., 2019. The Role of Laser Irradiance, Pulse

Repetition Rate, and Liquid Media in the Synthesis of Gold Nanoparticles by the

Laser Ablation Method using an Nd:YAG Laser 1064 nm at Low Energy. International

Journal of Technology, Volume 10(5), pp. 961–969

Kohlhepp, M., Uggowitzer, P.J., Hummel, M., Hoppel,

H.W., 2021 Formation of Die Soldering and the Influence of Alloying Elements on

the Intermetallic Interface. Materials, Volume 14(7), p. 1580

Krebs, H.U., Weisheit, M., Faupel, J., Süske, E.,

Scharf, T., Fuhse, C., Stormer, M., Sturm, K., Seibt, M., Kijewski, H., Nelke,

D., Panchenko, E., Buback, M., 2003. Pulsed Laser Deposition (PLD)--a Versatile

Thin Film Technique. In: Advances in Solid State Physics. Springer, pp

505–518

Kukuruzovic, D., Terek, P., Kovacevic, L, Skoric, B.,

Miletic, A., Panjan, P., Cekada, M., 2021. Investigation of CrAlN Coatings

Soldering Resistance for High Pressure Die Casting Tools. SVC Bulletin

Fall/Winter 2021, pp. 1–7

Lorusso, A., Gontad, F., Broitman, E., Chiadroni, E.,

Perrone, A., 2015. Characterisation of Pb thin Films Prepared by The Nanosecond

Pulsed Laser Deposition Technique For Photocathode Application. Thin Solid

Films, Volume 579, pp. 50–56

Masood, S.H., 2014. Advances in Fused Deposition

Modeling. In: Comprehensive Materials Processing, pp. 69–91

Mochtar, M.A., Aldila, R., 2020. Die Soldering

Behavior of H13 and Cr-Mo-V Tool Steel on die Casting Process on Nitriding-Shot

Pinning Die Surface Treatment. Materials Science Forum, 2020, Volume

1000, pp 381–390

Oerlikon, P., 2012. Technical Training Module. Internal

Company Course Training

Pane, J., Simbolon, D.H., Izzudin, H., Afandi, A.,

Hermanto, B., Sebayang, K., Humaidi, S., Situmorang, M., Sudiro, T., 2023.

Cyclic Oxidation Resistance of MoSi2 Added FeCrAlTiY Coatings on ST41 Steel at

700°C Prepared by a Flame Spraying Technique. International Journal of

Technology, Volume 14(1), pp. 15–25

Pokropivny, V., Lohmus, R., Hussainova, I.,

Pokropivny, A., Vlassov, S., 2007. Introduction to Nanomaterials and

Nanotechnology. Ukraine: Tartu University Press

Presuel-Moreno, F., Jakab, M.A., Tailleart, N.,

Goldman, M., Scully, J.R., 2008. Corrosion-Resistant Metallic Coatings, Materials

Today, Volume 11(10), pp. 14–23

Ramahdita, G., 2011. Karakterisasi Nanopartikel ZnO

Hasil Sintesis Dengan Metode Presipitasi dan Perlakuan Pra-Hidrotermal (Characterization

of Synthesized ZnO Nanoparticles Using Precipitation Method and

Pre-Hydrothermal Treatment), Thesis, Graduate Program, Departement Teknik

Metalurgi dan Material, Universitas Indonesia, Depok, p. 105

Saravanan, M., Devaraju, A., Venkateshwaran, N.,

Krishnakumari, A. Saarvesh, J., 2018. A Review on Recent Progress in Coatings

on AISI Austenitic Stainless Steel. Materials Today: Proceedings, Volume

5(6), pp. 14392–14396

Serekpayeva, M., Niyazbekova, R., Al Azzam, K.M.,

Negim, E., Yeleussizova, A., Ibzhanova, A., 2022. Investigation of the

Properties of Metallurgical Slags and Dust of Electro Filters to Obtain

Protective Anticorrosive Coatings. International Journal of Technology, Volume

13(3), pp. 544–552

Subramaniam, T., 2015. 11 Pulsed Laser

Deposition-DrVijayaRamnath-PDF Available online at: https://www.researchgate.net/publication/278672973_11_Pulsed_Laser_Deposition-DrVijayaRamnath-PDF,

Accessed on July 22, 2020

Vereschaka, A., Grigoriev, S., Sitnikov, N., Oganyan,

G., Sotova, C., 2018. Influence of Thickness of Multilayer Composite

Nano-Structured Coating Ti-TiN-(Ti, Al, Cr) N On Tool Life of Metal-Cutting

Tool. Procedia CIRP, Volume 77, pp. 545–548

Wang, Z., Li, J., Wang, Y., Wang, Z., 2017 An EIS

Analysis on Corrosion Resistance Of Anti-Abrasion Coating. Surfaces and

Interfaces, Volume 6, pp 33–39

Willmann, H., Mayrhofer, P.H., Hultman, L., Mitterer,

C., 2008. Hardness Evolution of Al–Cr–N Coatings Under Thermal Load. Journal

of Materials Research, Volume 23(11), pp 2880–2885

Yang, T.S., Yao, S.H., Chang, Y.Y., Deng, J.H., 2018

Contact Behavior of Composite CrTiSiN Coated Dies in Compressing of Mg Alloy

Sheets under High Pressure. Materials, Volume 11(1), p. 88