A Comparison of EFB to Ethanol Production by Integrating Between RBD Palm Oil and EFB Pulping Plant: An Assessment for Energy, Environmental and Economical Advantages

Corresponding email: qaismajnun@gmail.com

Published at : 28 Jun 2023

Volume : IJtech

Vol 14, No 4 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i4.6015

Setiawan, A.A.R., Putri, A.M.H., Bardant, T.B., Maryana, R., Sudiyani, Y., Muryanto, Triwahyuni, E., Dahnum, D., Rinaldi, N., Irawan, Y., Ahamed, T., Noguchi, R., 2023. A Comparison of EFB to Ethanol Production by Integrating Between RBD Palm Oil and EFB Pulping Plant: An Assessment for Energy, Environmental and Economical Advantages. International Journal of Technology. Volume 14(4), pp. 877-887

| Arief Ameir Rahman Setiawan | 1. Graduate School of Science and Technology, University of Tsukuba, 1-1-1 Tennodai, Tsukuba, 305-8572, Japan, 2. Research Centre for Sustainable Production System and Life Cycle Assessment, National |

| Ary Mauliva Hada Putri | Research Centre for Chemistry, National Research and Innovation Agency, 452 Bldg, Puspiptek, Tangerang Selatan, 15314, Indonesia |

| Teuku Beuna Bardant | Research Centre for Chemistry, National Research and Innovation Agency, 452 Bldg, Puspiptek, Tangerang Selatan, 15314, Indonesia |

| Roni Maryana | Research Centre for Chemistry, National Research and Innovation Agency, 452 Bldg, Puspiptek, Tangerang Selatan, 15314, Indonesia |

| Yanni Sudiyani | Research Centre for Chemistry, National Research and Innovation Agency, 452 Bldg, Puspiptek, Tangerang Selatan, 15314, Indonesia |

| Muryanto | Research Centre for Chemistry, National Research and Innovation Agency, 452 Bldg, Puspiptek, Tangerang Selatan, 15314, Indonesia |

| Eka Triwahyuni | Research Centre for Chemistry, National Research and Innovation Agency, 452 Bldg, Puspiptek, Tangerang Selatan, 15314, Indonesia |

| Deliana Dahnum | Research Centre for Chemistry, National Research and Innovation Agency, 452 Bldg, Puspiptek, Tangerang Selatan, 15314, Indonesia |

| Nino Rinaldi | Research Centre for Chemistry, National Research and Innovation Agency, 452 Bldg, Puspiptek, Tangerang Selatan, 15314, Indonesia |

| Yan Irawan | Research Centre for Chemistry, National Research and Innovation Agency, 452 Bldg, Puspiptek, Tangerang Selatan, 15314, Indonesia |

| Tofael Ahamed | Faculty of Life and Environmental Sciences, University of Tsukuba, 1-1-1 Tennodai, Tsukuba, 305-8572, Japan |

| Ryozo Noguchi | Graduate School of Agriculture, Kyoto University, Kitashirakawa Oiwake-cho, Sakyo-ku, Kyoto 606-8502, Japan |

Black liquor combustion; Cellulose hydrolysis; Energy effectiveness; Utilization

In commercial scale best practice, as also simulated in this paper, the

fiber and shell were simulated to be burned as an energy source. Empty Fruit

Bunch (EFB) becomes the rest challenging waste to deal with. Utilization of EFB

ash for fertilizer is no longer an interesting option since many Crude Palm Oil

(CPO) producing countries not allowing EFB burning in plantation sites (Walker et al., 2018; Van-Dam, 2012). Thus, a special incinerator was required for

converting EFB into ash. Mulching EFB to the plantation land was the second

cheapest practice and claimed to improve soil deterioration management by

avoiding run-off and erosion (Afandi et al., 2017). Along with global concern for the

environmental impact of the production process, the Global Warming Potential

(GWP) of the process becomes a challenging issue. The GWP per ton of EFB, if stockpiled

on land surfaces as the open lagoon-like mulching practice, is 180.90 kg CO2

equivalent (Nasution et al., 2020).

Converting EFB into ethanol is one of the promising options due to its

potential availability, as acknowledged in a previous review (Hossain et al., 2017). The conversion path

proposed by this review was similar to this study, which is through Saccharomyces

cerevisiae fermentation. The review also briefly introduced commercializing

other fermentation products as a co-product, xylitol. Selling dried yeast is

also a co-product option. A preliminary study utilizing EFB hydrolysate for

producing dried Saccharomyces cerevisiae yeast gave promising results.

The production cost per kilogram of dried yeast was less than Rp 20,000.00 or

US$ 1.27 (Hermansyah et al., 2015).

The potential profit from co-product is an advantage for covering the extra

cost in EFB-to-ethanol conversion. The extra cost came from the lignocellulose

pre-treatment requirement. Some studies even observed the utilization of advanced

physical process assistance for pre-treatment, such as microwaves (Harahap et al., 2019) and ultrasound (Hermansyah et al., 2019). However, the

production cost is still challenging compared to starch-based raw materials.

A previous study used tofu waste as raw material and Aspergillus

niger as hydrolyzing agent (Febrianti et al.,

2017). The study reported that substrate conversion efficiency was up to

88%, but the obtained bioethanol was 7.69 g/L. Bioethanol production through

fermentation other than yeast was reported using Clostridium ljungdahlii

(Anggraini et al., 2019). The

bacteria used synthetic gas as a feed, but the obtained ethanol concentration

was 1.09 g/L. Similar to the previous study, the obtained ethanol concentration

was considered low, which led to a great challenge in it is

refinery feasibility.

This research proposed integrating EFB-to-ethanol conversion units into other production plants to avoid transportation costs. The obtained ethanol can be self-utilized for gasoline substitutes in their transporting unit as previously proposed for biodiesel utilization in Refined, Bleached & Deodorized Palm Oil (RBDPO) production plant (Battle et al., 2021). This is one of the circular economy approaches at the enterprise management level. According to a previous review, the greatest innovative activity which can affect the diffusion of "circular" innovations is manifested at this level (Zaytsev et al., 2021). These substitutions will reduce overall GHG emissions. Transportation as one of the contributors to GHG emissions was confirmed by a preliminary assessment of GHG emission trends in food production and consumption in Malaysia (Petersen et al., 2014; Padfield et al., 2012).

This research proposed a

simulation for the integration of EFB into an ethanol conversion unit. A

comparative evaluation between two ways of integrating the conversion process

was conducted. Whether the EFB–to-Ethanol plant is integrated into a pulping

plant or integrated into an RBD palm oil production plant. The evaluation was based on their potential

energy-environment benefits. This is a step further from the Multi Criteria Decision Making (MCDM) technique applied in the assessment of composting for

organic waste management in the previous study (Shukor

et al., 2018). More calculated results based on reliable data

from the existing pilot plant were provided in this study to make it more

credible and traceable for validation.

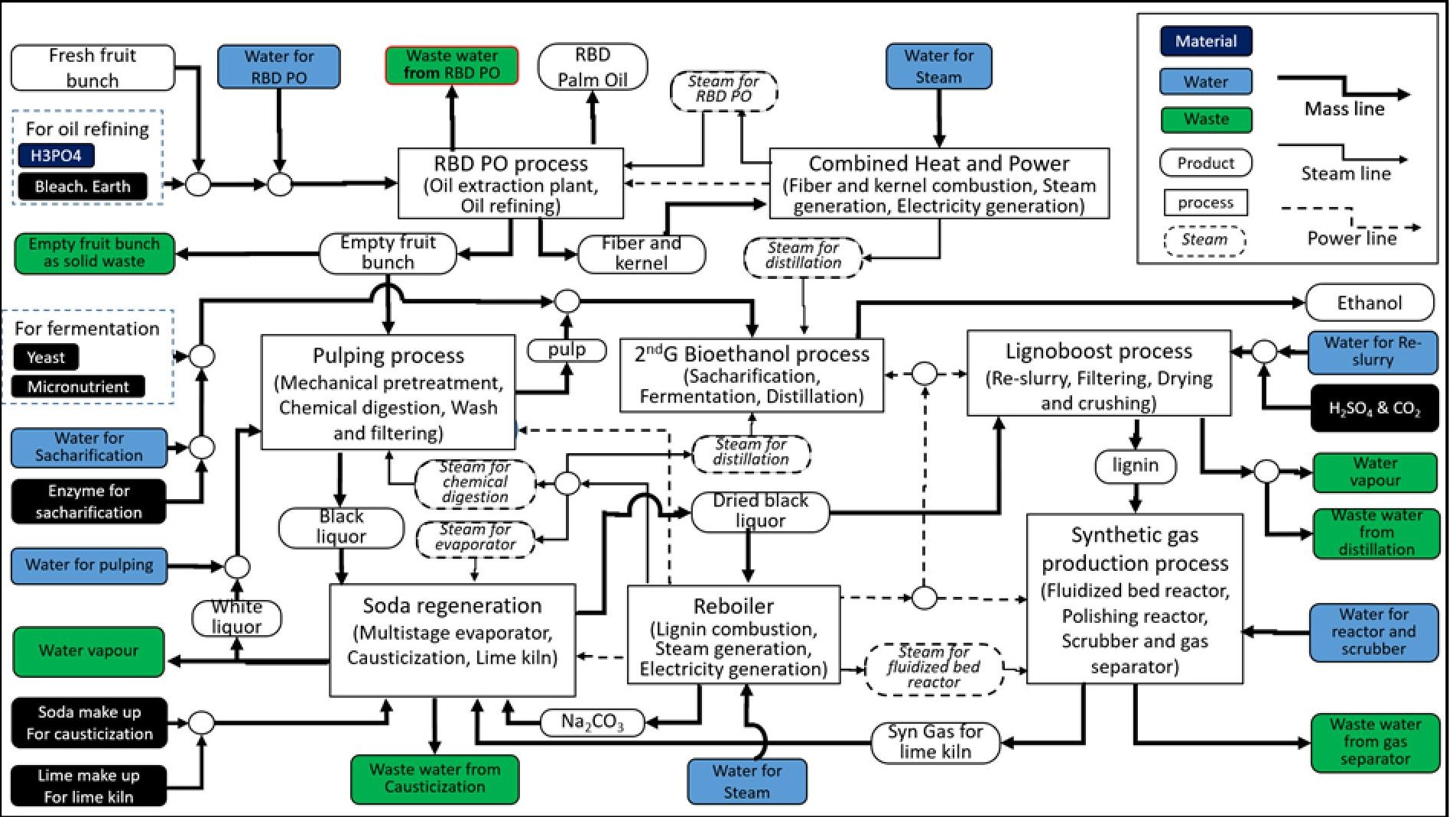

Figure 1 Brief scheme for the

first archetype, when 2nd G Bioethanol integrated into RBD palm oil plant.

Yellow boxes were units for pulping process. Red boxes were units for the RBD palm

oil process

The water, steam, and electricity requirement in the oil

extraction was then calculated. The oil needs to be refined to meet the

commercial requirement by eliminating free fatty acids and fruit wax. The

chemical and energy requirement was also calculated. The process adopted in

this research was the physical process with phosphoric acid as a wax coagulant

and the color adjustment by using bleaching earth. The physical process has a

higher global yield, uses fewer chemicals, and produces less effluent. Most big

companies where the data originated use certified seedlings from the Indonesian

Oil Palm Research Institute (IOPRI). Only a small amount of plantations use

seedling private seedling companies in Indonesia or certified imports from

Malaysia and other parts of the world (Harsono et

al., 2012). Thus, the amount of wax in palm oil fruit in the

observed CPO plant is almost equal. Only small deviations were reported for the

required energy and required phosphoric acid and bleaching earth for the RBD palm

oil process.

The required energy for operating RBD palm

oil plant supplies was simulated using a cogeneration system based on a

back-pressure steam turbine (BPT). This cogeneration system uses fiber and

shell as fuel, which comes from the oil extraction process. Furthermore, the

plant adopted in this study was calculated to meet energetically

self-sufficient so that the electricity produced could feed both the mills

(considered electrified mills) and the process equipment such as pumps,

agitators, and conveyors, among others and in addition to lighting

installations.

2.1.2. EFB-to-ethanol

integrated with EFB pulping plant scenario

In this simulation scenario, all four aforementioned units

were applied in EFB-to-ethanol integrated with EFB pulping plant, except the

RBD palm oil unit. The scheme can be observed in Figure 2. In this scheme, the

energy supply was solely from the black liquor combustion. The main difference

in energy supply can be seen in energy lines which only came from the

reboiler.

The

amount of lignin production was adjusted to the amount of lignin converted into

syn-gas. The produced syn-gas was calculated to equal the required syn-gas for

the lime kiln. Through a series of iteration calculations, energetically

self-sufficient design can be achieved. The setting value for iteration was to

meet a similar amount of ethanol produced from the first scenario. Thus, the

performance of both scenarios can easily be compared. The calculation required

energy included electricity for both the pulping mills (considered electrified

mills) and the process equipment, i.e, pumps, agitators, and conveyors, among

others and in addition to lighting installations.

3.1. General simulation

comparison

The total required energy as steam and electricity for producing 255.6

kg ethanol was 1.293 MW, as shown in Table 2. This amount of energy can be

supplied from the excess energy produced by the RBD Palm oil plant with a

capacity of 5 tons FFB or pulping plant with a capacity of 22.15 tons EFB. This

excess energy was sufficient without any additional fuel required (zero net

energy). EFB-to-ethanol plant integrated into RBD palm

oil plant scenario was preferable in energy

analysis. This is due to the flexibility of energy supply from fiber and kernel

combustion. The excess energy from these combustions was 1.06 MW, or equal to

82% of the required energy for ethanol production. The other 18% of energy came

from dried black liquor combustion from the pulping unit. This dried black

liquor needs to be completely burned for soda regeneration.

Table 1 General comparison of EFB-to-ethanol when integrated into RBD palm

oil plant or pulping plant

|

Parameters |

Unit |

RBD palm oil |

Pulp |

|

|

Material input | ||||

|

Fresh fruit bunch |

kg |

5000 |

0 |

|

|

Wet EFB available (Moist

73%) |

kg |

2632.81 |

22,151.01 |

|

|

Fraction of EFB used for ethanol |

% |

58.42 |

2.64 |

|

|

EFB used for ethanol |

kg |

1538.20 |

1538.20 |

|

|

Fraction of BL to lignin then syn-gas |

% |

2.55 |

2.55 |

|

|

Product output | ||||

|

Wet EFB excess (Moist 73%) (back to the farm) |

|

1,094.62 |

0 |

|

|

RBD palm oil |

kg |

1,126.92 |

0 |

|

|

liter |

1,444.77 |

0 |

| |

|

Wet Pulp (Moist 40%) |

kg |

0 |

17,379.43 |

|

|

Pulp (Atmospheric dried) |

kg |

0 |

10,427.65 |

|

|

Ethanol fuel grade (97%v) |

kg |

255.55 |

255.55 |

|

|

liter |

319.44 |

319.44 |

| |

|

Additional chemical requirement | ||||

|

Water |

m3 |

20.88 |

191,32 |

|

|

Bleaching earth |

kg |

10.76 |

0 |

|

|

H3PO4 |

kg |

0.57 |

0 |

|

|

Yeast |

kg |

7.179 |

7.179 |

|

|

Micronutrient (urea + NPK) |

kg |

13.04 |

13.04 |

|

|

Enzyme and additives (buffer & surfactant) |

liter |

170.08 |

170.08 |

|

|

Soda make up |

kg |

29.83 |

429.55 |

|

|

Lime makeup |

kg |

40.93 |

630.34 |

|

|

H2SO4 and CO2 |

kg |

4.37 |

62.86 |

|

The total required energy as

steam and electricity for producing 255.6 kg ethanol was 1.293 MW, as shown in

Table 2. EFB-to-ethanol plant integrated into RBD palm oil plant scenario was

preferable in energy analysis. This is due to the flexibility of energy supply

from fiber and kernel combustion. The excess energy from the combustion was

1.06 MW, or equal to 82% of the required energy for ethanol production. The

other 18% of energy came from dried black liquor combustion from the pulping

unit. This dried black liquor needs to be completely burned for soda

regeneration.

Table 2 Energy Utilization

Comparison of EFB-to-ethanol when integrated into RBD palm oil plant or pulping plant

(basic calculation: 255.6 kg of ethanol production capacity)

|

Parameters |

Unit |

RBD Palm Oil |

Pulp |

|

Required

electricity for EFB-to-ethanol plant |

MW |

0.14 | |

|

Required steam for EFB-to-ethanol plant |

MW |

1.153 | |

|

Total excess power

from black liquor combustion in the boiler (after excluding power consumed

for pulping plat), per ton of dried black liquor |

MW/tons |

0.1 |

0.1 |

|

Required

EFB to be processed for zero net energy |

tons

EFB |

2.6 |

22.15 |

|

Total produced dried black liquor |

tons |

1.00 |

14.90 |

|

Total

excess power from fiber and kernel combustion in the boiler (after excluding

power consumed for RBD Palm Oil plant) per ton of combined fiber and kernel. |

MW/tons |

1.06 |

0 |

|

Total

produced fiber and kernel |

tons |

1.033 |

0 |

|

Pollutant

component |

Source |

Amount

(kg) | |

|

RBD

Palm Oil |

Pulp | ||

|

To

water treatment plant | |||

|

Spent

bleaching earth, PFDA and Palm Oil

Mill Effluent (POME) |

Palm oil

extraction plant & oil refining |

5,418.67 |

|

|

Lignin and

spent yeast |

Distillation

bottom. |

2,847.35 |

2,847.35 |

|

CaCO3,

NaOH |

Causticization

lime kiln, scrubber and

gas separator |

1,491.98 |

22,890.71 |

|

Lignin and

NaOH |

Pulp washing |

7,647.26 |

94,303.02 |

|

To

environment/gas treatment | |||

|

Multi-stage

evaporator and lignin drier |

water vapor |

5,198.64 |

77,543.36 |

|

Causticization

and lime kiln |

CO2

and SOx |

6.43 |

177.40 |

The 2nd

generation bioethanol production process has its own appeal since its product

is used as a gasoline substitute and industrial chemicals on one end and

utilizes cheap, abundant, non-food raw material at the other end. In this

context, this study aimed to analyze EFB utilization as ethanol raw material

and as the possibility of converting the potential excess energy in RBD palm

oil production or pulping process into financial profit and reduce waste

simultaneously. This would encourage a reduction in dependence on fossil fuels

(consequently reducing GHG emissions) and improve the system's energy

performance. Integrating an EFB-to-ethanol unit into the RBD palm oil plant with a

capacity of 5 tons FFB processed daily could recycle 58.4% of EFB waste,

increasing income 18.47% of the basic income from selling RBD palm oil solely. This was

achieved by utilizing all the energy potency stored in fiber and kernel to

supply the required energy. To implement the integration, the RBD palm oil plant required almost fourfold processed water

and dealing with threefold wastewater with different pollutants. The types of

operation unit that needed to be installed was also more miscellaneous compared

to the integration of the EFB-to-ethanol unit into the EFB pulping plant. The integration of the EFB-to-ethanol unit into the

EFB pulping plant only required an additional distillation unit and

saccharification-fermentation tank to be installed. The required process water,

the pulping process, and the wastewater treatment unit only had an increasing

workload of 2-5 % which is usually compromised in the original pulping plant

design. This small additional investment gave extra income of 1.9% of the pulp

sales. However, the pulping production capacity needs to be 22.15 tons of

processed EFB daily for the ethanol to be comparable with the aforementioned

RBD palm oil integration. This is due to the small amount

of potential excess energy in dried black liquor. The results outlined in this paper are based on the

integration of technological considerations adopted in each scenario.

Therefore, limitations of the present research would be economical and

feasibility, especially in economic comparison for selling kernel or dried

black liquor as a side product, and logistic aspects regarding the cost of

sending EFB and/or black liquor to farms, industrial users, or municipalities.

Once these limitations have been overcome with data survey and market study,

plants like both proposed scenarios might reach a feasible economic stage and

play an important role in transitioning towards a circular economy that

promotes sustainability. Thus, it is recommended that a more detailed

socio-economic analysis should as well be considered in a future study. The study's main conclusion may be presented in a

short conclusions section, which may stand alone. It should not repeat the

results but provide significant findings and contributions to the study.

The

first author would express sincere gratitude to the Indonesia Endowment Funds

for Education for providing scholarships to pursue PhD program at University of

Tsukuba. This research is also part of project by Research Center for

Chemistry, National Research and Innovation Agency (BRIN) supported by the

Indonesia Endowment Funds for Education (LPDP) – Ministry of Finance of the

Republic of Indonesia for research grant No. KEP-02/LPDP/LPDP.4/2022 of 2022.

Aditiya, H.B., Mahlia,

T.M.I., Chong, W.T., Nur, H., Sebayang, A.H., 2016. Second Generation

Bioethanol Production: A Critical Review. Renewable and Sustainable Energy

Reviews, Volume 66, pp. 631–653

Afandi, A.M., Zuraidah, Y., Nurzuhaili, H.A.Z.A.,

Zulkifli, H., Yaqin, M., 2017. Managing Soil Deterioration and Erosion under

Oil Palm. Oil Palm Bulletin, Volume 75, pp. 1–10

Ahmad, F.B., Zhang, Z.,

Doherty, W.O.S., O’Hara, I.M., 2019. The Outlook of The Production of Advanced

Fuels And Chemicals From Integrated Oil Palm Biomass Biorefinery. Renewable and

Sustainable Energy Reviews, Volume 109, pp. 386–411

Anggraini, I.D., Keryanti, Kresnowati, M.T.A.P.,

Purwadi, R., Noda, R., Watanabe, T., Setiadi, T., 2019. Bioethanol Production via Syngas Fermentation of Clostridium Ljungdahlii in a Hollow Fiber Membrane Supported Bioreactor. International

Journal of Technology, Volume 10(3), pp. 481–490

Archer, S.A., Murphy, R.J.,

Steinberger-Wilckensa, R., 2018. Methodological Analysis of Palm Oil Biodiesel Life Cycle Studies. Renewable and Sustainable Energy Reviews, Volume 94, pp. 694–704

Febrianti, F., Syamsu, K., Rahayuningsih, M.,

2017. Bioethanol Production from Tofu Waste by Simultaneous Saccharification and Fermentation (SSF) using Microbial Consortium. International Journal of Technology, Volume 8(5), pp. 898–908

Harahap, A.F.P., Rahman, A.A., Sadrina, I.N.,

Gozan, M., 2019. Optimization of Pretreatment Conditions for Microwaveassisted Alkaline Delignification of Empty Fruit

Bunch by Response Surface Methodology. International Journal of

Technology, 10(8), pp. 1479–1487

Harsono, S.S., Prochnow, A., Grundmann, P.,

Hansen, A., Hallmann, C., 2012. Energy Balances and Greenhouse Gas Emissions of Palm Oil Biodiesel in Indonesia. GCB Bioenergy, Volume 4(2), pp. 213–228

Hermansyah, H., Wisman, A.P., Firdaus, D.,

Arbianti, R., Utami, T.S., Kurnia, A., 2015.

Effect of Aeration and Nutrients on Saccharomyces Cerevisiae Cultivation using

Lignocellulosic Hydrolysate from Empty Fruit Bunch. International

Journal of Technology, Volume 6(7), pp. 1110–1118

Hermansyah, H., Putri, D.N., Prasetyanto, A.,

Chairuddin, Z.B., Perdani, M.S., Sahlan, M., Yohda, M., 2019. Delignification of Oil Palm Empty Fruit Bunch using Peracetic Acid and Alkaline Peroxide Combined with the Ultrasound. International

Journal of Technology, Volume 10(8), pp. 1523–1532

Hossain, N., Zaini, J.H., Mahlia, T.M.I., 2017. A

Review of Bioethanol Production from Plant-based Waste Biomass by Yeast Fermentation. International

Journal of Technology, Volume 8(1), pp. 5–18

Hussain, M., Zabiri, H., Uddin, F., Yusup, S.,

Tufa, L.D., 2021. Pilot-scale Biomass Gasification System for Hydrogen Production from Palm Kernel Shell (part A): Steady-state Simulation. Biomass Conversion and Biorefinery, pp. 1–14

Hussain, M., Zabiri, H., Uddin, F., Yusup,

S., Tufa, L.D., 2021. Pilot-scale Biomass Gasification System for Hydrogen Production from Palm Kernel Shell (part B): Dynamic and Control Studies. Biomass

Conversion and Biorefinery, pp. 1–23

Jeon, H., Kang, K.E., Jeong, J.S., Gong,

G., Choi, J.W., , Abimanyu, H., Ahn, B.S., Suh, D.J., Choi, G.W., 2014. Production of Anhydrous Ethanol using Oil Palm Empty Fruit Bunch in a Pilot Plant, Biomass

and Bioenergy, Volume 67, pp. 99–107

Mikkila, M., Utanun, P., Luhas, J., Horttanainen,

M., Linnanen, L., 2021. Sustainable Circular Bioeconomy-feasibility of

Recycled Nutrients for Biomass Production within a Pulp and Paper Integration

in Indonesia, Southeast Asia. Sustainability 2021, Volume 13(18), pp. 10169

Nasution, M.A., Erwinsyah, Wulandari, A.,

Lydiasari, H., 2020. Reducing the Greenhouse Gas Emission from Palm Oil Industry. Ecology,

Environment and Conservation Paper. Volume 26, pp. 89–94

Batlle, E.A.O, Palacio, J.C.E., Lora,

E.E.S., Bortoni, E.D.C., Nogueira, L.A.H., Caballero,

G.E.C., Julio, A.A.V., Escorcia, Y.C., 2021. Energy, Economic, and Environmental Assessment of the Integrated Production of Palm Oil Biodiesel and Sugarcane Ethanol. Journal of Cleaner Production, Volume 311, p. 127638

Prabowo, B., Simanjuntak, F.S.H., Saldi, Z.S.,

Samyudia, Y., Widjojo, I.J., 2019. Assessment of Waste to Energy Technology in Indonesia: A Techno-economical Perspective on a 1000 Ton/Day

Scenario. International Journal of Technology, Volume 10(6), pp. 1228–1234

Padfield, R., Papargyropoulou,

E., Preece, C., 2012. A Preliminary Assessment of Greenhouse Gas

Emission Trends in the Production and Consumption of Food in Malaysia. International Journal of Technology, Volume 3(1), pp. 56–66

Petersen, A.M., Haigh, K., Görgens, J.F., 2014.

Techno-economics of Integrating Bioethanol Production from Spent Sulfite Liquor for Reduction of Greenhouse Gas Emissions from Sulfite Pulping Mills. Biotechnology for Biofuels, Volume 7(1), pp. 1–14

Shukor, J.A., Omar, M.F., Kasim, M.M., Jamaludin,

M.H., Naim, M.A., 2018. Assessment of Composting

Technologies for Organic Waste Management. International Journal of

Technology, Volume 9(8), pp. 1579–1587

Smirnova, O., Kharitonova, E., Babkin, I.,

Pulyaeva, V., Haikin, M., 2021. Small-scale Biofuel Production:

Assessment of Efficiency. International Journal of Technology, Volume 12(7), pp. 1417–1426

Tomani, P.E.R, 2010. The Lignoboost

Process. Cellulose Chemistry and Technology, Volume 44(1–3), pp. 53–58

Tomani, P., Axegård, P., Berglin,

N., Lovell, A., Nordgren, D., 2011. Integration of Lignin Removal

Into a Kraft Pulp Mill and use of Lignin as a Biofuel. Cellulose Chemistry and Technology, Volume 45 (7–8), pp. 533–540

Van-Dam, J.E.G., 2012. Options for Sustainability Improvement and Biomass use in Malaysia: Palm Oil Production Chain and Biorefineries for Non-food use of Residues and by-products Including other Agricultural Crops. AGRIS, Food and Agriculture Organization of United Nations 2012, Extent 37

Walker, SM., McMurray, A., Rinaldy, F., Brown,

K., Karsiwulan, D., 2018. Compilation of Best Management Practices to Reduce

Total Emissions from Palm Oil Production. Winrock International. In: Roundtable on Sustainable Palm Oil (RSPO)

Zaytsev, A., Dmitriev, N., Rodionov, D., Magradze, T., 2021.

Assessment of the Innovative Potential of Alternative Energy in the Context of

the Transition to the Circular Economy. International Journal of Technology, Volume 12(7), pp. 1328–1338