Traction Force Investigation of The New Working Body of The Sod Seeder

Corresponding email: s.nukeshev@kazatu.kz

Published at : 09 May 2023

Volume : IJtech

Vol 14, No 3 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i3.6008

Nukeshev, S., Yeskhozhin, K., Akhmetov, Y., Kossatbekova, D., Tleumbetov, K., Tanbayev, K., 2023. Traction Force Investigation of The New Working Body of The Sod Seeder. International Journal of Technology. Volume 14(3), pp. 536-548

| Sayakhat Nukeshev | Department of Technical Mechanics, NCJSC S. Seifullin Kazakh AgroTechnical Research University, Zhenis avenue 62, 010011 Astana, Kazakhstan |

| Kairat Yeskhozhin | Department of Technical Mechanics, NCJSC S. Seifullin Kazakh AgroTechnical Research University, Zhenis avenue 62, 010011 Astana, Kazakhstan |

| Yerzhan Akhmetov | Department of Technical Mechanics, NCJSC S. Seifullin Kazakh AgroTechnical Research University, Zhenis avenue 62, 010011 Astana, Kazakhstan |

| Dinara Kossatbekova | Department of Technical Mechanics, NCJSC S. Seifullin Kazakh AgroTechnical Research University, Zhenis avenue 62, 010011 Astana, Kazakhstan |

| Kaldibek Tleumbetov | Department of Technical Mechanics, NCJSC S. Seifullin Kazakh AgroTechnical Research University, Zhenis avenue 62, 010011 Astana, Kazakhstan |

| Khozhakeldi Tanbayev | Department of Technical Mechanics, NCJSC S. Seifullin Kazakh AgroTechnical Research University, Zhenis avenue 62, 010011 Astana, Kazakhstan |

Due to the depletion of pastures, fodder

provisioning is becoming an acute problem, therefore improving pastures by

sowing seeds undercover crops and in turf is essential. The main purpose of the

work is to reduce the traction force of the sod seeder by developing an

effective working body. As a result, a new technology for improving forage and

pasture lands and the design of a working body of sod seeder for site-specific

seeding of crops undercover crops are proposed. The new technology provides

simultaneous sowing of grass seed and fertilizer at two levels of soil horizon

without excluding the forage area from the exploitation: grass seed to a depth

of 40 mm and fertilizer to a depth of 120 mm. The seed sowing and fertilizer

application depths are adjustable, and the sowing width reaches 40 mm. The

traction force was determined by the dynamometric method during laboratory and field

experiments. Theoretical studies have determined the dependence of the traction

force on the average parameters of the cultivated soil layer and its physical

and mechanical properties, as well as the parameters of the working body.

According to the results of experimental and field studies, the traction force

range of the sod seeder was within 8.28–8.63 kN.

Cover crops; Hoe opener; Meadow and pasture restoration; Mineral fertilizers; Site-specific seeding; Traction force

Arid

pastures are a major source of forage for cattle and sheep in many countries.

In turn, high-yielding forage grass species are essential components of

sustainable pasture production and provide valuable ecosystem services (Adams et al., 2022; Karimipoor et al., 2021). Therefore, it

is necessary to improve pastures by sowing seeds under cover crops and on turf (Himmelbauer et al., 2013; Bathgate, Revell, and Kingwell, 2009). Currently, the radical

improvement of pastures, including a full range of operations to create a new

grass shank by sowing seeds of perennial grasses requires significant financial

costs and is carried out very rarely (Fulkerson and Lowe, 2022;

Soldatov et al., 2020; Zotov et al., 2012). The majority of technologies for

restoring the biological productivity of natural grasslands are based on

scattered grass seeding or direct seeding, which involves cutting furrows in

the turf and seeding grass seeds. Scattered seeding is not sufficiently

effective on neglected grasslands, and the use of herbicides significantly

increases the cost of technology and environmental safety requirements (Scotton, 2019; Deák et al., 2018;

A promising

alternative is to sow grass into a strip of mechanically destroyed turf without

excluding the forage area from exploitation (Saitov et al. 2021;

Kopecký and Studer, 2014; Sokolov et al., 2012; Marchenko, Marchenko,

and Pedai, 2010; Baker et al., 2007). In this

regard, it becomes necessary to develop a sod seeder, which provides lower

energy costs and improved working conditions for workers (Lekavi?ien? et al., 2019).

In addition, the development of the seeder is expected to reduce the number of

implements needed to create new grass by sowing perennial grass seeds, as well

as to increase the efficiency of the process by fertilizing both new and old

grass, which will increase profitability, thus contributes to the

competitiveness of agriculture (Sysuev et al., 2021; Cheremisinov and

Doronin, 2017; Nazarko, 2008). Due to its versatility, the

proposed seeder improves direct sowing processes not only for grass seeds but

also for grain crops. It also reduces the cost of purchasing various equipment,

allowing farmers to receive higher profits. Therefore, the research aims at

developing the design of the sod seeder’s main working body, i.e. the hoe

opener, by conducting theoretical research and obtaining mathematical

dependencies to determine the rational parameters and operating modes of the

proposed design, which will provide minimal traction force.

An

experimental model of an automated sod seeder contains a frame, seed, and fertilizer hopper, seeding units (devices)

for seeds and

fertilizers, petal agitator, seed and

fertilizer pipes, and

the main working body – the proposed hoe opener (Figure 1a). The hoe opener

consists of (1) a shank, (2) a point attached to the lower part of the shank,

(3) a knife, (4) a fertilizers tube; to which (5) a seeds tube is attached at

the back side of shank (Kazakhstan Republic, 2021). The lower

part of fertilizer tube (4) has a side notch, inside of which a spreader (6) in

the form of a cone is installed (Figure 1b).

The shank

(1) cuts a vertical slot in the turf with a width of 20 mm, and the knife (3)

loosens the soil or turf without turning the layer. The knife horizontally cuts

the turf with a width of 100 mm and cuts the roots of old-age grasses, thus

avoiding the oppression of the new crop. At the same time, mineral fertilizers

are delivered through the fertilizers tube (4) to the conic surface of the

spreader (6) and spread evenly in the trace of point (2) and knife (3) at a

depth of 8–12 cm. A petal agitator directs seeds into the seeding unit and then

the seeds are moved by the seed tube (5) into the soil at the depth of 2–6 cm

above the fertilizer layer. The resulting slot is closed (pinched) by the

rollers that are mounted on the rear part of the frame.

Figure 1

(a) The experimental model of the sod seeder. (b) The design scheme of the

experimental hoe opener: 1 – shank; 2 – point; 3 – knife; 4 – fertilizers tube;

5 – seeds tube; 6 – spreader

The seed

placement above from the fertilizer horizon excludes their suppression by

chemical reactions and contributes to the gradual feeding of the plant root

system. The lower, closer to the wet horizon placement of fertilizers promote

their better dissolution and migration in the soil environment. Pinching the

slots with special rollers prevents the evaporation of moisture through the

slots, the withdrawal of the land from the forage turnover, and possible

injuries to cattle during grazing. Repeated improvement of the forage area

should be made in the perpendicular direction.

Theoretical

studies related to the traction force of the new working body are based on the

methods of classical mechanics.

To study the

influence of the parameters of the hoe opener on its traction characteristics,

preliminary laboratory tests on the soil bin were carried out. The soil bin is

equipped with a measuring information system and an electronic dynamometer

DEP3-1D-10P-2 with data recording on a PC. The maximum permissible relative error is +0.45%.

Field experiments were carried out during the spring and

summer periods. The test conditions are shown in Table 1. To determine the tractive forces in the field

experiments, this study used a dynamometer (DEP1-1D-50P-2) with the 2nd

accuracy class according to ISO 376-2.

Before the field experiments, soil moisture and density were determined.

Soil moisture was determined in accordance with GOST 20915-2011 by taking soil

samples of field moisture and productive moisture in aluminum boxes by layer

horizons in four places located along the diagonal of the plot in 5 cm

intervals 0-5, 5-10, 10-15 cm respectively.

Soil density was determined using a soil density meter, i.e., the Wile Soil penetrometer

(model 41010). The measurement range was 0 to 3500 kN/m2. The

penetrometer density values show the green segment (0-14 kg/cm2)

(favorable growing conditions), the yellow segment (14-21 kg/cm2)

(acceptable growing conditions), and the red segment (21 kg/cm2 or

more) (an unfavorable growing conditions).

The uniformity of the seed placement depth is

determined by direct finding (excavation) of seeds in the row. Seeding units

with experimental working tools are determined for each row of working tools

(front and rear) by two strips in two adjacent passes of the seeder of one

experiment. The indicator of the depth of seeding is the distance from the

upper point of the ground ?ut to the center of the grain. The depth was

measured using a ruler with an accuracy of 1 mm.

Table 1 The test conditions

|

Indicators |

Value of indicators |

|

Type of work |

Sowing grass seed with

simultaneous fertilization |

|

Soil type and name by texture |

Southern carbonate chernozem. Heavy loam, turf |

|

Relief |

smooth, without slope |

|

Micro-relief |

Furrowed |

|

Soil moisture, %, in layers, cm: 0-5 |

16.5 |

|

5 - 10 |

19.46 |

|

10-15 |

21.85 |

|

15-20 |

22.14 |

|

20-25 |

22.65 |

|

Soil hardness, MPa,

in layers. cm: 0-5 |

2.1 |

|

5-10 |

3.6 |

|

10-15 |

3.5 |

|

15-20 |

3.3 |

|

20-25 |

4.3 |

|

Ridgeiness of the field

surface, cm |

3.2 |

|

Pre-treatment |

Not treated |

The scheme

of forces applied on the hoe opener and its point is shown in Figure 2. The

point represents a dihedral angle of KMM.

Three main elements can be distinguished here: the blade TKT (Nukeshev, et al., 2023),

which is directly involved in soil destruction; chamfers KM, KM1;

and frame M. The feature of cutting

elements of the tillage tool is that the blade at the top K of the

dihedral angle is quickly worn down and acquires a rounded shape. The chamfers KM and KM1 push aside the material already cut.

Consider the

soil particle A located on the

chamfer of CM. Two forces act on it

from the side of the chamfer: normal point pressure Nd and friction force Fd. If there is no relative motion of the A particle, then after some time it

takes position C, on the line of

translational velocity Such

behavior of the particle is possible if the friction force between the soil and

the point metal Fd and the tangential component of the normal

pressure Ndt are equal:

They are in turn equal to:

Figure 2 Forces acting on the hoe opener

(a) and its point (b). 2 represents

the angle of the hoe opener solution; 2b represents the width of the working body; r denotes the installation angle of the

hoe opener; while

denotes the

installation angle of the working body in the vertical plane

Substituting

Equation 2 into Equation 1, we obtain:

here is the friction angle between metal and soil;

la is the

limit angle of the point blade

solution.

Under the condition of Equation 3, the soil particle moves together

with the point. For the

successful running of the technological process and reducing its energy

consumption, the condition must be observed:

At

this angle ratio, when the point moves in the soil, particle A will not move to point C, however, moving in the direction of

the resultant force will take the position Cd.

In this case, the absolute displacement of the particle is less and equal to

the segment ARd, instead

of AC, in the absence of sliding. Thus, it is obvious that soil

particles undergo complex deformations when the point moves in it – sliding

with crumpling. The base of triangle ARC

fully characterizes the ratio of these deformations. Therefore, segment A1 characterizes the crumpling

deformation of the soil, and segment C1

characterizes the sliding deformation. Moreover, their ratio can be taken as a

measure of deformation in general:

Using the

sine theorem from triangle ACC' we

have:

It can be

seen from Equation 6 that the measure of soil deformation with a point depends

on two values: the angles of the point blade solution and external friction.

Moreover, this dependence is inversely proportional; as the solution angle

increases, the slip decreases, and the deformation of the crumple increases. On

the rectilinear section of the TM

chamfer, the nature of soil deformation does not change. The ratio of slip

measures C1 to crumpling measures A1 is constant or closer to constant.

However, it is violated on the curvilinear section T–T. In the center of the arc, the directions of translational

velocity and normal pressure Pd coincide. In

this case, a slip does not occur, and the clean crumpling of the soil

originated.

The sliding

of the particle will begin after the T

point, and the crumpling of the soil is on the wane. Their (C1 and A1) ratios will be established. The maximum savings in energy costs

will occur when the soil is treated with a clean slip. Such a case may occur at , and it is unrealistic since in

this case soil loosening will not occur. Therefore, such soil processing is

unproductive. It can be assumed that the determining position will be such that

the measures of crumpling and sliding will be equal or the first will be

somewhat less than the second. At the same time, energy consumption will be

minimal, and the soil will receive treatment. In this case:

This condition will be fulfilled if the triangle ACC' is isosceles. In this case, the angles:

where:

From the last three equations we obtain:

Obviously, for the sliding to be

greater than the crumpling, it is necessary to:

Thus, Equation

4 and Equation 7 give the condition for choosing the angle of solution of the

tillage tool, i.e., the point, and

its lower and upper limits, which will ensure tillage with sliding and crumpling:

To

justify the angle of installation of the working body in the vertical plane,

consider Figure 2a. The pushing force of the working body Rd acts on particle A.

It can be separated into the normal Nd

and tangential components Fd.

In this case, the angle between the normal and resultant forces is equal to , and the angle between the normal and

the vertical axis is equal to

The

external, pushing force is counteracted by the gravitational force G and the internal ground adhesion force

Fs and the frictional

force F. The latter force can be

accounted for by the coefficient of internal friction. According to the 3rd law

of mechanics, the external forces Rd

and Nd are

counteracted by Rp and Np equilibriums.

Consider

equilibrium effects of active forces on natural axis – in the direction of

point chamfer.

Here the weight of the soil

element G = mg, and the frictional

forces differ by the internal and external coefficients f1 and f,

respectively, where:

The

values of the coefficients are m denotes the mass of the cultivated

soil element; and g represents the

acceleration of gravity. With this

setup, the hoe opener will not

work satisfactorily, since the point works

to lift the soil layer, not to cut it. Undeformed clods will create slumping

furrows.

The hoe opener will work steadily if its thrust force is

directed horizontally or closer to it. Therefore, it is important to consider

the equilibrium of active forces in the direction of the horizontal axis:

Substituting

the values of the components in Equation 11, we obtain:

where

from:

Using

the above values and taking into account that

The

resulting angle is quite satisfactory. The point in the turf cuts slots with

the required size, where seeds and fertilizers are applied.

To determine the traction force

of the hoe opener, consider the equilibrium of external forces acting on it in

the directions of the horizontal and vertical axes:

Where: Rs

denotes the shear resistance force on the shear plane LK; Q

denotes the force of inertia of soil elements arising during its movement; Rd

denotes the resistance force of soil elements to compression deformation by the

point; P denotes the force applied to the working body; denotes the angle of soil internal friction; and

denotes the angle

of soil shear. From Equation 15 we define:

Substituting

the Equation 16 into the Equation 15:

The

last equation is presented in a simplified form:

It can be seen from Equation 17 that the traction force of the hoe

opener is composed of two independent quantities: the first is the resistance

of the soil to shear deformation, and the second is the resistance of the soil

elements to the acquisition of kinetic energy, that is, movement, which in turn

depend on the solution angle, installation angle of the working body, and the

external and internal friction angles of the soil.

The

reaction of the undeformed formation in front of the point is formed by the

shear resistance, which is equal to the:

where:

herewith:

here: h denotes the working body stroke depth; ur denotes the ultimate

resistance of the soil to compression; and

denotes the volumetric weight of the soil.

According to Newton's Law 2, the displaced elements of the soil acquire

the force of inertia:

where: w

The

acceleration of the movable element ???? (Equation

21) is equal to:

where: initial velocity denotes the absolute velocity of the soil

element; and t denotes the travel time of the element on the chamfer.

The travel time on the KM chamfer is equal to:

To determine the velocities of the soil element, consider the velocity

plan in Figure 3:

Figure 3 Velocities of moving soil elements

From the equation of the

traction force of the hoe opener (Equation 28), we can see that the first term

is resistance averaged from the parameters of the tilled soil layer and its

physical and mechanical characteristics, such as shear deformation angle and

ultimate compression resistance, and the second term is inertial resistance to

movement of soil elements, depending on the translational velocity of the tool

and its installation, solution, and friction angles.

In order to verification of calculations

and results, the average numerical values of the variables included in the

obtained formulas have been taken based on known theoretical data (Panov and Vetokhin, 2008; Sineokov

and Panov, 1977), they are: = 30°;

= 30°;

1 = 40°;

= 45°;

= 75°; 2b = 0.03 m; h = 0.1 m;

= 2.77 m/s;

ur

= 15 kg/cm;

= 103 kg/cm.

Accordingly, they obtain: A = 0.087; B1 = 0.22; B2

= 592; Rz = 748.93 N; Q = 28.19 N. The traction force of the

working body is equal to P = 720.73

N. The obtained result is close to the expected one. A comparison with other

simulation studies (Afify et al., 2020) shows that the findings are

significantly lower than the traction forces of the models investigated by

other researchers, especially when with a dependence on tool rake angle and

tool depth.

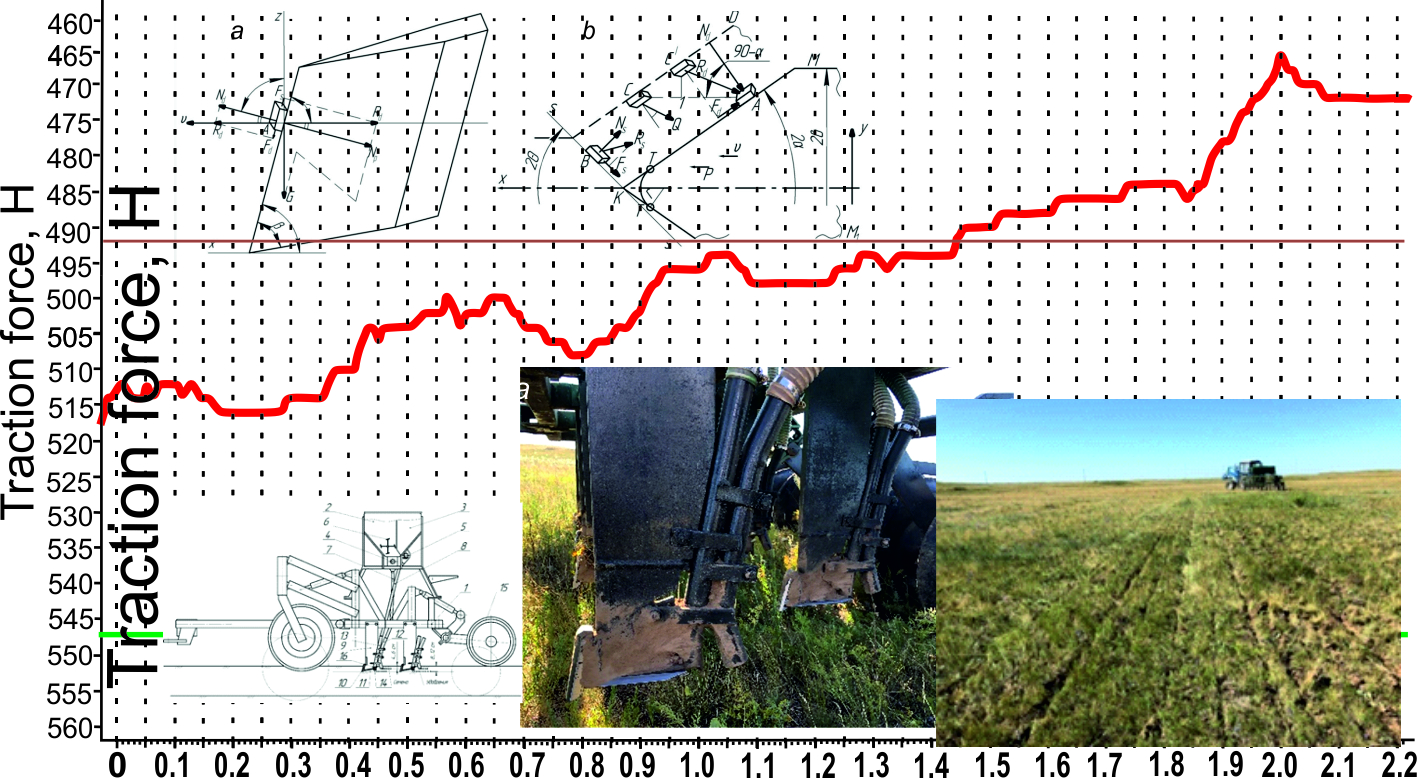

Approximation of the

experimental data (Figure 4) of the dependence of the experimental colter

traction resistance on the velocity of translational motion allowed us to

obtain the following equations:

According to

the results obtained by the dynamometric method, the force of one tool at a

working depth of 0.1 m varied from 238 to 808 N at speeds of 0.1–1.75 m/s.

Change of traction force depending on motion velocity has a parabolic

character. This is explained by the fact that at the initial moment of the

interaction of the working body with the soil, the inertial forces arise

because at this time the resting inertia of the soil is violated, its particles

acquire certain accelerations and a certain absolute velocity, which does not

coincide with the motion (sliding) line. The inertial force will be directed

along the line of the absolute velocity of the particles, only in the opposite

direction. In the steady-state process of soil disintegration, the tractive

force is minimal. However, as the translational velocity increases further, the

tractive force also increases. Determination of the total traction force of the

experimental sod seeder under field conditions showed that it varies from 8.28

to 8.63 kN. The decrease of traction

force on the experimental seeder is explained by the decrease in the length of

the point working surface and the change of its installation angle up to 75°

relative to the horizon.

Experiments have shown that the velocity of the unit has a significant influence on the value of traction resistance of the seeder with experimental working tools. With an increase of velocity from 3.7 to 8 km/h, the traction resistance of the experimental seeder sample increases by 4–4.5%, and it is lower than indicators of the prototype (Eurasian Patent, 2021) by 0.11–0.15 kN (Figure 5).

Figure 5

Dependence of tractive force on the velocity of the units

Field

experiments with seeding grass seeds into the turf have demonstrated that the experimental

model of the seeder provides a stable technological process of seeding

hard-to-bulk grass seeds at the depth of 1.8–6 cm with a simultaneous

site-specific application of mineral fertilizers at the depth of 8–12 cm. The

surface of the field after the passage of the seeder is characterized by an

even turf relief with traces (20 mm wide) of the working body shank. Visual

observation of the hoe opener operation at low speeds showed that the knife

(Figure 1a) loosens the soil or turf without turning the layer. At the same

time, it cuts the roots of old-age grasses and promotes the formation of soil

interlayer between fertilizer and seeds. Installation of the point at an angle

of 75° to the horizon excludes a soil layer turnover.

The

results of the laboratory and field tests allowed us to determine the technical

characteristics of the experimental planter (Table 2).

Table 2 Technical characteristics of the sod seeder

|

Indicators |

Meanings

|

|

Type of aggregation |

Trailerized |

|

Aggregate class, |

1-3 |

|

Working speed, km/hour max. |

7.6-10 |

|

Working

width, m |

3,6 |

|

Row

spacing, cm |

35 |

|

The number of rows to be tilled at the same time,

pcs. |

11 |

|

Productivity,

ha/h |

2.5-3.0 |

|

Depth of sowing of grain crops, cm |

2-8 |

|

Depth of grass seed placement, cm |

1.8-6 |

|

Fertilizer

placement depth, cm |

8-12 |

|

Overall dimensions of a planter in the transport

position, mm, max: |

|

|

-

Length, mm |

4000 |

|

-

width, mm |

3500 |

|

-

height, mm |

2100 |

|

Weight

(dry), kg |

2500 |

|

Ground clearance, mm not less |

300 |

|

Traction

force, kN |

8.28-8.63 |

Further research will be aimed at

improving the colter to ensure uniform application of liquid complex

fertilizers during sowing under cover crops and in the turf.

Based on

theoretical studies, substantiated that the traction force (759 N), as well as

the solution (25°–45°) and installation (73°–76°) angles of the hoe opener,

depend on its constructive and technological parameters. Determination of the

total traction force of the experimental sod seeder in field conditions has

shown that it varies within the range 8.28–8.63 kN by increasing the velocity

from 3.7 to 8 km/h and the traction resistance of the experimental sample of seeder

grows on 4–4.5%, thus it is lower than indicators of the prototype sample on

0.11–0.15 kN. Field experiments where performed grass seeds seeding into the

turf have shown that the experimental model of the sod seeder provides a stable

technological process of seeding hard-to-bulk grass seeds at the depth of 1.8–6

cm with a simultaneous site-specific application of mineral fertilizers at the

depth of 8–12 cm. The surface of the field after the passage of the sod seeder

is characterized by an even turf relief with traces (20 mm wide) of the working

body's shanks and knife. Visual observation of the work of a new working body

at low speed showed that the knife loosens the soil or turf without turning the

soil layer and at the same time it cuts roots of old-age grasses thereby

promoting the formation of a soil layer between fertilizer and seeds.

Installation of the point at an angle of 75° to the horizon eliminates the turn

of the soil layer.

This research was funded by the

Ministry of Education and Science of the Republic of Kazakhstan, grant number

AP05134800 (2018-2020) titled ‘The development of automated

grain-fertilizer-grass seeder for site-specific direct sowing of agricultural

crops under cover crops and sod with simultaneous application of mineral

fertilizers’.

Adams, J., Samimi, C., Mitterer, C., Bendix, J., Beck, E., 2022. Comparison of Pasture Types in The Tropical Andes: Species Composition, Distribution, Nutritive Value and Responses To Environmental Change. Basic and Applied Ecology, Volume 59, pp. 139–150

Afify, M. T., EL-Haddad, Z.A., Lamia, A.A.D., 2020. Modeling The Effect of Soil-Tool Interaction on Draft Force Using Visual Basic. Annals of Agricultural Science, Moshtohor, Volume 58(2), pp. 223–232

Baker,

C.J., Saxton, K.E., Ritchie, W.R., Chamen, W.C.T., Reicosky, D.C., Ribeiro,

M.F.S., Justice S.E., Hobbs P.R., 2007. No-tillage Seeding in Conservation

Agriculture. 2nd Edition. FAO and CAB International. UK:

Cromwell Press, Trowbridge

Bathgate,

A., Revell, C., Kingwell, R., 2009. Identifying The Value of Pasture

Improvement Using Wholefarm Modelling. Agricultural Systems, Volume 102(1–3),

pp. 48–57

Benincasa, P., Zorzi, A., Panella, F., Tosti, G., Trevini,

M., 2017. Strip Tillage and Sowing: Is Precision Planting Indispensable in

Silage Maize? International

Journal of Plant Production, Volume

11(4), pp. 577–588

Bowman,

M.T., Beck, P.A., Watkins, K.B., Anders, M. M., Gadberry, M. S., Lusby, K. S.,

Gunter, S. A., Hubbell, D. S., 2008. Tillage Systems for Production of

Small-Grain Pasture. Agronomy journal, Volume 100(5), pp. 1289–1295

Cheremisinov,

D.A., Doronin, M.S., 2017. On The Development of The Technological Scheme of a

Seeder for Seeding Grass Seeds Into Turf. In: Mat. III International

Scientific and Practical Conference Methods and Technologies in Plant Breeding

and Crop Production, pp. 406–410

Deák, B., Becker, T., Boch,

S., Wagner, V., 2018. Conservation, Management and Restoration of Semi-Natural and

Natural Grasslands in Central Europe - Editorial To The 13th EDGG Special

Feature. Tuexenia, Volume 38, pp. 305–310

Eurasian

Patent, 2021. Eurasian Patent No. 038584. Grain Fertilizer-Grass Anti-Erosion

Seeder / KATU Named After S. Seifullin

Fulkerson,

W.J., Lowe, K.F., 2022. Perennial Forage and Pasture Crops - Establishment snd

Maintenance. Encyclopedia of Dairy Sciences. 3rd Edition.

Academic Press. pp. 759–768

Himmelbauer,

M.L., Vateva, V., Lozanova, L., Loiskandl, W., Rousseva, S., 2013. Site Effects

on Root Characteristics and Soil Protection Capability of Two Cover Crops Grown

in South Bulgaria. Journal of Hydrology and Hydromechanics, Volume

61(1), pp. 30–38

Karimipoor, Z., Rashtian, A.,

Amirkhani, M., Ghasemi, S., 2021. The Effect of Grazing Intensity on Vegetation

Coverage and Nitrogen Mineralization Kinetics of Steppe Rangelands of Iran

(Case Study: Nodoushan Rangelands, Yazd, Iran). Sustainability, Volume 13 (15), p. 8392

Kazakhstan

Republic, 2021. Kazakhstan Republic Patent No. 35155, Cereal Seeder

(?2020/0206.1) / KATU Named After S.Seifullin

Kopecký,

D., Studer, B., 2014. Emerging Technologies Advancing Forage and Turf Grass

Genomics. Biotechnology Advances, Volume 32(1), pp. 190–199

Lekavi?ien?, K., Šarauskis, E., Naujokien?, V., Buragien?,

S., Kriau?i?nien?, Z. 2019. The Effect of The Strip Tillage Machine Parameters on The Traction

Force, Diesel Consumption and CO2 Emissions. Soil and Tillage

Research, Volume 192, pp. 95–102

Marchenko,

O.S., Marchenko, N.M., Pedai, N.P., 2010. Combined Aggregate MPTD-12 for Strip

Sowing of Grass Seeds and Grass Mixtures on Meadows and Pastures. Agricultural

Machinery and Technology, Volume 5, pp. 15–17

Nazarko,

O., 2008. Seeding Forages into Existing Shanks Using Minimal Tillage. Report Manitoba Forage Council 06.08,

Canada’s Agricultural Producers Addressing Environmental Issues (CAPAEI)

Program, Winnipeg, Canada

Nukeshev, S.,

Yeskhozhin, K., Karaivanov, D., Ramaniuk, M., Akhmetov, E., Saktaganov, B.,

Tanbayev, K., 2023. A Chisel Fertilizer for In-Soil Tree-Layer Differential

Application in Precision Farming. International Journal of Technology, Volume 14(1), pp. 109–118

Panov,

I.M., Vetokhin, V.I., 2008. Physical Bases of Soil Mechanics. Ukraine: Phoenix

Revenko,

V.YU., Belousov, M.M., 2014. Test Results of a Machine for Strip-Seeding Grass in

Turf. International Agroengineering, Volume 4(12), pp. 53–61

Saitov,

V., Kurbanov, R., Demshin, S., Sozontov, A., 2021. Improving of the sod seeders

SDK of strip grass seed sowing. In: Mottaeva, A. (eds) Proceedings of

the XIII International Scientific Conference on Architecture and Construction

2020, Volume 130

Scotton, M., 2019. Mountain Grassland Restoration: Effects of

Sowing Rate, Climate and Soil on Plant Density and Cover. Science of the Total Environment, Volume 651, pp. 3090–3098

Sineokov,

G.N., Panov, I.M., 1977. Teoriya i Raschet Pochvoobrabatyvayushchih Mashin (Theory

and Calculation of Tillage Machines). Russia: Mashinostroenie

Sokolov,

A.V., Zamana, S.P., Patlai V.V., Fedorovsky T.G., Kindsfater, V.Y., 2012.

Improving The Technological Process and Means for Direct Grasses Undersowing

into Grassland Sod of Natural Fodder Lands. Fodder Production, Volume.

4, pp. 44–46

Soldatov, E., Dzhibilov, S.,

Soldatova, I., Guluyeva, L., 2020. Restoration of Degraded Mountain Pastures of

The Central Caucasus by Targeted Sowing of Seeds of Perennial Grasses. In:

E3S Web of Conferences, Volume 175

Sysuev, V., Kurbanov, R.,

Demshin, S.L., Saitov, V.?., Doronin, M.S., 2021. Parameters and Operating

Modes of The Coulter Group of The Sod Seeder. In: IOP Conference Series: Earth and

Environmental Science, Volume 723, p.

022050

Sysuev,

V.A., Demshin S.L., Gaididei S.V., 2022. Results of Research of The Combined

Seeder for Strip Sowing of Grasses Into Sod. Agricultural Science

Euro-North-East, Volume 23(2), pp. 263–273

Zhao, T., Zhao, Y., Higashi, T., Komatsuzaki, M., 2012. Power Consumption of No-Tillage Seeder Under Different Cover Crop Species and Termination for Soybean Production. Engineering in Agriculture. Environment and Food, Volume 5(2), pp. 50–56,

Zotov, A.A., Kosolapov, V.M., Kobzin, A.G., Trofimov, I.A., Ulanov, A.N., Shevtsov, A.V., Shel'menkina Kh., Shchukin, N.N., 2012. Senokosy I Pastbishcha Na Osushaemykh Zemlyakh Nechernozem'ya (Hayfields and Pastures on The Drained Lands of The Non-Chernozem Region). Kazkhstan: IP Izotova K.U