Catalytic Cracking of Palm Fatty Acid Distillate with NaOH and KOH Catalyst Supported by Gamma Alumina

Corresponding email: rismawati.rasyid@umi.ac.id

Published at : 17 May 2024

Volume : IJtech

Vol 15, No 3 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i3.5980

Rasyid, R., Prasetyo, D., Fitriani, N., Syarif, T., 2024. Catalytic Cracking of Palm Fatty Acid Distillate with NaOH and KOH Catalyst Supported by Gamma Alumina. International Journal of Technology. Volume 15(3), pp. 770-779

| Rismawati Rasyid | Departement of Chemical Engineering, Faculty of Industrial Technology, Universitas Muslim Indonesia, Makassar, Indonesia |

| Dicky Prasetyo | Departement of Chemical Engineering, Faculty of Industrial Technology, Universitas Muslim Indonesia, Makassar, Indonesia |

| Nurul Fitriani | Departement of Chemical Engineering, Faculty of Industrial Technology, Universitas Muslim Indonesia, Makassar, Indonesia |

| Takdir Syarif | Departement of Chemical Engineering, Faculty of Industrial Technology, Universitas Muslim Indonesia, Makassar, Indonesia |

This article describe about the study of produce fuel from

palm fatty acid distillate with a similar composition to

fossil fuels through catalytic

cracking method using alkaline heterogeneous catalyst. The catalytic cracking reaction was operated at batch reactor with a

constant temperature of 370oC, a volume of 50 mL of feedstock, a

pressure of 1 atm, and two

kinds of catalysts: NaOH/g-Al2O3

and KOH/g-Al2O3 which

has been characterization with X-ray diffraction and scanning electron

microscopy. The best catalyst to produce biofuel type biogasoline (C5-C15)

is KOH/g-Al2O3 (5%) with a

yield of 70% and selectivity to biogasoline of 74.46%. Meanwhile, the best

catalyst to produce biofuel type biodiesel (C15-C22) is NaOH/g-Al2O3 (5%) with a

yield of 80% and selectivity to biodiesel of 67.72%.

Biodiesel; Biogasoline; Catalytic Cracking; Palm fatty acid distillate

The depletion of fossil fuels, coupled with the rapid growth in living

standards, has led to a significant increase in fuel prices and the subsequent

impact on greenhouse gas emissions. This has prompted researchers to prioritize

the development of renewable and non-polluting fuels, which hold the promise of

achieving global energy security while also mitigating the effects of climate

change (Ibrahim, et al., 2020; Singh et al., 2020; Wakoc, et al., 2018). Palm

oils are widely considered to be the most promising feedstock for the

production of such alternative fuels, known colloquially as biofuels.

Nevertheless, if palm oil is used as a raw resource for biofuels for an

extended period, it will eventually compete with foodstuffs. Using byproducts

of palm oil processing, which still contain a lot of fatty acids as a raw

material is a very wise decision (Oliveira, et

al., 2021; Arita et al., 2020; Onlamnao and Tippayawong, 2020; Zaher, et

al., 2017).

Among all biofuel preparation technologies, catalytic cracking is considered a promising method due to its simple process which can be carried out at atmospheric pressure, has a higher cracking conversion efficiency, higher light alkene selectivity, less carbon deposition and the production of several types of liquid products similar to petroleum-based fuels. Furthermore, with appropriate catalysts, catalytic cracking can be used to produce gasoline, kerosene, and diesel, and it has good compatibility with various feedstocks as well as a lower cost (Ulfiati et al., 2022; Zhang, et al., 2021; Orazbayev, et al., 2020; Nieuwelink et al., 2020; Singh et al., 2020; Mammadova et al., 2018). The cracking reaction is characterized primarily by a break in the "carbon-carbon" bond, indicating an endothermic reaction—the higher the temperature, the faster the reaction (Wang et al., 2019). In comparison to the transesterification process, the catalytic cracking process is a more efficient method that offers greater flexibility in product output. The transesterification process, on the other hand, involves several complex steps, including the separation of products and by-products and the initial treatment of high FFA to prevent saponification reactions. Additionally, this process produces only one type of biofuel, and the production time can be relatively long, with processing times of around 5 hours and purification times of up to 24 hours (Wahyono et al., 2022; Rasyid et al., 2018). Meanwhile, when compared to the hydrocracking process, which requires high temperatures 350oC and 29.6077 atm pressures, the catalytic cracking process is more cost-effective because it can be operated at lower temperatures and atmospheric pressure (Trisunaryanti et al., 2020; Al-Muttaqi et al., 2019; Rasyid et al., 2015).

Currently, to meet the requirements of vehicle fuel

standards, catalytic cracking must reduce the acid value and oxygen content of

the biofuel which are biogasoline (C5-C15) dan

biodiesel (C16-C22) to improve fuel

properties such as density, calorific value, dynamic viscosity, and other

parameters (Sardi et al., 2022; Makertihartha et al., 2020). There is no doubt that

catalysts play an important role in the catalytic cracking of fatty

acids to produce biofuel. Alkaline catalysts

such as sodium hydroxide (NaOH) and potassium hydroxide (KOH) are commonly used

in the production of biofuels because their rate of reaction is much faster

than that of acid catalysts (Min et al., 2015).

High catalytic activity, shorter reaction time, simple operating

conditions, low cost, and availability are just a few of the advantages of NaOH

and KOH catalysts. However, homogeneous base catalysts, on the other hand, are

extremely sensitive to free fatty acids and water. Therefore, a homogeneous

catalyst was modified into a heterogeneous catalyst by the addition of a

catalyst support (Widayat et al.,

2016).

Heterogeneous catalysts can be designed to graft and trap

active molecules on the surface or within the pores of solid supports such as

silica, alumina, or CaO (Thangaraj et

al., 2019). Gamma alumina (-Al2O3) is used as a catalyst support because it has a large surface area

(150-300 m2/g) and an amphoteric acid and base active site with

various strengths depending on the method of production. Furthermore,

-Al2O3 serves the primary function of providing surface area for the active

component, with the purpose of increasing contact between the active core and

the reactants while maintaining active phase activity (Rasyid et al., 2018). The presence of

acid sites on Al2O3, which are associated with Lewis

acidity and very weak Brönsted acidity, makes it an effective catalyst for

deoxygenation with minimal aromatization (Istadi et

al., 2021). Thus, making heterogeneous NaOH/g-Al2O3

and KOH/g-Al2O3

catalysts may be a feasible method to integrate the required acidic and basic

characteristics to overcome defects in NaOH and KOH catalysts and avoid an

excessive production of aromatic hydrocarbons by acid solid catalysts (Zheng et al.,

2019).

Therefore, the

catalytic cracking of palm fatty acid distillate for biofuels was carried out

using heterogeneous NaOH/-Al2O3

and KOH/

-Al2O3

catalysts. Mechanically, NaOH/g-Al2O3

and KOH/g-Al2O3

catalysts were created by combining NaOH and KOH as primary catalysts and

-Al2O3

as catalysts support. This research aims to produce a fuel with a similar

composition to fossil fuels.

2.1. Tools

2.2. Preparation of Catalysts

The catalyst was prepared from sodium hydroxide (NaOH) p.a

merck and potassium hydorxide (KOH) p.a merck as catalyst site active element which impragnated into

support gamma alumina (g-Al2O3) from merck (p.a). Wet

impregnation was used to prepare the catalysts. NaOH 0.5 N was impregnated into 10

grams of g-Al2O3 to

prepare NaOH/g-Al2O3 catalyst, then it was stirred with a magnetic

hotplate stirrer while the water in the mixture evaporated to form a paste. The mixture of the catalysts would be dried at 110oC within 8 hours. Afterward, the mixture was calcined

for 3 hours at a temperature of 500oC. Furthermore, the same process was carried out with

KOH 0.5 N to preparation KOH/g-Al2O3

catalyst.

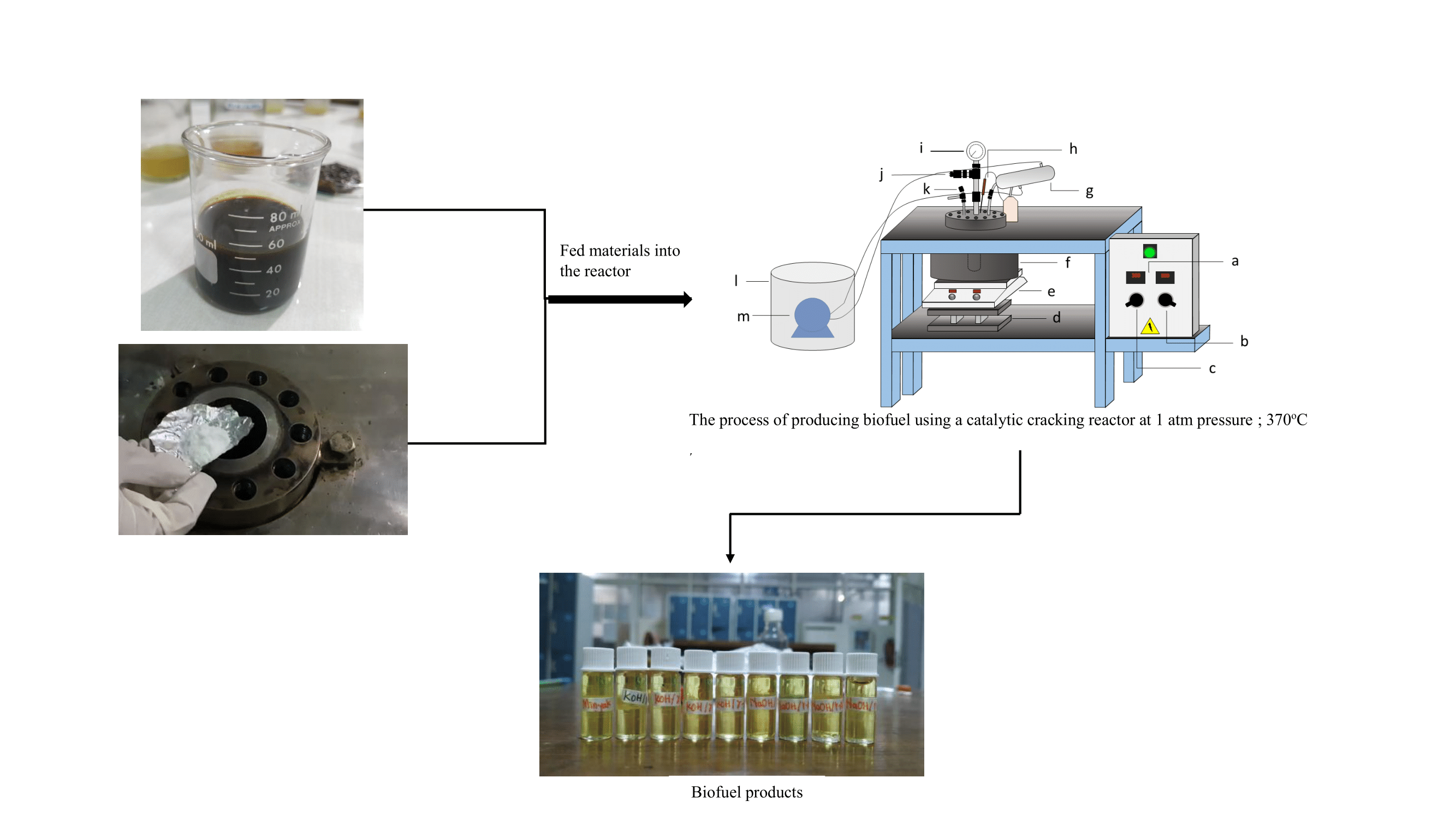

2.3. Catalytic

Cracking Process

A batch reactor

with a pressure of 1 atm was used to conduct the reaction. The reactor is

filled with 50 mL of palm fatty acid distillate from palm oil

refining, 0.5 grams of NaOH/-Al2O3

catalyst (1% of the raw ingredients), and a

magnetic stirrer. The reaction is then performed for two hours after the

reactor heater is turned on until it reaches a temperature of 370°C (Aziz et al., 2020). The biofuel product

will evaporate from the reactor to the liquid product container during the

reaction and flow through the condenser. Remaining in the reactor is the

residue, and the amount of gaseous product that hasn't condensed is estimated

using the mass balance equation by deducting the initial amount of raw material

from the final product. Furthermore, the catalytic cracking

process is carried out with a NaOH/

-Al2O3

catalyst (3, 5, 7)% and KOH/

-Al2O3

catalyst (1, 3, 5, 7)%.

·

Scanning Electron

Microscopy (SEM) and X-Ray Diffraction (XRD) at the following conditions: 40

KV, 15 mA, CuK/1.54060 Time/step of 23.9700 s, step size of 0.0220 deg, and

Scan axis Gonio were used to characterize the catalyst.

· Gas chromatography-mass spectrometry (GC-MS) with an Agilent capillary number of 19.091 S-493, HP-5MS of 5% phenyl methyl siloxane, nominal length of 30.0 m, nominal diameter of 250 um, nominal film thickness of 0.25 um, and nominal initial pressure of 10.5 psi was used to analyze the product's component compounds.

3.1. Characterization of NaOH/Al2O3 and KOH/

Al2O3 Catalyst

3.1.1 X-Ray Diffraction (XRD) Analysis

X-ray Diffraction (XRD) was used to identify content that was impregnated on the support of catalyst (Al2O3) as the NaOH/

Al2O3 and KOH/

Al2O3 catalysts (Figure 2).

Figure 2 XRD diffractogram (a) NaOH/Al2O3 catalyst, and (b) KOH/

Al2O3 catalysts

According to ICDD (International Center for Diffraction Data) 00-010-0425, Gamma Alumina (g-Al2O3) has peaks at 2? = 37°, 39°, 45°, and 67°. As shown in Figure 2, NaOH/g-Al2O3 has peaks 2? that are similar to g-Al2O3, such as 37o, 39o, and 67o, but there are new peaks formed due to impregnation, indicating the presence of deposited NaOH catalyst. Likewise, the KOH/Al2O3 catalyst has peaks 2? that are similar to

Al2O3, notably 37o, 39o, and 67o, and there are new peaks are formed due to impregnation, proving the presence of deposited KOH catalyst (Singh et al., 2020; Yu et al., 2019; Wako et al., 2018).

3.1.2 Scanning Electron Microscopy (SEM) Analysis

The surface morphology of the catalyst support revealed a regular crystal structure before impregnation, whereas after impregnation revealed that the impregnated active site had attached and distributed to the support's main structure.

3.2. Gas Chromatography-Mass Spectrometry Analysis of Palm Fatty Acid Distillate

Palm fatty acid distillate was GC-MS analyzed before the catalytic cracking process to determine the compound composition of the raw material used (Table 1). The by-product of palm oil processing used in this study still contains triglyceride components, specifically free fatty acids. As noted by (Oliveira et al., 2021), the conversion of palm oil into cooking oil can result in up to 6% of the by-product of feed CPO being left behind. The byproduct is palm oil fatty acid distillate, which contains a high concentration of free fatty acids. There are also significant amounts of hydrocarbon compounds (Table 1). This shows that palm oil waste has the potential to be used as a raw material in the production of biofuels.

3.3. Product Yield Analysis Results

The yield of the product obtained in the biofuel production process by catalytic cracking of palm fatty acid distillate with NaOH/Al2O3 and KOH/

Al2O3 catalysts was directly proportional to the catalyst concentration up to 5% and experienced product yields at 7% catalyst concentration (Figure 4). Studies by (Thambiyapillaia and Ramanujam, 2021; Akah, Williams, and Ghrami, 2019; Prabasari, et al., 2019) have demonstrated that the addition of a catalyst to a catalytic cracking reaction can increase the reaction rate, resulting in higher yields. However, it is important to note that if the catalyst's performance has already reached its optimum limit, adding more of it beyond that point will not lead to further improvements in the reaction's effectiveness.

Despite the similarities in the line chart, the amount of yield produced by each catalyst is different. The yield obtained with the NaOH/Al2O3 catalyst was greater than the yield obtained with the KOH/

Al2O3 catalyst. The product yield obtained with the NaOH/g-Al2O3 (5%) catalyst was 80% while the higher yield of KOH/g-Al2O3 (5%) was 70%. This is due to the active site distribution of the NaOH/

Al2O3 catalyst obtained through scanning electron microscopy analysis appearing wider and adhering more to the catalyst support (Figure 3).

3.3. Selectivity Product

The highest conversion of biodiesel product from the catalytic cracking of palm fatty acid distillate was obtained with NaOH/g-Al2O3 (5%) catalyst, which was 67.72%. This shows that the NaOH/-Al2O3 catalyst is more selective towards long-chain biofuels (C15-C-22) compared to the KOH/g-Al2O3 catalyst, which produces less than 20% biodiesel.

Meanwhile, the conversion of biogasoline products from the catalytic cracking of palm fatty acid distillates with the NaOH/Al2O3 catalyst shows data that is directly proportional to the increase in the catalyst. The highest biogasoline product with NaOH/

Al2O3 catalyst was obtained at 7% catalyst, which was 48.88%, indicating that if the catalyst is increased again, the conversion may increase or decrease. However, when compared to the catalytic cracking of palm fatty acid distillate with a KOH/

Al2O3 catalyst, better results were obtained, where the optimum biogasoline production point was obtained with a KOH/

Al2O3 catalyst (5%) and a bio gasoline yield of 74.46%. This shows that the KOH/

Al2O3 catalyst is more selective towards short-chain biofuels (C5-C15) than the NaOH/

Al2O3 catalyst. According to (Aziz et al., 2021b; Istadi et al., 2021; Senter et al., 2021), catalysts that produce short-chain biofuels have high performance. The product's selectivity is proportional to the Lewis to Brønsted ratio (L/B ratio). When the L/B ratio is high, the Lewis acid site is dominant. Because of the catalyst's low L/B ratio, the NaOH/

Al2O3 catalyst promotes the formation of long chains (biodiesel).

Palm fatty acid distillate (PFAD) can be converted into biogasoline (C5–C15) and biodiesel (C16–C22) at a pressure of 1 atm using NaOH/Al2O3 and KOH/

Al2O3 as catalysts in a catalytic cracking process. KOH/

Al2O3 (5%) is the best catalyst for producing biofuel type biogasoline (C5-C15), with a yield of 70% and a selectivity to biogasoline of 74.46%. Meanwhile, the best catalyst for producing biofuel type biodiesel (C15-C22) is NaOH/

Al2O3 (5%), which has an 80% yield and a 67.72% selectivity for biodiesel. Furthermore, the product of this research can be utilized as a blend of commercial fuels, given that they contain the same compounds and that the combustion products are easily decomposed, minimizing pollution to the environment. It is also intended to reduce the use of fossil fuels, ensuring global energy availability. This research can be expanded with different pre-treatments in the manufacture of catalysts to increase their effectiveness, as well as the addition of appropriate promoters.

DRPM KEMENDIKBUDRISTEK for assistance with

funding in the PTUPT research scheme (Number : 2327.I/B.07/UMI/VII/2022). The

academic community of Fakultas Teknologi Industri Universitas Muslim Indonesia,

where the research is held at the Chemical Engineering Process Laboratory.

Akah,

A., Williams, J., Ghrami, M., 2019. An Overview of Light Olefins Production via

Steam Enhanced Catalytic Cracking. Catalysis Surveys from Asia, Volume

23, pp. 265–276

Al-Muttaqi,

M., Kurniawansyah, F., Prajitno, D.H., Roesyadi, A., 2019. Hydrocarbon Biofuel

Production by Hydrocracking Process with Nickel-Iron Supported on HZSM-5

Catalyst. In: IOP Conference Series: Materials Science and Engineering,

Volume 543(1), p. 012055

Arita, S., Nazarudin, N., Rosmawati, R., Komariah, L.N.,

Alfernando, O., 2020. The

Effect of Combined H-USY and ZSM-5 Catalyst in Catalytic Cracking of Waste

Cooking Oil to Produce Biofuel. In: AIP Conference Proceedings, Volume

2242(1), p. 040047

Aziz,

I., Ardine, E.A.F., Saridewi, N., Adhani, L., 2021a. Catalytic Cracking of

Crude Biodiesel into Biohydrocarbon Using Natural Zeolite Impregnated Nickel

Oxide Catalyst. Jurnal Kimia Sains dan Aplikasi, Volume 24(7), pp. 222–227

Aziz, I., Kurnianti, Y., Saridewi, N., Adhani, L.,

Permata, W., 2020. Utilization

of Coconut Shell as Cr2O3 Catalyst Support for Catalytic

Cracking of Jatropha Oil into Biofuel. Jurnal Kimia Sains dan Aplikasi, Volume

23(2), pp. 39–45

Aziz,

I., Retnaningsih, T., Gustama, D., Saridewi, N., Adhani, L., Dwiatmoko, A.A.,

2021b. Catalytic Cracking of Jatropha Oil into Biofuel over Hierarchical

Zeolite Supported NiMo Catalyst. In: AIP Conference Proceedings, Volume

2349(1), p. 020004

Ibarra,

Á., Hita, I., Azkoiti, M.J., Arandes, J.M., Bilbao, J., 2019. Catalytic

Cracking of Raw Bio-oil under FCC Unit Conditions over Different Zeolite-based

Catalysts. Journal of Industrial and Engineering Chemistry, Volume 78,

pp. 372–382

Ibrahim,

H., Silitonga, A.S., Rahmawaty, Dharma, S., Sebayang, A.H., Khairil.,

Sumartono, Sutrisno, J., Razak, A., 2020. An Ultrasound Assisted

Transesterification to Optimize Biodiesel Production from Rice Bran Oil. International

Journal of Technology, Volume 11(2), pp. 225–234

Istadi,

I., Riyanto, T., Buchori, L., Anggoro, D.D., Pakpahan, A.W., Pakpahan, A.J.,

2021. Biofuels Production from Catalytic Cracking of Palm Oil Using Modified HY

Zeolite Catalysts over A Continuous Fixed Bed Catalytic Reactor. International

Journal of Renewable Energy Development, Volume 10(1), pp. 149–156

Makertihartha,

I.G.B., Fitradi, R.B., Ramadhani, A.R., Laniwati, M., Muraza, O., Subagjo,

2020. Biogasoline Production from Palm Oil: Optimization of Catalytic Cracking

Parameters. Arabian Journal for Science and Engineering, Volume 45, pp.

7257–7266

Mammadova,

T., Abbasov, M., Movsumov, N., Latifova, T., Hasanova, A., Kocharli, Z., Irada,

K., Abbasov, V., 2018.

Production of Diesel Fractions by Catalytic Cracking of Vacuum Gas Oil and Its

mixture with Cottonseed Oil under the influence of a Magnetic Field, Egyptian

Journal of Petroleum, Volume 17, pp. 1029–1033

Min,

P.H., Shahbaz, K., Rashmi, W., Mjalli, F.S., Hashim, M.A., Alnashef, I.M.,

2015. Removal of Residual Calatyst from Palm Oil-based Biodiesel Using New

Ionic Liquids Analogous. Journal of Engineering Science and Technology,

Volume 4(4), pp. 35–49

Nieuwelink,

A.E., Velthoen, M.E., Nederstigt, Y.C., Jagtenberg, K.L., Meirer, F.,

Weckhuysen, B.M., 2020. Single Particle Assay to Determine Heterogeneities

within Fluid Catalytic Cracking Catalysts. Chemistry-A European Journal,

Volume 26, pp. 8564– 8554

Oliveira,

B.F.H.d., de-França, L.F., Fernandes-Corrêa, N.C., Ribeiro, N.F.D.P.,

Velasquez, M., 2021. Renewable Diesel Production from Palm Fatty Acids

Distillate (PFAD) via Deoxygenation Reactions. Catalysts, Volume 11(9),

pp. 1–16

Onlamnao,

K., Tippayawong, N., 2020. Organic Liquid Products from Cracking of Used

Cooking Oils with Commercial Catalysts. Chemical Engineering Transactions,

Volume 78, pp. 55–60

Orazbayev,

B., Kozhakhmetova, D., Wójtowicz, R. Krawczyk, J., 2020. Modeling of a

Catalytic Cracking in the Gasoline. Energies, Volume 13(18), pp. 1–13

Prabasari,

I.G., Sarip, R., Rahmayani, S., Nazarudin, 2019. Catalytic Cracking of Used

Cooking Oil Using Cobalt-impregnated Carbon Catalysts. Makara Journal of

Science, Volume 23(3), pp. 162–168

Rasyid,

R., Prihartantyo, A., Mahfud, M., Roesyadi, A., 2015. Hydrocracking of

Calophyllum inophyllum Oil with Non- Sulfide CoMo Catalysts. Bulletin of

Chemical Reaction Engineering and Catalysis, Volume 10(1), pp. 61–69

Rasyid, R., Sabara, Z., Ainun-Pratiwi, H., Juradin,

R., Malik, R., 2018. The

Production of Biodiesel from A Traditional Coconut Oil Using NaOH/?-Al2O3

Heterogeneous Catalyst. Makassar. In: IOP Conference Series: Earth and

Environmental Science, Volume 175, p. 012025

Sardi,

B., Ningrum, R.F., Ardianyah, V.A., Qadariyah, L., Mahfud, M., 2022. Production

of Liquid Biofuels from Microalgae Chlorella sp. via Catalytic Slow Pyrolysis. International

Journal of Technology, Volume 13(1), pp. 147–156

Senter,

C., Mastry, M.C., Zhang, C.C., Maximuck, W.J., Gladysz, J.A., & Yilmaz, B.,

2021. Role of Chlorides in Reactivation of Contaminant Nickel on Fluid

Catalytic Cracking (FCC) Catalysts. Applied Catalysis A: General, Volume

611, p. 117987

Singh, H. K. G., Yusup, S., Quitain, A. T., Abdullah,

B., Ameen, M., Sasaki, M., Kida, T., Cheah, K. W., 2020. Biogasoline Production from Linoleic Acid via

Catalytic Cracking over Nickel and Copper-doped ZSM-5 Catalysts. Environmental

Research, Volume 186, p. 109616

Thambiyapillaia,

S., Ramanujam, M., 2021. An Experimental Investigation and Aspen HYSYS

Simulation of Waste Polystyrene Catalytic Cracking Process for the Gasoline

Fuel Production. International Journal of Renewable Energy Development, Volume

10(4), pp. 891–900

Thangaraj,

B., Solomon, P.R., Muniyandi, B., Ranganathan, S., Lin, L., 2019. Catalysis in

Biodiesel Production. Clean Energy, Volume 3(1), pp. 2–23

Trisunaryanti,

W., Triyono. T., Ghoni, M.A., Fatmawati. D.A., Mahayuwati. P.N., Suarsih, E.,

2020. Hydrocracking of Callophyllum Inophyllum Oil Employing Co and/or Mo

Supported on g-Al2O3 for

Biofuel Production. Bulletin of Chemical Reaction Engineering &

Catalysis, Volume 15 (3), pp. 743–751

Ulfiati,

R., Dhaneswara, D., Harjanto, S., Fatriansyah, J.F., 2022. Synthesis and

Characterization ZSM-5 Based on Kaolin as a Catalyst for Catalytic Cracking of

Heavy Distillate. International Journal of Technology, Volume 13(4), pp.

860–869

Wahyono,

Y., Hadiyanto, Budihardjo, M.A., Hariyono, Y., Baihaqi, R.A., 2022.

Multifeedstock Biodiesel Production from a Blend of Five Oils through

Transesterification with Variation of Moles Ratio of Oil: Methanol. International

Journal of Technology, Volume 13(3), pp. 606–618

Wako,

F.M., Reshad, A.S., Bhalerao, M.S., Goud, V.V., 2018. Catalytic Cracking of

Waste Cooking Oil for Biofuel Production Using Zirconium Oxide Catalyst. Industrial

Crops & Products, Volume 118, pp. 282–289

Wang,

C., Tian, X., Zhao, B., Zhu, L., Li, S., 2019. Experimental Study on Spent FCC

Catalysts for the Catalytic Cracking Process of Waste Tires. Processes, Volume

7(6), p. 335

Widayat,

W., Wicaksono, A.R., Firdaus, L.H., Okvitarini, N., 2016. Synthesis H-Zeolite

Catalyst by Impregnation KI/KIO3 and Performance Test Catalyst for Biodiesel

Production Synthesis H-Zeolite Catalyst by Impregnation KI/KIO3 and Performance

Test Catalyst for Biodiesel Production. In: IOP Conference Series:

Materials Science and Engineering, Volume 107(1), p. 012044

Yu,

H., Liu, Y., Liu, J., Chen, D., 2019. High Catalytic Performance of an

Innovative Ni/Magnesium Slag Catalyst for The Syngas Production and Tar Removal

from Biomass Pyrolysis. Fuel, Volume 254, p. 115622

Zaher,

F., Gad, M.S., Aly, S.M., Hamed, S.F., Abo-Elwafa, G.A., Zahran, H.A., 2017.

Catalytic Cracking of Vegetable Oils for Producing Biofuel. Egypt Journal

Chemical, Volume 60(2), pp. 291–300

Zhang,

Y., Li, Z., Wang, Z. Ji, Q., 2021. Optimization Study on Increasing Yield and

Capacity of Fluid Catalytic Cracking (FCC) Units. Processes, Volume 9,

p. 1497

Zheng,

Z., Lei, T., Wang, J., Wei, Y., Liu, X., Yu, F., Ji, J., 2019. Catalytic

Cracking of Soybean Oil for Biofuel over ?-Al2O3/CaO Composite Catalyst. Journal

of The Brazilian Chemical Society, Volume 30(2), pp. 359–370