Mass Transfer Phenomena during the Ultrasound-assisted Extraction of Algal Oil from Spirulina sp.

Published at : 10 Jul 2024

Volume : IJtech

Vol 15, No 4 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i4.5974

Nisya, A.F., Rochmadi, R., Budiman, A., 2024. Mass Transfer Phenomena during the Ultrasound-assisted Extraction of Algal Oil from Spirulina sp. International Journal of Technology. Volume 15(4), pp. 927-936

| Alinda Fitrotun Nisya | 1 Department of Chemical Engineering, Faculty of Engineering, Universitas Gadjah Mada, Jalan Grafika No.2 Yogyakarta, 55281, Indonesia 2 Department of Chemical Engineering, Faculty of Industrial Te |

| Rochmadi Rochmadi | Department of Chemical Engineering, Faculty of Engineering, Universitas Gadjah Mada, Jalan Grafika No.2 Yogyakarta, 55281, Indonesia |

| Arief Budiman | Department of Chemical Engineering, Faculty of Engineering, Universitas Gadjah Mada, Jalan Grafika No.2 Yogyakarta, 55281, Indonesia |

Recently, microalgae is potential to be developed because it is easy to cultivate. This study investigated the effect of the solvent ratio on the mass transfer of algal oil at various residence times from 15 minutes to 60 minutes during ultrasound-assisted extraction process at 25 kHz and stirred at 150 rpm. The highest amount of the algal oil yielded was 3.01%, obtained by a ratio of isopropyl alcohol to n-hexane of 2:3 ratio at 60 minutes. A mathematical model was applied to obtain the mass transfer coefficient, diffusivity coefficient, and Henry’s constant contributing to the mass transfer rate. A GC-MS analysis was conducted to show the type of fatty acids and the fatty acid methyl ester produced by the extraction that showed the trans-esterification reaction. The lowest yield was obtained by 3:1 isopropyl alcohol to n-hexane ratio which had the lowest kca and De (4.7999×10-5 min-1 and 2.0000×10-9 cm2/min, respectively).

Algal oil; Fatty acid; Mass transfer; Spirulina sp; Ultrasound-assisted extraction

Microalgae, containing lipids,

has become one of the potential renewable energy resources (Setyawan et al., 2018; Chisti, 2008). They are potentially developing

in Indonesia, which has an extensive water area. Besides, they can grow in

fresh and saltwater (Daneshvar et al.,

2018; Clemens et al., 2011). The proteins, lipids, and carbohydrates contained in a microalga reach

6-52%, 7-23%, and 7-23%, respectively, depending on the strain type and growth

condition (Dewati et al., 2022; Kang et

al., 2011). Microalgae are

classified into Cyanophycae, Bacillariophyceae, Chrysophycae,

and Chlorophyceae based on their pigments. They also have high

photosynthetic efficiency, rapid growth rate, and small cultivation area (Clarens et al., 2010). Spirulina sp. is one of the green algae

found in various environments, like brackish water, freshwater, and seawater,

and thus easy to cultivate in Indonesia (Rilisa and Suantika, 2021)

Microalgae are the third generation of biomass

resources (Sardi et al., 2022), the

first and second of which have disadvantages. The first comes from food, such

as palm oil, corn oil, canola oil, and bean, and creates a conflict regarding

the fulfillment of food and energy (Haque et al.,

2015; Mohr and Raman, 2013). Meanwhile, the second comes

from non-food materials such as jatropha and waste biomass containing

cellulose, which require a high operational cost to produce

energy (Jamilatun et al., 2020; Balan,

2014).

Lipids in microalgae

comprise the storage (non-polar) lipids and the structural (polar) ones that

include oils (Sharma,

Schuhmann, and Schenk, 2012). The storage ones have the primary form of triglycerides as the energy source (D’Alessandro and Antoniosi-Filho, 2016). A polar lipid is the membrane’s primary structure that plays a role in metabolism (Casal and

Oliveira, 2007). Non-polar lipids, such as free

fatty acids (saturated, unsaturated, and polyunsaturated) and acylglycerol (mono-acyl,

di-acyl, and tri-acyl), can be easily esterified (Asikainen et

al., 2015). In contrast, polar lipids, such

as glycolipid and phospholipid, have long carbon chains and are highly

unsaturated, thus uneasily converted into biodiesel using conventional methods (Atadashi et

al., 2012).

The

ultrasound-assisted extraction method often functions to get algal oils from

microalgae cells by cavitation (Vilkhu et

al., 2008). It is

environmentally friendly since it takes less time and saves more energy than conventional

extraction methods (Sela, Budhijanto, and

Budiman, 2021; Adam et al., 2012). Ultrasound energy produces chemical and

physical effects because cavitation bubbles collapse. These effects can lead to

biodiesel production (Suganya,

Kasirajan, and Renganathan, 2014).

However, an organic

solvent is required for lipid extraction (Pradana et al., 2020; Wang et al., 2014) by first examining its polarity,

surface tension, viscosity, and vapor pressure (Lavilla and Bendico, 2017). Extracting polar and non-polar lipids needs a mixture of polar and

non-polar solvents like chloroform and methanol as the most frequently used

solvents for lipid extraction from any living tissue for their high speed and

nature is quantitative (Halim, Danquah, and Webley, 2012).

The oil extracted can be processed as biodiesel as a renewable energy

resource. The cetane number of biodiesel is higher than that of petroleum

diesel (Guo et al., 2016). Besides, the combustion

emission profile in biodiesel is better, meaning that it is good for the

environment. These reasons make biodiesel an excellent alternative to fossil

fuels (da-Silva et al., 2012).

Research on the

ultrasound-assisted extraction of lipids from microalgae found that the

sonication amplitude and duration of lipid extraction affected the percentage

of lipid extraction from Dunaliella sp., which had a positive

correlation (Shahi et al., 2021). The analysis of the fatty acid

profile of algal oil through an ultrasound-assisted Soxhlet extraction from

microalgae showed the potency for producing biodiesel (Wong and Shahirah, 2019). The power, time, and pulse were the most dominant factors in the yielded

oil developed by STATISTICA software (Wiyarno,

Mohd-Yunus, and Mel, 2014). However, the mass transfer phenomena during ultrasound-assisted

extraction have not been studied, especially in algal oil extraction. This

research aimed to observe the effect of the ratio of the polar solvent to the

non-polar one on the yield and the mass transfer phenomena.

2.1. Materials

The microalga used in

this study was Spirulina sp. obtained from Nogotirto Algae Park Sleman,

Yogyakarta, Indonesia. The components of this biomass were identified by the

proximate analysis, as shown in Table 1. Before the extraction, the microalga

was sifted to 0.06 mm to enlarge the contact area so that the cell walls would be

broken during the extraction process by ultrasonic waves (Liu et al., 2022; Lavilla and Bendicho, 2017).

The solvents used

were n-hexane technical grade, Merck, and isopropyl alcohol 99.5%,

Merck. The technical grade n-hexane solvent was used because it cost less than

the pro-analytic grade and is enough to extract the lipid. While isopropyl

alcohol 99.5% was used because the trans-esterification reaction was expected

to happen.

2.2. Methods

This extraction

method used an ultrasound device that contained a

generator, transducer, stirrer, and ultrasonic probe. The ultrasonic probe and

generator generated the ultrasonic waves at 100 Watt. Cavitation bubbles were

released using a transducer, producing high shear stress to break cells (solid

phase). The sample was placed in an ultrasound device for 15, 30, 45, and 60

minutes at a frequency of 25 kHz and a stirring speed of 150 rpm. The solvents

used were mixed isopropyl alcohol and n-hexane with ratios of 1:3, 2:3,

1:1, 3:2, and 3:1.

After the extraction process, the separation

process was needed to separate the solid and liquid phases through vacuum

filtration. After the filtration, the oil and solvent had to be separated. The

separation process used a distillation apparatus at 800C. The oil condensed

while the solvent evaporated. The algal oil was weighed until it got a constant

weight. After the weighing, the oil sample was analyzed using GC-MS to identify

the type of fatty acid. The scheme of the extraction process is illustrated in

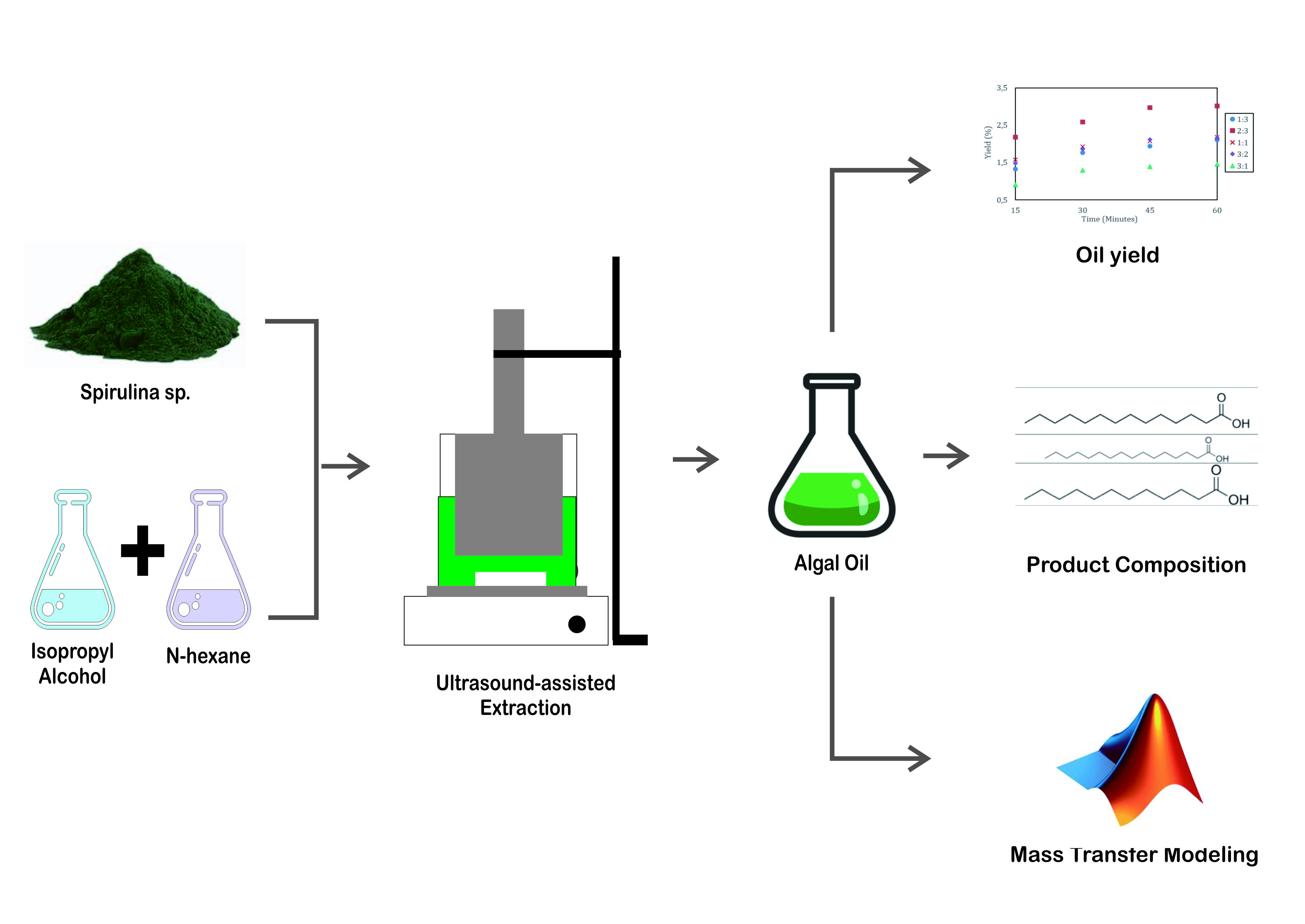

Figure 1.

Figure 1 Extraction Process

The oil concentration from the extraction

process was calculated using Equation (1).

Here, Cf was the concentration of

extract in a liquid phase (g/mL), m was the mass of extract (g), and V was the

volume of liquid (mL).

3.1. Oil Yield

In this study, oil

yield refers to the essential indicator to evaluate extraction efficiency. The

oil extracted from microalgae was processed into biodiesel as a renewable

energy resource. There are two groups of solvents: polar and non-polar (Saini et al., 2021). The former included methanol, ethanol, and

isopropyl alcohol, while the latter included chloroform and n-hexane. The

solvents used in this study were chosen based on polarity (high polarity was

polar solvent, and the low polarity was non-polar solvent), boiling point

temperature to reduce energy consumption during the separation process, and

toxicity to ensure the solvent was safe (González-Fernández et al., 2020). Their properties are shown in Table 1.

Although all the solvents had suitable polarity index and boiling point

temperature, which should be below the boiling point of algal oil (about 180 0C

when using the boiling point of petroleum diesel), safety must be under

consideration.

LC50

referred to toxicity. The lower number of LC50, the more toxic the

substance. LC50 of isopropyl alcohol is extremely higher than

methanol because methanol is toxic and can form high vapor concentrations at

room temperature, which can be easily absorbed through respiration during

exposure (Moon, 2017). It is essential to choose a safer solvent to

minimize the hazard in the process and environment. Moreover, methanol causes

high environmental pollution in the transesterification process based on a life

cycle assessment study (Wahyono et

al., 2022). So, isopropyl

alcohol was chosen as the polar solvent (polarity index was 3.92) and n-hexane

as the non-polar solvent (polarity index was 0.1), although LC50

does not correlate with mass transfer phenomena.

The oil yield was calculated by Equation (2).

The mass of lipids, protein, and carbohydrates in microalgae was calculated

using the proximate analysis data shown in Table 2.

Table 1 Properties of Solvent

|

Solvent |

Polarity Index |

Boiling point |

LC50 (inhalation, rat) |

|

methanol |

5.1 |

64.7 0C |

128.2 ppm, 4 hours |

|

isopropyl alcohol |

3.92 |

82 0C |

>10,000 ppm, 6 hours |

|

chloroform |

2.7 |

61 0C |

125 ppm, 4 hours |

|

n-hexane |

0.1 |

68.7 0C |

48,000 ppm, 4 hours |

Table 2 The

results of proximate analysis of Spirulina powder

|

Component |

Content (%) |

|

Water |

11.25 |

|

Ash |

6.63 |

|

Lipid |

0.81 |

|

Protein |

48.32 |

|

Carbohydrate |

32.99 |

The extraction using

a single solvent was examined in this experiment, shown in Figure 2. Isopropyl

alcohol with a polarity index of 3.92 was used as a polar solvent, while n-hexane

with a polarity index of 0.1 was taken as the non-polar one. The yield of the

polar lipid solvent was higher than that of the non-polar one because the polar

lipids contained in the microalga were more than 50 percent of the total lipids

(Arif et al., 2019; Breuer et

al., 2013). Besides, other

polar cellular components, such as protein, pigments, and carbohydrates (Irawati et al., 2020; Agustini et al.,

2015), were also present

in this extraction product. The yield at 60 minutes of extraction time reached

1.31% using isopropyl alcohol and 0.72% using n-hexane. The yield of

n-hexane solvent was not saturated at the long extraction time, indicating the

mass transfer rate using n-hexane was relatively slow.

The effect of the

mixed solvent on the oil yielded is illustrated in Figure 3, indicating that

the ratio of the polar solvent to the non-polar one affects the yield. The

lowest yield was at the ratio of 3:1, showing that the extraction process needs

a non-polar solvent more than a polar solvent. This finding was in contrast to

the extraction yield using a single solvent. The non-polar solvent, if being

too much, can lower the yield. The ratio of the solvents, therefore, should be

optimized. Based on the experiment, the highest yield was 3.01% when the extraction

ran under the ratio of 2:3.

In an extraction

using mixed solvents (in this case, isopropyl alcohol and n-hexane), both are

added simultaneously to the microalgae biomass to extract both polar and

non-polar lipids. Besides, the aqueous phase contains non-lipid components,

such as proteins and carbohydrates (Wang et al., 2021; Halim, Danquah, and Webley, 2012).

The comparison using a single solvent and a

mixed solvent is shown in Table 3. The highest yield from a single solvent was

achieved by using isopropyl alcohol at 60 minutes of extraction (1.31%), while

the lowest yield using mixed solvent at the same extraction time was 1.46%. It

was indicated that using mixed solvent gave a higher yield.

Figure 2 Algal Oil Yield by Single Solvent Extraction

Figure 3 Algal Oil Yield by Solvent Mixture Extraction

Table 3 The Comparison of Yield Using Single Solvent and

Mixed Solvent

|

Yield at 60 minutes of extraction |

Single solvent |

Mixed solvent |

|

Maximum yield |

1.31 |

3.01 |

|

Minimum yield |

0.72 |

1.46 |

The ratio of microalgae mass to solvent

volume at the 3:2 polar to non-polar solvent ratio is illustrated in Figure 4.

Three solid-to-solvent ratios were investigated namely 1:1, 2:3, and 3:10

biomass-to-solvent ratios. The highest yield was 2.18%, achieved by the 3:10

biomass-to-solvent ratio, while the lowest yield was obtained by an extraction

process using the 1:1 biomass-to-solvent ratio.

Figure 4 Algal Oil Yield in Various Biomass to Solvent Ratios

3.2. Product Composition

Algal oils produced

by various isopropyl alcohol to n-hexane ratios were analyzed based on

the % area of the peak in the GC-MS analysis results, as shown in Figure 5. The

algal oils had three groups of components: fatty acids, hydrocarbons, and

alcohol. The classification was based on the name of the compound and its

molecular formula.

Overall, the

hydrocarbon composition was relatively constant except in the 3:1 isopropyl

alcohol to n-hexane ratio. It declined from above 50% to 42.10%.

Meanwhile, the highest alcohol peak area was found in the extracted oil with

the 3:1 isopropyl alcohol to n-hexane ratio.

The highest %peak

area of fatty acid and its derivative products was found at the 3:1 isopropyl

alcohol to n-hexane ratio, while the lowest was at the 1:3 ratio. These

findings indicated that Spirulina sp. has polar lipids more than

non-polar lipids because polar lipids pull the polar substances.

Figure 5 The Composition of Algae Oil

The fatty acid compositions are shown in Table

4. In this study, the compositions of fatty acid (FA) and fatty acid methyl

ester (FAME) in algal oil were palmitic acid, linoleic acid, methyl palmitate,

and methyl linoleate.

Table 4 The Compositions of FA and FAME in Algae Oil

|

Solvent (isopropyl alcohol to n-hexane) ratio |

FA |

FAME | ||

|

Palmitic Acid |

Linoleic Acid |

Methyl Palmitate |

Methyl Linoleate | |

|

1:3 |

11.99 |

8.61 |

2.78 |

1.17 |

|

2:3 |

8.17 |

19.53 |

3.58 |

4.65 |

|

1:1 |

7.72 |

18.79 |

2.03 |

5.86 |

|

3:2 |

6.17 |

19.15 |

2.78 |

5.12 |

|

3:1 |

5.81 |

26.87 |

6.30 |

5.69 |

The FAME yielded from the fatty acid, as

illustrated in Figure 6, reached the highest amount when using the 3:1

isopropyl alcohol to n-hexane ratio, with the highest amount of alcohol

solvent. This phenomenon indicated that the trans-esterification reaction that

reacted isopropyl alcohol and fatty acid (FA) into fatty acid methyl ester

(FAME) occurred in this extraction process.

Figure 6 FAME Yield to FA in Algal Oil

3.3. Mass Transfer Modeling

Algal oil extraction is a mass transfer

phenomenon from the solid (microalga cells) to the liquid (solvent). Such a

phenomenon can be modeled by Equation 3, and the equilibrium equation can be

approached by Henry’s law as in Equation 4 as follows:

In the solid phase, the mass

transfer can be arranged from Equation 5 to Equation 8 with the assumption that

microalga’s shape was round and the operation condition was isothermal.

Equations 3, 4, and 8 are

simultaneous differential equations that have boundary conditions, as in Equations

9, 10, and 11.

Here, kca

is volumetric mass transfer coefficient (min-1), Cf is

the concentration of lipid in a liquid phase (g/ml), Cf* is the

saturated concentration of lipid in a liquid phase (g/ml), CA is

lipid concentration in the solid phase (g/ml), H is Henry constant, r is the

radius of microalgae particles (cm), De is effective diffusivity (cm2/min).

MATLAB processed these simultaneous differential equations to get kca, De, and H constants, as shown in Table 5.

Table 5 Constants of kca, De, and H

in various solvent ratios

|

Solvent (isopropyl alcohol to n-hexane) ratio |

kca (min-1) |

De (cm2/min) |

H |

|

1:3 |

1.31×10-3 |

1.11×10-7 |

8.57 |

|

2:3 |

1.48×10-4 |

9.39×10-7 |

12.61 |

|

1:1 |

1.64×10-4 |

5.61×10-6 |

8.83 |

|

3:2 |

1.52×10-4 |

6.10×10-7 |

8.87 |

|

3:1 |

4.80×10-5 |

2.00×10-9 |

10.04 |

The highest mass transfer coefficient, Henry’s

constant, and effective diffusivity were reached when the algal oil was

extracted at the 1:3, 2:3, and 1:1 isopropyl alcohol to n-hexane ratios,

respectively. All the data obtained concluded that De and H, besides

kca, are factors in the oil yield. The lowest oil yield was obtained

by 3:1 isopropyl alcohol to n-hexane solvent ratio, which had the lowest number

of kca (4.80×10-5 min-1) and De

(2.00×10-9), while Henry's constant was the second highest (10.04).

At this solvent ratio, the GC-MS' peak area of the fatty acid result was the

highest. It indicates that other solvent ratios extracted more other compounds

than lipids.

The yield of mixed

solvent was higher than single solvent. When using a single solvent, polar

solvent achieved a higher yield than non-polar solvent. The ratio of solvents

in algal oil extraction affects the oil and substances yielded. In this study,

the highest oil yield, namely 3.01%, was obtained at the 2:3 isopropyl alcohol

to n-hexane ratio. The products yielded were not only affected by the mass

transfer coefficient but also by the effective diffusivity coefficient and

Henry's constant. Based on the extraction process yields analysis, the large

amount of the polar solvent indicated that polar lipids dominated the fatty

acid in the algal oil and were converted to biodiesel under a

trans-esterification reaction through the ultrasound-assisted extraction

process. This statement was confirmed by the high amount of fatty acid methyl

ester yielded using the highest volume of alcohol.

Adam, F., Abert-Vian, M., Peltier, G., Chemat, F., 2012. ‘Solvent-Free’

Ultrasound-Assisted extraction of Lipids from Fresh Microalgae Cells: A Green,

Clean and Scalable Process. Bioresource Technology, Volume 114, pp.

457–465

Agustini, T.W., Suzery, M., Sutrisnanto, D., Ma’ruf, W.F.,

Hadiyanto, 2015. Comparative Study of Bioactive Substances Extracted from Fresh

and Dried Spirulina sp. Procedia Environmental Sciences, Volume 23, pp.

282–289

Arif, M., Bai, Y., Usman, M., Jalalah, M., Harraz, F.A., Al-Assiri, M.S.,

Li, X., Salama, E.-S., Zhang, C., 2020. Highest Accumulated Microalgal Lipids (Polar and Non-polar) for

Biodiesel Production with Advanced Wastewater treatment: Role of Lipidomics. Bioresource

Technology, Volume 298, p. 122299

Asikainen, M., Munter, T., Linnekoski, J., 2015. Conversion

of polar and non-polar algae oil lipids to fatty acid methyl esters with solid

acid catalysts – A model compound study. Bioresource Technology, Volume 191,

pp. 300–305

Atadashi, I.M., Aroua, M.K., Abdul Aziz, A.R., Sulaiman, N.M.N., 2012.

Production of Biodiesel Using High Free Fatty Acid Feedstocks. Renewable and

Sustainable Energy Reviews, Volume 16(5), pp. 3275–3285

Balan, V., 2014. Current Challenges in Commercially

Producing Biofuels from Lignocellulosic Biomass. ISRN Biotechnology,

Volume 2014, pp. 1–31

Breuer,

G., Evers, W.A.C., de Vree, J.H., Kleinegris, D.M.M., Martens, D.E., Wijffels,

R.H., Lamers, P.P., 2013. Analysis of Fatty Acid Content and Composition in

Microalgae. Journal of Visualized Experiments, Volume 80

Casal, S., Oliveira, B., 2007. Fatty Acids Analysis by Gas

Chromatography (GC). Encyclopedia of Chromatography, Second Edition, J.

Cazes, Taylor & Francis, pp. 1-15

Chisti, Y., 2008. Biodiesel from Microalgae Beats Bioethanol. Trends

in Biotechnology, Volume 26(3), pp. 126–131

Clarens, A.F., Resurreccion, E.P., White, M.A., Colosi, L.M., 2010.

Environmental Life Cycle Comparison of Algae to Other Bioenergy Feedstocks. Environmental

Science & Technology, Volume 44(5), pp. 1813–1819

Clemens, S., Aarts, M.G.M., Thomine, S., Verbruggen, N., 2013. Plant

Science: The Key to Preventing Slow Cadmium Poisoning. Trends in Plant

Science, Volume 18(2), pp. 92–99

D’Alessandro, E.B., Antoniosi-Filho, N.R., 2016. Concepts and Studies on

Lipid and Pigments of Microalgae: A Review. Renewable and Sustainable Energy

Reviews, Volume 58, pp. 832–841

da-Silva, C., Vieitez, I., Jachmanin, I., De, F., Cardozo, L.,

de-Oliveir, J.V., 2012. Non-Catalytic Production of Ethyl Esters Using

Supercritical Ethanol in Continuous Mode. Biodiesel - Feedstocks,

Production, and Applications, pp. 251–280

Daneshvar, E., Zarrinmehr, M.J., Hashtjin, A.M., Farhadian,

O., Bhatnagar, A., 2018. Versatile Applications of Freshwater and Marine Water

Microalgae in Dairy Wastewater Treatment, Lipid Extraction and Tetracycline

Biosorption. Bioresource Technology, Volume 268, pp. 523–530

Dewati, P.R., Rochmadi, Rohman, A., Budiman, A., 2022. Degradation Rate

of Astaxanthin from Haematococcus pluvialis. Food Research, Volume

6(4), pp. 254–258

González-Fernández, M.J., Manzano-Agugliaro, F.,

Zapata-Sierra, A., Belarbi, E.H., Guil-Guerrero, J.L., 2020. Green Argan Oil

Extraction from Roasted and Unroasted Seeds by Using Various Polarity Solvents

Allowed by The EU Legislation. Journal of Cleaner Production, Volume

276, p. 123081

Guo, S., Yang, Z., Gao, Y., 2016. Effect of Adding Biodiesel

to Diesel on the Physical and Chemical Properties and Engine Performance of

Fuel Blends. Journal of Biobased Materials and Bioenergy, Volume 10(1), pp.

34–43

Halim, R., Danquah, M.K., Webley, P.A., 2012. Extraction of Oil from

Microalgae for Biodiesel Production: A Review. Biotechnology Advances,

Volume 30(3), pp. 709–732

Irawati,

D., Abdillah, A.A., Pramono, H., Sulmartiwi, L., 2020. The Effect of Using

Different Polar Solvents on the Stability of Thermal Extraction Phycocyanin

From Spirulina Platensis. IOP Conference Series: Earth and Environmental

Science, Volume 441(1), p. 012050

Haque,

S.M., Bhat, A.H., Khan, I., 2015. Biomass: An Ageless Raw Material for

Biofuels. Agricultural Biomass Based Potential Materials. Springer

International Publishing, pp. 435–454

Jamilatun, S., Budhijanto, Rochmadi, Yuliestyan, A.,

Aziz, M., Hayashi, J., Budiman, A., 2020. Catalytic Pyrolysis of Spirulina Platensis

Residue (SPR): Thermochemical Behavior and Kinetics. International Journal

of Technology, Volume 11(3), pp. 522–531

Kang, K.H., Ryu, B.M., Kim, S.K., Qian, Z.J., 2011. Characterization of

Growth and Protein Contents from Microalgae Navicula incerta with the

Investigation of Antioxidant Activity of Enzymatic Hydrolysates. Food

Science and Biotechnology, Volume 20(1), pp. 183–191

Lavilla, I., Bendicho, C., 2017. Fundamentals of Ultrasound-Assisted

Extraction. Water Extraction of Bioactive Compounds: From Plants to Drug

Development, Elsevier, pp. 291–316

Liu, Y., Liu, X., Cui, Y., Yuan, W., 2022. Ultrasound for Microalgal Cell Disruption and Product Extraction:

A review. Ultrasonics Sonochemistry,Volume 87, p. 106054

Mohr, A., Raman, S., 2013. Lessons from First Generation Biofuels and

Implications for the Sustainability Appraisal of Second Generation Biofuels. Energy

Policy, Volume 63, pp. 114–122

Moon, C.S., 2017. Estimations of the Lethal and

Exposure Doses for Representative Methanol Symptoms in Humans. Annals of

Occupational and Environmental Medicine, Volume 29(1), pp. 1–6

Pradana, Y.S., Dewi, R.N., Livia, K.D., Arisa, F.,

Rochmadi, Cahyono, R.B., Budiman, A., 2020. Advancing Biodiesel Production from

Microalgae Spirulina sp. by a Simultaneous Extraction–transesterification

Process using Palm Oil as a Co-solvent of Methanol. Open Chemistry, Volume

18(1), pp. 833–842

Rilisa, C., Suantika, G., 2021. Biological, Technical,

and Financial Feasibilities Study of Spirulina sp. Biomass Production with

Modified Commercial Medium in Indonesia. 3BIO: Journal of Biological

Science, Technology and Management, Volume 3(2), pp. 12–21

Saini,

R.K., Prasad, P., Shang, X., Keum, Y.-S., 2021. Advances in Lipid Extraction

Methods—A Review. International Journal of Molecular Sciences, Volume

22(24), p. 13643

Sardi, B., Ningrum, R.F., Ardiansyah, V.A., Qadariyah,

L., Mahfud, M., 2022. Production of Liquid Biofuels from Microalgae Chlorella

sp. via Catalytic Slow Pyrolysis. International Journal of Technology,

Volume 13(1), pp. 147–156

Sela, K., Budhijanto, W.,

Budiman, A,, 2021. Protein Extraction from Spirulina platensis by Using

Ultrasound Assisted Extraction: Effect of Solvent Types and Extraction Time. Key

Engineering Materials, Volume 872, pp. 33–37

Setyawan, M., Budiman, A., Mulyono, P., Sutijan, 2018.

Optimum Extraction of Algae-oil from Microalgae using Hydrodynamic Cavitation. International

Journal of Renewable Energy Research, Volume 8(1), pp. 451–458

Shahi, T., Zenouzi, A., Beheshti, B., Almasi, M., 2020. Comparison of

Four Lipid Extraction Methods from Microalgae Dunaliella sp. for Biodiesel

Production. Iranian Journal of Chemistry and Chemical Engineering,

Volume 39(4), pp. 371–378

Sharma, K.K., Schuhmann, H., Schenk, P.M., 2012. High Lipid

Induction in Microalgae for Biodiesel Production. Energies, Volume 5(5),

pp. 1532–1553

Suganya, T., Kasirajan, R., Renganathan, S.,

2014. Ultrasound-enhanced Rapid in Situ Transesterification of Marine

Macroalgae Enteromorpha Compressa for Biodiesel Production. Bioresource

Technology, Volume 156, pp. 283–290

Vilkhu, K., Mawson, R., Simons, L., Bates, D., 2008. Applications and

Opportunities for Ultrasound Assisted Extraction in the Food Industry - A

Review. Innovative Food Science and Emerging Technologies, Volume 9(2),

pp. 161–169

Wahyono, Y., Hadiyanto, Budihardjo, M.A., Hariyono, Y.,

Baihaqi, R.A., 2022. Multifeedstock Biodiesel Production from a Blend of Five

Oils through Transesterification with Variation of Moles Ratio of Oil:

Methanol. International Journal of Technology, Volume 13(3), pp. 606–618

Wang,

J., Yu, Z., Yin, F., Li, D., Liu, H., Song, L., Zhou, D., 2021. Comparison of Different

Solvents for Extraction of Oils from By?Products of Shrimps Penaeus Vannamei

and Procambarus Clarkia. Journal of Food Processing and Preservation,

Volume 45(9), pp. 1-9

Wang, M., Yuan, W., Jiang, X., Jing, Y., Wang, Z., 2014. Disruption of

Microalgal Cells Using High-frequency Focused Ultrasound. Bioresource

Technology, Volume 153, pp. 315–321

Wiyarno, B., Mohd-Yunus, R., Mel, M., 2014. A Study on The Ultrasonic

Oil Extraction and Insitu Transesterification of Microalgae Biodiesel. CHEMICA:

Jurnal Teknik Kimia, Volume 1(2), p. 41

Wong, Y.C., Shahirah, R., 2019. Effect of Different Solvent and Ratio

Towards Microalgae Oil Production by Ultrasonic Assisted Soxhlet Extraction

Techniques. Oriental Journal of Chemistry, Volume 35(4), pp. 1377–1383