Industry 4.0 Adoption in Supply Chain Operations: A Systematic Literature Review

Published at : 17 May 2024

Volume : IJtech

Vol 15, No 3 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i3.5958

Asrol, M., 2024. Industry 4.0 Adoption in Supply Chain Operations: A Systematic Literature Review. International Journal of Technology. Volume 15(3), pp. 544-560

| Muhammad Asrol | Industrial Engineering Department, BINUS Graduate Program – Master of Industrial Engineering, Bina Nusantara University, Jakarta, Indonesia, 11480 |

Industry 4.0 adoption in industry and business has grown extensively.

Supply chain had an opportunity to adopt Industry 4.0 in improving flexibility,

efficiency, and response to consumer demands. Considering Industry 4.0,

adoption in supply chain operations must be realized as an opportunity and

challenge for practitioners. Hence, this study conducted a systematic

literature review with a qualitative and quantitative approach to formulate

supply chain 4.0 dimensions and operations in assessing readiness for adopting

industry 4.0. A Preferred Reporting Item for Systematic Review and Meta-analyses

(PRISMA) and bibliometric analysis are performed to analyze the literature

related to industry 4.0 adoption in supply chain operations. This research

combined a qualitative and quantitative analysis in reviewing the literature to

deliver a broader benefit of Industry 4.0 in supply chain operations. This

study found 525 papers related to Industry 4.0. Moreover, only twenty papers

discussed supply chain specifically. Literature analysis using quantitative and

qualitative approach showed that industry 4.0 adoption in the supply chain is

limited to the maturity model with digital transformation. This study proposed

five comprehensive dimensions to capturing supply chain operations: technology

and information technology (IT) infrastructure, supply chain integration and

coordination, manufacturing operations and inventory, leadership and human

resources, and sustainability. The proposed dimensions for supply chain

operations are based on a conceptual analysis of literature. Further

verification and empirical analysis is needed to gain deeper insights. While

digital technology and transformation are the main focus of Industry 4.0

adoption in many sectors, supply chain management requires broader applications

as it involves various sectors and stakeholders. To further analyze this, a

readiness and maturity model needs to be developed to assess the adoption of

Industry 4.0 in the supply chain, taking into consideration the proposed

dimensions.

Industry 4.0; Maturity; Readiness; Supply chain; Systematic literature review

Supply chain management was first considered during the second world war to achieve an efficient operation. Ballou (2007) has defined the concept of Supply Chain Management (SCM) as coordinating stakeholder across product flow to achieve goals. Definitely, SCM organized 3 main flows, including product/material, cost, and information, with primary and secondary stakeholders (Asrol, Yani, and Taira, 2021). The supply chain goals are generally defined as two main focuses, fulfilling consumer demand and achieving maximum profit (Chopra and Meindl, 2013). Moreover, supply chain management and operations face a huge challenge to achieve an efficient and effective process to fulfil consumer demand.

During the

advancement of technology and information system, supply chain management is

improved. Since the concept of Industry 4.0 was first introduced in 2013 (Kagermann, Wahlster, and Helbig, 2013), supply

chain management with the advancement of technology and digital transformation

must be considered in the industry (Wagire et

al., 2021). As we know, Industry 4.0 is the new industrial

revolution into a digital and smart factory system that provides an opportunity

to adopt business intelligence and digital transformation in the business model

operation (Lasi et al., 2014). (Schumacher, Erol, and Sihn, 2016) put a strong

line of industry 4.0 as the integration of manufacturing systems among vertical

and horizontal stakeholders through digital transformation in the entire value

chain. Regarding these definitions, a supply chain as the integration of

stakeholders in the industrial production system must be prepared to adopt the

industry 4.0 revolutions to achieve benefits in winning competitive advantages.

The implementation

of Industry 4.0 offers exciting potential for the industry’s transformation.

Moreover, some considerations must be realized. One of the Industry 4.0

opportunity is to build a sustainable business model that is organized by

value, supply chain, customer relationship, efficiency, productivity, and

financial model (Dudukalov et al., 2021; De-Man

and Strandhagen, 2017). Scholars have provided the concept and practical

applications of Industry 4.0, e.g., blockchain and IoT for sustainable supply

chain (Esmaeilian et al., 2020; Alladi et

al., 2019), digital SCM to managing risk and disruption (Ivanov and Dolgui, 2020). Further, the supply

chain considerations in Industry 4.0 adoption need attention to support

business transformation and sustainability (Zhang et

al., 2021; Manavalan and Jayakrishna, 2019). a comprehensive

literature review is required to understand the effects of Industry 4.0 on the

supply chain regarding preparing to industry’s supply chain to adopt the

technology since practitioners lose of the initial stage to apply the concept

and technology (Shao et al., 2021; Kenge et

al., 2020). In this context,

a readiness level assessment is required to identify the current industry’s

performance in achieving supply chain 4.0 adoption.

Research on the readiness and maturity level

of Industry 4.0 in the supply chain has been conducted by several scholars. Caiado et al. (2021) and Monshizadeh et al. (2023) developed a fuzzy

system to assess readiness, while Lassnig et al.

(2021) proposed a SCOR-based readiness with a Likert-scale to evaluate

Industry 4.0 adoption. Azevedo and Santiago (2019) provided

a qualitative and quantitative assessment of Industry 4.0 adoption in

Manufacturing. Most of the research found that it is applied in small and

medium enterprises for manufacturing system assessment. The dimensions and

attributes to assess the readiness were limited to manufacturing operations and

avoiding the SCM perspective. Previous research has provided models with

various dimensions to assess the readiness level for Industry 4.0. Schumacher, Erol, and Sihn (2016) designed nine

dimensions to assess industry maturity and achieve Industry 4.0 adoptions

through surveys in related industries. Rajnai and

Kocsis (2018) proposed technology, culture, organization, and culture as

dimensions to assess Industry 4.0 readiness level. Machado

et al. (2019) evaluated the digital readiness and capability of

the industry with self-check tools to investigate the industry's maturity

level. Hizam-hanafiah, Soomro,

and Abdullah, (2020) proposed six

dimensions, including technology, people, strategy, Leadership, process, and

innovation, with technology being the most important dimension to assess

Industry 4.0 readiness

Various dimensions

and models to assess industry 4.0 readiness. Moreover, we found a lack of

applications to adopt for supply chain readiness (Lassnig

et al., 2021). Most of the dimensions adopted in the model focus

on the effect of digital technology and transformation, while the other supply

chain perspectives lack attention. In this case, it is required to define

dimensions to assess the current readiness level. Even though some literature

has provided dimensions and indicators for industry 4.0 adoption, as far as the

author's knowledge, there is scarce literature to define the supply chain

implementation, and it only focuses on digital technology and transformation.

Therefore, this research provides a systematic literature review (SLR) with a

combination of a qualitative and quantitative approach to formulate the supply

chain dimensions in adopting industry 4.0 implementation. This approach is

proposed to reduce the systematically biased result (Tangpong,

2011) and authors' subjective decision and lead to a valid research

mapping and gaps also further research recommendations.

The objective of

the research is to conduct a systematic literature review (SLR) with a

quantitative and qualitative approach to formulate the supply chain 4.0 concept

and readiness dimensions in adopting industry 4.0. Future research is also

provided to draw potential fields to be explored to fill the gap in the future.

The original contribution of the paper is to provide common dimensions applied

in industry 4.0 for supply chain implementation and propose a new comprehensive

dimension for supply chain 4.0 readiness.

This paper is

organized as follows: in section 2, the step-by-step systematic literature

review model is explored. Section 3, result and discussion, delivers a

systematic literature review analysis and provide future research discussion

and implementation. Finally, section 4 concludes the paper with contributions,

limitations, and recommendations for further research.

2.1. Research stages

Figure 1 Research framework

2.2. Data sources

Figure 2 Year of publication distribution of related literature

2.3. Data analysis and performed further research agenda

In the first stage,

literature is collected from Scopus and another database. For the Scopus

database, we apply two keywords: ‘industry 4.0 readiness’ and ‘industry 4.0

maturity’. Terms of maturity and readiness are found as the most keywords to

describe any industry 4.0 adoption in Industry (Frederico

et al., 2020). After moving some duplicate literature, we found

654 kinds of literature. We apply the screening and eligibility process by

removing articles from the conference homepage and excluding 113 irrelevant

articles.

We have 525 kinds of literature for

further statistical descriptive analysis to see the article types, sources and

publishers, and year of publication distribution. A quantitative with

bibliometric analysis is also applied using VOSviewer tools to find the

research gap and propose the supply chain 4.0 adoption in the industry. A

tabular list of relevant literature is provided to find supply chain dimensions

to apply in the industry. Finally, we synthesize the further research agenda in

implementing supply chain 4.0 in the industry. The further research agenda is

formulated based on the keywords networks and literature relations described by

Vosviewer, qualitative analysis of the previous research in industry 4.0 and

supply chain adoption, and proposed dimensions to assess supply chain 4.0

readiness. Further research agenda is focused on how to apply the dimensions

and research gap found in qualitative and quantitative analysis of previous

research.

3.1. Statistical descriptive of the relevant

literature

Figure 3 Publisher with ten papers and more with topic industry 4.0

Figure 4 Reviewed articles type distribution

Previous research has extensively described that industry

4.0 adoption is an opportunity to improve industrial operations and efficiency.

Moreover, most of the applications of Industry 4.0 operations are only focused

on the operations at the firms. As stated by (Frederico

et al., 2020) that there is a limited application of Industry 4.0

in the supply chain. Considering the definition of the supply chain by (Chopra and Meindl, 2013) and (Ballou, 2007),

supply chain management organizes many activities, internal and external, of

the firms which aim to improve efficiency and effectiveness, produce a

high-quality product and the lowest cost, and maximize profit, it is confirmed

that this subject is noteworthy to involve in industry 4.0 adoption. According

to Tripathi and Gupta (2021) and Dallasega,

Rauch, and Linder (2018), considering the supply chain in Industry 4.0

adoption can enhance business activities and transform the entire process from

manufacturing to distribution and sales.

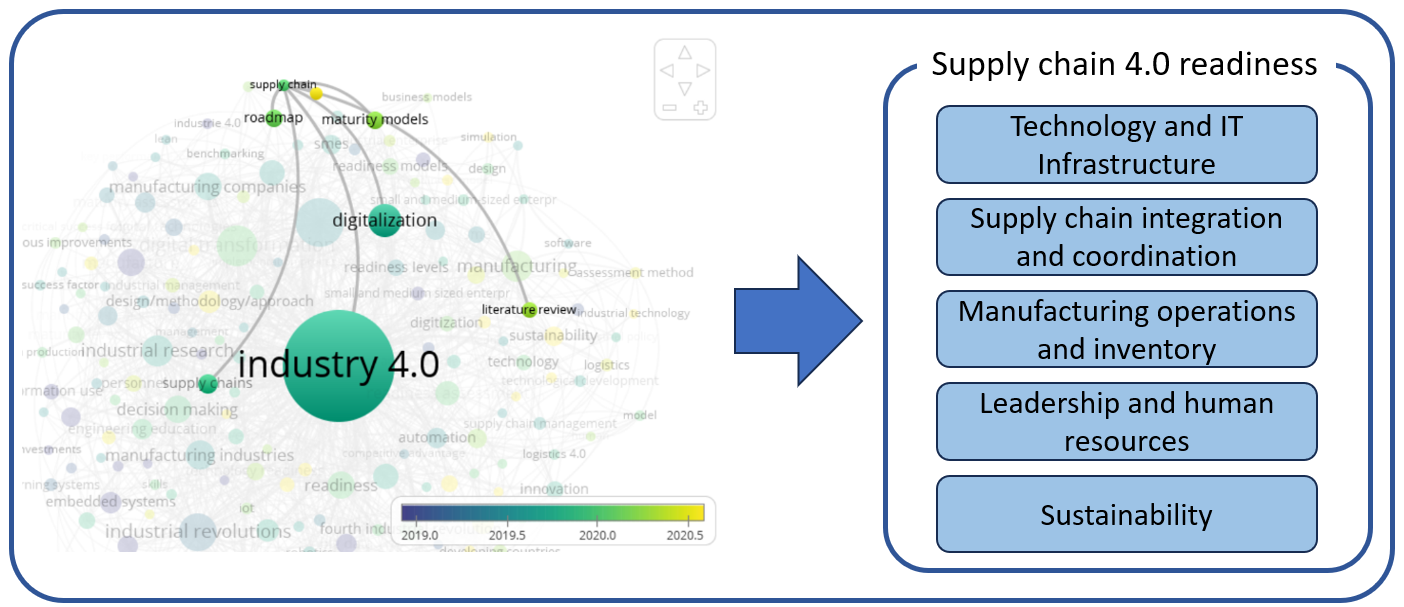

A bibliometric analysis using VOSviewer was applied to

analyze the relevant literature quantitatively. Using a keyword network

analysis, we found that there are five clusters of keywords linked to each

other to Industry 4.0, as shown in Figure 5. A full counting method is applied

in this analysis to see the full links and contribution of the authors to the

keywords and article (Perianes-Rodriguez, Waltman,

and Van-Eck, 2016). We found that the relations between Industry 4.0 and

supply chain terms are scarce. It is also confirmed that the application of

Industry 4.0 in the supply chain is limited in the current literature and has

not been largely discussed. Our result also confirmed that the Industry 4.0

adoption in supply chain operation was mostly published after 2020, as

described in Figure 6.

Figure 6 The relations of Industry

4.0 and supply chain in literature

3.2. Reporting findings of

SLR on supply chain 4.0

The terms of Industry 4.0 has been largely

discussed in developing a system and business process. Industry 4.0 aims to

connect the system between a real and virtual factory with the cyber-physical

system and the Internet of Things to achieve efficient production. In terms of

the objective of the concept, research related to Industry 4.0 has been largely

found in the literature. Most of the research discusses the conceptual model,

maturity, and readiness level of the business in adopting Industry 4.0.

The Industry 4.0 also influences to the upstream and downstream of the

value chains (Asdecker and Felch, 2018),

offering a quick response to consumer demand (Manavalan

and Jayakrishna, 2019) and improving the supply chain flexibility and

transportation (Tjahjono et al., 2017).

In the context of carrying out the benefit of Industry 4.0, therefore the

supply chain operations must be considered in further Industry 4.0

applications. Moreover, the previous analysis clearly found that there is a

limited discussion about the supply chain in industry 4.0 adoption. Literature

extracted from the database shows that only a few papers contribute to supply

chain 4.0, as shown in Table 1.

Table 1 Literature contribution to supply chain 4.0

|

No |

Author

|

Main contribution |

Type |

|

1 |

(Tjahjono et al., 2017) |

Industry 4.0 increased

flexibility, quality standards, efficiency, and productivity. It was found

that not all parts of Industry 4.0 affect supply chain operations. |

Conference

proceeding |

|

2 |

(Asdecker and Felch, 2018) |

Formulate maturity model

for delivery process in the supply chain using supply chain operation

reference model. Maturity model is designed by the company’s production

strategy |

Journal Article |

|

3 |

(Dallasega, Rauch, and Linder, 2018) |

A review paper found that

Industry 4.0 improve productivity and enhances product development to

distribution processes of the supply chain |

Journal Article |

|

4 |

(Methavitakul and Santiteerakul, 2018) |

Developing dimensions and

sub-dimensions of Industry 4.0 performance assessment |

Conference

Proceedings |

|

5 |

(Krykavskyy, Pokhylchenko, and Hayvanovych, 2019) |

Identifying main drivers

in supply chain 4.0 and highlighting digital technology as the main driver. |

Journal Article |

|

6 |

(Machado et al., 2019) |

Provided a case study of

seven companies to assess the current industry 4.0 maturity level |

Conference

proceeding |

|

7 |

(Frederico et al., 2020) |

A review paper to

formulate a framework in the supply chain 4.0 maturity model with a limited

number of papers. |

Journal Article |

|

8 |

(Van Hoek et al., 2020) |

Find the opportunity to

adopt industry 4.0, human interaction in technology adoption, and

sustainability combination in supply chain 4.0. |

Journal Article |

|

9 |

(Hizam-hanafiah, Soomro, and Abdullah, 2020) |

A review paper that found

technology as the most important dimension in supply chain 4.0 adoption |

Journal article |

|

10 |

(Hajoary, 2020) |

Formulate ten dimensions

for Industry 4.0 readiness and maturity assessment |

Journal article |

|

11 |

(Agca et al., 2020) |

Formulate industry 4.0 and

supply chain 4.0 dimensions for maturity assessment |

Book |

|

12 |

(Hellweg et al., 2021) |

A review paper that

focuses on the digital technology dimension of supply chain 4.0 adoption |

Journal Article |

|

13 |

(Tripathi and Gupta, 2021) |

Interconnectivity is the

core of Industry 4.0 that enables it to be adopted in the supply chain |

Journal Article |

|

14 |

(Dudukalov et al., 2021) |

A statistical research

approach to provide evidence of the effect of digital transformation on the

supply chain |

Conference

Proceedings |

|

15 |

(Lassnig et al., 2021) |

Define the difference

between digital transformation in the supply chain for a small and large

company |

Journal article |

|

16 |

(Shayganmehr et al., 2021) |

Design an assessment

system of trust and coordination for supply chain readiness in industry 4.0

adoption |

Journal article |

|

17 |

(Khan et al., 2021) |

Using a knowledge-based

view approach to assess supply chain digitalization readiness level. |

Journal article |

|

18 |

(Reyes, Mula, and Díaz-Madroñero, 2021) |

Linking the lean supply

chain with Industry 4.0 in supply chain 4.0 implementation |

Journal article |

|

19 |

(Wagire et al., 2021) |

Developing a maturity

model to assess Industry 4.0 |

Journal article |

|

20 |

(Bentaher and Rajaa, 2022) |

Proposed an intelligent

supply chain framework based on a literature review |

Journal article |

Previous

scholars defend the one point that Industry 4.0 contributes to supply chain

operations, despite its lack of definition and applications. (Tjahjono et

al., 2017) And (Dallasega, Rauch, and

Linder, 2018) agreed that Industry 4.0 adoption might improve supply

chain flexibility, productivity, product quality, and distribution. Supply

chain operations have advantages to win competitive advantages and fulfilling

consumer expectations. Besides that, another research also found that the

implementation of Industry 4.0 in a supply chain may improve the

decision-making process and human-machine interaction system (Van Hoek et al., 2020; Manavalan and Jayakrishna,

2019).

Most of the literature provides the industry

4.0 maturity and readiness model assessment with various dimensions and models.

After the extraction process, Table 1 provides a supply chain 4.0 readiness and

maturity assessment with various dimensions. From the listed literature, this

paper draws a conclusion, as far as the author's knowledge, that previous

research was only focused on digital technology and transformation in assessing

supply chain 4.0 adoption. Most scholars (see: (Dudukalov

et al., 2021; Hellweg et al.,

2021; Khan et al., 2021; Lassnig et

al., 2021; Hizam-hanafiah, Soomro, and Abdullah, 2020; Gupta et al., 2020;

Krykavskyy, Pokhylchenko, and Hayvanovych, 2019))

stated that digital technology and transformation as the most important

dimensions in supply chain 4.0 adoption. Moreover, (Tjahjono

et al., 2017) delivered that the industry 4.0 adoption for the

supply chain is possible to support consumer demand fulfilment and

transportation. Focusing on industry 4.0 adoption in the supply chain for

digital technology and transformation is not a wise decision since the supply

chain is not only about the facility but also about the production process,

delivery, coordination, stakeholder, and distribution as defined in (Chopra and Meindl, 2013; Ballou, 2007).

3.3. Formulating supply chain 4.0

dimensions

In assessing supply chain 4.0 readiness considers complex factors, indicators must be defined in a specific manner. These indicators are compromised into groups called dimensions (Rajnai and Kocsis, 2018). To formulate supply chain 4.0 dimensions, literature that discussed industry 4.0 related to supply chain implementation is analyzed. Before, a list of literature that discusses supply chain 4.0 adoption has been delivered. After that, literature that focuses on the supply chain 4.0 maturity and readiness model is extracted. The literature that applied to supply chain 4.0 assessment provides a various number of dimensions as depicted in Figure 4.

Figure 7 Number of dimensions considered for supply chain

4.0 in literature

The number of dimensions in each research is

diverse. Most papers published before 2020 served less than 5 dimensions to

assess industry 4.0 and supply chain 4.0 readiness, while articles published

after 2020 provide 5-10 dimensions, except (Shayganmehr

et al., 2021) that focus on supply chain coordination. We found

that most research that proposed industry 4.0 adoption in supply chain adoption

has delivered dimensions. Moreover, it is limited to digital technology and

transformation.

The supply chain dimensions in industry 4.0

adoption readiness that is mentioned in the literature is limited. Since most

of the literature focus on digital technology and transformation, we proposed

new dimensions to assess supply chain 4.0 readiness to capture supply chain

operation completely. Five dimensions are proposed, Technology and IT

infrastructure, Supply chain integration and coordination, Manufacturing

operations and inventory, Leadership, and human resource and Sustainability.

Before, Hizam-hanafiah, Soomro, and Abdullah,

(2020) also clustered dimensions for industry 4.0 readiness assessment.

This research proposed dimensions for supply chain 4.0 readiness assessment

since it was limited to find in the literature. Table 2 shows the proposed

dimensions to assess supply chain 4.0 readiness. The first column provides

supply chain 4.0 dimensions from previous literature. We cluster dimensions

based on meaning and usage. Column 2 shows the number of dimensions that has

meaning and usage extracted from the literature. Proposed dimensions are

provided in column 3 based and general meaning and its relation to the previous

research dimensions.

Table 2 Proposed supply

chain 4.0 dimensions

|

Dimensions from

existing literature |

Number of

dimensions |

Proposed dimensions |

|

Information and communication technology

(ICT) policies, IT network Infrastructure, Technological structure,

Infrastructure, Technology, Autonomous system, Big data handling, Smart

manufacturing, industry 4.0 base technology, Digitalization of the vertical

and horizontal value chain, Innovative digital technology, Technology and

digitalization, Digital awareness, Cybersecurity, Technology, Learning

machine, End to end IT enabled planning, Digitalization of product equipment,

Technology levers, Technological advancements, Information technology. |

21 |

Technology and IT

infrastructure |

|

Collaboration, Supply chain integration,

Supply chain visibility, Connectivity, Coordination, Digitalization of

vertical and horizontal value chain, Partnership, Flexibility, Lead times,

Supply chain flow, Customers, Services, Supplier enabled, Supply chain

performance, Agility, Supply chain planning. |

16 |

Supply chain

integration and coordination |

|

Product and service-oriented, Real-time

monitoring and control, Value chain and processes, Business, Process and

method, Process performance requirements, Efficiency, Industrial improvement,

Cost, Asset, Lean manufacturing practice, Use of smart technologies in

logistics, Use of smart technologies in production, Manufacturing,

and Operations, Product, Business Model, Inventory control using real-time,

Inventory control, Use of smart technologies in the warehouse, and

Digitalization of product equipment. |

20 |

Manufacturing

operations and inventory |

|

Human resources, Organizational, Managerial,

and capability supporter, Skilled human resources, Startup culture,

Leadership, People, and Innovation. Worker IT skills, People and culture,

Organizational strategy, Talent for the future, Management strategy,

Enterprise transformation management, Strategic outcomes, Responsibility,

Management strategy, Training Policy, Strategy, and Organization, and

Innovation incubating. |

20 |

Leadership and

human resources |

|

The regulatory environment, Human resources,

People and culture, Regulations, Swift trust, Waste management and quality,

Sustainable development, Innovation capability, People and culture,

Sustainability, and Government support. |

11 |

Sustainability |

As

also stated in the previous research, technology, and IT infrastructure are the

most dimensions considered in supply chain 4.0. Using technology and IT

infrastructure in supply chain operations may improve stakeholders'

connectivity and information sharing to enhance supply chain effectiveness (Preindl, Nikolopoulos, and Litsiou, 2020). There

are twenty-one dimensions from previous research related to technology and IT

infrastructure. It is also confirmed that applying Industry 4.0 to the supply chain

should pay attention to technological advancement and infrastructure. Further,

technology is not the only dimension to consider in supply chain 4.0 adoption.

This research found that supply chain

integration and coordination and Manufacturing operations and inventory are

also needed to consider in supply chain 4.0 since its operations involve many

stakeholders. Integrations and coordination using Industry 4.0 technology are

still distant, even if it may improve supply chain performance and competitive

advantages (Preindl, Nikolopoulos, and Litsiou, 2020;

Asrol et al., 2018). In this context, supply chain integration

and coordination are clustered based on any dimensions from previous research

that are related to the dimensions. It is found that sixteen dimensions from

previous research clustered into supply chain integration and coordination

which confirmed that this dimension has not been considered, even though the

context is supply chain operations.

For the manufacturing operations and

inventory, it is found that twenty dimensions from previous research related to

this proposed dimension. In other research, (Sanders,

Elangeswaran, and Wulfsberg, 2016) also consider Industry 4.0 in

Manufacturing operations with a lean approach, which illustrates this scope is

necessary to be included in the supply chain 4.0 modelling. We proposed

Manufacturing operations and inventory due to fulfilling industry 4.0 requirements

in the focal company in the supply chain. Manufacturing operations and

inventory involve warehouse operations, productions process and models,

efficiency, business model, and smart technology practice in the supply chain,

which mostly deal with industry 4.0 adoption.

Leadership and human resource dimension are

proposed to deal with resources capability in organization, innovation, and

technology (Chumnumporn et al., 2022; Naruetharadhol

et al., 2022). We found twenty dimensions from previous research

related to this proposed dimension. Human interaction and organization with

good Leadership may assist industry 4.0 adoption in supply chain operations.

Table 3 Previous research related to proposed dimensions

Finally,

this research proposed sustainability dimensions to assess the readiness of

supply chain 4.0 adoption in the industry. This dimension is to fulfil gaps in

industry 4.0 adoption study that received limited attention in economic,

social, and institutional aspects (Fogaca, Grijalvo,

and Neto, 2022; Oesterreich, Schuir, and Teuteberg, 2020). The sustainability dimension is clustered

based on eleven dimensions from previous research which confirmed that this

dimension had not been mentioned before. However, considering sustainability in

Industry 4.0 and supply chain operation has been suggested by previous research

(Berawi et al., 2020; Manavalan and

Jayakrishna, 2019; De-Man and Strandhagen, 2017). Therefore,

sustainability dimension is required in the supply chain 4.0 adoption and

readiness.

An overview of previous research related to the proposed dimensions is

shown in Table 3. It was found that Technology and IT infrastructure are the

most applied dimensions in the literature, in line with our previous analysis.

Supply chain integration and coordination and manufacturing operation and

inventory are also found in 15 and 14 papers related to this dimension,

respectively. Leadership and human resource found nine papers discuss this

dimension, while sustainability is the most limited dimension considered in

previous research.

3.4. Further research agenda

Existing literature drawing Industry 4.0

maturity and readiness has delivered meaningful concepts and applications.

Moreover, Industry 4.0 adoption is not limited to business and operations in a

focal company. It needs to expand along the supply chain flow to improve the

value chain and met consumer expectations. A systematic literature review has

revealed that the Industry 4.0 topic is a fascinating topic. 525 kinds of

literature were extracted.

However, due to a requirement to adopt

Industry 4.0 in the supply chain, a bibliometric analysis also found

interesting facts. Supply chain keywords that are related to Industry 4.0 is

limited in the last 3 years and need to fill the gap since its offer a great

benefit to efficiency and effectiveness. From the enormous number of literature

related to Industry 4.0 topics, only 20 papers discussed supply chain 4.0

adoption. These papers cover a range of topics related to Industry 4.0 adoption

in the supply chain, including maturity and readiness assessment, case studies

on supply chain readiness, digital transformation in the supply chain, and the

importance of Supply Chain 4.0 for improving operational efficiency.

Previous research has formulated various

dimensions related to Industry 4.0 and supply chain 4.0 readiness. Moreover,

most of the dimensions promote the importance of digital technology and

transformation adoption. Stakeholders push to apply Industry 4.0 in the supply

chain. However, the implementation only focuses on digital transformation and

tends to remove other important supply chain sectors (Wagire

et al., 2021; Krykavskyy, Pokhylchenko, and Hayvanovych, 2019).

In fact, in adopting Industry 4.0 is not only focused on technology advancement

and transformation but also it is potentially to minimize production waste,

energy use optimization, and green-house gas impact (Kiel

et al., 2017). To adopt the focus and benefit of Industry 4.0 in

the supply chain, this paper has drawn dimensions of the previous research and

proposed five comprehensive dimensions: Technology and IT infrastructure,

Supply chain integration and coordination, Manufacturing operations and

inventory, Leadership and human resources, and Sustainability.

The proposed dimensions need to decompose to

detail indicators and design the assessment model of readiness and maturity.

For further research agenda, a self-assessment approach is recommended for the

practitioner to monitor current supply chain performance using the proposed

dimensions. In future research, each dimension must be decomposed into

indicators that are adapted from the individual dimensions from the previous

research. In designing an assessment model, dimensions and indicators must be

defined completely. Dimensions describe supply chain 4.0 in many perspectives

while indicators explain the performance of the dimensions (Juwana, Muttil, and Perera, 2012). As found in

the listed literature, previous research has provided Industry 4.0 readiness.

A literature review

with a qualitative and quantitative approach for the Industry 4.0 maturity and

readiness has been delivered. Supply chain 4.0 met a lack of discussion and

implementation during the industry 4.0 adoption. This paper found 525 papers discuss

industry 4.0 readiness and maturity and are limited to the implementation of

supply chain 4.0. Papers that discussed supply chain 4.0 focused on the

importance of digital technology and transformation in the adoption, while

supply chain needs another perspective. A quantitative and qualitative approach

in reviewing process using PRISMA and VOSviewer approach, this paper has

proposed a comprehensive dimension to assess supply chain 4.0 readiness. The

proposed dimensions are Technology and IT infrastructure, Supply chain

integration and coordination, Manufacturing operations and inventory,

Leadership and human resources, and sustainability formulated by the dimensions

mentioned in the previous research. For further research, it needs to design a

completed supply chain 4.0 readiness model assessment with the proposed

dimensions which needs to decompose into a qualitative and quantitative

dimension. A multi-methodology with a hard and soft system approach is required

to design the model since it found a valid result. However, limitations

regarding this study must be considered. First, the source of the literature

review is a single database with some paper addition. Including another

database may propose a unique result. Second, the proposed dimensions are formulated

based on the previous dimensions in the literature. To decide a dimension into

a cluster dimension is a subjective decision of the author. Verification by a

prominent expert is needed to accomplish this part.

Agca, O., Gibson, J.,

Godsell, J., Igantius, J., Wyn Davis, J., Xu, O., 2020. An Industry 4 Readiness

Assessment Tool. Warwick Manufacturing Group

Alladi, T., Chamola, V.,

Parizi, R.M., Choo, K.K.R., 2019. Blockchain Applications for Industry 4.0 and

Industrial IoT: A Review. Institute of Electrical and Electronics Engineers

(IEEE) Access, Volume 7, pp. 176935–176951

Asdecker, B., Felch, V.,

2018. Development of an Industry 4.0 Maturity Model for the Delivery Process in

Supply Chains. Journal of Modelling in Management, Volume 13(4), pp.

840–883

Asrol, M., Marimin, M.,

Machfud, M., Yani, M., 2018. Method and Approach Mapping of Fair and Balanced

Risk and Value-added Distribution in Supply Chains: A Review and Future Agenda.

International Journal of Supply Chain Management, Volume 7(5), pp. 74–95

Asrol, M., Yani, M., Taira,

E., 2021. Risk Management for Improving Supply Chain Performance of Sugarcane

Agroindustry. Industrial Engineering and Management Systems, Volume

20(1), pp. 9–26

Azevedo, A., Santiago, S.B.,

2019. Design of an Assessment Industry 4.0 Maturity Model: An Application To

Manufacturing Company. In: Proceedings of the International Conference

on Industrial Engineering and Operations Management, Volume 2019, pp. 208–217

Ballou, R.H., 2007. The

Evolution and Future of Logistics and Supply Chain Management. European

Business Review, Volume 19(4), pp. 332–348

Bentaher, C., Rajaa, M.,

2022. Supply Chain Management 4.0: A

Literature Review and Research Framework. European Journal of Business and

Management Research, Volume 7(1), pp. 117–127

Berawi, M.A., Suwartha, N.,

Surjandari, I., Zagloel, T.Y.M., Asvial, M., Harwahyu, R., Suryanegara, M.,

Setiawan, E.A., Maknun, I.J., Kusrini, E., Kartohardjono, S., Sofyan, N.,

Yuwono, A.H., Harjanto, S., Putra, N., Budiyanto, M.A., Whulanza, Y., 2020. Accelerating

Sustainable Energy Development through Industry 4.0 Technologies. International

Journal of Technology, Volume 11(8), pp. 1463–1467

Caiado, R.G.G., Scavarda,

L.F., Gavião, LO., Ivson, P., Nascimento, D.L.D.M., Garza-Reyes, J.A., 2021. A

Fuzzy Rule-based Industry 4.0 Maturity Model for Operations and Supply Chain

Management. International Journal of Production Economics, Volume 231,

pp. 1–21

Chopra, S., Meindl, P.,

2013. Supply Chain Management: Strategy, Planning and Operation. 5th

Edition. Pearson

Chumnumporn, K., Jeenanunta,

C., Simpan, S., Srivat, K., Sanprasert, V., 2022. The Role of a Leader and the

Effect of a Customer’s Smart Factory Investment on a Firm’s Industry 4.0

Technology Adoption in Thailand. International Journal of Technology,

Volume 13(1), pp. 26–37

Dallasega, P., Rauch, E.,

Linder, C., 2018. Industry 4.0 as an Enabler of Proximity for Construction

Supply Chains: A Systematic Literature Review. Computers in Industry,

Volume 99, pp. 205–225

De-Man, J.C., Strandhagen,

J.O., 2017. An Industry 4.0 Research Agenda for Sustainable Business Models. Procedia

CIRP, Volume 63, pp. 721–726

Dudukalov, E.V., Terenina,

I.V., Perova, M.V., Ushakov, D., 2021. Industry 4.0 Readiness: The Impact of

Digital Transformation on Supply Chain Performance. In: XXII

International Scientific Conference Energy Management of Municipal Facilities

and Sustainable Energy Technologies (EMMFT-2020), Volume 244, p. 08020

Esmaeilian, B., Sarkis, J.,

Lewis, K., Behdad, S., 2020. Blockchain for the Future of Sustainable Supply

Chain Management in Industry 4.0. Resources, Conservation and Recycling,

Volume 163, p. 105064

Fogaca, D., Grijalvo, M.,

Neto, M.S., 2022. An Institutional Perspective in the Industry 4.0 Scenario: A

Systematic Literature Review. Journal of Industrial Engineering and

Management, Volume 15(2), pp. 309–322

Frederico, G.F.,

Garza-Reyes, J.A., Anosike, A., Kumar, V., 2020. Supply Chain 4.0: Concepts,

Maturity and Research Agenda. Supply Chain Management: An International

Journal, Volume 25(2), pp. 262–282

Gupta, S., Modgil, S.,

Gunasekaran, A., Bag, S.. 2020. Dynamic Capabilities and Institutional Theories

for Industry 4.0 and Digital Supply Chain. Supply Chain Forum: An

International Journal, Volume 21(3), pp. 139–157

Hajoary, P.K.. 2020.

Industry 4.0 Maturity and Readiness Models: A Systematic Literature Review and

Future Framework. International Journal of Innovation and Technology

Management, Volume 17(7), p. 2030005

Hellweg, F., Lechtenberg,

S., Hellingrath, B., Thomé, A.M.T., 2021. Literature Review on Maturity Models

for Digital Supply Chains. Brazilian Journal of Operations & Production

Management, Volume 18(3), pp. 1–12

Hizam-hanafiah, M., Soomro,

M.A., Abdullah, N.L., 2020. Industry 4.0 Readiness Models: A Systematic

Literature Review of Model Dimensions. Information, Volume 11(7), pp.

1–13

Ivanov, D., Dolgui, A.,

2020. A Digital Supply Chain Twin for Managing the Disruption Risks and

Resilience in the Era of Industry 4.0. Production Planning & Control,

Volume 32(9), pp. 775–788

Juwana, I., Muttil, N.,

Perera, B.J.C., 2012. Indicator-based Water Sustainability Assessment - A

Review. Science of the Total Environment , Volume 438, pp. 357–371

Kagermann, H., Wahlster, W.,

Helbig, J., 2013. Securing the Future of German Manufacturing Industry:

Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0. In: Final

Report of the Industrie 4.0 Working Group

Kenge, R., Khan, Z., Kenge,

R., Khan, Z., 2020. A Research Study on the ERP System Implementation and

Current Trends in ERP. Shanlax International Journal of Management,

Volume 8(2), pp. 34–39

Khan, S.A., Naim, I.,

Kusi-Sarpong, S., Gupta, H., Idrisi, A.R., 2021. A Knowledge-based Experts’

System for Evaluation of Digital Supply Chain Readiness. Knowledge-Based

Systems, Volume 228, p. 107262

Kiel, D., Müller, J.M.,

Arnold, C., Voigt, K.I., 2017. Sustainable Industrial Value Creation: Benefits

and Challenges of Industry 4.0. International Journal of Innovation

Management, Volume 21(8), p. 740015

Krykavskyy, Y.,

Pokhylchenko, O., Hayvanovych, N., 2019. Supply Chain Development Drivers in

Industry 4.0 in Ukrainian Enterprises. Oeconomia Copernicana, Volume

10(2), pp. 273–290

Lasi, H., Fettke, P.,

Kemper, H.G., Feld, T., Hoffmann, M., 2014. Industry 4.0. Business and

Information Systems Engineering, Volume 6(4), pp. 239–242

Lassnig, M., Müller, J.M.,

Klieber, K., Zeisler, A., Chirl, M., 2021. A Digital Readiness Check for the

Evaluation of Supply Chain Aspects and Company Size for Industry 4.0. Journal

of Manufacturing Technology Management, Volume 33(9), pp. 1–18

Machado, C.G., Winroth, M.,

Carlsson, D., Almström, P., Centerholt, V., Hallin, M., 2019. Industry 4.0

Readiness in Manufacturing Companies: Challenges and Enablers Towards Increased

Digitalization. Procedia CIRP, Volume 81, pp. 1113–1118

Manavalan, E., Jayakrishna,

K., 2019. A Review of Internet of Things (IoT) Embedded Sustainable Supply

Chain for Industry 4.0 Requirements. Computers and Industrial Engineering,

Volume 127, pp. 925–953

Methavitakul, B.,

Santiteerakul, S., 2018. Analysis of Key Dimension and Sub-dimension for Supply

Chian of Industry to Fourth Industry Performance Measurement. In: 2018

IEEE International Conference on Service Operations and Logistics, and

Informatics (SOLI), pp. 191–195

Moher, D., Liberati, A.,

Tetzlaff, J., Altman, D.G., Antes, G., Atkins, D., Barbour, V., Barrowman, N.,

Berlin, J.A., Clark, J., Clarke, M., Cook, D., D'Amico, R., Deeks, J.J.,

Devereaux, P.J., Dickersin, K., Egger, M., Ernst, E., Gotzsche, P.C., Grimshaw,

J., Guyatt, G., Higgins, J., Ioannidis, J.P.A., Kleijnen, J., Lang, T.,

Magrini, N., McNamee, D., Moja, L., Mulrow, C., Napoli, M., Oxman, A., Pham,

B., Rennie, D., Sampson, M., Schulz, K.F., Shekelle, P.G., Tovey, D., Tugwell,

P., 2009. Preferred Reporting Items for Systematic Reviews and Meta-analyses:

the PRISMA Statement. Revista Espanola de Nutricion Humana y Dietetica,

Volume 18(3), pp. 172–181

Monshizadeh, F., Sadeghi

Moghadam, M. R., Mansouri, T., Kumar, M., 2023. Developing An Industry 4.0

Readiness Model Using Fuzzy Cognitive Maps Approach. International Journal

of Production Economics, Volume 255, p. 108658

Naruetharadhol, P.,

Srisathan, W.A., Gebsombut, N., Wongthahan, P., Ketkaew, C., 2022. Industry 4.0

for Thai SMEs: Implementing Open Innovation as Innovation Capability

Management. International Journal of Technology, Volume 13(1), pp. 48–57

Neugebauer, R., Hippmann,

S., Leis, M., Landherr, M., 2016. Industrie 4.0 - From the Perspective of

Applied Research. Procedia CIRP, Volume 57, pp. 2–7

Oesterreich, T.D., Schuir,

J., Teuteberg, F., 2020. The Emperor’s New Clothes or an Enduring IT Fashion?

Analyzing the Lifecycle of Industry 4.0 Through the Lens of Management Fashion

Theory. Sustainability, Volume 12(21), p. 8828

Perianes-Rodriguez, A.,

Waltman, L., Van-Eck, N.J., 2016. Constructing Bibliometric Networks: A

Comparison Between Full and Fractional Counting. Journal of Informetrics,

Volume 10(4), pp. 1178–1195

Preindl, R., Nikolopoulos,

K., Litsiou, K., 2020. Transformation Strategies for the Supply Chain: the

Impact of Industry 4.0 and Digital Transformation. Supply Chain Forum: An

International Journal, Volume 21(1), pp. 26–34

Rajnai, Z., Kocsis, I.,

2018. Assessing Industry 4.0 Readiness of Enterprises. In: 2018 IEEE 16th

World Symposium on Applied Machine Intelligence and Informatics (SAMI),pp. 225–230

Reyes, J., Mula, J.,

Díaz-Madroñero, M., 2021. Development of a Conceptual Model for Lean Supply

Chain Planning in Industry 4.0: Multidimensional Analysis for Operations

Management. Production Planning and Control, Volume 34(12), pp.

1209–1224

Sanders, A., Elangeswaran,

C., Wulfsberg, J., 2016. Industry 4.0 Implies Lean Manufacturing: Research

Activities in Industry 4.0 Function as Enablers for Lean Manufacturing. Journal

of Industrial Engineering and Management, Volume 9(3), pp. 811–833

Schumacher, A., Erol, S.,

Sihn, W., 2016. A Maturity Model for Assessing Industry 4.0 Readiness and

Maturity of Manufacturing Enterprises. Procedia CIRP, Volume 52, pp.

161–166

Shao, X.F., Liu, W., Li, Y.,

Chaudhry, H.R., Yue, X.G., 2021. Multistage Implementation Framework for Smart

Supply Chain Management Under Industry 4.0. Technological Forecasting and

Social Change, Volume 162, p. 120354

Shayganmehr, M., Gupta, S.,

Laguir, I., Stekelorum, R., Kumar, A., 2021. Assessing the Role of Industry 4.0

for Enhancing Swift Trust and Coordination in Humanitarian Supply Chain. Annals

of Operations Research, Volume 335(3), pp. 1053–1085

Tangpong, C., 2011. Content

Analytic Approach to Measuring Constructs in Operations and Supply Chain

Management. Journal of Operations Management, Volume 29(6), pp. 627–638

Tjahjono, B., Esplugues, C.,

Ares, E., Pelaez, G., 2017. What does Industry 4.0 Mean to Supply Chain? Procedia

Manufacturing, Volume 13, pp. 1175–1182

Tripathi, S., Gupta, M.,

2021. Indian Supply Chain Ecosystem Readiness Assessment for Industry 4.0. International

Journal of Emerging Markets, Volume 18(8), pp. 1917–1947

Van Eck, N., Waltman, L.,

2010. Software Survey: VOSviewer, a Computer Program for Bibliometric Mapping. Scientometrics,

Volume 84(2), pp. 523–538

Van Hoek, R., Sankararaman,

V., Udesen, T., Geurts, T., Palumbo-Miele, D., 2020. Where We are Heading and

the Research that Can Help us get there – Executive Perspectives on the

Anniversary of the Journal of Purchasing and Supply Management. Journal of

Purchasing and Supply Management, Volume 26(3), p. 100621

Wagire, A.A., Joshi, R.,

Rathore, A.P.S., Jain, R., 2021. Development of Maturity Model for Assessing

the Implementation of Industry 4.0: Learning from Theory and Practice. Production

Planning and Control, Volume 32(8), pp. 603–622

Yani, M., MacHfud, Asrol,

M., Hambali, E., Papilo, P., Mursidah, S., Marimin, M., 2022. An Adaptive Fuzzy

Multi-Criteria Model for Sustainability Assessment of Sugarcane Agroindustry

Supply Chain. IEEE Access, Volume 10, pp. 5497–5517

Zhang, C., Chen, Y., Chen,

H., Chong, D., 2021. Industry 4.0 and its Implementation: a Review. Information

Systems Frontiers, pp. 1–11