Optimized Calibration Plan based on Gray Model GM(1,1) applied in Physical-Photometric and Chemical Laboratories Accredited by ISO/IEC 17025

Corresponding email: cavf1@alu.ua.es

Published at : 18 Sep 2024

Volume : IJtech

Vol 15, No 5 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i5.5938

Velásquez, C., Espín, F., Iturra, F., Chasi, C., 2024. Optimized Calibration Plan based on Gray Model GM(1,1) applied in Physical-Photometric and Chemical Laboratories Accredited by ISO/IEC 17025. International Journal of Technology. Volume 15(5), pp. 1438-1448

| Carlos Velásquez | 1. Dept. of Applied Mathematics, University of Alicante, Apdo. 99, 03080, Alicante, Spain 2. Modalidad en Línea, Universidad Central del Ecuador, Quito 170521 Ecuador 3. Instituto de Investigación |

| Francisco Espín | 1. Instituto de Investigación Geológico y Energético, Quito 170518, Ecuador. 2. Departamento de Luminotecnia, Luz y Visión, Universidad Nacional de Tucumán, San Miguel de Tucumán Tucumán T4000, Argen |

| Francisco Iturra | Instituto de Investigación Geológico y Energético, Quito 170518, Ecuador |

| Consuelo Chasi | Instituto de Investigación Geológico y Energético, Quito 170518, Ecuador |

The competence of laboratories to perform testing and

calibration services for the industry is assured by the ISO/IEC 17025

accreditation. To comply with this standard, it is imperative to ensure

metrological traceability through the regular calibration of laboratory

equipment at defined schedules, which is time-consuming and demands significant

financial resources. The present work applies first-order gray models GM(1,1)

using calibration uncertainties to establish an optimized calibration plan that

considers different natural characteristics of laboratory activities, thus

providing technical support to ensure metrological traceability for a wide

range of laboratory tests. A luminous intensity distribution test on LED

luminaires and a fire assay method for determining gold were considered.

Applying the proposed approach, the outcoming times between calibrations were

longer than previously established, reducing 11% of the financial resources for

the physical-photometric laboratory and 54% for the chemical laboratory.

Therefore, it also increases the availability of calibrated pieces of

equipment. Moreover, results showed that this method suits physical and

chemical laboratory tests. In conclusion, this methodology could increase the

time between calibrations and reduce the financial resources needed while

maintaining technical competence or confidence in laboratory results.

Fire assay; Gray model; ISO/IEC 17025 accreditation; Luminous intensity; Uncertainties

The

ISO/IEC 17025:2017 standard "General

requirements for the competence of testing and calibration laboratories"

There are different ways of carrying out the laboratory calibration

program, usually adopted by guidelines suggested by the

International Laboratory Accreditation Cooperation and the International Organization of Legal Metrology in

ILAC G24 OIML D10 (Legal International Organization of Metrology, 2007).

Most laboratories apply year-to-year calibration and instrumental drift

calculation methods.

A

“dynamic calibration program” changes the paradigm of fixed calibration times.

It encourages laboratories to determine, through a series of evaluations, the

behavior of the measurement equipment and the most appropriate calibration

times (Silva and Rodrigues, 2013). The calibration time can

be determined by verifying the behavior of the measuring equipment between

calibrations or by estimating the variation of measurement uncertainty over

time

Estimating

the calibration time for measurement equipment is a complex issue that involves

economic risks when estimating time is too short (Pashnina, 2020) and technical risks when the estimated time

is excessively long (Gaber, 2021). An adequate procedure in

planning laboratory activities affects the production of its clients

Various

statistical approaches prove useful in determining a calibration interval (Butdee and Khanawapee, 2021; Velásquez et al., 2021b), with extensive research

conducted on the topic. Results expose methodologies used to define calibration

ranges, among them chain methodology, simple linear model, and decisional

model. Additionally, a large number of variables must be considered, such as

the maximum permissible errors required by the laboratory, frequency of use of

the equipment, type of application, robustness, other requirements determined

by manufacturers (Toteva, Slavov, and Vasileva, 2017), and other factors such as laboratory infrastructure

(electrical installations, environmental conditions), detect anomalies in

equipment (El-Hadad, Tan, and Tan, 2022) or the competence of the personnel operating

the equipment (Nugraha et al., 2022).

These

models have been generally applied to a single equipment or laboratory. This

work presents a new use of gray model study applied to physic and chemical

laboratories for its calibration ranges that have not been developed. The

first-order gray model GM(1,1) is a good alternative explored in some research.

It suggested that due to the characteristic of the technique to project values

whose nature of change is unknown (gray action)(Zeng, Ma, and Shi, 2020), it is advantageous to be

applied when projecting the changes over time of uncertainties of different

laboratory equipment (Lin and Liu, 2005). Applying this methodology allows adjusting

calibration intervals considering the reasons for a change of the equipment

with adequate predictions.

The

model GM(1,1) used in this research needs as a mathematical parameter the

calibration uncertainties of equipment involved in the complete test. A

calibration certificate usually provides much information to the laboratory,

mainly the correction and the uncertainty values

The

measured value could be adjusted by applying the certificate correction.

However, the uncertainty is related to the accuracy and repeatability status of

the equipment as well as the supplier's method of calibration. Through a

periodic calibration process of all the equipment whose measurements influence

the test results, values of bias and uncertainty are obtained, so that is why

the importance of ensuring correct calibrations and their intervals.

Due to

their nature, there are physical or chemical laboratories. In both, uncertainty

is the fundamental value representing the quality of an assay or a calibration

result. Its calculation and application are described through “The Guide to the

Expression of Uncertainty in Measurement,” also known as GUM

Even

though conceptually, the uncertainty term is always the same, in practice,

physical and chemical laboratories have differences in their estimates.

However, it is possible to apply an approximation of GM(1,1) regardless of the

nature of the activities of the laboratories.

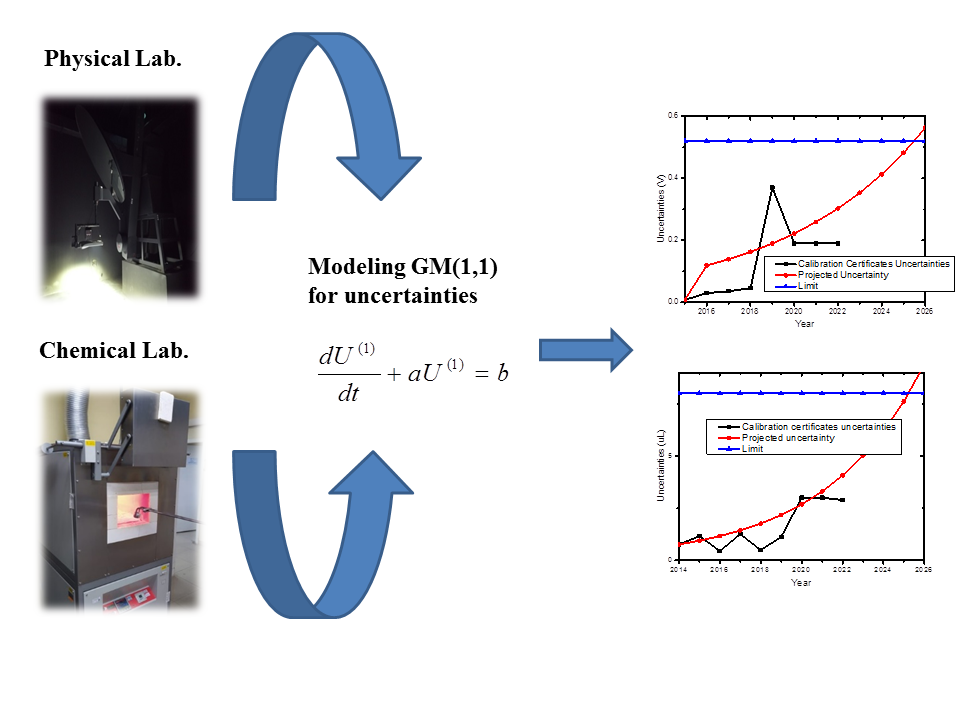

In this

work, physical-photometric and chemical-accredited laboratories were the scopes

of application (Figure 1a and Figure 1b) (Velásquez et al.,

2023). In the case of the physical-photometric

laboratory, the assay to determine luminous intensities distribution in LED

luminaires employing a goniophotometer was analyzed. On the other hand, for

chemical laboratories (Juiña, Silva,

and Velásquez, 2024), the

analysis focused on the determination of gold concentration in minerals using

the 'fire assay' method combined with Atomic Absorption Spectrophotometry.

|

The based GM(1,1) methodology proposed was applied in two different

assays of different natures: physical-photometric and chemical. It is essential

to understand the annual cost of equipment calibration and the traceability

chain of each one. The traceability relationship between two laboratory

equipment in the chain (Figure 2, Figure 3) is ![]() . The

. The ![]() Represents if there is a

traceability transfer.

Represents if there is a

traceability transfer.

2.1. Traceability Chain for Physical-Photometric Laboratory

An accredited test in the

physical-photometric laboratory measures luminous intensities distribution in

LED luminaires using a C-type rotating mirror goniophotometer. The standard

methods for the test are CIE 121, "The

Photometry and Goniophotometer of Luminaires"

The test begins with stabilizing the

luminaire by turning it on for two hours at a constant voltage with a power

supply regulated at ±0.2%. Next, vector detection is developed through

spherical coordinates, where its direction will be given by the axial

(C-Planes) and azimuthal (Gamma Angles) angles and its magnitude by the light

intensity, describing the photometric volume of interest. Additionally, during

the test, a temperature of 25°C ± 1.2°C must be maintained because temperature

variation has an impact on the test

The

measurement of luminous intensities is absolute (cd) for LED luminaires. The

calibration of the goniophotometer is done with a work standard lamp. The work

standard lamp is traceable to the reference standard lamp with its electrical

parameters. The traceability chain is presented in Figure 2.

Figure 2 Traceability chain method of the test in the

physical-photometric laboratory

The photometric scheme has an

incandescent technology standard reference lamp (Z1), an incandescent

technology work lamp (Z2), a SENSING GMS-2000 Goniophotometer (Z3), and routine

test LED luminaires (Z10). The electrical magnitudes were supervised by a

Metrel MI 2892 Electrical Network Analyzer (Z2) and a Yokogawa WT310 Digital

Power Meter to detect voltage (Z5), current (Z6), and THDs (Z7). The

environmental conditions were measured with a verification equipment

Thermohygrometer TESTO 176P1 (Z8) and a routine measurement equipment

Thermohygrometer TESTO 174H (Z9).

2.2. Traceability Chain for Chemical Laboratory

The Chemical Laboratory performs

mineralogical and elemental tests in various geological matrices. Among other

trials, it determines gold by the “fire assay”, the reference technique for

gold quantification (Buitrón et al., 2021). It is based on the “ASTM E1335, Standard Test

Methods for Determination of Gold in Bullion by Fire Assay Cupellation

Analysis” and the “3111 Metals by Flame Atomic Absorption Spectrometry”. This

method is preferred over others due to its application to a broad spectrum of

samples, excellent versatility, and high accuracy (Buitrón et al., 2021). It is also considered that the nugget effect

is reduced due to the large amount of sample that can be used.

The equipment used for the assay are as

follows: Weights brand Mettler Toledo E2 type (Z1), a scale brand Precisa model

XB4200C (Z2), a scale brand Mettler Toledo model XP 205 (Z3), a scale brand

Citizen model CX 220 (Z4), a pipette of 500 brand Socorex (Z5), a pipette of

5000

brand Socorex (Z6), a pipette of 100

brand Socorex (Z7), a pipette

of 1000

brand Socorex (Z8), a dispenser of 10 mL brand Brand (Z9), certified

reference material of gold-containing minerals from Rocklabs (Z10), a certified

standard of gold from Inorganic Ventures (Z11), an Atomic Absorption

Spectrophotometer brand Perkin Elmer (Z12) two Thermo hygrometers brand

Traceable (Z13 and Z14), two

thermometers brand Fluke (Z15 and Z16), two muffles brand Incinerar (Z17 and

Z18), a muffle brand Carbonate (Z19), a stove brand Polenco (Z20) and a

hotplate brand SCP Science (Z21).

As is shown in Figure 3, a

series of verifications are carried out to ensure the quality of the results.

Weights are used to verify scales that later are used to verify the volumetric

material (Pipettes and Dispenser). Meanwhile, standard solutions are prepared

using pipettes and certified reference material to calibrate and verify an

Atomic Absorption Spectrophotometer. Temperature equipment (muffles, hotplate,

and stove) is verified by a verified thermometer. In addition, humidity and

temperature conditions are monitored using a thermohygrometer.

The samples to be analyzed are dried in

an oven at 50 °C. In the first stage of the test, high-temperature equipment is

required. The sample is roasted at 700 °C to eliminate interferences; then, the

sample is melted with a lead-based flux charge at 1000 °C. Balances are used to

prepare the flux charge and weigh the sample. In the second stage, gold is

recovered from the lead as a doré through a cupellation process at 950 °C.

Finally,

acid digestion of the doré is carried out in a digester at 60 °C, and the

resulting solution is analyzed using an atomic absorption spectrometer (Buitrón et al., 2021). By applying the Lambert-Beer law, which relates the

concentration of a substance to its absorbance, we can determine the

concentration of gold in mg/Kg of the sample. The traceability chain is presented

in Figure 3.

Figure 3 Traceability chain method of the test in the chemical

laboratory

2.3. Gray

model GM(1,1) applied to uncertainty growth in the function of time

Gray models have an acceptable

behavior when it is necessary to model data for which we have incomplete

information or to project a value in a trend whose natural causes that would

explain its behavior are unknown. The use of the laboratory equipment represents

its consumption. In consequence, there must be a loss, no matter how small, of

its precision the longer it has been used. This behavior is quantified in the

dispersion that occurs when taking successive measurements. When the equipment

is calibrated year after year, it is possible to observe its uncertainty growth

as a function of time.

The deterioration of the equipment due

to its use has imponderables that may be unknown. For this reason, it is possible

to apply GM(1,1) to the modeling of these data. However, the requirements of a

test method or a laboratory to comply with its quality standards establish a

limit tolerance. We can use this limit as a benchmark to identify the maximum

calibration interval of each piece of equipment.

Following reasoning similar to (Wang, Zhang, and Jiang, 2017), it is possible to define Equation 1:

Where U(1) is the uncertainty accumulated of

equipment, is the development coefficient, b

is the gray action, and t is time.

Using a discretization k for the calibration intervals (in

this case, years), the solution is represented in Equation 2 for a vector of uncertainties year a year

The

predicted uncertainty for period k+1

is given by Equation 3:

As

Equation 1 and the vector Y show, it

is necessary to use the amount n of

calibration uncertainty data the laboratory uses to find the constants a and b. With these results and using Equation 3, it is possible to find

the projected values and identify the period in which the uncertainty will be

outside its tolerance.

3.1. Implementation algorithm GM(1,1) given a vector of uncertainties Y

The

first step to implementing the proposed methodology is to use the following

algorithm that will allow the solving of GM(1,1) for each vector Y associated with each piece of

equipment present in the different traceability chains Figures 1 and 2:

Step 1:

Define the vector Y with its n calibration data

Step 2:

Calculates the cumulative vector of uncertainties,

Step 3:

Define the system of n-1 equations

(Equation 2).

Step 4:

Solve for a and b using the method of

least squares for n-1

equations

Step 5:

Define the tolerance limit (L)

allowed by the test method or laboratory

Step 6:

Project the uncertainties (Equation 3) until

Step 7: Find the period it is needed for, k.

In most cases, effective

data modeling is achieved through the use of algorithms, particularly when

there is a substantial amount of data available to feed the model. An

illustrative example is presented in Figure 4 and Figure 5.

3.2. Weighting of the experimental system based on its traceability chain

If the

experimental scheme for the two tests is understood as a single calibration

scheme, it is inferred that together, there must be a maximum calibration time

for the set.

The

idea of an automatic test system (ATS) composed of individual equipment has

previously been explored (Jinzhe and Jiulong, 2017a).This idea is a

solution to the exaggerated calibration times that result from the application

of different techniques for intervals of calibration.

Some

equations to determine calibration intervals have in their denominator the

difference between the corrections of two successive calibrations. If the

correction is equal, the calibration time tends to infinity, which is incorrect

from a conceptual point of view. Interpreting the calibration time of the

entire test system as a maximum calibration time for any equipment limits these

calculation overruns that can appear even in the use of GM(1,1). So that the

maximum calibration time can be calculated by Equation 4 for i individual equipment:

Figure 4 Modeling result by GM(1,1) of the electrical parameter

meter (voltmeter) in luminous intensities test in luminaires

Figure 5 Modeling result by GM(1,1) of a pipette in the gold concentration test

The

weighting factor will then be relative to each piece of equipment`s influence

on the test result, which can be visualized in the traceability chains. It is

possible to create a matrix in

which Z represents each piece of

equipment and

their relationship in

the transfer of traceability. If there is a relationship, a value of 1 is

associated; otherwise, 0. So, weighting must follow the relationship in

Equation 5 in j relations (Jinzhe and Jiulong, 2017b; Wang, Zhang, and Jiang, 2017).

Results

are shown in Table 1. Once the weighting is applied, we get tmax=4 years for the

Physical-Photometric laboratory and tmax=10

years for the Chemical laboratory. Then, the calibration plan must consider the

time delivered by the GM(1,1) algorithm for each piece of equipment if it is

less than tmax and tmax if it is greater.

Changes in calibration plans represent greater efficiency (Velásquez et al.,

2024) in terms of financial resources (Woodhead and Berawi, 2020).

The Physical-Photometric and Chemical laboratories pay around 4600 USD and 1000

USD annually, respectively, in a year-to-year calibration plan. The implementation

of this methodology has effectively minimized the technical risks associated

with the shift calculation, particularly the occurrence of exaggeratedly high

values in subsequent calibrations. Additionally, it resulted in savings of 11%

and 54% in each case for the following year.

The projection of the

behavior of each piece of equipment is obtained by working together as a single

experimental scheme in the test, weighing the importance of each one in the

traceability chain. This proves to be a critical factor, as obtaining a maximum

timeframe within these weight limits not only mitigates the duration of

calibration but also enables the formulation of an optimized calibration plan.

The methodology tested with chemical and physical laboratories found that the

technique can be applied regardless of its particular characteristics.

Table 1 matrix Physical-Photometric laboratory and

matrix Chemical laboratory

The ISO/IEC 17025

standard requires the calibration of systems and equipment. Calibration

intervals must be flexible, but the options for calculating them can generate

some technical complications. The main problem is a long calibration interval

in which the technical concept of "calibration" loses meaning. The

gray model GM(1,1) applied to the uncertainty of calibration of historical data

allows for the projection of the uncertainty of equipment for the following

period. The tolerance defined by the laboratory or the test/calibration method

is a limit with which we can compare the projected values and satisfactorily

estimate the next calibration period. The GM(1,1) technique has considerable

technical efficiency and saves the economic resources allocated to calibration

in the year-to-year plan. Two different tests were studied with this

methodology. The results are applicable in the physical or chemical nature of

laboratories. There was a reduction of 11% and 54% in financial resources,

respectively, while maintaining technical confidence. However, if this

methodology is applied, it is essential to have a verification plan to maintain

the security of its technical competence with additional measures. Based on the

results obtained, interesting future work is to model a risk analysis

associated with the differential model used.

The authors thank TRANSELECTRIC

E.P. for its facilities for the use of the IIGE lighting laboratory and the

lighting laboratory and chemical laboratory of IIGE for opening their

information on measurement equipment.

Brusil, C., Arcos, H., Espin, F.,

Velasquez, C., 2020. Analysis

of Harmonic Distortion of LED Luminaires Connected to Utility Grid. In: 2020 IEEE ANDESCON, pp. 1–6

Brusil, C., Espín, F., Velásquez,

C., 2021. Effect of Temperature in

Electrical Magnitudes of LED and HPS Luminaires. International Journal of

Electrical and Computer Engineering Systems, Volume 12(4), pp. 225–234

Buitrón, D.O., Barona D.D., Iturra F.M., Leon, J.F.,

2021. Validación

del Método Para la Determinación de Oro por Ensayo al Fuego Combinado con

Espectrometría de Absorción Atómica en Muestras Geológicas Mineras Metalúrgicas

(Validation of The Gold Determination Method by Fire Assaycombined with Atomic

Absorption Spectrometry in Geological, Mine And Metallurgical Samples). InfoANALÍTICA, Volume 9(1), 2021, pp. 119–136

Butdee, S., Khanawapee, U., 2021. Quality Prediction

Modeling of a Preform Fastener Process using Fuzzy Logic and DEFORM Simulation.

International Journal of Technology, Volume 12(1), pp. 33–42

Commission Internationale de L’Eclairage (CIE),

2009. The Photometry and

Goniophotometry of Luminaires - Supplement 1: Luminaires for Emergency

Lighting. Central Bureau of the CIE, CIE

121 -SP1, Vienna, Austria

Commission Internationale de L’Eclairage (CIE), 2015. Test Method for LED Lamps, LED

Luminaires and LED Modules. CIE S025, Vienna, Austria

Deepradit, S., Ongkunaruk, P., Pisuchpen, R., 2020.

Tactical Procurement Planning under Uncertainty in Aromatic Coconut

Manufacturing. International Journal of Technology, Volume 11(4), pp.

698–709

Delker, C.J., Auden, E.C.,

Solomon, O.M., 2020. Calculating Interval Uncertainties for Calibration

Standards That Drift with Time. The Journal of Measurement Science,

Volume 12(4), pp. 9–20

EL-Hadad, R., Tan, Y.-F., Tan, W.-N., 2022. Anomaly

Prediction in Electricity Consumption Using a Combination of Machine Learning

Techniques. International Journal of Technology, Volume 13(6), pp.

1317–1325

Ellison, S.L.R., 2014. Implementing Measurement

Uncertainty for Analytical Chemistry: the Eurachem Guide for Measurement

Uncertainty. Metrologia, Volume 51(4), p. S199

Gaber, S.E., 2021. Adjusting External Calibration

Intervals for Auxiliary Devices in Testing Laboratories According to

Intermediate Checks Results. Water Science, Volume 35(1), pp. 82–88

González, A.G., Herrador, M.Á.,

Asuero, A.G., Martín, J., 2018. A

Practical Way to ISO/GUM Measurement Uncertainty for Analytical Assays

Including In-House Validation Data. In: Quality Control in Laboratory, pp.

109–130

Illuminating Engineering Society, 2019. ANSI/IES LM-79-19 - Approved Method: Optical and

Electrical Measurements of Solid-State Lighting Products. Illuminating

Engineering Society, New York, USA

International Organization for Standardization (ISO), 2017. ISO/IEC 17025:2017 General Requirements for The

Competence of Testing and Calibration Laboratories. International Organization

for Standardization

Jinzhe, X., Jiulong, X., 2017a. Calibration Interval

Optimization and Calibration Conclusion Risk Analysis on Automatic Test System.

In: ICEMI 2017 - Proceedings of IEEE 13th International

Conference on Electronic Measurement and Instruments, pp. 236–241

Jinzhe, X., Jiulong, X., 2017b. Calibration Interval

Optimization and Calibration Conclusion Risk Analysis on Automatic Test System.

In: 13th IEEE International Conference on Electronic Measurement

& Instruments (ICEMI), pp. 236–241

Joint Committee for Guides in Metrology, 2008. Évaluation

Des Données De Mesure-Guide Pour L’expression De L’incertitude De Mesure (Evaluation

of Measurement Data-Guide to The Expression of Uncertainty in Measurement).

Joint Committee for Guides in Metrology

Juiña, D., Silva, B., Velásquez,

C., 2024. Análisis

De Riesgo De La Declaración De Conformidad De La Potencia De Luminarias a Un

Nivel Determinado De Confianza (Risk Analysis of the Declaration of

Conformity of Luminaire Power at a Given Level of Confidence). Killkana Técnica, Volume 7(1), pp. 46–60

Kopke,

V., Mourão, S., Brito, M., 2024. Determination of the Calibration Interval of

Measuring Instruments: Which Method Should I Use? IEEE Instrumentation &

Measurement Magazine, Volume

27(2), pp. 59–62

Legal International Organization of Metrology, 2007. ILAC-G24-OIML

D 10 Guidelines for The Determination of Calibration Intervals of Measuring

Instruments. Legal International Organization of Metrology

Lin, K.-H., Liu, B.-D., 2005. A Gray System Modeling Approach to the Prediction of

Calibration Intervals. IEEE Transactions on Instrumentation and Measurement,

Volume 54(1), pp. 297–304

Muscas, C., Peretto, L.,

Sasdelli, R., Briani, A., 2001. An

Automatic Test Equipment for the Calibration of Voltage Transducers. IEEE

Transactions on Instrumentation and Measurement, Volume 50(6), pp.

1638–1643

Nugraha, E., Sari, R.M.,

Sutarman, Yunan, A., Kurniawan, A., 2022. The Effect of Information Technology,

Competence, and Commitment to Service Quality and Implication on Customer

Satisfaction. International Journal of Technology, Volume 13(4), pp. 827–836

Pashnina, N., 2020. Corrigendum to “Determination of

Optimal Calibration Intervals by Balancing Financial Exposure Against

Measurement Costs”. Flow Measurement and Instrumentation, Volume 60C,

pp. 115–123

Silva, M.D.G.D., Rodrigues, A.B., 2013. Reliability Data

Calibration Based on Load Point Interruption Indices Using Nonlinear and

Quadratic Optimization. In: 2013 IEEE Grenoble Conference, pp. 1–6

Taymanov, R., Teteruk, R., Sapozhnikova, K.,

Medvedevskikh, S., 2023. Metrological Reliability of Measuring Instruments and

the Possibilities for its Improvement. In: XXXIII International

Scientific Symposium Metrology and Metrology Assurance (MMA), Sozopol,

Bulgaria, pp. 1–5

Toteva, P., Slavov,

S., Vasileva, D., 2017. Comparison

of the Methods for Determination of Calibration and Verification Intervals of

Measuring Devices. In: MATEC Web of Conferences, Volume 94, p. 04012

Velásquez, C., Castro, M.Á., Rodríguez, F., 2021b. Analysis

of a Reinterpretation of Gray Models Applied to Measuring Laboratory Equipment

Uncertainties. In: Modelling for Engineering & Human Behaviour,

Torregrosa, J.R., Cortés, J.C., Hervás, J.A., Vidal-Ferrándiz, A.,

López-Navarro, E., (ed.), Universitat Politécnica de Valencia, pp. 252–255

Velásquez, C., Castro, M.A.,

Rodríguez, F., Espín, F., Falconi, N., 2021a. Optimization of the Calibration Interval of a Luminous

Flux Measurement System in HID and SSL Lamps Using a Gray Model Approximation. In:

2021 IEEE Fifth Ecuador Technical Chapters Meeting (ETCM), pp. 1–7

Velásquez, C., Espín, F., Castro, M.Á., Rodríguez, F.,

2024. Energy Efficiency in Public Lighting Systems Friendly to the Environment

and Protected Areas. Sustainability, Volume 16(12), p. 5113

Velásquez, C., Espín, F.,

Rodríguez, F., Castro, M.Á., 2023. Heat

Transfer Modeling in Road Lighting LED Luminaire. In: AIP Conference

Proceedings, Volume 2872(1), p. 020013

Velásquez, C., Juiña, D., Iturra, F., Silva, B., Barona,

D., 2024. Methodology for Declaration of Conformity Under ISO/IEC 17025

Associating Confidence Levels and Risk Analysis. In: Innovation and Research – Smart

Technologies & Systems, Vizuete, M.Z., Botto-Tobar, M., Casillas, S.,

Gonzalez, C., Sánchez, C., Gomes, G., Durakovic, B., (ed.), pp. 30–42

Wang, J., Zhang, Q., Jiang, W., 2017. Optimization of

Calibration Intervals for Automatic Test Equipment. Measurement: Journal of

the International Measurement Confederation, Volume 103, pp. 87–92

Wibawa, A., Ichsani, D., Yuniarto, M.N., 2021. Holistic

Operation & Maintenance Excellence (HOME): Integrating Financial &

Engineering Analysis to Determine Optimum O&M Strategies for a Power Plant

during its Lifetime. International Journal of Technology, Volume 12(4),

pp. 813–828

Woodhead, R., Berawi, M.A. 2020. Value Creation and the Pursuit of Multi Factor Productivity Improvement. International Journal of Technology, Volume 11(1), pp. 111–122

Zeng, B., Ma, X., Shi, J., 2020. Modeling Method of the Grey GM(1,1) Model with Interval Grey Action Quantity and Its Application. Complexity, Volume 2020, pp. 6514236