XRD Measurement for Particle Size Analysis of PMMA Polymer Electrolytes with SiO2

Published at : 03 Nov 2022

Volume : IJtech

Vol 13, No 6 (2022)

DOI : https://doi.org/10.14716/ijtech.v13i6.5927

Sun, C.C., You, A.H., Teo, L.L., 2022. XRD Measurement for Particle Size Analysis of PMMA Polymer Electrolytes with SiO2. International Journal of Technology. Volume 13(6), pp. 1336-1343

| Cha Chee Sun | Faculty of Engineering and Technology, Multimedia University, Jalan Ayer Keroh Lama, 75450 Melaka, Malaysia |

| Ah Heng You | Faculty of Engineering and Technology, Multimedia University, Jalan Ayer Keroh Lama, 75450 Melaka, Malaysia |

| Lay Lian Teo | Faculty of Engineering and Technology, Multimedia University, Jalan Ayer Keroh Lama, 75450 Melaka, Malaysia |

PMMA-based polymer

electrolytes with LiCF3SO3 lithium salt, EC plasticizer,

and SiO2 filler are prepared using the solution cast method. SiO2

filler sizes at 10 ?m and 63 ?m are used to estimate the particle size in the

polymer electrolytes system. EIS analysis calculates ionic conductivity based

on the Cole-Cole plot generated in frequency ranging from 0.1 Hz to 1 MHz. The

calculation results in ionic conductivity at 1.44 × 10-4 S/cm and

8.1 × 10-5 S/cm for 10 ?m and 63 ?m SiO2 filler,

respectively. FWHM measurement is performed for each diffraction peak based on

the XRD spectra. Debye-Scherrer equation is used to estimate the resultant

particle size. Peak broadening effect caused by the instrument is considered

for a more accurate estimation of particle size in the polymer electrolyte

system. Linear regression is employed to determine the average particle size

arising from these diffraction peaks. The results showed that larger filler

size results in the formation of a larger particle size.

Debye-scherrer equation; PMMA; Polymer electrolytes; SiO2; XRD

Over

the decades, polymer electrolytes have been an attractive candidate in battery

industries for replacing conventional liquid electrolytes in numerous

applications (Tang et al., 2021; Zhou et al., 2019;

Arya et al., 2017). The absence of liquid substances in polymer

electrolytes eliminates leakage, which is a crucial drawback in liquid

electrolyte batteries. However, the absence of liquid substances hinders the

battery’s performance. Researchers have employed numerous approaches to improve

ionic conductivity, which is the most crucial measurement in determining the

performance of a battery. Incorporating ceramic filler to form composite

polymer electrolytes is proven capable of restraining polymer crystallization,

which subsequently leads to drastic increase in ionic conductivity. Nonetheless,

several attractive characteristics such as good compatibility with electrodes,

superior mechanical properties, and high lithium transference number eventually

pushed composite polymer electrolytes to be the most promising candidate in

realizing batteries with high electrochemical performance capability (Priyono et al., 2019; Zhang

et al., 2018; Mauger et al., 2017; Jodi et al., 2016). Various types of host polymers

have been investigated particularly poly (ethylene oxide) (PEO), poly(methyl

methacrylate) (PMMA), poly(acrylonitrile) (PAN), poly(vinylidene

fluoride) (PVDF), poly(vinyl alcohol) (PVA), poly(vinyl pyrrolidone) (PVP),

poly(propylene oxide) (PPO), and poly(vinyl chloride) (PVC).

Dhatarwal

et al. (2018) investigated the electrochemical performance

of PMMA/PEO polymer electrolyte dispersed with different types of fillers,

including SiO2. The reported ionic conductivity falls in the range

of 10–5 to 10–6 S/cm at room temperature with stable

voltage up to 3V. The PVC/PMMA? Li4Ti5O12 films prepared by Al-Muntaser et al. (2020). The polymer matrix

reported electrical properties at 2.39 × 10-7 S/cm along with

improved amorphous properties. The author applied the Scherrer equation and

obtained a crystallite size of 40 nm through X-ray Diffraction (XRD) pattern

analysis. Mallaiah et al. (2021) prepared

PEO/PVDF?NaNO3 blended polymer electrolyte with constant wt% of salt and

varying wt% of the host polymer. It is observed that maximum ionic conductivity

is obtained at 9.334 × 10-5 S cm-1 with PEO:PVDF = 80:20.

Addition of ionic liquid into PVDF/HFP

polymer electrolyte prepared by Gupta et al. (2020)

has increased ionic conductivity tremendously up to 2.05 × 10-2 S/cm. Debye-Scherrer

equation is then used to analyze crystallite size, and the work reported

particle size in the range of 4.4 ?. The PVP + CH3COONa:Al2O3 nanocomposite

polymer electrolyte prepared by Kumar et al. (2019)

recorded the highest ionic conductivity up to 6.25 × 10-5 S/cm at

room temperature with an average crystallite size of 18 nm.

In the present work, composite

polymer electrolytes are prepared with PMMA host polymer, lithium

trifluoromethanesulfonate (LiCF3SO3) salt, ethylene

carbonate (EC) plasticizer, and silicon dioxide (SiO2) filler. PMMA

is selected as the host polymer owing to its good compatibility with the

lithium electrode interface. The high dielectric constant of EC promotes

lithium salt dissociation to form Li+ cations, which move freely

throughout the polymer matrix. Adding SiO2 inert filler is mainly

linked to dominant interfacial conductivity. The surface area of filler

interacts with negatively charged anions through the Lewis-acid effect, thus

creating more Li+ cations, which enhance ionic conductivity and

lithium transference number (Xu et al., 2020; Tominaga

et al., 2013). Most of the XRD

analysis retrieved from the literature do not focus on estimating crystallite

size. Thus, this work is intended to perform an in-depth analysis of the XRD

spectrum, particularly to investigate the effect of filler size and resultant

crystallite size on the ionic conductivity of polymer electrolytes.

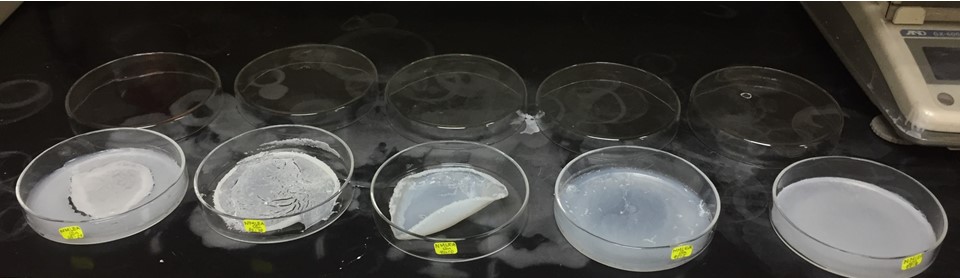

In the present work, PMMA host polymer, LiCF3SO3 lithium salt, EC plasticizer, and SiO2 fillers are used as received from Sigma Aldrich without further purification process. Polymer electrolyte films are prepared by using the solution cast method (Tran et al., 2020). Each material is weighted according to e required wt% and mixed together. The mixture is dissolved in tetrahydrofuran (THF) with continuous stirring at room temperature for 24 hrs. The solution is then cast onto a petri dish and allowed for drying in a fume hood at room temperature until a thin film polymer electrolyte is formed. Figure 1 illustrates the polymer electrolyte film preparation by using the solution cast method. Electrochemical Impedance Spectroscopy (EIS) measurement is performed using Gamry Instrument with frequency between 0.1 Hz to 1 MHz. The polymer electrolyte film is trimmed into smaller samples of equal sizes and placed in between two metal electrodes to determine the ionic conductivity of the polymer electrolyte. X-ray spectroscopy is carried out on the polymer electrolyte membranes by using the XPERT-PRO diffractometer system, which uses 1.54 Å CuK? radiation. The electrolyte membranes are scanned with and angle 2? ranging from 10° to 90° to determine the crystallinity structure and estimation of crystallite size.

Figure 1

Polymer electrolytes sample preparation by using solution cast method

3.1. EIS Measurement

Ionic conductivity is the most important

parameter determining polymer electrolyte performance. Figure 2 shows the

Nyquist pole obtained from EIS measurement by using amry Instrument with

frequency ranging from 0.1 Hz to 1 MHz.

A small arc appears at high frequency region followed by a linear line

extending towards low frequency region. This indicates the presence of bulk

ionic conduction, where resistor and capacitor appear parallel. Bulk resistance

(Rb) is read from the interception point between the line and the

horizontal axis. Ionic conductivity is then calculated by using the expression

shown in Equation (1)

where t is the

sample’s average thickness (cm), RB is the bulk resistance (?) read

from the Nyquist plot, and A is the contact area of the polymer electrolyte

sample, fixed at 2.56 cm2.

Ionic conductivity for 10 ?m SiO2 filler results in 1.44 × 10-4

S/cm, while 63 ?m SiO2 filler results in 8.1 × 10-5 S/cm.

These results are in good agreement with PMMA?LiCF3SO3?EC?Al2O3

performed in earlier work (Eric-Koh et al., 2021a;

2021b; Sun et al., 2019; Yap et al., 2019;

Sun et al., 2018). Pal et al.

(2018) achieved 3.0 × 10-4 S/cm for PMMA?LiClO4?PC

with 1wt% TiO2. On the other hand, Li et

al. (2021) reported 1.13 mS/cm for PMMA gel polymer electrolyte added

with 150 nm SiO2. Incorporating a small filler size can reduce the

porous structure of host polymer, creating new pathways for the transportation

of Li+ ions in the polymer matrix. Since it is easier for Li+

ions to hop from one coordination site to the other, this faster movement of

ions leads to the achievement of higher ionic conductivity.

Figure 2 Nyquist plot for

polymer electrolytes with 10 ?m (?) and 63 ?m (?)

3.2. XRD

Analysis

Composite polymer electrolytes are

prepared by using SiO2 as the filler. For this, two filler grain

sizes used in this study are 10 µm and 63 µm, to study the relationship between

filler size and crystallite size in the polymer matrix. Figure 3 shows the XRD

patterns of these two types of filler sizes.

Figure 3 XRD patterns of PMMA-based composite polymer

electrolytes with different SiO2 filler grain sizes

Although both filler sizes used are in the

micron range, however, it is obvious that 63 µm SiO2 gives

diffraction peaks with higher intensity than 10 µm SiO2. This

conveys preliminary information on the existence of severe dissimilarities in

the overall crystalline structure of these polymer electrolyte systems.

Particle size is calculated by using Debye-Scherrer (Sengwa

et al., 2014; Scherrer, 1918) equation, as shown in Equation (2).

Where K

is set constant at 0.9, ? =1.54 Å for X-ray wavelength with CuK?

radiation, ? is the particle

broadening, and ? (degree)is the position at which the peak broadening occurs.

Polymer electrolyte film broadening (?sample) arising at each peak position

is measured at full-width-half-maximum (FWHM) by the X-PERT PRO instrument (Saadiah et al., 2019). The effect of peak

broadening due to the measurement instrument is also considered to further

improve the accuracy of this calculation. The values of particle size (d) calculated from each diffraction peak

are tabulated in Table 1.

Table 1 Particle size for SiO2 at

different diffraction peaks.

|

Filler Size |

Peak Position |

FWHM ?sample |

Particle size, d |

|

10 µm |

15.5508 |

0.0687 |

2.0379 |

|

17.4953 |

0.0275 |

5.1176 |

|

|

20.8451 |

0.0034 |

49.2916 |

|

|

26.6432 |

0.0051 |

29.7576 |

|

|

36.5805 |

0.0034 |

51.0578 |

|

|

39.4965 |

0.0034 |

51.5077 |

|

|

42.5067 |

0.0051 |

31.0701 |

|

|

45.8233 |

0.0051 |

31.4371 |

|

|

50.2149 |

0.0043 |

39.7798 |

|

|

54.9635 |

0.0206 |

7.6162 |

|

|

59.977 |

0.0051 |

33.4327 |

|

|

68.2631 |

0.0084 |

20.5308 |

|

|

63 µm |

16.2544 |

0.0240 |

5.8436 |

|

18.2752 |

0.0103 |

13.8670 |

|

|

21.0543 |

0.0043 |

36.6378 |

|

|

26.7728 |

0.0052 |

29.7656 |

|

|

36.5843 |

0.0051 |

30.4980 |

|

|

39.5177 |

0.0034 |

51.5111 |

|

|

42.4822 |

0.0051 |

31.0675 |

|

|

45.7933 |

0.0051 |

31.4336 |

|

|

50.1325 |

0.0034 |

53.5188 |

|

|

54.86660 |

0.0051 |

32.6257 |

|

|

59.9179 |

0.0034 |

55.9548 |

|

|

68.0040 |

0.0103 |

16.5147 |

Figure 4 Linear

regression plots of improved Scherrer equation for SiO2 filler size

(a) 10 µm and (b) 63 µm.

Based

on Table 1, averaging crystallite size is analysed using a linear regression

method. Equation (2) is first rearranged, followed by natural logarithm to

derive an equation resembling linear line expression, as shown in Equation (3).

The

regression equation obtained for each SiO2 filler size is included

in Figure 4. For the smaller size at 10 µm, the intercept value at the vertical

axis is The average crystallite value is computed as

. Subsequently, the same method can also

calculate the average crystallite value for 63 µm grain size. As such, the

resultant average crystallite value is

. At this point, it is observed that a larger

filler grain size leads to the formation of a larger particle size, which hinders

the movement of Li+ ions, thus reducing the resultant ionic

conductivity. Nonetheless, the average crystallite size obtained in this work

is in close agreement with those reported in the literature, which resides in

the nano- size range (Gupta

et al., 2020;

Kumar et al., 2019; Lim et al., 2017).

PMMA-LiCF3SO3-EC-SiO2 polymer

electrolytes are prepared by using 10 ?m and 63 ?m SiO2 filler,

respectively. Particle size in a polymer electrolyte system is calculated by

using the Debye-Scherrer equation. The peak broadening effect caused by

instrument is considered in the equation for a more accurate estimation of

particle size. Particle size for polymer

electrolytes with 10 ?m and 63 ?m SiO2 are estimated at 16.8094 nm

and 27. 2087 nm respectively. Thus, it can be concluded that a smaller filler

size results in a smaller particle size in the polymer electrolyte system. This

reduces the porosity structure of polymer electrolytes and promotes the

movement of Li+ ions, thus leading to higher ionic conductivity.

This

project is funded by IR Fund 2021 (MMUI/210019).

Al-Muntaser, A.A., Abdelghany, A.M., Abdelrazek, E.M., Elshahawy,

A.G., 2020. Enhancement of Optical and Electrical Properties of PVC/PMMA Blend

Films Doped with Li4Ti5O12 Nanoparticles. Journal

of Materials Research and Technology, Volume 9(1), pp. 789–797

Arya, A., Sharma, A.L., 2017. Polymer Electrolytes for Lithium Ion

Batteries: A Critical Study. Ionics, Volume 23(3), pp. 497–540

Dhatarwal, P., Choudhary, S., Sengwa, R.J., 2018. Electrochemical

Performance of Li+-Ion Conducting Solid Polymer Electrolytes Based on

PEO–PMMA Blend Matrix Incorporated with Various Inorganic Nanoparticles for the

Lithium Ion Batteries. Composites Communications, Volume 10, pp. 11–17

Eric-Koh, R.W., Sun, C.C., Yap, Y.L., Cheang, P.L., You, A.H., 2021a.

Measurement of Lithium Transference Number in PMMA Solid Polymer Electrolytes

Doped with Micron-sized Fillers. Journal of Mechanical Engineering and

Technology, Volume 13(2), pp. 30–42

Eric-Koh, R.W., Sun, C.C., Yap, Y.L., Cheang, P.L., You, A.H., 2021b.

Investigation of Lithium Transference Number in PMMA Composite Polymer

Electrolytes Using Monte Carlo (MC) Simulation and Recurrence Relation. Journal

of Electrochemical Science and Technology, Volume 12(2), pp. 217–224

Gupta, A., Jain, A., Tripathi, S.K., 2020. Structural and

Electrochemical Studies of Bromide Derived Ionic Liquid-Based Gel Polymer

Electrolyte for Energy Storage Application. Journal of Energy Storage,

Volume 32, p. 101723

Jodi, H., Zulfia, A., Deswita, E.K., Kartini, E., 2016. A Study of

the Structural and Electrochemical Properties of Li3PO4-MMT-PVDF

Composites for Solid Electrolytes. International Journal of Technology,

Volume 7(8), pp. 1291–1300

Kumar, M.S., Rao, M.C., 2019. Effect of Al2O3

on Structural and Dielectric Properties of PVP-CH3COONa Based Solid

Polymer Electrolyte Films for Energy Storage Devices. Heliyon, Volume

5(10), p. e02727

Li, Z., Heng, D., Hu, L, Yan, G., Xin, L.,

Yankun, C., Yan, W., 2021. Size Effect of Nano SiO2 Microspheres in

PMMA Gel Polymer Electrolyte and Its Application in All-Solid-State

Electrochromic Devices. Acta Materiae Compositae Sinica, Volume 38(5),

pp. 1446–1454

Lim, C.S., Teoh, K.H, Ng, H.M., Liew, C.W., Ramesh, S., 2017. Ionic

Conductivity Enhancement Studies of Composite Polymer Electrolyte Based on Poly

(Vinyl Alcohol)-Lithium Perchlorate-Titanium Oxide. Advanced Materials

Letters, Volume 8(4), pp. 465–471

Mallaiah, Y., Jeedi, V.R., Swarnalatha, R., Raju, A., Reddy, S.N.,

Chary, A.S., 2021. Impact Of Polymer Blending on Ionic Conduction Mechanism and

Dielectric Properties of Sodium Based PEO-Pvdf Solid Polymer Electrolyte

Systems. Journal of Physics and Chemistry of Solids, Volume 155, p. 110096

Mauger, A., Armand, M., Julien, C.M., Zaghib, K., 2017. Challenges and

Issues Facing Lithium Metal for Solid State Rechargeable Batteries. Journal

of Power Sources, Volume 353, pp. 333–342

Pal, P., Ghosh, A., 2018. Influence of TiO2

Nano-Particles on Charge Carrier Transport and Cell Performance of PMMA-LiclO4

Based Nano-Composite Electrolytes. Electrochimica Acta, Volume 260, pp.

157–167

Priyono, B., Syahrial, A.Z., Nugraha, M.R., Sepala, D., Faizah, A.S.,

2019. Optimizing the Performance of Microcomposites Li4Ti5O12/Sn

with Sn and Li4ti5O12/Sn@C Anode and Activated Carbon Content Variables for

Lithium-ion Batteries. International Journal of Technology, Volume

10(5), pp. 1010–1023

Saadiah, M.A., Zhang, D., Nagao, Y., Muzakir, S.K., Samsudin, A.S.,

2019. Reducing Crystallinity on Thin Film Based CMC/PVA Hybrid Polymer for

Application as a Host in Polymer Electrolytes. Journal of Non-Crystalline

Solids, Volume 511, pp. 201–211

Scherrer, P., 1918. Estimation of The Size and Internal Structure of

Colloidal Particles by Means of Röntgen. Nachrichten von der Gesellschaft

der Wissenschaften zu Göttingen, Volume 2, pp. 96–100

Sengwa, R.J., Dhatarwal, P., Choudhary, S., 2014. Role of Preparation

Methods on The Structural and Dielectric Properties of Plasticized Polymer

Blend Electrolytes: Correlation Between Ionic Conductivity and Dielectric

Parameters. Electrochimica Acta, Volume 142, pp. 359–370

Sun, C.C., You, A.H., Teo, L.L., 2019. Characterizations of

PMMA-Based Polymer Electrolyte Membranes with Al2O3. Journal

of Polymer Engineering, Volume 39(7), pp. 612–619

Sun, C.C., You, A.H., Teo, L.L., Thong, L.W., 2018. Effect of Al2O3

in Poly (Methyl Methacrylate) Composite Polymer Electrolytes. In: AIP

Conference Proceedings, Volume 1958 (1), p. 020028

Tang, S., Guo, W., Fu, Y., 2021. Advances in Composite Polymer

Electrolytes for Lithium Batteries and Beyond. Advanced Energy Materials,

Volume 11(2), p. 2000802

Tominaga, Y., Endo, M., 2013. Ion-Conductive Properties of

Polyether-Based Composite Electrolytes Filled with Mesoporous Silica, Alumina and

Titania. Electrochimica Acta, Volume 113, pp. 361–365

Tran, H.K., Wu, Y.S., Chien, W.C., Wu, S.H., Jose, R., Lue, S.J.,

Yang, C. C., 2020. Composite Polymer Electrolytes Based on PVA/PAN for

All-Solid-State Lithium Metal Batteries Operated at Room Temperature. ACS

Applied Energy Materials, Volume 3(11), pp. 11024–11035

Xu, Z., Yang, T., Chu, X., Su, H., Wang, Z., Chen, N., Yang, W.,

2020. Strong Lewis Acid–Base and Weak Hydrogen Bond Synergistically Enhancing

Ionic Conductivity of Poly (Ethylene Oxide) @ SiO2 Electrolytes for a

High Rate Capability Li-Metal Battery. ACS Applied Materials &

Interfaces, Volume 12(9), pp. 10341–10349

Yap, Y.L., You, A.H., Teo, L.L., 2019. Preparation and

Characterization Studies of PMMA–PEO-Blend Solid Polymer Electrolytes with SiO2

Filler and Plasticizer for Lithium Ion Battery. Ionics, Volume 25(7),

pp. 3087–3098

Zhang, X., Fergus, J.W. 2018. Solid Electrolytes for Lithium

Batteries. International Journal of Technology, Volume 9(6), pp.

1178–1186

Zhou, D., Shanmukaraj, D., Tkacheva, A., Armand, M., Wang, G.,

2019. Polymer Electrolytes for Lithium-Based Batteries: Advances and Prospects.

Chem, Volume 5(9), pp. 2326–2352