The Evaluation of Displacement Ductility of Low Confinement Spun Pile to Pile Cap Connections

Corresponding email: mulia@eng.ui.ac.id

Published at : 28 Jun 2023

Volume : IJtech

Vol 14, No 4 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i4.5889

Orientilize, M., Prakoso, W.A., Lase, Y., Purnomo, S., Sumartono, I.H., Agustin, W., 2023. The Evaluation of Displacement Ductility of Low Confinement Spun Pile to Pile Cap Connections . International Journal of Technology. Volume 14(4), pp. 823-832

| Mulia Orientilize | Civil Engineering Department, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, 16424, Indonesia |

| Widjojo A Prakoso | Civil Engineering Department, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, 16424, Indonesia |

| Yuskar Lase | Civil Engineering Department, Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, 16424, Indonesia |

| Sidiq Purnomo | PT Wijaya Karya Beton Tbk, WIKA Tower 1 FL. 2-5, Jl. D.I. Panjaitan Kav. 9-10 Jakarta, 13340, Indonesia |

| Ignatius Harry Sumartono | PT Wijaya Karya Beton Tbk, WIKA Tower 1 FL. 2-5, Jl. D.I. Panjaitan Kav. 9-10 Jakarta, 13340, Indonesia |

| Winda Agustin | PT Wijaya Karya Beton Tbk, WIKA Tower 1 FL. 2-5, Jl. D.I. Panjaitan Kav. 9-10 Jakarta, 13340, Indonesia |

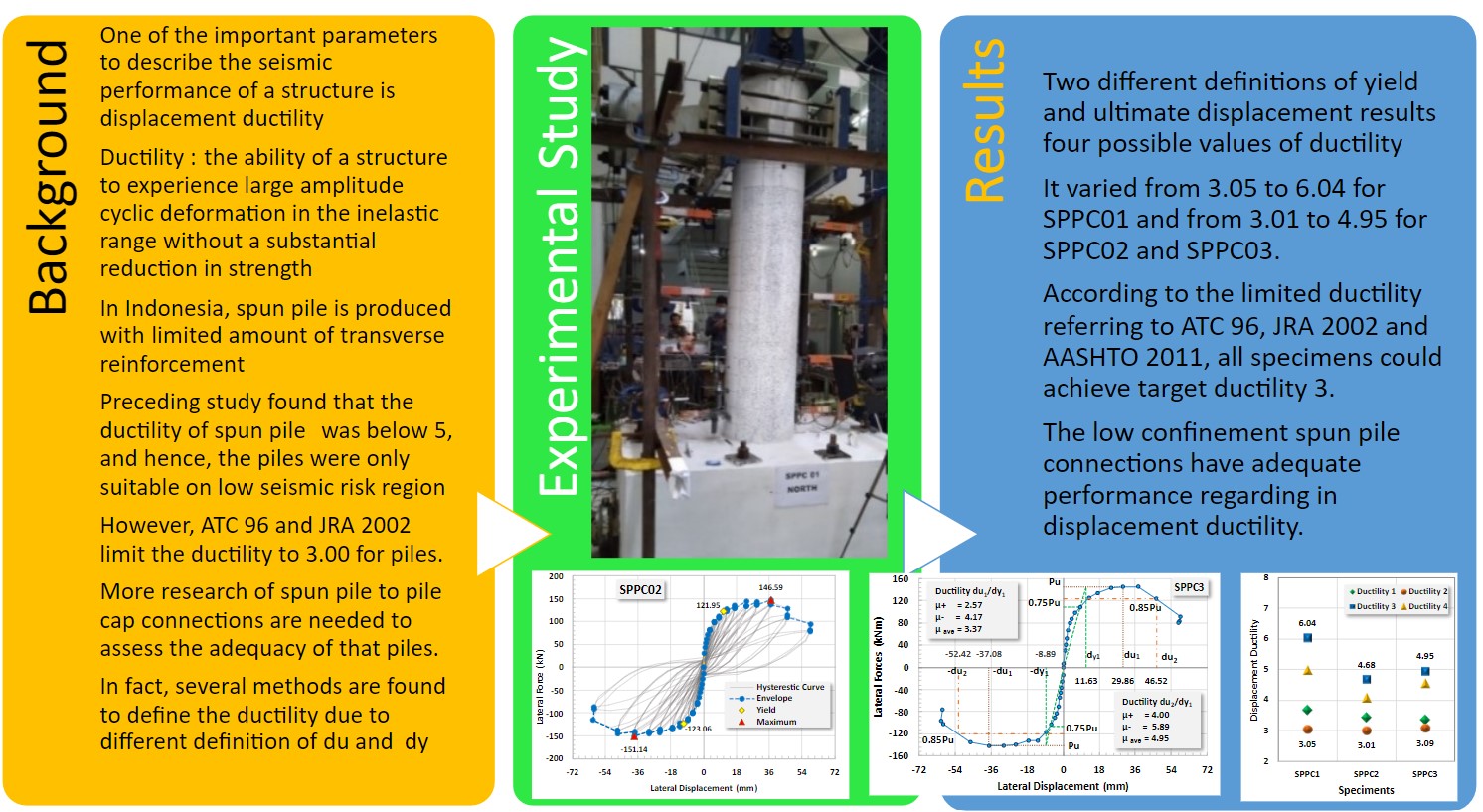

Experimental study was carried out on three low

confinement spun piles to pile cap connections.

The detail followed the typically fixed connection in Indonesia.

Reinforced concrete was filled to the spun pile to strengthen the connection region,

except SPPC01. Different concrete types were used, shrinkage and non-shrinkage

for SPPC02 and SPPC03, respectively. SPPC02 and SPPC03 could reach the targeted

drift of 3.5% whereas SPPC01 was stopped at a drift of 2.75%. There was no

shear failure detected during the test. The connection behaved as a fixed

connection indicated by the fracture failure of the prestressed bars near the

connection region. Analysis of the test results focused on displacement

ductility. Two definitions of yield and ultimate displacement were employed to

seek the possible ductility values. It varied from 3.05 to 6.04 for SPPC01 and

from 3.01 to 4.95 for SPPC02 and SPPC03. The non-shrinkage concrete did not

affect the strength of the connection but slightly improved the post-peak

behavior. The ductility is 6–12% higher than spun piles with ordinary

concrete. According to the limited

ductility referring to ATC 96, JRA 2002, and AASHTO 2011, all specimens could

achieve target ductility 3. Hence, it can be concluded that the low confinement

spun pile connections performed well in displacement ductility.

Displacement ductility; Experimental study; Low-confinement; Spun pile

The

connection of pile to pile cap in the foundation plays an important role to

transfer the force from the upper to the bottom structure and vice versa. This part is critical since the change of

area, stress, and stiffness occurs suddenly

NEHRP

Several methods have been

proposed to estimate the displacement ductility of the pile. Curvature

ductility is one of the main factors affecting it. To be ductile, the pile section should meet

the required curvature ductility demand

The spun pile is a precast prestressed

pile that is massively used in bridges and wharves. Experimental and numerical

studies of this pile and its connection to the pile cap have been performed by

many researchers. In China, the study

was performed on different connection details

In Indonesia, the spun pile is produced

with a limited amount of transverse reinforcement and below the minimum

requirement in accordance with

Indonesia should move forward to PBD

for the bottom structure since based on the recent seismic risk map, where the

ground acceleration tends to increase

Three

full-scale spun pile connections were tested until failure to evaluate their

seismic performance. To represent the real condition, the pile was picked from

the stocking yard. A length of 220mm was

cut from the middle part which has less confinement according to the research

objective. The spiral pitch is 120mm

where the volumetric ratio is 0,113%.

To clarify the quantity of transverse reinforcement, the amount is

compared to three equations and presented in Table 1. As can be seen, the

equations result in different required quantities. The revised equation

proposed by

Table 1 The requirement of transverse reinforcement

2.1. The Specimens

Figure

1 shows the DED of the specimens. The

450mm in diameter spun pile was chosen with a wall thickness of 80mm. The spun

pile was made of 57Mpa of concrete strength, reinforced by a 10@7.1mm PC bar,

and confined by a spiral of 4mm in diameter. The connection between the spun

pile and the pile cap was designed based on the common practice in Indonesia.

The spun pile was embedded in the pile cap at a depth of 100mm. The required

embedment length of the rebar was 620mm. To reduce the depth of the pile cap,

the length was 500mm straight and the 200mm was bent 30 degrees as shown in

Figure 1. SPPC01 was an empty spun pile, whereas SPPC02 and SPPC03 were filled

with concrete and reinforced by 6D19 as shown in Figure 2.

Figure

1 The connection details (a) SPPC01; (b) SPPC02/3

and (c) the test set-up

SPPC02

represents the typical connection where for ease in construction the concrete

infill was cast together with the pile cap. Additional rebar of 6D19 was added

and embedded into the pile cap to improve the connection strength. Shrinkage of the concrete infill was a

concern and therefore in the preceding research, non-shrink concrete was used

Figure

2 The cross-section of

SPPC01 and SPPC02

The pile cap was cast

by 30Mpa of concrete strength and the actual strength of 28 days age was 34MPa.

Due to the pandemic situation, the experimental test was delayed and the

concrete age of SPPC03 was based on a 56-day test which was 36.5 MPa. The strength

of steel employed in the experiment is presented in Table 1.

2.2. The Test Set-Up

Figure

1 shows the test setup. The specimen was attached to a strong floor and tied

with 10 anchoring bolts. It was loaded vertically as 500kN which was equal to

0.1fc’Ag. A

reverse cyclic lateral load was applied after the vertical force was fully

applied. The horizontal loading

protocol followed the ACI 437-07, where the test was conducted until a targeted

drift of 3.5% was achieved or until the strength of the specimen was dropped by

more than 25%. Seven and two transducers were employed to measure horizontal

and vertical displacement, respectively. The concrete strain gauge was put on

the spun pile and pile cap which was located 100mm from the connection. The strain

of the reinforcement bar was measured through 6 strain gauges which were placed

next to the connection in the loading plane. Meanwhile, four strain gauges were

attached to the prestressed wire at a similar location.

3.1. The Hysteretic Curves

SPPC02 and SPPC03 were tested until they

reached a drift of 3.5% whereas SPPC01 was stopped at a drift of 2.75% since

its strength drop more than 50%. Figure 3 shows the hysteretic curve and the

envelope of all specimens. As can be

seen, the presence of the reinforced concrete infill in SPPC02 and SPPC03

changes the performance of the spun pile connection significantly. It improves

strength and energy absorption. The envelope of SPPC02 and SPPC03 are very closed which

indicates that different concrete type does not affect the strength of the

connection.

3.2. The Crack Pattern

The crack pattern on the spun pile is

shown in Figure 4. There was a slight shear-flexural crack was detected at

several places. The crack initiated from the tensile face and propagated to the

center of the spun pile. The majority of the crack was a result of flexural

failure. The crack propagated until 650mm from the connection region of SPPC02

and almost 800mm of SPPC03. Meanwhile, the last crack of SPPC01 was detected at

depth of 400mm above the connection.

Light

damage was found on the pile cap of SPPC01. Concrete crushing of the pile at

the connection region was observed when drift reach 2%. A similar failure mode occurred on SPPC02 and

SPPC03. The first crack of the spun pile was at a drift of 0.35% and 0.5%. The

pile cap suffered moderate damage where a crack was detected on its surface

with a depth of less than 100mm. It started from the connection region and then

it propagated to a radius of 150 to 180mm from the pile face.

Figure 4 The Crack

Patterns (a)SPPC01, (b) SPPC02, (c) SPPC03

The

prestressed wires of all specimens suffered a fracture. Nine bars of SPPC01 were found fractured and

one was necking. Meanwhile, seven bars

of SPPC02 dan SPPC03 were fractured and one was found necking in SPPC03. The locations were +20-30mm from the

pile cap surface. It indicated that the

anchorage length of the PC wires was sufficient to prevent the slip of the

connection. The amount of reinforcement in the pile cap was also adequate since

the concrete spalling only occurred on the concrete cover.

Figure 5 Determination

of ductilities: a)SPPC01; b)SPPC02; c)SPPC03 and d) the summary of ductility values

3.3. The Ductility

Displacement

ductility is determined as a ratio of ultimate displacement (du) to

yield displacement (dy). For reinforced concrete structures, dy

is not well defined due to the nonlinearity of two materials, i.e., concrete

and steel. The are two common methods to define yield displacement. Firstly, It

is based on an equivalent area of the bilinear elastoplastic curve and it is

constructed where the energy absorption is equal

The

ultimate deformation has several assumptions.

The two most definitions used by a researcher are the displacement

corresponding to the peak load

Figure 6 The

ratio of dissipated energy (Ed) to input energy (Ei): a)SPPC01, b)SPPC02,

c)SPPC03

To

confirm the occurrence of yielding, the dissipated energy was observed. It is

the energy absorbed by the structure during the inelastic stage which is

indicated by the area of the hysteresis curve of each cycle. The input energy

is the area below the force-displacement curve. Figure 6 presents the ratio of

the dissipated energy (Ed) to the input energy (Ei). The significant yield is

shown as the minimum ratio where the amount of dissipated energy starts to

increase rapidly. The data appears scattered for SPPC01 and a drift of 0.35% is

the lowest point before it escalated. The significant yield occurred at a drift

of 0.75% for SPPC02 and SPPC03. The comparisons of possible occurrences of

yielding are presented in Table 4. Dy1

has a closer value to the significant yield than dy2 for

SPPC01. Meanwhile, dy2 estimates the occurrence of significant yield

better than dy1 for SPPC02 and SPPC03.

The

summary of ductility values based on two different yields and ultimate

displacements is presented in Figure 5.

The range of ductility values of SPPC01 is relatively large about 3

scales. Meanwhile, SPPC02 and SPPC03

have ductility from 3.01 to 4.95. Referring to the meaning of ductility as the

capacity of the structure to deform up to the post-peak stage without

significant loss of strength, hence, du2 is the precise definition.

The results are named ductility #3 and #4.

The difference in value is lesser from 0.5 to 1 as follows: 4.98 and

6.04 for SPPC01, 4.07 and 4.68 for SPPC02, and 4.55 to 4.95 for SPPC03. Based

on significant yielding, ductility #5 was determined and the results were 6.10,

3.78, and 3.66 for SPPC01, SPPC02, and SPPC03, respectively. The values are lower than ductility #3 and #4

for SPPC02 and SPPC03.

Table 4 The comparison of possible yield displacement (dy)

|

Specimens |

dy1 (mm) |

dy2 (mm) |

Significant Yielding

(sy) (mm) |

Ductility #5 (du2/sy) | ||

|

Push |

Pull |

Push |

Pull | |||

|

SPPC01 |

6.12 |

-6.67 |

7.59 |

-7.88 |

6.3 (0.35%) |

6.10 |

|

SPPC02 |

10.83 |

-10.95 |

11.75 |

-13.30 |

13.5 (0.75%) |

3.78 |

|

SPPC03 |

11.63 |

-8.89 |

12.13 |

-9.96 |

13.5 (0.75%) |

3.66 |

SPPC01 seems more ductile than the other specimens. This finding is cross-checked with the dissipated energy since the structure is expected to be ductile to absorb the earthquake energy. The comparison of the cumulative dissipated energy is shown in Figure 8. Poor energy dissipation is noticed on SPPC01 where the cumulative energy dissipation at drift 2.75% is 34% lower than SPPC02.

The experimental study showed that the spun pile to pile cap

connections behaved as fixed restrained with no slip detected. The failure mode

was crushing of the concrete and almost all prestressed wires fractured at the

connection region. Flexural crack dominated the crack pattern.

The

displacement at post-peak load with the strength reduction of 15% is

appropriate to determine ultimate displacement du. Meanwhile, the

secant stiffness approach is preferred to define yield displacement dy.

Four variation values of ductility were obtained based on two definitions of du

and dy. The range values are considered large which are 3.05 to 6.04

for SPPC01, 3.09 to 4.95 for SPPC02, and 3.01 to 4.68 for SPPC03. All specimens

could reach the ductility limit, of three, referring to ATC 96 and JRA 2002.

Hence, the low confinement spun pile showed adequate performance.

SPPC01, the empty spun pile, showed

poor energy dissipation than SPPC02 and SPPC03 which reveals from the

cumulative dissipated energy and the wider crack distribution on the spun pile.

Non-shrinkage concrete strength affects the post-peak behavior of SPPC03 where

its strength drops more faintly than SPPC02. It has slightly better

displacement ductility when post-peak is defined as the maximum displacement.

The

research was supported by the Indonesia Ministry of Research and Universitas

Indonesia through Applied Research, contract number NKB-254/UN2.RST/

HKP.05.00/2021 and PT Wijaya Karya Beton, Tbk.

ACI Committee, 2019. ACI 318-19: Building Code Requirements for

Structural Concrete and Commentary. American Concrete Institute: Farmington

Hills, MI, USA AASHTO, 2011. AASHTO Guide Specifications for LRFD Seismic Bridge

Design. AASHTO. 2nd ed Antonius., P., Harprastanti, P., 2019. Experimental Study of the

Flexural Strength and Ductility of Post Burned Steel Fiber RC Beams. International

Journal of Technology, Volume 10(2), pp. 428–437 Bang, J.W., Oh, S.J., Lee, S.S., Kim, Y.Y., 2016. Pile-cap

Connection Behavior Dependent on the Connecting Method between PHC pile and

Footing. Journal of the Korea Institute for Structural Maintenance and

Inspection, Volume 20(3), pp. 25–32 Budek, A., Benzoni, G., 2009. Obtaining Ductile Performance from

Precast, Prestressed Concrete Piles. PCI Journal, Volume 54(3), pp.

64–80 Budek-Schmeisser, A., Benzoni, G., 2008. Rational Seismic Design

of Precast, Prestressed Concrete Piles. PCI Journal, Volume 53(5), pp.

40–53 Chai, Y.H., Hutchinson, T.C., 2002. Flexural Strength and Ductility

of Extended Pile-Shafts. II: Experimental Study. Journal of Structural

Engineering, Volume 128(5), pp. 595–602 Chiou, J.S., Tsai, Y.C., Chen, C.H., 2011. Simple Estimation for

Ductility Capacity of a Fixedhead Pile in Cohesive Soils. Canadian Geotechnical

Journal, Volume 48(10), pp. 1449–1460 Fanous, A., Sritharan, S., Suleiman, M., Huang, J.W., Arulmoli,

A.K., 2010. Minimum Spiral Reinforcement Requirements and Lateral Displacement

Limits for Prestressed Concrete Piles in High Seismic Regions. Reports and

White Papers, pp. 1–164 FEMA P-750, 2009. NEHRP Recommended Seismic Provisions.

Federal Emergency Management Agency Guo, Z., He, W., Bai, X., Chen, Y.F., 2017. Seismic Performance of

Pile-Cap Connections of Prestressed High-Strength Concrete Pile with Different

Details. Structural Engineering International, Volume 27(4), pp. 546–557 Irawan, C., Djamaluddin, R., Raka, I.G.P., Suprobo, P., 2018.

Confinement Behavior of Spun Pile Using Low Amount of Spiral Reinforcement - An

Experimental Study. International Journal on Advanced Science, Engineering

and Information Technology, Volume 8(2), pp. 501–507 Irawan, C., Raka, I.G.P., Djamaluddin, R., Suprobo, P., 2017. Ductility

and SEismic Performance od Spun Pile Under Constant Axial and Reverse Flexural

Loading. International Symposium on Concrete Technology (ISCT 2017), pp.

35–44 Ling, J.H., Lim, Y.T., Jusli, E., 2023. Methods to Determine Ductility of

Structural Members: A Review. Journal of the Civil Engineering Forum, Volume

9(2), pp. 181–194 Pramono, S., Prakoso, W.A., Rohadi, S., Karnawati, D., Permana,

D., Prayitno, B.S., Rudyanto, A., Sadly, M., Sakti, A.P., Octantyo, A.P., 2020.

Investigation of Ground Motion and Local Site Characteristics of the 2018

Lombok Earthquake Sequence. International Journal of Technology.

Volume 11(4), pp. 743–753 Wang, T., Yang, Z., Zhao, H., Wang, W., 2014. Seismic Performance

of Prestressed High Strength Concrete Pile to Pile Cap Connections. Advances

in Structural Engineering, Volume 17(9), pp. 1329–1342 Yang, Z., Li, G., Nan, B., 2020. Study on Seismic Performance of

Improved High-Strength Concrete Pipe-Pile Cap Connection. Advances in

Materials Science and Engineering, Volume 2020, pp. 1–22 Yang, Z., Wang, W., 2016. Experimental and Numerical Investigation

on The Behaviour of Prestressed High Strength Concrete Pile-to-Pile Cap

Connections. KSCE Journal of Civil Engineering, Volume 20(5), 1903–1912

Zhang,

X., Niu, S., Yan, J.B., Zhang, S., 2019. Seismic Behaviour of Prestressed

High-Strength Concrete Piles Under Combined Axial Compression and Cyclic

Horizontal Loads. Advances in Structural Engineering, Volume 22(5), pp.

1089–1105