Experimental Study of Linear Profile Modification in Spur Gear Leg

Published at : 17 May 2024

Volume : IJtech

Vol 15, No 3 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i3.5851

Pramono, A.S., Wikarta, A., Mu’iz, F., 2024. Experimental Study of Linear Profile Modification in Spur Gear Leg. International Journal of Technology. Volume 15(3), pp. 665-676

| Agus Sigit Pramono | Department of Mechanical Engineering, Faculty of Industrial Technology and Systems Engineering, Institut Teknologi Sepuluh Nopember, Kampus ITS Keputih-Sukolilo Surabaya 60111, Indonesia |

| Alief Wikarta | Department of Mechanical Engineering, Faculty of Industrial Technology and Systems Engineering, Institut Teknologi Sepuluh Nopember, Kampus ITS Keputih-Sukolilo Surabaya 60111, Indonesia |

| Fakhul Mu’iz | Department of Mechanical Engineering, Faculty of Industrial Technology and Systems Engineering, Institut Teknologi Sepuluh Nopember, Kampus ITS Keputih-Sukolilo Surabaya 60111, Indonesia |

Gears with the involute profile are assumed to be rigid and

good at producing mating gear. They are also deformable and deflectable,

indicating additional space is required to avoid interference from the

unpredictable shaft, misalignment, and dynamic factors. In addition, load and

rotational speed cause frequent mild to severe interference leading to a

significant reduction in its lifespan. This study conducted an experimental

comparison between standard and modification involute gear profiles in a ratio

of 1:2 to reduce interference. It was carried out using 18 pinion teeth with a

72 mm base diameter at three and four levels of torque load and speed. The load

was also mounted a strain gauge on pinion gears to conduct strain measurement

on the gear leg. Finally, it was applied using a mechanical brake measured by a

dynamic torque meter. The experimental test obtained microstrain when the

modified spur gear contacted for 3.04 – 6.67 milliseconds depending on the

rotation speed and torque load. Modification of the linear involute profile

significantly reduced the tooth leg strain at the rate of 5.6% to 13.99%.

Meanwhile, the maximum microstrain reduction of 13.99% occurred at a speed of

1100 rpm and a torque load of 65%.

Interference; Involute profile; Modification profile; Spur gear; Strain reduction

Modern-day mechanical gears are

widely used in transmission systems to transmit torque included in the wave

energy converter (Ariefianto,

Hadiwidodo, and Rahmawati, 2022). Despite

manufacturing new transmission systems with magnetic gears, no physical contact

between materials has been identified (Rahman,

Hassan, and Ihsan, 2022; Niguchi, Hirata and Zaini, 2013). (Li

and Bird, 2018) stated

that these various benefits of mechanical gears prevent the need for

lubrication, high durability, and a high-speed-reduction ratio. Its main

shortcoming includes lower torque density. Therefore, continuous efforts are

carried out to extend the service life and reduce mechanical gear vibrations.

When a backlash is overly narrow, it causes overheating, overload, noise, and

jamming, while a loose one leads to a significant impact load and excessive

vibrations (Dyaneshwar

and Mangrulkar, 2016).

The amount of backlash can be determined by considering various factors. The first factor is based on the module range or diametral pitch, while the second factor involves evaluating the diametral pitch and the centre of the distance axis. A third factor utilizes the second parameter of diametral pitch and line velocity. However, it is often difficult to determine the exact amount of backlash required due to manufacturing imperfections. (Karba et al., 2019).

Planned backlash aims to increase

the distance between the shafts or cut the side of the gear. The study by (Sharma,

Moorthy and Kumar, 2015) used

the finite element method to investigate strain reduction in the spur gear leg.

Unplanned backlash with unpredictable magnitude cause problems involving

various parameters, such as tooth and shaft deflections, load, rotational

speed, bearing clearance, temperature, and lubrication. The concept of a second

factor caused by material stiffness and contact stress was further developed to

address contact stress between non-metal and non-metal (Rahman,

Shoukaku, and Iwai, 2021).

Meanwhile,

(Eritenel

et al., 2003) conducted

a numerical study using the finite element method. The study found that the

fillet radius caused bending deflection, which influenced the base stiffness as

defined by (Joshi

and Karma, 2011),

and this in turn affected the magnitude of the backlash.

(Guo,

Keller, and LaCava, 2012) conducted

a study on the effect of bearing clearance distance on planetary stress. The

study found that increased bearing clearance leads to a higher non-torque

workload. Preliminary studies have been conducted using numerical simulations

and approximation equations to determine the minimum gap width in the

elastohydrodynamic lubrication (EHL) channel (Dowson

and Higginson, 2014; Lubrecht, Venner and Colin, 2009). (Li

and Kahraman, 2011) selected

a similar approach involving the pre-calculation of dynamic tooth strength.

Meanwhile, (Jeon

et al., 2011) designed

the last factor using an inaccurate profile of 0.015 to 0.033 EDM.

This study addressed the

requirement for adequate backlash by implementing a critical profile

modification. Prior research has explored the transformation of the tooth

profile using the modeling and dynamic simulation (Liang,

Zuo, and Feng, 2018),

artificial neural networks (Devendiran

and Manivannan, 2015b),

and genetic algorithms (Devendiran

and Manivannan, 2015a).

One of the critical problems in the industry is determining what to do,

assuming the service life of the gear is shorter than expected. According to

studies, the easiest and most expensive solution is replacing the gear or

modifying its tooth through lead modification processes in the axial direction

to reduce the effect of load concentration due to misalignment. Profile

modification targets tooth deflection due to mechanical loads. Therefore, the

available backlash does not provide free space, which causes low to high

interferences, leading to jamming.

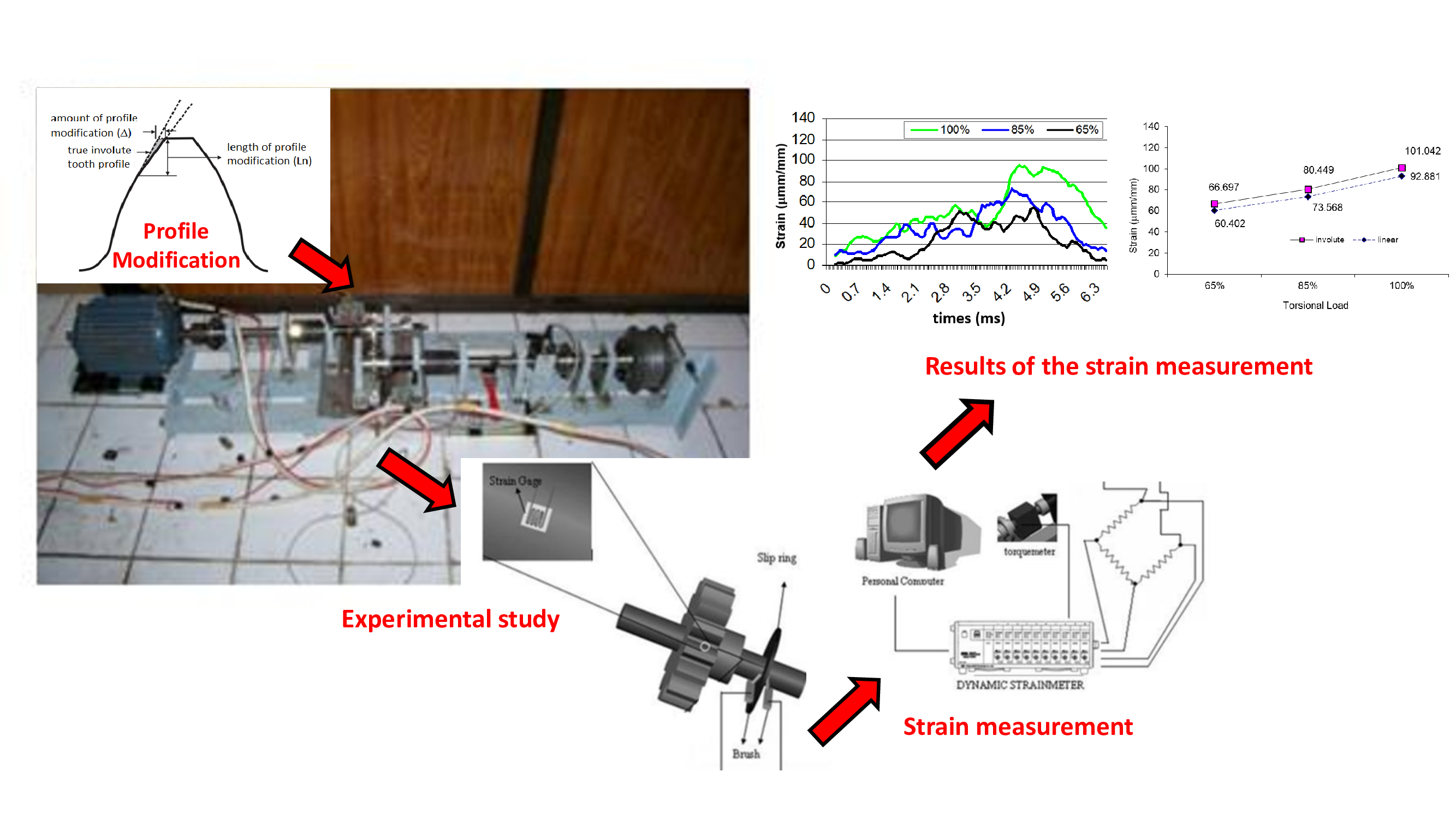

The tooth profile modification on

the gears occurs in the dedendum and addendum areas. Addendum modifications,

also known as profile tips or relief modifications, are more common than

dedendum due to their inability to reduce bending strength. The amount (?) and

length of profile modification (Ln)

are the parameters used to modify the profile tip, as presented in Figure 1.

Amount profile modification is an important parameter determined by the actual

operating conditions. It is estimated by determining the mechanical and thermal

loads deflection and the error profile of the manufacturing process.

This study was conducted using the tooth flexural deflection and contact deformation with a linear tip relief profile (Markovi? and Vrcan, 2016; Buljanovic and Obsieger, 2009). Modifications to the linear tooth profile led to a lower dynamic response compared to the unmodified tooth profile. Furthermore, the modifications involved different gear types, including spur (Ghosh and Chakraborty, 2016; Li et al., 2016), helical (Wu, Wang and Han, 2012), and planetary gears (Bahk and Parker, 2013) studied through finite element modeling and simulation.

Figure

1 Profile of modification parameters

Experimental methods were employed to measure

the stress-strain in the root tooth, including the use of strain gauges (Lisle, Shaw, and

Frazer, 2019) and

photoelasticity (Raptis and

Savaidis, 2018).

The experimental fatigue method was conducted by calculating the cycle and

administering the load in stages (Concli, 2021; Liang,

Zuo, and Feng, 2018).

It is more challenging to take dynamic robot tooth measurements in real-time

because it requires data logger equipment capable of speedily recording dynamic

data and writing the entanglement problem. Most dynamic photoelasticity

measurement methods use a stroboscope to produce quasi-static or momentary

photos (Patil, Patil, and

Nulke, 2018).

Few related studies existed on using a high-speed camera to record real-time

data using transient dynamic photoelasticity measurements. In the symmetric gear tip relief profile, it can not only

reduce the bending stress but also reduce the contact stress (Molnár, Csoban, and Zwierczyk, 2021).

Another way to increase bending strength is to use

asymmetric gears formed from two involute profiles with

different contact angles on the drive and coast sides. Several studies have

been conducted on these gears. For instance, (Pramono and Rizal,

2021) researched the influence of the asymmetric factor to reduce

bending stress, using the contact-angle cosine ratio of the drive and coast

sides as the asymmetric factor, representing the symmetric spur gear. The

greater the asymmetric factor, the higher the contact angle difference and

decreased bending stress. Furthermore, (Mallesh et al.,

2009) studied the effect of profile shift on the bending

stress of asymmetric gears with x values of 0, 0.1, 0.2, 0.3, 0.4, and 0.5. The

results showed that the larger the profile shift, the smaller the bending

stress, applicable to different asymmetric values with contact angles of 20o

to 30o. (Mallesh and VG,

2020) also investigated modeling using the

asymmetric factor and profile shift. The increase in pressure angle on the

drive side leads to a decrease in contact ratio and tooth thickness on the

addendum circle and a rise in pressure angle. The tooth thickness on the

addendum circle decreases for gears with increased profile shifts as the

pressure angle on the drive side rises. Consequently, the bending stress at the

critical section reduces significantly.

(Mo et al.,

2022) compared the analytically obtained

meshing stiffness increased with a rise in asymmetric factors. In addition, the

modification of teeth allows for a smoother transition between single and

double ones.

Besides reducing bending stresses, asymmetric

gears with tip relief can also lead to a decline in contact stresses, as (Karpat and

Ekwaro-Osire, 2008) using Archard's analytical equation. As the amount of tip relief

increases, the wear depth, particularly at the beginning and end of the mesh,

decreases. Similarly, as the number of wear cycles increases, the effect of the

tip relief modi?cation on wear depths decreases slightly.

(Y?lmaz, Dogan, and

Karpat, 2017) proposed the

asymmetric trochoid profile to

decrease maximum bending stress and move the upper critical point. It is

evaluated that effect of rim thickness on bending stress is more significant

for those less than 1.3×module because of higher rim deformations.

Although asymmetric gear has the

advantage of increasing bending and contact strength, it also has the

disadvantage of rotating in only one direction, indicating it cannot be used

for two-way transmission. When the drive side is worn, it must be replaced,

unlike the symmetric gear, which can be reversed. Therefore, further study is

needed to investigate the performance difference between symmetric and

asymmetric gears.

This

experimental study involved a linear comparison between the standard and

modified involute gear profile at a ratio of 1: 2, where the number of pinion

teeth and diameter are 18 and 72 mm.

Strain measurements were taken using a strain gauge mounted on one

pinion tooth, with slip rings used to avoid entangling the cable during

rotation. Load torque was measured using a mechanical brake.

The various experimental stages include making standard tooth profiles

and modifications, designing, manufacturing, and setting up test equipment or

benches. The last experiment tested both the standard and the modified profile

by following procedures, as shown in Figure 2.

Figure 2

Flowchart of experiment procedures for spur gear with profile modification

2.1 Determination of the Number of Pinion Teeth

Involute

gears can be readily generated by rack-type cutters, such as hob. Gear

generation can also be also accomplished with gear-type cutters using a shaper

or planer machine. In the production of standard straight gears, a

small number of teeth can lead to undercutting at the dedendum. The undercut

not only weakens the tooth with a wasp-like waist but also removes some of the

useful involute adjacent to the base circle. To determine the minimum number of

teeth required to avoid undercutting, one can refer to Equation (1) (Michalec et al., 2009).

where :

However, if a smaller number of teeth is desired without undercutting,

standard spur gears may require modifications such as profile shifting, which

is described by Equation (2) (Michalec et al., 2009).

where :

In this study, standard spur

gears without undercutting were used, following Equation (1), and with a

contact angle of 20 degrees, the number of pinion teeth was determined to be

18.

2.2. Profile

Modification

Straight

gears are made of a standard involute surface gear profile and a linear

modified involute, which start at distances of 1 1.8 mm and 1.6 mm,

respectively. The cut at the tip of the tooth is 0.104 mm and 0.091 for the

pinion and gear, respectively, as shown in Figure 3.

Figure 3 Profile of

modification (a) pinion and (b) gear

2.3.

Design and Prototype of Test Bench

A

test device was designed to measure the stress on the tooth root, as shown in Figure

4. The device is powered by a 1500 rpm motor with 1.5 horsepower. A Dynamic

Torquemeter with a maximum torque of 160 Nm is mounted on the motor shaft and

connected to the pinion spur gear shaft. A slip ring is installed near the

pinion spur gear with a strain gauge attached to one of the root teeth. The

slip ring is further connected to a series of bridge stones and a dynamic data

logger linked to a PC. Once the pinion spur gear is

paired with the driven spur gear, slip rings are installed. Finally, a brake

system is installed as a load at the drive shaft's end.

2.4. Determination

of Time for One Contact Gear

Due to the varying rotating speeds, it

is necessary to calculate the time of one contact gear for each rate. It takes

1/8.33 = 0.12 seconds for the motor shaft speed of 500 rpm or 8.33 rps to

completely rotate for 18 teeth. Therefore, one gear contact takes 0.12/18 = 0.0066

seconds or 6,67 milliseconds. The same calculation is carried out for other

speeds, and the results are presented in Table 1.

Table 1 Contact duration on one teeth pair

|

Angular speed |

Contact duration of one teeth pair (ms) | |

|

rpm |

rps | |

|

500 |

8.33 |

6.67 |

|

700 |

11.66 |

4.78 |

|

900 |

15.00 |

3.72 |

|

1100 |

18.33 |

3.04 |

The stain gage mounted on one

of the root teeth is a uniaxial strain gage that follows the bending direction

with microstrain units. Following Hook's law, the bending stress in the elastic

zone can be obtained, where the strain is proportional to the stress with a

constant of proportionality.

The measurement resulting from a strain gauge is shown on a

graph where the abscissa and the ordinate axis represent time and strain,

respectively. Figure 5 shows the pinion with a rotation of 500 rpm. The maximum

strain decreases due to linear modification for all load levels, which reduces

the level of dynamic interference.

Figure 5

The results of the strain measurement on one teeth pair in contact at 500 rpm:

(a) pinion involute, (b) pinion linear

The

data involved maximum strain in facilitating comparison and further analysis. Figure

6 shows that the increase in torsional load raises the strain in the gear leg

for all speeds in standards and modified involute profiles. This is in line

with a theory that increasing the load will enlarge strain on the tooth foot

and raise the tooth deflection, thereby causing interference.

In Figure

7, an increase in rotation at a constant load led to a rise in the strain and

all load levels in accordance with the characteristics of an AC motor using a

speed controller with an inverter. Furthermore, an increase in rotation led to

a rise in the motor shaft and a slight rotation of the AC.

At 500

rpm rotation and 65% load, the profile modification reduced the strain by

9.44%, 8.55%, and 8.08% for 65%, 85%, and 100% loads, respectively. Meanwhile,

at 1100 rpm rotation and 65% load, a maximum strain reduction of 13.99% was

obtained, while at 85% load, it decreased by 11.48%. However, at 100% load, the

strain decreased again to 9.41%, indicating that interference starts with

increased tooth deflection.

Figure 6 Comparison of strain as a function of load at (a) 500 rpm, (b) 700 rpm, (c) 900 rpm, and (d) 1100 rpm

An

evident increase in load leads to a decrease in strain reduction. This is

because the increase in load raises the deflection, thereby increasing the

level of interference. An increase in load raises interference levels in all

rotations by 500, 700, 900, and 1100 rpm, causing strain to decrease.

Other

studies mostly came from simulations since experiments are rarely conducted.

Even though experiments were performed, they did not carry out variations in

loading and rotation. Therefore, the effectiveness of modifying the involute

spur gear in various conditions experienced by the gear pair cannot be

determined.

This study confirms the

findings of (Li

et al., 2016) that modifying the involute

spur gear can reduce impact and noise at the contact point by decreasing the

strain value on the modified pinion gear. This reduction in strain helps to

achieve an appropriate amount of backlash to prevent overheating, noise,

impact, and excessive vibration.

This

study proves that the reduction in strain value can occur in various loading

and rotation conditions. Preliminary studies on tooth profile modification (Dai,

Cooley, and Parker, 2016; Ghosh and Chakraborty, 2016; Bahk and Parker, 2013;

Wu, Wang and Han, 2012) only focused on specific

loading conditions. Therefore, the impact of profile modification is unknown

for various conditions in spur gear pairs.

This dynamic experimental study also has advantages compared

to other studies focused on maximum conditions. The contact between the spur

gears for 3 - 6 ms can be well observed using the measuring instrument.

Furthermore, the measurement results in microstrain can be graphed as shown in

Figure 8. This cannot be found in the photoelasticity experimental method (Raptis and

Savaidis, 2018).

Figure 7 Maximum strain ratio as a

function of speed at (a) 65%, (b) 85%, and (c) 100% load

Figure 8 Reduction of strain between standard and

modified linear profile

In conclusion, several experimental studies determined

the effect of tooth profile modification on standard and linearly modified gear

profiles by comparing and analyzing the results. The reduction in micro-strain

was observed for a duration of 3.04 – 6.67 milliseconds, depending on the

rotation speed and torque load. Modifying the linear involute profile

significantly reduced tooth leg strain, ranging from 5.6% to 13.99%, depending

on the load and speed. The maximum reduction in micro-strain of 13.99% was

achieved at a rate of 1100 rpm and a torque load of 65%, increasing tooth

strength against bending loads. It is important to note that reducing tooth leg

strain is crucial for ensuring the longevity and durability of gears in various

real-world scenarios. Further studies could explore the impact of tooth profile

modification on other gear types and sizes and investigate the effect of

different parameters, such as lubrication, on gear performance. Overall, the

findings of this study have a valuable contribution to understanding modified

gear profiles and their impact on gear strength and durability.

Ariefianto, R.M., Hadiwidodo, Y.S., Rahmawati, S.,

2022. Experimental Study of a Wave Energy Converter Using a Unidirectional

Cascaded Gear System in a Short-Wave Period. International Journal of

Technology, Volume 13(2), pp. 321–331

Bahk,

C.-J., Parker, R.G., 2013. Analytical Investigation of Tooth Profile

Modification Effects on Planetary Gear Dynamics. Mechanism and Machine

Theory, Volume 70, pp. 298–319

Buljanovic,

K., Obsieger, B., 2009. Influence of Tip Relief Profile Modification of Spur

Involute Gears on Stresses. International Journal Advanced Engineering,

3, pp. 149–158

Concli,

F., 2021. Tooth Root Bending Strength of Gears: Dimensional Effect for Small

Gears Having a Module Below 5 mm. Applied Sciences, Volume 11(5), p.

2416

Dai,

X., Cooley, C.G., Parker, R.G., 2016. Dynamic Tooth Root Strains and

Experimental Correlations in Spur Gear Pairs. Mechanism and Machine Theory,

Volume 101, pp. 60–74

Devendiran,

S., Manivannan, K., 2015a. An Intelligent Gear Fault Diagnosis Model Based on

EMD and Evolutionary Algorithms. International Journal of Mechanical &

Mechatronics Engineering IJMME-IJENS, Volume 15(1), p. 10

Devendiran, S., Manivannan, K., 2015b. Vibration

Signal Based Multi-fault Diagnosis of Gears using Roughset Integrated PCA and

Neural Networks. International Journal of Mechanical & Mechatronics

Engineering IJMME-IJENS, Volume 15(01), p. 11

Dowson,

D., Higginson, G.R., 2014. Elasto-Hydrodynamic Lubrication: International

Series on Materials Science and Technology. Elsevier

Dyaneshwar,

S., Mangrulkar, K.S., 2016. Effect Of Backlash on Bending Stresses in Spur

Gears. International Journal of Scientific Development and Research,

Volume 7, pp. 349–354

Eritenel,

T., Houser, D.R., Vijayakar, S.M., Casella, J.M., 2003. Effect of Tooth

Deflection and Corner Contact on Backside Separation (Backlash) of Gear Pairs. In:

9th International Power Transmission and Gearing Conference, Parts A

and B. ASME 2003 International Design Engineering Technical Conferences and

Computers and Information in Engineering Conference. Volume 4, pp. 103–110

Ghosh,

S.S., Chakraborty, G., 2016. On Optimal Tooth Profile Modification for

Reduction Of Vibration And Noise In Spur Gear Pairs. Mechanism and Machine

Theory, Volume 105, pp. 145–163

Guo,

Y., Keller, J., LaCava, W., 2012. Combined Effects of Gravity, Bending Moment,

Bearing Clearance, and Input Torque on Wind Turbine Planetary Gear Load

Sharing: Preprint. In: American Gear Manufacturers Association;

(AGMA) Fall Technical Meeting, Dearborn, Michigan: National Renewable

Energy Lab. (NREL), Golden, CO (United States). Available online at:

https://www.osti.gov/biblio/1050766, Accessed on September 3, 2020

Jeon,

E.C., Lee, S.Y., Song, H.B., Chun, J.D., Kim, S.Y., 2011. Study for the

Verification of the Tooth Profile Accuracy of the Automatic Gear Design

Program. Global Journal of Technology and Optimization, Volume 2(1), pp.

97–103

Joshi, A., Karma, V.K., 2011. Effect on

Strength of Involute Spur Gear by Changing the Fillet Radius Using FEA. International

Journal Of Scientific & Engineering Research, Volume 2(9), p. 5.

Karba,

B., Y?ld?r?m, N., Erdo?an, F., Vardar, M., 2019. A Study on Prediction &

Validation Of Meshing Gear Pair Backlash Under Various Manufacturing And

Assembly Errors. In: MATEC Web of Conferences. Volume 287, p.

07001

Karpat, F., Ekwaro-Osire, S., 2008. Influence

Of Tip Relief Modification On The Wear Of Spur Gears With Asymmetric Teeth. Tribology

Transactions, Volume 51(5), pp. 581–588

Li,

K., Bird, J.Z., 2018. A Review Of The Volumetric Torque Density Of Rotary

Magnetic Gear Designs. In: 2018 XIII International Conference on

Electrical Machines (ICEM). IEEE, pp. 2016–2022

Li,

S., Kahraman, A., 2011. Influence of Dynamic Behaviour on Elastohydrodynamic

Lubrication of Spur Gears. In: Proceedings of the Institution of

Mechanical Engineers, Part J: Journal of Engineering Tribology, Volume 225(8),

pp. 740–753

Li,

X.Y., Wang, N.N., Lv, Y.G., Zeng, Q.L., Hidenori, K., 2016. Tooth Profile

Modification and Simulation Analysis of Involute Spur Gear. International

Journal of Simulation Modelling, Volume 15(4), pp. 649–662

Liang,

X., Zuo, M.J., Feng, Z., 2018. Dynamic Modeling of Gearbox Faults: A Review. Mechanical

Systems and Signal Processing, Volume 98, pp. 852–876

Lisle,

T.J., Shaw, B.A. Frazer, R.C., 2019. Internal Spur Gear Root Bending Stress: A

Comparison of ISO 6336: 1996, ISO 6336: 2006, VDI 2737: 2005, AGMA, ANSYS

Finite Element Analysis and Strain Gauge Techniques. In: Proceedings of

the Institution of Mechanical Engineers, Part C: Journal of Mechanical

Engineering Science, Volume 233(5), pp. 1713–1720

Lubrecht,

A.A., Venner, C.H., Colin, F., 2009. Film Thickness Calculation in

Elasto-Hydrodynamic Lubricated Line and Elliptical Contacts: The Dowson,

Higginson, Hamrock Contribution. In: Proceedings of the Institution of

Mechanical Engineers. Part J: Journal of Engineering Tribology, Volume

223(3), pp. 511–515

Mallesh,

G., Math, V.B., Ashwij, P.S.D.R., Shanbhag, R., 2009. Effect of Tooth Profile

Modification in Asymmetric Spur Gear Tooth Bending Stress by Finite Element

Analysis. In: 14th National Conference on Machines and Mechanisms

(NaCoMM09), NIT, Durgapur, India, pp. 17–18

Mallesh,

G., VG, P.K., 2020. Optimization of Asymmetric Spur Gear Tooth. International

Research Journal of Engineering and Technology (IRJET), Volume 7, pp.

363–370

Markovi?,

K., Vrcan, Ž., 2016. Influence of Tip Relief Profile Modification on Involute

Spur Gear Stress. Transactions of FAMENA, Volume 40(2), pp. 59–70

Michalec,

G., Buchsbaum, F., Tanaka, H., Shuett, L., Chiaramonte, J., Sondej, S.,

Hasranah, M., Quinteros, L.C., Epstein, M., 2009. Elements of Metric Gear

Technology. Stock Drive Products & Sterling Instrument. Available

online at: https://gearkade.

com/wpcontent/uploads/2019/08/Elements-of-Metric-Gear-Technology.Pdf, Accessed

on February 11, 2022

Mo,

S., Li, Y., Luo, B., Wang, L., Bao, H., Cen, G., Huang, Y., 2022. Research on

The Meshing Characteristics of Asymmetric Gears Considering The Tooth Profile

Deviation’, Mechanism and Machine Theory, Volume 175, p. 104926

Molnár,

J., Csoban, A., Zwierczyk, P.T., 2021. Analysis of Tip Relief Profiles for

Involute Spur Gears. ECMS, Volume 35(1), pp. 147–151

Niguchi, N., Hirata, K., Zaini, A., 2013. Electromagnetic

Vibration Analysis and Measurement of a Magnetic Gear. IEEJ Journal of

Industry Applications, Volume 2(6), pp. 261–268

Patil,

P.J., Patil, A.A., Nulke, S.S., 2018. Dynamic Analysis of Helical Gear To

Evaluate Bending Stress At Root Of Tooth Using Photoelastic Coating And Finite

Element Method. International Journal of Advance Research in Science and

Engineering, Volume 7(3), pp. 133–147

Pramono,

A.S., Rizal, M.Z., 2021. Influence Of Asymmetric Factor on Spur Gears To

Dynamic Bending Stress. In IOP Conference Series: Materials Science and

Engineering, Volume 1034(1), p. 012010

Rahman, A., Hassan, N., Ihsan, S.I., 2022. Fuzzy

Logic Controlled Two Speed Electromagnetic Gearbox for Electric Vehicle. International

Journal of Technology, Volume 13(2), pp. 297–309

Rahman,

J., Shoukaku, Y., Iwai, T., 2021. An Experimental Study of the Effect of Load

and Moving Speed on Free Rotating Rubber Contact using Fluorescence Microscopy.

International Journal of Technology, Volume 12(4), pp. 781–790

Raptis, K.G., Savaidis, A.A., 2018. Experimental

Investigation of Spur Gear Strength Using Photoelasticity. Procedia

Structural Integrity, Volume 10, pp. 33–40

Sharma,

A., Moorthy, H., Kumar, P., 2015. Stress Variation Due To Change In Centre

Distance Of Spur Gears Using Finite Element Analysis. In: International

Conference on Computer Aided Engineering (CAE), pp. 119–124

Wu,

Y., Wang, J., Han, Q., 2012. Static/Dynamic Contact FEA and Experimental Study for

Tooth Profile Modification of Helical Gears. Journal of Mechanical Science

and Technology, Volume 26(5), pp. 1409–1417

Y?lmaz,

T.G., Dogan, O., Karpat, F., 2017. Stress Analysis of Thin Rimmed Spur Gears with

Asymmetric Trochoid. In: Proceedings of the 3rd World Congress on Mechanical,

Chemical, and Material Engineering (MCM'17), p. 132