Characterization of Palm Biodiesel Deposit on The Locomotive Engine Fuel Filters: Composition, Physical, Chemical Properties

Corresponding email: ihwan.haryono@brin.go.id

Published at : 24 Dec 2024

Volume : IJtech

Vol 15, No 6 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i6.5781

Haryono, I., Ma'ruf, M., Setiapraja, H., Fajar, R., Mansur, D., 2024. Characterization of Palm Biodiesel Deposit on The Locomotive Engine Fuel Filters: Composition, Physical, Chemical Properties . International Journal of Technology. Volume 15(6), pp. 1873-1885

| Ihwan Haryono | Research Center for Energy Conversion and Conservation, National Research and Innovation Agency, KST B.J Habibie Serpong, South Tangerang, Banten 15310-Indonesia |

| Muhammad Ma'ruf | Research Center for Energy Conversion and Conservation, National Research and Innovation Agency, KST B.J Habibie Serpong, South Tangerang, Banten 15310-Indonesia |

| Hari Setiapraja | Research Center for Energy Conversion and Conservation, National Research and Innovation Agency, KST B.J Habibie Serpong, South Tangerang, Banten 15310-Indonesia |

| Rizqon Fajar | Research Center for Transportation Technology, National Research and Innovation Agency, KST B.J Habibie Serpong, South Tangerang, Banten 15310-Indonesia |

| Dieni Mansur | Research Center for Chemistry, National Research and Innovation Agency, KST B.J Habibie Serpong, South Tangerang, Banten 15310-Indonesia |

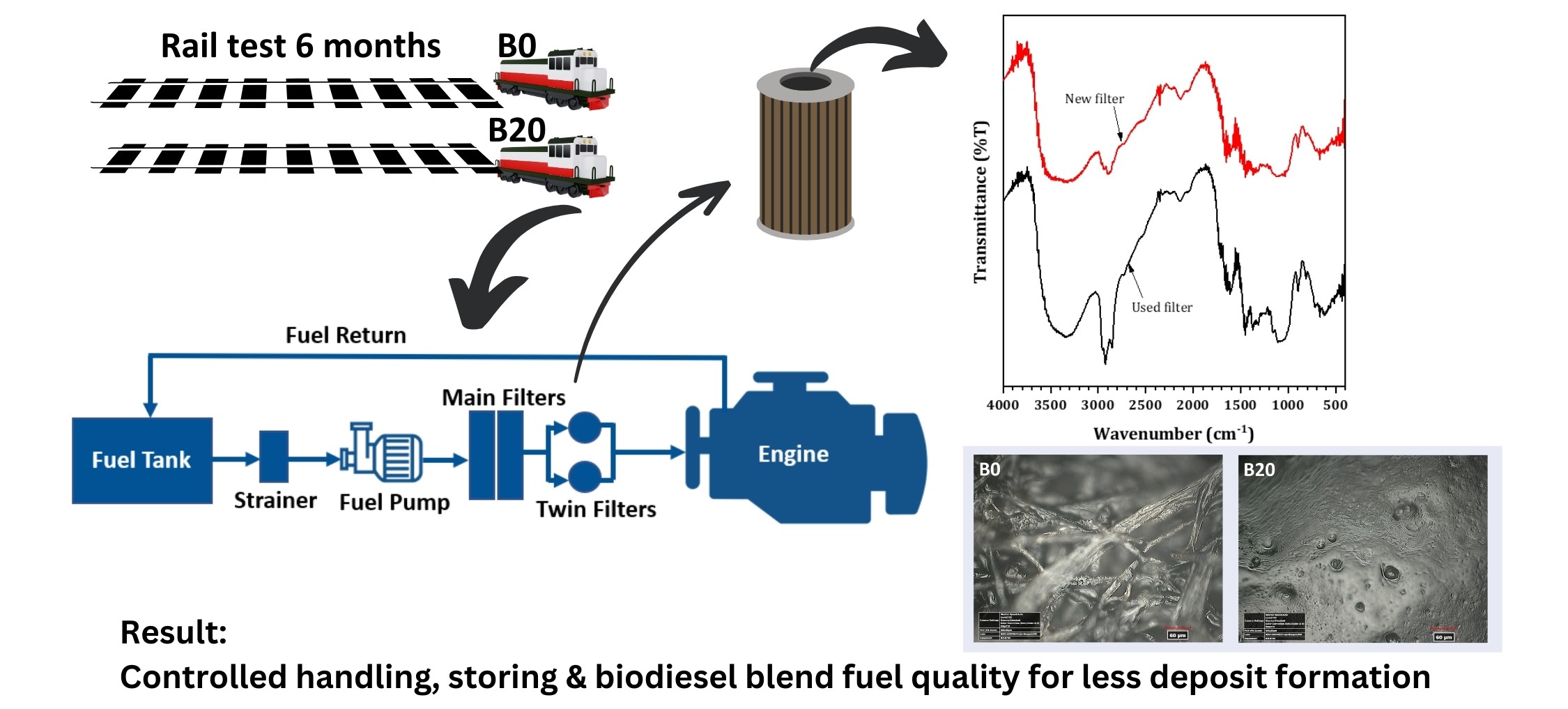

High ratio biodiesel blend fuel has become mandatory for all sectors including road and non-road vehicles since 2016. All stakeholders of biofuel in Indonesia had conducted a specified investigation through road tests 40,000 km to evaluate the high biodiesel effect on performance, emissions, and engine components. An improvement in fuel properties of biodiesel FAME has also been stated in the new fuel standard. Moreover, the recommendation for proper high biodiesel ratio handling and storage also socialized to all stakeholders. However, shorter fuel filter mileage and fuel degradation for long storing still remain issues for the implementation of biodiesel in Indonesia. An assessment of biodiesel in a locomotive in Indonesia was conducted through a rail test conducted for 6 months with a coal train in Sumatera Island with a blend ratio of 20% by volume (B20) and pure diesel fuel (B0) as a reference. The purpose of this rail test was to investigate the effect of B20 on various factors at railway application. This paper is presented a detailed analysis of the deposits formed in the used main and used twin filters of the locomotive for one maintenance period. An analysis of morphology, elemental analysis, and its physical and chemical properties was done by using a digital microscope, thermogravimetric analysis (TGA), Fourier transform infrared spectroscopy (FT-IR), and gas chromatography-mass spectrometry (GC-MS), respectively. An analysis showed that B20 had more deposits on the main filter compared with B0, while it had fewer deposits on the twin filter. Deposit in both of main and twin filters for B20 was identified mostly from hydrocarbons and fatty acid methyl esters. Analysis results also recommended that the fuel filter mileage of B20 was still possible to be prolonged with the current fuel filter standard by considering to deposit formation for both B0 and B20 still under tolerance level.

B20; FAME; Fuel filter; Locomotive; Palm biodiesel

Biodiesel is a promising alternative fuel to support the implementation of sustainable fuels and reduction of exhaust gas emissions from transportation sector in Indonesia (Wirawan et al., 2024; Tjahjono et al., 2021). Several improvements have been applied to the automotive sector, including the specified development of a fuel system for biodiesel, appropriate handling and storage of biodiesel, and limitations on the amount of water and mono-glycerides permitted biodiesel. Those improvements are required to meet specified engine performance and emission from various biodiesel production processes and feedstock resources (Zhang et al., 2022; Said et al., 2018; Susila, Rachimoellah, and Sutantra, 2011). Many studies have reported the effects of using biodiesel fuel in automotive applications with various engine technologies and biodiesel resources (Lee and Cho, 2024; Reksowardojo et al., 2023; Mokhtar et al., 2023; Pandey, Mishra, and Verma, 2022; Kumbhar et al., 2021). Nevertheless, a few studies have reported the utilization of high-ratio biodiesel with a blending volume above 10% in the locomotive applications. An implementation of biodiesel on a locomotive had similar results to automotive, which could raise an issue in the intake system and fuel filter clogging (Stead et al., 2019). Skinner et al. (2007) reported that the utilization of biodiesel could decrease fuel filter mileage and reduce fuel economy. At the same time, it has an advantage on low exhaust gas emission except for NOx without any significant reduction in engine power. Utilization of high-ratio biodiesel fuels could also affect to accelerate the replacement time of fuel filters due to their faster deposit formation (Heck, Mohammad, and Abi-Akar, n.d.; Komariah et al., 2018; Graver, Frey, and Hu, 2016; Ge et al., 2009).

Deposit in

the engine could be in various forms, including carbonaceous, polymeric,

carboxylate salts, and inorganic salts. Further, a typical deposit in an engine

fuelled with biodiesel was a sticky deposit due to its saturated fatty acid

contents. High temperature and pressure of the advanced injection system would

lead to building deposits at the injector due to cavitation in the injector and

fuel thermal stress. While storage sediment, biodiesel, lubricant adulteration,

metal catalyst, water as well as bio-contaminant were also the sources of

deposit for both in injector and fuel filter (Barker et al., 2020). Deposit formation in the

injector formed due to hydrocarbon decomposition and condensation as a result

of the unburn product of low volatility, high viscosity, and density of

biodiesel. Carbonaceous deposits could occur in injectors at a temperature

higher than 350°C (Hoang, Le, and Pham, 2020; Hoang and Le, 2019). Deposit

formation in biodiesel fuel is also affected by its long chains, low ignition

point, and high boiling point, resulting in a higher maximum evaporation rate

point (MEP) compared to diesel fuel (Suryantoro et al., 2016). Moreover, Hoang also reported

that the degradation of lubricating oil would also

influence deposit formation in the combustion chamber (Hoang and Pham, 2018). While the deposit in the fuel

filter was in a sticky form which was mainly influenced by biodiesel

contaminants such as monoglyceride, water, and metal content which occur at a

temperature below its pour point. These types of deposits would be easily removed

as the temperature increase. However, if there is some solid deposit from

diesel fuel accumulated in the void space of the fuel filter, then it is mixed

with a sticky deposit of biodiesel then, which would result in fuel filter

clogging (Paryanto et al., 2022). Csontos et al.

(2020; 2019) evaluated deposit characteristics by using Gas

Chromatography-Mass Spectrometry (GC-MS), X-ray Fluorescence Spectroscopy-Energy

Dispersive X-ray Spectrometry (XRF-EDX), Fourier-Transform Infrared

Spectroscopy (FTIR), and Thermogravimetric (TGA). They identified that

carboxylic acid (CA) and unreacted CA, oxidized polymer compounds, glycerol,

sterol, other impurities, and contaminants could be from biodiesel degradation

and its production process (Csontos

et al., 2020; 2019). Meanwhile, Barker et al. (2009) have reported that carbon with C16-C18

was the main component of the injector deposit (Barker et al., 2009). However, some studies also have

reported that the utilization of biodiesel fuel would not have a significant

difference in fuel filter mileage compared with pure fossil diesel fuel (Petiteaux and Monsallier, 2019;

Nelson, 2012). Lammert,

Barnitt, and McCormick (2009) have recognized unsuitable cold flow properties of

biodiesel for implementation in low-temperature conditions during the winter

season.

In a previous study, a used fuel filter of B20 from one

period of fuel filter changing was analyzed with uncontrolled properties of

B20, locomotives, and trips. It found that the B20 fuel filter had shorter

mileage (Ma’ruf

and Haryono, 2020).

Furthermore, an evaluation with rail test B20 was conducted on a

coal train in Sumatera Island to evaluate the effect of B20 on the locomotive

in the more controllable testing environment, including fuel, locomotive, and

trip. Specified locomotives with controlled B20 properties were prepared for

this evaluation during its six months rail test. This paper reports

specifically on the characteristic of a used fuel filter diesel locomotive for

3 months fuelled with B20 and pure diesel fuel. This rail test has been used as

a reference to improve the biodiesel production process, the application of

proper handling and storing of B20, and the development of engine components,

especially fuel filters. Thus, the target for a longer lifetime of biodiesel

fuel filters with high concentrations can be achieved with the use of diesel

oil (B0).

Deposit formation in fuel filters is influenced by fuel impurities

and contaminants and fuel flow rate. In this rail test, fuel properties were

controlled with specified fuel sources, handling, and storing. Periodic

sampling and analyzing of tested fuel were conducted during the rail test to

ensure the fuel properties meet the requirements stated by the Directorate

General of Oil and Gas of Indonesia. However, a contaminant from the

surrounding environment during the rail test, such as coal dust, could not be

controlled. Here, the period analysis of tested fuels showed a deviation of

less than 5%. The fuel flow rate, which is indicated by the mode of

operation of the locomotive, was controlled by a constant trip with the same

locomotive. Here, the trainload represented by carried coal could not also be

set in the same amount for each trip. Nevertheless, the trainload for every

trip was recorded to analyze the deviation of load. Furthermore, a source of

error could also be possible during the sampling process, preparation, and

analysis of the samples.

2.1. Materials

A rail

test was conducted using two types of fuels: a biodiesel blend with a ratio of

20% by volume (B20) and industrial diesel fuel available in the Indonesian

market (B0). Table 1 shows the fuel properties for both B0 and B20. In this

study, the fuel properties shown in Table 1 were tested using the specified

ASTM methods, except for oxidation stability, which was measured according to

EN 15751 standard. B20 exhibited better properties in terms of cetane number,

density, flash point, sulfur content, distillation, and lubricity compared to

B0, as shown in Table 1. However, B20 had some disadvantages, such as higher

water content and monoglyceride levels, which could lead to deposit formation

in the fuel filter.

2. Testing Methods and Analysis

An analysis of the deposit and its contents of the fuel

filter was done for the used main and twin filters of the coal train fuelled

with B20 and B0. Two trains were run at the same time for 6 months, and

periodic maintenance was at 3 months. Here, the sampling of used fuel filterss

was at fuel filter changing on 3 months based on a recommendation from the

locomotive manufacturer. In this study,

used main and twin filter deposits were identified for their morphology,

elemental analysis, and chemical and physical analysis by using a Hirox

microscope with type KH-8700, thermogravimetric (TGA) with differential

thermogravimetric (DTG), gas chromatography-mass spectrometry (GC-MS) type 6890

and Fourier-transform infrared spectroscopy (FTIR) Shimadzu–IR Prestige 21,

respectively. Here, a filter size of 1 cm2 was soaked in 10ml of

acetone, chloroform dichloromethane (DCM), and n-hexane as organic solvents

before GC-MS analysis. The purposes of using various solvents were to evaluate

and determine the effectivity of solvent on dissolving precipitate. A Whatman microfiber filter paper

with a diameter of 47 mm and pore of 0.7 µm was utilized to filter precipitate

matter in solvent to avoid small solid particles entering the GC-MS column.

2.3. Diesel Locomotive Coal Train

A rail test was conducted with a locomotive from Electro-Motive Diesel (EMD) Model GT 38 AC. The locomotive has three stages of fuel filtration, including a strainer, main filter, and twin filter. A strainer is installed to filter contaminants with sizes >10 microns and water. While the main filter and twin filter was intended to filter particle with a size of 5-10 micron and 3-4 microns, respectively. Figure 1 shows the fuel filtration system for the EMD locomotive for both fuelled with B20 and B0.

Figure 1

Schematic diagram of fuel system in EMD locomotive

Morphology and deposit content was evaluated

on the main and twin fuel filter of the locomotive fueled with B20 after 3

months of use. Further, an evaluation of the fuel filter with B0 fuel had also

been done with B0 as a reference condition. Here, deposit evaluation on the

strainer was not conducted due to fewer deposits found as it just filtered

coarse bulk particles such as rocks or gavel for both locomotives with B20 and

B0.

3.1. Morphology and Thickness of Deposit

Figure 2 shows an evaluation of morphology and thickness of deposit on used main filters with B20 and B0 fuel after 3 months by using a 3D digital microscope at a magnification of 500 times and 100 times, respectively. The used main filter for B20 was fully covered by deposit so that the fuel fiber could not be recognized, while the fiber and pores of the used main filter with B0 were still clearly observable. An evaluation of deposit thickness on the used main filter showed that B20 was higher compared with B0, with an average of 822 µm and 699 µm, respectively. Moreover, it is found that the deposit characteristic of B20 was soft so that B20 was still possible to flow through the used main filter with less resistance. A measurement of differential pressure also showed that the pressure difference between the upstream and downstream of the filter did not change significantly. Therefore, it could be the reason for similar power of locomotive after 3 months with B20 (EBTKE, 2018).

Figure 2 Main filter condition after 3 months of usage: (a) B0; and (b) B20

Visual inspection of deposit on the used twin filter showed that fibers were still clearly visible for both B20 and B0 as shown in Figure 3. However, the granule deposit size of B20 was bigger compared with B0, which covers the used twin filter surface uniformly. Figure 3 also shows the thickness of the deposit at the used twin filter fueled with B20 and B0. Measurement results showed that B20 and B0 had an average thickness of 601 µm and 621 µm, respectively, as shown in Figure 3. The lower deposit thickness of B20 compared with B0 could be considered due to most of the contaminants B20 was filtered on the main filter resulted in less filtered deposit in twin filters. Blend fuel of FAME biodiesel is characterized by solid-formed deposit and the wet flexible waxy precipitate, which resulted from impurities of diesel fuel and FAME. Moreover, contaminants of blend fuel could also be from thermal oxidation and metal-catalyzed oxidation of high-temperature recirculation fuel. In our previous investigation on used locomotive fuel filters, we identified some elements contained in the deposit of the used filters, either organics or un-organics. An analysis of three samples of a used locomotive, water separator, and generator fuel filter has found metal elements such as Al, Si, S, and Ca. An accumulated combination of those solid and wet waxy deposits would result in suddenly blocked fuel filter (Paryanto et al., 2022; Ma’ruf and Haryono, 2020; Wadumesthrige et al., 2010).

Figure 3

Twin filter condition after used for 3 months: (a) B0; and (b) B20

3.2. Physical and chemical properties of the filter

Figure 4 Spectrum FTIR of B20 fuel

Based on the spectrum of FTIR, as shown

in Figure 4, the peaks on a new filter generally also appeared on the used filter.

However, several new peaks appeared on the used filter, such as at wave numbers

1259 and 1232 cm-1, which were the C-O-C group of ester, probably

derived from biodiesel. Furthermore, wave numbers of 626 and 468 cm1

were the naphthalene group, and 609 cm-1 was SO2 group

derived from petrodiesel fuel.

The filtered impurities after using B20 fuel originated from biodiesel and petrodiesel. One of the efforts to improve the quality of biodiesel blends can be done by reducing the content of impurities in B0, which implies minimizing the interaction in the biodiesel blend. The used filter was also analyzed by Thermogravimetric (TG) analysis to understand its thermal properties compared with the new filter. TG analysis was conducted at N2 conditions with a heating rate of 10°C /min from room temperature to 600°C. Figure 5 shows TG or weight loss and derivative thermogravimetry (DTG) curves of the filters.

Figure 5 TG and DTG curves of the used

filter (a) and new filter (b)

3.3.

Composition of deposit on the filters

The filter used was analyzed with an

elemental analyzer to determine the percentage of carbon, hydrogen, and oxygen

in the deposited materials. As well as FTIR analysis, a new filter was also

used for comparison because the elements in the filter material were detected.

Table 3 shows the elemental analysis results. Carbon [C] and hydrogen [H]

contents in the used filter increased compared to the new one by 20.4% and 3%,

respectively, caused by fuel or engine crust passing through the filter. The

nitrogen [N] content was minimal and can be neglected as a trace element.

Meanwhile, the oxygen [O] content in the used filter was lesser than in the new

one because of the high added carbon from trapped fuel, while the O value was

calculated based on the difference between the percentages of C, H, and N. The

value of detected O in the used filter was derived from the filter material,

fuels, or sulfur oxide. The existence of sulfur compounds on the used filter

was confirmed by FTIR analysis at peak 609 cm-1 (Table 1) because

the elemental analyzer could only detect C, H, and N.

Table 3 Analysis of used and new filters

|

Element

[wt. %] |

Used filter |

New

filter |

|

Carbon

|

66.0 |

45.6 |

|

Hydrogen

|

9.3 |

6.4 |

|

Nitrogen

|

0.5 |

0.8 |

|

Oxygen* |

24.2 |

47.2 |

*) calculated

by 100% - (C+H+N)

The deposited substance on the main and twin filters with B20

or B0 fuels was identified by GCMS. Among solvents used for diluted chemicals

on the B0 fuel filter, chloroform appears to have a better solvent than the

others (acetone, dichloromethane, and n-hexane) due to more chemicals

identified, as shown in Figure 6. Based on the identified compounds, the

chemicals trapped on the used filter of B0 were hydrocarbons ranging from C12 -

C27, which were dominated by pentadecane, 2,6,10,14-tetramethyl- (C19H40).

Alkane hydrocarbon compounds with carbon number C17 are in a solid form at

20°C and were naturally trapped on the filter, leading to a blockage. The

presence of C12-C16 compounds in Figure 6 can be attributed to the lack of

pretreatment of the filter before soaking it in the organic solvent. As a

results, the C12-C16 compounds remained on the filter even at 20°C.

Additionally, naphthalene compounds caused blockage due to their high melting

point and solid form at room temperature. These compounds may have been formed

through the aromatization of straight-chain alkanes (Venkataraman and Eser,

2008).

Figure 6 Identified

chemicals collected by chloroform solvent from the used filter after passing B0

fuel

Chloroform was a more effective solvent

in the used filter that passed through B0. Similarly, in the used filter that

passed through B20, many chemical compounds were also dissolved using

chloroform as the solvent. The identified chemicals on the used filter with B20

fuels using chloroform solvent can be seen in Figure 7. The identified

chemicals were alkane hydrocarbons and fatty acid methyl ester, mainly

Hexadecanoic acid, methyl ester (C17H34O2),

and 9-Octadecenoic acid, methyl ester, (E) - (C19H36O2).

The identified hydrocarbon and fatty

acid methyl ester compounds were constituent chemicals of petrodiesel oil and

palm biodiesel, respectively. Chemical compounds such as Methyl tetradecanoate

and Tridecanoic acid 12-methyl-, methyl esters were derived from fatty acid C14

(myristic acid) that solid phase at room temperature. Likewise, Hexadecanoic

acid, methyl ester (C17H34O2), and Methyl

stearate (C19H38O2) were derived from C16:0

(palmitic acid) and C18:0 (stearic acid) fatty acids, respectively, also in

solid form at room temperature. The presence of these chemicals in a fuel caused filter blockage.

Figure 7 GC-MS

analysis of compounds collected by chloroform solvent from the used filter

after passing B20 fuel

The study on deposit analysis of used fuel filters

showed that B20 had higher deposit content in the main filter while less

deposit was formed in the twin filter compared with B0. An evaluation of 3

months of usage showed deposit filled almost all surfaces of the main filter,

while the coverage of the deposit in the twin filter was not as much as in the

main filter with visible porosity and filter fibers. Furthermore, the used

filter of rail locomotive fuelled by B20 identified various deposit compounds

which contained alkane hydrocarbon compounds with carbon number C17 and fatty

acid methyl esters C15 - C19. However, deposit formation on both B0 and B20 was

at a tolerance level so that it did not require faster changing. This rail test

also showed that controlled handling, storing and quality of B20 would result

in less formed deposits in fuel filters.

This study

was supported by the Indonesia Palm Oil Plantation Management Fund. The authors acknowledge the Ministry of

Energy and Mineral Resources of Indonesia, Indonesia Railways Company (PT KAI),

the State oil and natural gas mining company of Indonesia (PT PERTAMINA), the

Indonesia biofuel company association, and all members of laboratory for

Thermodynamics, Engine, and Propulsion that contributed to this study.

| Filename | Description |

|---|---|

| R2-ME-5781-20221208171014.jpg | Figure 1 |

| R2-ME-5781-20221208171050.jpg | Figure 2 |

| R2-ME-5781-20221208171105.jpg | Figure 3 |

| R2-ME-5781-20221208171127.jpg | Figure 4 |

| R2-ME-5781-20221208171152.jpg | Figure 5a |

| R2-ME-5781-20221208171226.jpg | Figure 5b |

| R2-ME-5781-20221208171255.jpg | Figure 6 |

| R2-ME-5781-20221208171326.jpg | Figure 7 |

Barker, J., Reid, J., Wilmot, E.,

Mulqueen, S., Smith,

S.A., Scurr, D., Snape, C., Kersting, R., Gauld, R., Mulvey, R., 2020. Investigations

of Diesel Injector Deposits Characterization and Testing (No.

2020-01-2094). SAE Technical Paper. https://doi.org/10.4271/2020-01-2094

Barker, J., Richards, P., Goodwin, M.,

Wooler, J., 2009. Influence of High Injection Pressure on Diesel Fuel

Stability: A Study of Resultant Deposits. SAE International Journal of Fuels

and Lubricants, Volume 2(1), pp. 877–884.

https://doi.org/10.4271/2009-01-1877

Cardeño, F., Lapuerta, M., Rios, L., Agudelo,

J.R., 2020. Reconsideration of Regulated Contamination Limits to Improve

Filterability of Biodiesel and Blends with Diesel Fuels. Renewable Energy,

Volume 159. pp. 1243–1251, https://doi.org/10.1016/j.renene.2020.06.079

Csontos, B., Alim, R., Bernemyr, H., Hittig,

H., Pach, M., 2019. Contaminants Affecting the Formation of Soft Particles

in Bio-Based Diesel Fuels during Degradation (No. 2019-01-0016). SAE

Technical Paper. https://doi.org/10.4271/2019-01-0016

Csontos, B., Bernemyr, H., Erlandsson, A.,

Forsberg, O., Pach, M., Hittig, H., 2020. Characterization of Deposits

Collected from Plugged Fuel Filters. SAE International Journal of Advances

and Current Practices in Mobility, Volume 2(2), pp. 672–680, https://doi.org/10.4271/2019-24-0140

Directorate General of EBTKE (EBTKE),

2018. Report on the Study and Rail Test for the Use of Biodiesel 20% (B20)

at PT Kereta Api Indonesia (Persero). The Directorate General of New

Renewable Energy and Energy Conservation, The Ministry of Energy and Mineral

Resources

ELTahry, O., Salehi, F.M., Morina, A., Ferrari, L., Farooq, U., Forsberg, C., 2022. Chemical

Analysis of Deposits Separated from Blocked Fuel Filters. International Journal of Fuels and Lubricants, Volume 15(1), pp. 29–41, https://doi.org/10.4271/04-15-01-0002

Ge, H., Scharffbillig, J., Ahlberg, C.,

Clark, E., 2009. A Biodiesel Blend Handling Guide. A Publication of the:

Minnesota Biodiesel Technical Cold Weather Issues. Team Handling Subcommittee.

Minnesota Departement of Agriculture, Available online at https://www.dieselplace.com/, Accessed on January 25, 2021

Graver, B.M., Frey, H.C., Hu, J., 2016.

Effect of Biodiesel Fuels on Real-World Emissions of Passenger Locomotives. Environmental

Science & Technology, Volume 50(21), pp. 12030–12039. https://doi.org/10.1021/acs.est.6b03567

Heck, D.A., Mohammad,

A., Abi-Akar, H., (n.d.). A 2,000,000 Mile Evaluation of the Performance

and Operational Impacts of B20 Biodiesel Usage in A Long-Haul Trucking Company.

Iowa Central Community College, Fort dodge, Iowa, 50501 (D.A.H); and

Caterpillar Inc., Mossville, IL, 61552 (A.M., H.A-A.), Available

online at https://ifl.iowacentral.edu/assets/reports/2_MMH_FINAL_MANUSCRIPT.pdf, Accessed on January 25, 2021

Hoang, A.T., Le, A.T., 2019. Trilateral Correlation of Spray

Characteristics, Combustion Parameters, and Deposit Formation in The Injector

Hole of A Diesel Engine Running on Preheated Jatropha Oil and Fossil Diesel

Fuel. Biofuel Research Journal, Volume 21, pp. 909–919. https://doi.org/10.18331/BRJ2019.6.1.2

Hoang, A.T., Le, A.T., Pham, V.V., 2019. A Core Correlation of Spray Characteristics,

Deposit Formation, and Combustion of a High-Speed Diesel Engine Fueled with

Jatropha Oil and Diesel Fuel. Fuel, Volume 244, pp. 159–175. https://doi.org/10.1016/j.fuel.2019.02.009

Hoang, A.T., Pham, V.V., 2018.

A Study of Emission Characteristic, Deposits, and Lubrication Oil Degradation

of A Diesel Engine Running on Preheated Vegetable Oil and Diesel Oil. Energy

Sources, Part A: Recovery, Utilization, and Environmental Effects, Volume

41(5), pp. 611–625. https://doi.org/10.1080/15567036.2018.1520344

Komariah, L.N., Hadiah, F., Aprianjaya, F.,

Nevriadi, F., 2018. Biodiesel Effects on Fuel Filter; Assessment of Clogging

Characteristics. Journal of Physics:

Conference Series, Volume 1095(1),

p. 012017. https://doi.org/10.1088/1742-6596/1095/1/012017

Kumbhar, V.S., Pandey, A., Varghese,

A., Patil, V., 2021. Comparative Assessment of Performance, Combustion, and

Emission of Compression Ignition Engine Fuelled with Different Generations of

Biodiesel. International Journal of Sustainable Engineering, Volume

14(6), pp. 2082–2096. https://doi.org/10.1080/19397038.2021.1943043

Lammert, M., Barnitt, R., McCormick, R.,

2010. Field Evaluation of Biodiesel (B20) Use by Transit Buses. SAE

International Journal of Commercial Vehicles, Volume 2(2), pp. 209–221. https://doi.org/10.4271/2009-01-2899

Lee, K., Cho, H., 2024. Comparative Analysis

of Performance and Emission Characteristics of Biodiesels from Animal Fats and

Vegetable Oils as Fuel for Common Rail Engines. Energies, Volume 17(7), p.

1711. https://doi.org/10.3390/en17071711

Ma’ruf, M., Haryono, I., 2020. An Effect of

Biodiesel (B20) on Life Time Locomotive Fuel Filter. Majalah Ilmiah

Pengkajian Industri; Journal of Industrial Research and Innovation, Volume

13(3), pp. 201–208. https://doi.org/10.29122/mipi.v13i3.3787

Mancini, A., Imperlini, E., Nigro, E.,

Montagnese, C., Daniele, A., Orrù, S., Buono, P., 2015. Biological and

Nutritional Properties of Palm Oil and Palmitic Acid: Effects on Health. Molecules,

Volume 20(9), pp. 17339-17361. https://doi.org/10.3390/molecules200917339

Mokhtar, M., Sukmono,

A., Setiapraja, H., Ma’ruf, M., Yubaidah, S., Haryono, I., Rochmanto, B.,

Soewono, R., Adhi Sukra, K., Thahar, A., Manurung, E., Wibowo, C., Widodo, S.,

Supriyadi, F., Abriyant, R., Suntoro, D., Faridha, F., Reksowardojo, I., 2023. Towards Nationwide Implementation of

40% Biodiesel Blend Fuel in Indonesia: A Comprehensive Road Test and Laboratory

Evaluation. Biofuel Research Journal, Volume 10(3), pp. 1876–1889. https://doi.org/10.18331/BRJ2023.10.3.2

Nelson, R., 2012. Current Status of Biodiesel

in Railroads and Technical Issues. Final Report To: National Biodiesel Board

Pandey, A.K., Mishra, V.B., Verma, V., 2023.

Performance Characteristics Analysis of CI Engine Using Dual Biodiesel. International

Journal of Engine Research, Volume 24(5), pp. 1804-1812. https://doi.org/10.1177/14680874221098845

Paryanto, I., Budianta,

I.A., Alifia, K.C.H., Hidayatullah, I.M., Darmawan, M.A., Judistira, Prakoso,

T., Indarto, A., Gozan, M., 2022. Modelling Of Fuel Filter Clogging of B20 Fuel

Based on The Precipitate Measurement and Filter Blocking Test. ChemEngineering,

Volume 6(6), p. 84. https://doi.org/10.3390/chemengineering6060084

Petiteaux, M., Monsallier, G., 2009.

Impacts of Biodiesel Blends on Fuel Filters Functions, Laboratory and Field

Tests Results (No. 2009-01-1876). SAE Technical Paper. https://doi.org/10.4271/2009-01-1876

Reksowardojo, I.K., Setiapraja, H., Mokhtar,

Y., Yubaidah, S., Mansur, D., Putri, A.K., 2023. A Study on Utilization of

High-Ratio Biodiesel and Pure Biodiesel in Advanced Vehicle Technologies. Energies,

Volume 16(2), p. 718. https://doi.org/10.3390/en16020718

Said, N.H., Ani, F.N., Said, M.F.M., 2018. Emission

and Performance Characteristics of Waste Cooking Oil Biodiesel Blends in a

Single Direct Injection Diesel Engine. International Journal of Technology. Volume

9(2), pp. 238–245. https://doi.org/10.14716/ijtech.v9i2.1204

Skinner, I., Hill, N., Kollamthodi, S.,

Mayhew, J., Donnelly, B., 2007. Railways and Biofuel. First UIC Report.

Available Online at https://uic.org/IMG/pdf/railways_and_biofuels_final_ report.pdf. Accessed on January 26, 2021

Stead, C., Wadud, Z., Nash, C., Li, H., 2019.

Introduction of Biodiesel to Rail Transport: Lessons from the Road Sector. Sustainability

MDPI, Volume 11 (904), pp. 8–10. https://doi.org/10.3390/su11030904

Suryantoro, M.T., Sugiarto, B., Chistian, D.,

Samudra, B., Gusfa, Z., 2016. Deposit Characterization of a Diesel Engine

Combustion Chamber by Droplets at Hot Chamber Temperature: Effect of

Temperature on Evaporation Time and Deposit Structure. International Journal

of Technology, Volume 7(8), pp. 1373–1381. https://doi.org/10.14716/ijtech.v7i8.6936

Susila, I.W., Rachimoellah, Sutantra, I.N., 2012. The Performance of Diesel Engine Using Biodiesel

Fuel from Rubber Seed Oil Production by Catalytic Method. International

Journal of Technology, Volume 3(1), pp. 24–34. https://doi.org/10.14716/ijtech.v3i1.79

Tjahjono, T., Kusuma, A., Adhitya, M., Purnomo, R., Azzahra, T.,

Purwanto, A.J., Mauramdha, G., 2021. Public Perception Pricing into Vehicle Biofuel

Policy in Indonesia. International Journal of Technology, Volume 12(6),

pp. 1239–1249. https://doi.org/10.14716/ijtech.v12i6.5219

Venkataraman, R., Eser, S.,

2008. Characterization of Deposits Formed on Diesel Injectors in Field

Test and From Thermal Oxidative Degradation of N-Hexadecane in A Laboratory

Reactor. Chemistry Central Journal, Volume 2, pp. 1–11. https://doi.org/10.1186/1752-153X-2-25

Wadumesthrige, K., Johnson, N., Galant, M.W.,

Hidayatullah, I.M., Tang, H., Simon Ng, Y., Salley, S.O., 2010. Deterioration

of B20 from Compression Ignition Engine Operation. SAE International Journal

of Fuels and Lubricants, Volume 3(2), pp. 638–649. https://doi.org/10.4271/2010-01-2120

Wirawan, S.S., Solikhah,

M.D., Setiapraja, H., Sugiyono, A., 2024. Biodiesel Implementation in

Indonesia: Experiences and Future Perspectives. Renewable and Sustainable

Energy Reviews, Volume 189, p. 113911. https://doi.org/10.1016/j.rser.2023.113911

Zhang, Y., Zhong, Y., Lu, S., Zhang, Z., Tan,

D., 2022. A Comprehensive Review of the Properties, Performance, Combustion,

and Emissions of the Diesel Engine Fueled with Different Generations of

Biodiesel. Processes, Volume 10, p. 1178. https://doi.org/10.3390/pr10061178