Comparative Study of The Seismic Performance Between Simply Supported PSC Box Girder Bridge Equipped with Shear Panel Damper and Lead Rubber Bearing

Corresponding email: ali.awaludin@ugm.ac.id

Published at : 18 Sep 2024

Volume : IJtech

Vol 15, No 5 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i5.5750

Santoso, A.K., Sulistyo, D., Awaludin, A., Setiawan, A.F., Satyarno, I., Purnomo, S., Harry, I., 2024. Comparative Study of The Seismic Performance Between Simply Supported PSC Box Girder Bridge Equipped with Shear Panel Damper and Lead Rubber Bearing. International Journal of Technology. Volume 15(5), pp. 1321-1330

| Alvin Kurniawan Santoso | Department of Civil and Environmental Engineering, Faculty of Engineering, Universitas Gadjah Mada, Yogyakarta, 55281, Indonesia |

| Djoko Sulistyo | Department of Civil and Environmental Engineering, Faculty of Engineering, Universitas Gadjah Mada, Yogyakarta, 55281, Indonesia |

| Ali Awaludin | Department of Civil and Environmental Engineering, Faculty of Engineering, Universitas Gadjah Mada, Yogyakarta, 55281, Indonesia |

| Angga Fajar Setiawan | Department of Civil and Environmental Engineering, Faculty of Engineering, Universitas Gadjah Mada, Yogyakarta, 55281, Indonesia |

| Iman Satyarno | Department of Civil and Environmental Engineering, Faculty of Engineering, Universitas Gadjah Mada, Yogyakarta, 55281, Indonesia |

| Sidiq Purnomo | Engineering Section, PT. Wijaya Karya Beton Tbk., Boyolali, 57300, Indonesia |

| Ignatius Harry | Engineering Section, PT. Wijaya Karya Beton Tbk., Boyolali, 57300, Indonesia |

Several bridges in Indonesia are designed using

elastomeric bearing (ERB) with a low capability of reducing seismic responses.

This results in a significant demand for larger pier cross-sectional dimensions

and a greater number of reinforcements, necessitating the consideration of

seismic isolation devices to optimize the pier configuration. Lead rubber

bearing (LRB) has been widely used as a seismic isolation device due to the

natural period shifting and sufficient energy dissipation, but it costs a lot.

A shear panel damper equipped with a gap (SPDG) was proposed regarding its

capability to provide high damping at low cost as an alternative device to LRB.

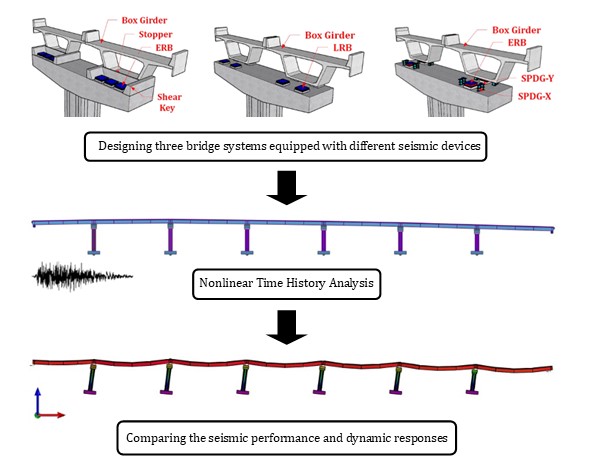

This study compared the seismic performance of three structural systems of

simply supported prestressed concrete (PSC) box girder bridges. Those were

analyzed using Nonlinear Time History Analysis (NLTHA) with the OpenSees

software. As a result, both SPDG and LRB increased the structural flexibility

and generated similar relative pier responses to the conventional bridge with

ERB. For example, SPDG generated the relative responses of the top pier

displacement, base shear, and bending moment up to 64.76%, 83.55%, and 65.66%,

while LRB was 64.92%, 83.39%, and 66.89%, respectively. Meanwhile, the bridge’s

structural performance equipped with LRB and SPDG showed a fully operational

and operational limit, while the one with ERB reached the life safety limit due

to the longitudinal earthquake. The life safety limit due to the transverse

earthquake was also observed in the three bridge models. In conclusion, SPDG is

applicable in the seismic isolation system as it has a similar performance to

the LRB.

Elastomeric Rubber Bearing; Lead Rubber Bearing; Nonlinear Time History Analysis; Simply supported bridge; Shear Panel Damper Plus Gap

The role of seismic isolation devices is crucial in

accommodating the deformation of superstructures caused by earthquake forces.

Unfortunately, many bridges in Indonesia are equipped with elastomeric bearings

(ERB), which have low damping and limited seismic capacity. This leads to a

significant force demand being transmitted to the piers (Xiang, Goto, and

Alam, 2021; Xiang, Alam, and Li, 2019) and

increases the cross-sectional area as well as the number of pier reinforcements

to provide uniform seismic resistance. To optimize the design and minimize pier damage, it is necessary to utilize seismic

isolation devices with high damping, such as lead

rubber bearings (LRB) (Edalathi and Tahghighi,

2019; Sugihardjo et al., 2010).

Meanwhile, despite the fact that Indonesia is an earthquake-prone area, many

practicing engineers would rather use ERB instead of LRB due to budget

constraint. This increases the anxiety of many people regarding the structural

safety during strong earthquakes. Besides, the application of LRB would require

more effort for design and manufacture. Therefore, this study proposed a shear

panel damper equipped with a gap (SPDG), as it has a low cost with high damping

and a large seismic capacity (Nakashima et al., 1994) to overcome the disadvantages of LRB. Moreover, the proposed device could be easily replaced

without lifting the superstructure because the installation was accompanied by

other devices that provided vertical load capacity (Xiang,

Alam, and Li, 2019).

LRB acts as a bilinear elastic-plastic (Hameed

et al. 2008; Naeim and Kelly, 1999) with maximum deformation of 250% (Hamaguchi et

al., 2019; AASHTO, 2014). Meanwhile, the

behavior of the shear panel damper (SPD) is influenced by its web, which is

typically constructed using low-yield or mild steels with high ductility,

allowing it to deform easily up to a certain deformation limit (Yao,

Wang, and Zhu 2021; Zhang et al., 2013). In a study conducted by Liu, Aoki, and Shimoda (2013), it was found that SPD with a square plate and flange

deformed by 16-25%. Awaludin et al. (2022) developed SPD with a rectangular hollow shape that

laterally deformed up to 15% of the body height, and a stable post-yield

resistance was obtained when the web depth-thickness ratio was 25. Furthermore,

the SPD’s web was vulnerable to buckle due to the vertical load and needed to

be supported by ERB to provide an equitable vertical load capacity. This ERB

also provides lateral stiffness with 100% maximum deformation in the elastic

behavior (Yenidogan, 2021). Setiawan

and Takahashi (2018) also found that

the use of gaps in friction dampers reduced the structural stiffness without

any force resistance below the gap length. This simply means that the gap needs

to be applied to SPD to increase structural flexibility (Setiawan,

2018).

The previous study concluded that the application of LRB

increased the flexibility of a simply supported bridge and protected the pier

from more severe damage (Santoso et al., 2022;

Santoso, 2022). In this study, three structural systems of

simply supported prestressed concrete (PSC) box girder bridges are compared

using numerical analysis. This bridge is located in Makassar, Indonesia, and is

classified as a critical bridge according to SNI 2833:2016 (BSN,

2016). Several analytical methods have been employed

to investigate seismic performance, such as Nonlinear Time History Analysis

(NLTHA), pushover analysis, and modal analysis. NLTHA was performed to simulate

the structure’s dynamic response by applying five selected and scaled ground

motion records. A pushover analysis was conducted to determine the actual

pier’s capacity, while a modal analysis was performed to obtain structural

flexibility.

2.1. Bridge Modeling

Figure 2 Bridge model: (a) Model A, (b)

Model B, (c) Model C, and (d) Pier cross-section

Figure 3 SPDG mechanism based on Setiawan and

Takahashi (2018)

2.2. Ground Motion Modification

Five

selected earthquakes were classified as far-fault events, as the bridge is

situated in Makassar with an epicentral distance exceeding 10 km from the

earthquake source. This classification is based on the deaggregation analysis

of the Makassar earthquake as outlined in the study conducted by Sunardi and Nugraha (2016). ASCE (2010) allows for the selection of the ground motion

by considering the respective similar spectral shape of the designed bridge in

such a way that the allowable range of magnitude (Mw), fault

distance (R), source mechanism, and site class were relaxed. Moreover,

the magnitude, which is 5, fault distance

500 km, and shallow crustal

mechanism (strike-slip and reverse) were still considered based on the BMKG

earthquake repository described by Sunardi and

Nugraha (2016) as a lack of

references on the deaggregation of Makassar earthquake. Meanwhile, site class D

of soil represented by Vs30 in the range of 175–350 m/s was

determined based on the soil investigation report of the specific bridge

location. The amplitude scaling method was used to modify the ground motion

selected, and a single scale factor was applied to preserve the variation of

earthquake energy with the fundamental period found in the original record (ASCE, 2017; ASCE, 2010; Kalkan and Chopra, 2010).

2.3. Limit State

The performance level

is an indicator for observing and evaluating the structural performance

simultaneously and an instrument for ensuring structural capability during

service life. NCHRP (2013) classified the performance level into five

categories, also known as damage levels, as shown in Table 1. The determination

of the level depends on several parameters, which include steel strain,

concrete strain, and drift ratio. The damage levels I to IV are still

repairable. Meanwhile, level V required component replacement. So, the

performance level of fully operational (FO), operational (O), life safety (LS),

near collapse (NC), and collapse limits (C) are equivalent to damage levels.

3.1. Structural

Systems Comparison

This study incorporated

three parameters as design criteria for predicting the seismic responses of

isolated structures. These parameters are the stiffness ratio, yield strength

ratio, and ultimate strength ratio, which are utilized to control the seismic

behavior. Furthermore, pushover analysis was used to determine the pier

strength and stiffness parameters, while the formula proposed by AASHTO (2014) and Chen, Ge, and Usami (2007) ware used to calculate the seismic device.

The pier’s elastic stiffness

was observed to be less than the effective stiffness of all seismic devices

because its ratio exceeded one, as shown in Figure 4(a). However, the energy

dissipation started when the yield and the inelastic deformation occurred in

the seismic device. In Figure 4(b), the yield strength ratios of Models B and C

were below one, meaning that the initial yield of the structural system

occurred in the seismic devices rather than the pier. The ratio between the

maximum strength of the seismic devices and the pier is shown in Figure 4(c),

of which the ratios of Models B and C were above one. This implies the pier

potentially collapsed before the seismic devices failed. This makes the design

of an optimal isolated bridge system based on the basic concept to be

difficult, as the demand force has to be calculated to prevent the devices from

failing. Meanwhile, the yield strength ratio was considered an appropriate

design approach for seismic isolation devices.

Figure 4 (a) stiffness ratio, (b) yield strength ratio, (c)

ultimate strength ratio

3.2. Dynamic Responses Comparison

The effectiveness of the

seismic isolation device application was evaluated by considering the maximum

relative percentage of the pier responses, such as displacement, base shear,

and bending moment. The percentage was calculated by comparing the maximum

responses of the seismic-equipped bridge systems in Models B and C with the

conventional bridge system in Model A. The results of Models A and B were

obtained from Santoso et al. (2022), while Model C was

compared to the previous results.

Figure 5(a) shows a

comparison of the maximum top pier displacement in three models, represented by

pier P9. It was observed that the longitudinal displacements were smaller

compared to the transverse. In this case, all piers have rectangular

cross-sections with the same stiffness in both lateral directions, as shown in

Figure 2(d). Therefore, the reason is that a free cantilever pier in the

transverse direction provided less stiffness than those in the longitudinal

that was supported by a series of piers. Furthermore, the longitudinal

displacements in Model A were the largest of the other models, but some

transverse displacements in Model C were larger than in Model A based on some

earthquakes. This was influenced by the larger lateral stiffness and the yield

strength ratio of the bearing system to the substructure, where Model C was

larger than Model B, as shown in Figure 4. Besides, the bridge system with SPDG

generated the maximum relative displacement of 64.76% and 36.75%, while the one

with LRB showed 64.92% and 45.92% in the longitudinal and transverse

directions, as shown in Table 2.

Models B and C consistently show lower base shear results compared to

Model A, as shown in Figure 5(b). The seismic devices were capable of reducing

the spectral acceleration, while the larger pier in Model A produced stiffer

piers, thereby resulting in a greater base shear than the other models.

Meanwhile, both Models B and C showed comparable relative base shear, as

summarized in Table 3. The relative base shears in Models B and C reached

83.39% and 83.55% in the longitudinal directions, as well as 63.66% and 60.60%

in the transverse directions, respectively. In manual calculation, the maximum

shear capacity of Model A pier was 38740.32 kN, while Models B and C piers were

27377.12 kN. It was observed that the piers in all models did not exceed the

maximum shear capacity, meaning that the shear yielding did not occur.

Table 2 Top pier relative

displacement in longitudinal (X) and transverse (Y) directions

|

Model |

Maximum

Relative Displacement X (%) |

Maximum

Relative Displacement Y (%) | ||||||||||

|

P8 |

P9 |

P10 |

P11 |

P12 |

P13 |

P8 |

P9 |

P10 |

P11 |

P12 |

P13 | |

|

B |

58.2 |

55.2 |

57.7 |

56.7 |

55.6 |

64.9 |

28.9 |

24.8 |

45.9 |

24.7 |

44.1 |

28.0 |

|

C |

55.2 |

41.3 |

40.7 |

34.7 |

35.6 |

64.8 |

13.5 |

5.4 |

36.8 |

7.2 |

28.0 |

17.7 |

Table 3 Relative base shear

in longitudinal (X) and transverse (Y) directions

|

Model |

Maximum

Relative Base Shear X (%) |

Maximum

Relative Base Shear Y (%) | ||||||||||

|

P8 |

P9 |

P10 |

P11 |

P12 |

P13 |

P8 |

P9 |

P10 |

P11 |

P12 |

P13 | |

|

B |

76.4 |

76.7 |

77.1 |

78.7 |

81.3 |

83.4 |

60.5 |

55.9 |

56.5 |

58.5 |

63.7 |

61.4 |

|

C |

74.7 |

72.5 |

72.7 |

74.8 |

78.5 |

83.6 |

54.0 |

43.3 |

50.7 |

50.3 |

60.6 |

58.9 |

Table 4 Relative bending

moment in longitudinal (X) and transverse (Y) directions

|

Model |

Maximum

Relative Bending Moment X (%) |

Maximum

Relative Bending Moment Y (%) | ||||||||||

|

P8 |

P9 |

P10 |

P11 |

P12 |

P13 |

P8 |

P9 |

P10 |

P11 |

P12 |

P13 | |

|

B |

60.6 |

60.5 |

61.5 |

60.7 |

59.8 |

66.9 |

43.2 |

39.4 |

48.6 |

40.1 |

44.2 |

39.1 |

|

C |

58.2 |

50.1 |

50.1 |

45.5 |

46.2 |

65.6 |

32.4 |

31.7 |

45.4 |

29.7 |

39.6 |

32.6 |

3.3. Seismic Performance and Damage Comparison

The top pier displacement and curvature responses are two indicators for

measuring pier performance and damage. Table 5 shows the summary of the maximum

top pier displacements and performance levels in each pier. It was observed

that Models B and C showed better performances compared to Model A,

particularly in the longitudinal direction. This means that fully operational

limits were obtained in Models B and C, while Model A was in the life safety

limit state. It is important to note that life safety limit states were also

observed in all models due to the transverse earthquakes. In addition, damage

levels I and II were displayed in Models B and C, while damage level III was

shown in Model A due to longitudinal earthquakes. Table 5 also shows that all

bridge models reached damage level III due to transverse earthquakes.

Therefore, the application of SPDG was able to provide comparable performance

and protect the pier from more severe damage, just as in the bridge equipped

with LRB.

3.4. Seismic Device Responses

Figure 7 Seismic device’s responses on pier P9 due to

the transverse earthquakes

Three bridge models with

different structural systems have been investigated in this study using

numerical analysis. The results showed that the bridge models with seismic

devices, such as SPDG and LRB, were more flexible compared to the conventional

bridge equipped with ERB. Basically, SPDG started to dissipate seismic energy

when the deformation exceeded the gap length then the metal web experienced

yielding. The yielding state initiated an inelastic behavior that provided low

post-yield stiffness to accommodate the superstructure’s deformation.

Meanwhile, the designed gap allowed the device to deform at a zero-stiffness

state that increased the maximum shear strain capacity by 3% to prevent

failure. As a result, piers in the bridge with SPDG have comparable responses

to LRB. The relative responses to the conventional bridge, i.e., top pier

displacement, base shear, and bending moment, generated up to 64.76%, 83.55%,

and 65.66%, while LRB generated up to 64.92%, 83.39%, and 66.89%, respectively.

The practical design of isolated bridges with SPDG was also made easy when the

appropriate parameters were defined based on the target performance. Therefore,

the yield strength ratio needs to be considered as a criterion for designing

the SPDG and predicting the structural responses due to seismic excitation. It

was observed that the bridge with SPDG, which was designed in the yield

strength ratio’s range of 0.53–0.73, showed comparable seismic performance to

the bridge with LRB. Those were fully operational and operational limits due to

the longitudinal earthquakes, and life safety limit due to the transverse

earthquakes. In addition, the influence of vertical direction earthquakes will

increase vertical deformation. Consequently, the friction between two-separated

plates on the top of SPDG potentially occurred. This might inflict a large

buckling displacement and influenced the hysteretic behavior. Thus, it should

be considered while designing the vertical gap of SPDG.

The authors are grateful to the Department of Civil and Environmental

Engineering at Universitas Gadjah Mada and PT. Wijaya Karya Beton Tbk. for the

data support.

American

Association of State Highway and Transportation Officials (AASHTO), 2012. LRFD

Bridge Design Specifications. American Association of State Highway and

Transportation Officials, Washington, USA

American

Association of State Highway and Transportation Officials (AASHTO), 2014. Guide

Specifications for LRFD Seismic Bridge Design, 2nd Edition. American

Association of State Highway and Transportation Officials. Washington, USA

American

Society of Civil Engineers (ASCE), 2010. ASCE 7-10: Minimum Design

Loads for Buildings and Other Structures. American Society of Civil

Engineers, Virginia, USA

American

Society of Civil Engineers (ASCE), 2017. ASCE 7-16: Seismic

Evaluation and Retrofit of Existing Buildings. American Society of Civil

Engineers, Virginia, USA

Awaludin, A.,

Setiawan, A.F., Satyarno, I., Wu, S., Haroki, Y., 2022. Finite Element Analysis

of Bi-directional Shear Panel Damper with Square Hollow Section under Monotonic

Loading. Journal of the Civil Engineering Forum, Volume 8(2), pp. 157–168

Badan Standardisasi Nasional (BSN), 2016. SNI 2833:2016

Seismic Design of Bridge. Badan

Standardisasi Nasional, Jakarta, Indonesia

Berry, M.P., Eberhard, M.O., 2008. Performance Modeling Strategies for

Modern Reinforced Concrete Bridge Columns. Report PEER 2007/07, Pacific

Earthquake Engineering Research Center, Berkeley, California

Carreno, R., Lotfizadeh, K.H., Conte, J.P., Restrepo, J.I., 2019. Material

Model Parametes for The Giuffre-Menegotto-Pinto Uniaxial Steel Stress-Strain

Model. Journal of Structural Engineering, Volume 146, pp. 1 – 21

Chen, W., Duan, L., 2014. Bridge Engineering Handbook 2nd Edition, Seismic Design. CRC Press, New York, USA

Chen, Z., Ge, H., Usami, T., 2007. Study on

Seismic Performance Upgrading for Steel Bridge Structures by Introducing

Energy-dissipation Members. Journal of Structural Engineering, Volume

53A, pp. 540–549

Edalathi, A.A., Tahghighi, H., 2019.

Investigating The Performance of Isolation Systems inn Improving the Seismic

Behavior of Urban Bridge. Archives of Civil Engineering, Volume 65, pp.

155 – 175

Fillippou, F., Popov, E., Bertero, V., 1983. Effects

of Bond Deterioration on Hysteretic Behavior of Reinforced Concrete Joints.

Report EERC 83-19, Pacific Earthquake Engineering Research Center, Berkeley,

California

Hamaguchi, H., Wake, T., Yamamoto, M., Kikuchi,

M., 2019. Practical Application of Lead Rubber Bearings with Fail-safe

Mechanism. Journal of Structural and Construction Engineering, Volume

12, pp. 187 – 196

Hameed, Koo, M., Do, T.D., Jeong, J. Effect of

Lead Rubber Bearing Characteristics on The Response of Seismic-isolated

Bridges. KSCE Journal of Civil Engineering, Volume 12(3), pp. 187-196

Kalkan, E., Chopra, A.K., 2010. Practical

Guidelines to Select and Scale Earthquake Records for Nonlinear Response

History Analysis of Structures. Report 2010-1068, U.S. Geological Survey,

California, USA

Kappos A.J., Saiidi, M.S., Aydinoglu, M.N.,

Isacovic, T., 2012. Seismic Design and Assessment of Bridges, Springer, New

York, USA

Liu, Y., Aoki, T., Shimoda, M., 2013. Strain

Distribution Measurement of a Shear Panel Damper Developed for Bridge

Structure. Journal of Structures, Volume 2013, pp. 1–11

Mander, J.B., Priestley, M.N.J., Park, R.,

1988. Theoretical Stress-strain Model for Confined Concrete. Journal of

Structural Engineering, Volume 144, pp. 1804-1826

Menegotto, M., Pinto, P., 1973. Method of

Analysis for Cyclically Loaded RC Plane Frames Including Changes in Geometry

and Non-elastic Behavior of Elements Under Combined Normal Force and Bending.

IABSE Symposium on Resistance and Ultimate Deformability of Structure Acted on

by Well Defined Repeated Loads: Proceeding, Volume 11, pp. 15 – 22

Naeim, F., Kelly, J.M.,

1999. Design

of Seismic Isolated Structures: From Theory to Practice. John Wiley & Sons Inc.,

New York, USA

Nakashima, M., Iwai, S., Iwata, M., Takeuchi,

T., Konomi, S., Akazawa, T., Saburi, K., 1994. Energy Dissipation Behavior of

Shear Panels Made of Low Yield Steel. Earthquake Engineering and Structural

Dynamics, Volume 23, pp. 1299-1313

National

Cooperative Highway Research Program (NCHRP), 2013. Performance-Based

Seismic Bridge Design: A Synthesis of Highway Practice. Transportation

Research Board, Washington, USA

Omrani, R.,

Mobasher, B., Liang, X., Gunay, S., Mosalam, K.M., Zareian, F., Taciroglu, E.,

2015. Guidelines for Nonlinear Seismic Analysis of Ordinary Bridge: Version

2.0. Report No. 15-65A0454, California Department of Transportation,

California, USA

Santoso, A.,

Sulistyo, D., Awaludin, A., Setiawan, A.F., Satyarno, I., Purnomo, S., Harry,

I., 2022. Structural Systems Comparison of Simply Supported PSC Box Girder

Bridge Equipped with Elastomeric Rubber Bearing and Lead Rubber Bearing. Civil

Engineering Dimension, Volume 24, pp. 19–30

Santoso, A.K., 2022. Perbandingan Penggunaan Shear Panel Damper dan Lead

Rubber Bearing untuk Meningkatkan Performa Seismik Struktur Jembatan Box Girder

Tumpuan Sederhana (Comparative Study on Seismic Performance Between Simply

Supported Box Girder Bridge Equipped with Shear Panel Damper and Lead Rubber

Bearing). Master’s Thesis, Graduate Program, Universitas Gadjah Mada,

Yogyakarta, Indonesia

Setiawan,

A.F., 2018. Development of High Seismic Performance Integrated Bridge Pier

Connected by Hysterical Damper, Doctor’s Dissertation, Graduate Program, Kyoto

University, Kyoto, Japan

Setiawan,

A.F., Takahashi, Y., 2018. A High Seismic Performance Concept of Integrated

Bridge Pier with Triple RC Columns Accompanied by Friction Damper Plus Gap. Journal

of Japan Society of Civil Engineers, Volume 74, pp. 131–147

Steelman J.,

Fahnnestock, L., Filipov, E., LaFave, J., Hajjar, J., Foutch, D., 2013. Shear

and Friction Response of Nonseismic Laminated Elastomeric Bridge Bearings

Subject to Seismic Demands. Journal of Bridge Engineering, Volume 18,

pp. 612 – 623

Sugihardjo,

H., Tavio, Manalu, I., Lesmana, Y., 2018. Seismic Study of Lead-Rubber Bearing

Application in Kutai Kertanegara Steel Arch Bridge. International Journal on

Advanced Science Engineering Information Technology, Volume 8, pp. 540 –

546

Sunardi, B.,

Nugraha, J., 2016. Peak Ground Acceleration at Surface and Spectral

Acceleration for Makassar City Based on A Probabilistic Approach. Jurnal Meteorologi dan Geofisika, Volume 17, pp 33–46

Vecchio, F.J., Collins, M.P., 1986. The

Modified Compression-field Theory for Reinforced Concrete Elements Subject to

Shear. Journal Proceedings, Volume 83, pp. 219-231

Xiang, N., Alam, M., Li, J., 2019. Yielding Steel

Dampers as Restraining Devices to Control Seismic Sliding of Laminated Rubber

Bearings for Highway Bridges: Analytical and Experimental Study. Journal of

Bridge Engineering, Volume 24(11), pp. 1–15

Xiang, N., Goto, Y., Alam, M., Li, J., 2021.

Effect of Bonding or Unbonding on Seismic Behavior of Bridge Elastomeric

Bearings: Lessons Learned from Past Earthquakes in China and Japan and

Inspirations for Future Design. Advances in Bridge Engineering, Volume

2(1), pp. 1-17

Yao, Z., Wang, W., Zhu, Y., 2021. Experimental

Evaluation and Numerical Simulation of Low-yield-point Steel Shear Panel

Dampers. Engineering Structures, Volume 245, pp. 1-17

Yenidogan, C.,

2021. Earthquake-Resilient Design of Seismically Isolated Buildings: A Review

of Technology. Vibration, Volume 4, pp. 602–647

Zhang, C.,

Zhang, Z., Aoki, T., Zhang, M., 2013. Research on The Dynamic Performance of

Low-Yield-Strength Shear Panel Damper for Bridge Application. Journal of

Shanghai Jiaotong University, Volume 18, pp. 118 – 128