Polypropylene-based Bio-nano Composites Reinforced with Cellulose Nanocrystals and Added with Mono-diacylglycerols as Antistatic Agent

Corresponding email: dwisetyaningsih@apps.ipb.ac.id

Published at : 10 Jul 2024

Volume : IJtech

Vol 15, No 4 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i4.5746

Setyaningsih, D., Sarfat, M.S., Fahma, F., Indrasti, N.S., 2024. Polypropylene-based Bio-nano Composites Reinforced with Cellulose Nanocrystals and Added with Mono-diacylglycerols as Antistatic Agent. International Journal of Technology. Volume 15(4), pp. 952-964

| Dwi Setyaningsih | 1 Department of Agroindustrial Technology, IPB University, Bogor 16680, West Java, Indonesia 2 Surfactant and Bioenergy Research Center, IPB University, Bogor 16144, West Java, Indonesia |

| Muhammad Syukur Sarfat | 1 Department of Agroindustrial Technology, IPB University, Bogor 16680, West Java, Indonesia 2 Surfactant and Bioenergy Research Center, IPB University, Bogor 16144, West Java, Indonesia |

| Farah Fahma | Department of Agroindustrial Technology, IPB University, Bogor 16680, West Java, Indonesia |

| Nastiti Siswi Indrasti | Department of Agroindustrial Technology, IPB University, Bogor 16680, West Java, Indonesia |

This research aims to identify the

performance and mechanical characteristics of polypropylene-based

antistatic bio-nano composites reinforced with 2% mono-diacylglycerols

(M-DAG) and 0, 0.5, 2.5% cellulose nanocrystals (CNC) and

compared to pure PP. Based on the results of SEM on cross-section, there

was an agglomeration of M-DAG and CNC on the PP matrix. XRD diffractogram pattern of

antistatic bio-nano composites showed peaks representing the

diffraction structure of glycerol monostearate and cellulose I. The FTIR

spectrum of each formulation was very similar to the characteristic peaks of PP

and showed three distinct peaks compared to pure PP. The melting temperature of antistatic composites without CNC (176.54oC)

was higher than pure PP (175.44oC). Thermal stability of antistatic bio-nano

composites with 0, 0.5, and 2.5% CNC were 472.07, 470.25, and 475.15 oC,

respectively, higher than pure PP (468.27oC). The best

mechanical properties were 2.5% CNC with 11.071 MPa flexural modulus, 30.376 MPa tensile strength, 23.796%

tensile elongation, 1.659 J/m2 impact strength, which were higher

than pure PP, and it generated antistatic activity of 1010 - 1012 /sq resistivity.

Antistatic bio-nano composites; Biopolymers synthesis; Cellulose nanocrystals; Mono-diacylglycerols; Polypropylene

The trend of using synthetic polymer-based materials is predicted to increase in terms of fulfilling human needs. Synthetic polypropylene (PP) is known for having a high softening point or glass transition, high resistance to bending stress, low water absorption, good electrical resistance, light dimensional stability, high impact strength, non-toxicity properties, and the degree of crystallinity ranges from 40 to 60% with the melting temperature range from 130 to 171°C (Shubhra, Alam, and Quaiyyum, 2013). But PP is susceptible to high temperatures, flammable, prone to UV degradation, susceptible to oxidation, difficult to paint, and harmful to the environment due to its non-degradable nature (Purnomo, Baskoro, and Muslim, 2021; Shieddieque et al., 2021), but PP is recyclable (Jain and Tiwari, 2015). Therefore, to overcome the weakness, it is necessary to modify PP into bio-nano composites. Antistatic bio-nano composites are synthesized by adding natural antistatic materials.

Nanocomposites are multicomponent materials consisting of several

different phases in which at least one phase size is in the nanoscale (less

than 100 nm) (Sandri et

al., 2016). The antistatic bio-nano

composites synthesized using mono-diacylglycerols (M-DAG) as an antistatic agent (Salsabila et

al., 2021), cellulose nanocrystals (CNC) as a reinforcement, and PP

as a thermoplastic matrix (Clemons and

Rick, 2020; Sabaruddin, Md-Tahir, and Lee, 2019; Gwon et al., 2018).

A combination of M-DAG and CNC is expected to

produce a synergistic effect to improve the quality

of the antistatic bio-nano composites. The

addition of M-DAG and CNC to the PP matrix had a positive impact on

the characteristics of the resulting bio-nano composites and antistatic bio-nano composites (Sabaruddin, Md-Tahir, and Lee, 2019; Gwon et al.,

2018).

M-DAG

is an ester of glycerol and free fatty acid (FFA)

which has unreacted or free hydroxyl groups. MAG, or

monoglyceride, has a single fatty acyl chain, while DAG, or diacylglyceride,

has two fatty acyl chains (Sarfat et al., 2022).

This free hydroxyl group makes M-DAG a non-ionic surfactant that is degradable

and bio-compatible, so it is widely used in the food, cosmetic, and

pharmaceutical industries. This free hydroxyl group allows M-DAG to be used as

a stabilizer and an antistatic agent in bio composites or plastics (Salsabila et al., 2021).

M-DAG used in this research was produced from palm fatty acid distillates

(PFAD) from the refining process of crude palm oil (CPO) (Setyaningsih, Suwarna, and Muna, 2020; Setyaningsih et

al., 2020).

CNC

is a cellulose-based nanomaterial that has better mechanical characteristics

such as tensile strength (7.5 GPa) (Tang et al., 2017),

tensile modulus (100 - 140 GPa) (Tang et al., 2017),

high surface area (569 m²/g) (Brinkmann et al., 2016),

with a diameter average of 8 nm (Rochardjo et al., 2021) compared

to other cellulose-based nanomaterials such as cellulose nanofiber (CNF) which

has a tensile

strength of 0.3833 GPa (Kafy et al., 2017),

a tensile modulus of 23.9 GPa (Kafy et al., 2017) and

surface area of 430 m²/g (Moser, Henriksson,

and Lindström, 2016).

However, there are disadvantages of CNC, namely low stability starting from

283.55 0C, which causes CNC to be very

susceptible to high heat treatment when used as a reinforcing material in

polymer matrices. M-DAG can be used as a lubricant and stabilizer to protect CNC from thermal degradation during processing.

Therefore,

a combination of M-DAG and CNC as additive materials for the synthesis of

PP-based antistatic bio-nano composites has a prospect as next-generation

material

that is more flexible in use and exhibits superior

performance and mechanical characteristics compared to pure PP. There has never

been researched that combines M-DAG and CNC simultaneously as reinforcement in

the PP matrix. Therefore, this study aims to evaluate the performance and

mechanical characteristics of PP-based antistatic bio-nano composites

reinforced with varying concentrations of M-DAG and CNC, and compare them to

those of pure PP.

2.1. Raw

Materials

The raw materials for synthesizing

antistatic bio-nano composites were PP, M-DAG, and CNC. PP (PT Chandra Asri Petrochemical Tbk) has a melt

flow index of 10 g/10 minute and a density of 0.903 g/cm3.

M-DAG (SBRC-LPPM-IPB) has a crystallinity index of 92.85%, a diameter of 0.11–1.78 nm, and a thermal degradation rate of 200.50 oC. CNC (CelluForce Co.) has a density of 1.5 g/cm3, a crystallinity index of 98.95%, and diameter of 3.39–12.72 nm, a length of 44 – 108 nm, and thermal degradation of 296.96 oC. The supporting materials consist of maleic

anhydride polypropylene (MAPP)(BYK Chemie GmbH),

antioxidant (AO) (BASF Schweiz AG, Switzerland), and mineral oil (MO) (Arkema France).

2.2. Methodology

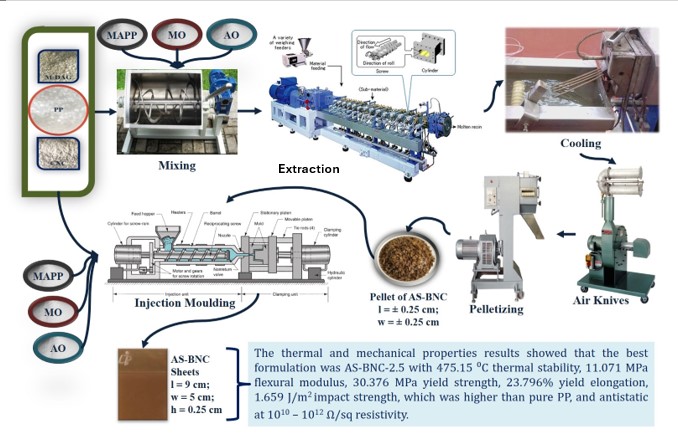

Figure 1 The Stages

of the synthesis of antistatic bio-nano composites

2.2. Antistatic

Bio-nano Composites Characterization

Infrared

spectrum analyzed using Fourier

transform IR (FT-IR) Thermo Fisher Scientific Nicolet iS5 spectrophotometer

with cleaning pump and wavelengths 300 cm-1 to 4000 cm-1,

128 accumulated scans, resolution 4 cm-1, in ATR and transmittance

module. Thermal properties analysis used differential scanning calorimetry

(DSC) TA Instruments, New Castle, UK model Q200. Dynamic DSC scans were conducted in the temperature range from 23 to 400 °C at a

heating rate of 10 °C/min. The crystallization and melting behaviors were

recorded in a nitrogen atmosphere, at the range mass used of 21.8 to 29.0 mg.

where W is the corrected energy

absorbed by breaking the specimen (J), is the thickness of the specimen (mm), and

is the width of the specimen (mm).

where is flexure strength

(N/mm2/MPa),

is flexure

modulus (N/mm2/MPa),

is the thickness of the beam (mm), and

is the

deflection at the center of the span (mm).

where /sq), Rs is the surface resistance

(ohms),

is the

ratio of the circumference

of a circle to its diameter equal to 3.14, R1 is the outer

radius of the center electrode (cm), R2 is the inner radius

of the outer ring electrode (cm).

3.1. Morphology

Analysis

Figure 2

Morphological analysis of antistatic bio-nano composites using SEM

Based on the results of the SEM analysis on the cross-section, M-DAG

agglomeration was found on the PP matrix because it shows a morphological form

of M-DAG, while the CNC is not visible. This indicates a chemical reaction or

physical interaction between M-DAG and the PP matrix. Physical interaction

occurs when the polar groups (palmitate) are oriented to the PP matrix. In

contrast, the polar groups (glyceryl) are oriented away from the PP matrix

towards the antistatic bio-nano composite surface, and it is possible to interact physically with CNC. Another

possibility is that the polar group (glyceryl) reacts with the O group of the

maleic anhydride during the synthesis process. In addition, there was no

fibrillation on the surface of the antistatic

bio-nano composites cross-section. This implies that

no significant plastic deformation occurred in the antistatic bio-nano composites layer during fracture, although the CNC concentration is increased. According

to Shojaeiarani, Bajwa, and

Chanda (2021), the

rheological properties of CNC-filled polymer melts depend on factors such as

the degree of CNC particle dispersion, their orientation state, and aspect

ratio. Consequently, the rheological properties of the antistatic bio-nano

composites in our study were also influenced by these factors. In particular,

the homogeneous dispersion of CNC particles led to more effective load transfer

to the reinforcements.

3.2. Degree of Crystallinity and

Particle Size Analysis

Crystallinity analysis was

carried out on AS-BNC using XRD analysis to observe changes in the crystal structure as a function

of chemical treatment and to measure the degree of crystallinity (CrI) using

the deconvolution method with a ratio between the area corresponding to the

crystal peak and the total area (Park

et al., 2010). Figure 3A shows the XRD

diffractogram of AS-BNC. XRD diffractogram patterns were recorded using Cu K

irradiation, = 1.5418 A.

The results of the XRD diffractogram analysis of AS-BNC showed with seven peaks with peak heights ranging from 87.09 – 1000 I rel of AS-BNC-5, 84.61 – 1000 I rel of AS-BNC-0.5, and 90.91 – 1000 I rel of AS-BNC-2.5 (Table 2). The XRD diffractogram pattern showed peaks representing the diffraction structure of glycerol monostearate and cellulose I. The diffraction characteristic of glycerol monostearate can be observed in the peak range between 5o to 30o (Yusuf et al., 2013). The diffraction characteristics of cellulose I could be observed around peaks at 15o (001), 22.5o (002), and 34o (040) (Park et al., 2010), Couret et al. (2017) said the peaks at 15o (1-10), 17o (110), 21o(102/012), 23o (200), and 34o (004) represent the diffraction structure of cellulose I.

The XRD diffractogram of PP

showed the pattern, which has seven

peaks with peak heights ranging from 85.41 – 1000 I rel. According to Guerra, Wan, and McNally (2019), the XRD patterns showed the most intense peaks for PP at = 16.5o

(100),

19.2o

(300), 20o

(040), 22o

(130), and for the GNPs at

= 32o (002).

The identification results of the

particle size, degree of crystallinity, and percent of amorphous components in

AS-BNC showed the average particle

sizes between 15.84 to 16.01

nm, 89.81

to 91.10 % degree of

crystallinity, and 8.90 to 10.19

% amorphous components (Table

2). The

particle size of AS-BNC was increased with the increase in CNC concentration.

The degree of crystallinity of AS-BNC-2.5 is higher than that of pure PP.

3.3. Infrared Spectrum Analysis

The FTIR spectrum of each treatment (Figure 3B) was very similar to the characteristic peaks of PP and depicted distinct

tri peaks for the antistatic bio-nano composites compared to the pure PP. The

first distinct absorption peak ranging from 1200 cm-1 to 1000 cm-1

were primarily assigned to C–O–C bond, C–C bending, and ring structures (with

typical sharpening at 1071.50 cm-1 with %T of 85.14% and 1166.98 cm-1

with %T of 69.93% (AS-BNC-0), 1080.18 cm-1 with %T of 83.03% and

1166.02 cm-1 with %T of 64.77% (AS-BNC-0.5), and 1085.01 cm-1

with %T of 74.86% and 1166.02 cm-1 with %T of 51.02% (AS-BNC-2.5),

which correspond to typical cellulose and glycerol compound (Al-Haik et al. 2020). In the band around 1080 cm-1, the %T decreased as the

concentration of CNC added to the PP matrix increased, while the %T in Pure PP

was lower than each of the AS-BNC, which was 70.79%. This indicated the

presence of an increasing C–O–C bond due to ring deformation of maleic acid compounds

or ring widening and C–O stretching. The same phenomenon occurred in the band

around 1166 cm-1, which showed a decrease of %T with increasing

concentration of CNC addition to the PP matrix, but lower than Pure PP (68.11%),

except for AS-BNC-0. This indicated the presence of an increasing C–C bending.

The

second distinct band is related

to the wavelength near 2900 cm-1.

This broadband was

assigned to stretching

vibration of C–H hydroxyl groups asymmetric stretching of cellulose and glycerol. In this

band, % transmittance (T) decreased as the concentration of CNC increased,

while %T in pure PP was higher than AS-BNC. The

presence of these bands confirmed the interaction of CNC and the distribution

of M-DAG in the PP matrix. Due to this interfacial adhesion, the overall

mechanical properties were enhanced for the AS-BNC. Hobuss

et al. (2020) determined the asymmetric and

symmetric C–H stretching mode of the fatty acid chain methylene group at 2922

cm-1 and 2853 cm-1. The third

distinct peak was 3315 cm-1, which is

related to O–H [ (O–H)] stretching, a characteristic of hydroxyl groups. This band showed that %T decreased as the concentration of CNC

increased, while %T of pure PP was higher than AS-BNC. Hobuss et al. (2020)

set the O–H stretch at 3360 cm-1.

The

bands at 1377.23 cm-1 and 1457.28 cm-1 in all treatments

were characteristics of PP (Fang et al., 2012).

The absorption bands at 1738.90 cm-1 (Pure PP), 1742.76 cm-1

(AS-BNC-0), 1738.90 cm-1 (AS-BNC-0.5), and 1742.76 cm-1

(AS-BNC-2.5) were observed, which were assigned to the absorption of carbonyl

groups (C=O) of maleic anhydride

(MA) (Rahman, Hassan, and Heidarian, 2018; Zhou et al., 2013). Finally, the spectrum on the peak 1166.02 cm-1 indicated

the C-C bending, which was the backbone of PP (Fang et al., 2012).

The

infrared (IR) spectrum of the antistatic bio-nano composites revealed several

characteristic peaks. Specifically, peaks between 3300 cm-1 and 3250

cm-1 were assigned to O–H stretching modes, while those between 3000

cm-1 and 2750 cm-1 corresponded to the stretching modes

of CH, CH2, and CH3 groups. The peak at 1750 cm-1

was indicative of carbonyl stretching (C = O).

The peaks between 1500 cm-1 to 1250 cm-1 were

characteristic of the deformation of the CH2 and CH3

groups. The peaks between 1250 cm-1 to 1150 cm-1 were

referred as the C–O and C–C bonds. The peak at 1100 cm-1 was also

characteristic of the strain of the C–O bond and ester group (–C–O–C–). The

"wag" vibration and asymmetric angular deformation of CH and CH2

groups were found at 750 cm-1 (Hobuss et

al., 2020).

3.4. Thermal Properties and Melt

Flow Index Analysis

Based on the identification results of the thermal

properties (Figure 3C and Table 3),

it was found that the melting temperature

of AS-BNC-0 was 176.54oC

higher than that of pure PP 175.44 oC.

The melting temperature of AS-BNC-0.5

and AS-BNC-2.5 were 171.70oC and

174.38oC,

respectively, slightly lower than that of pure PP. However,

when compared between AS-BNC-0.5 and AS-BNC-2.5, AS-BNC-2.5 had a higher

melting temperature than AS-BNC-0.5. This indicated an opportunity for

increasing melting temperature with an increase in CNC concentration. According to Al-Haik et

al. (2020) and Hejna et al. (2017),

the melting temperature of bio-nano composites with the addition of 2%, 4%, and

5% CNC on the PP matrix showed a higher value when compared to pure PP and the

addition of 4% CNC had the higher melting temperature than 3% CNC. According to

Yousefian and Rodrigue (2016),

the distribution of CNC particles in the polymer matrix greatly influenced the

thermal properties of the resulting bio-nano composites.

Thermal stability of AS-BNC-0, AS-BNC-0.5,

and AS-BNC-2.5 was 472.07 oC, 470.25oC, 475.15oC respectively, higher

than pure PP (468.27 oC).

Therefore, the addition of 2.5%

CNC and 2% M-DAG to

the PP matrix can increase the thermal degradation of the resulting antistatic

bio-nano composites. The higher the degree of crystallinity of the antistatic

bio-nano composites, the higher the thermal stability, except for the

antistatic bio-nano composites treated with AS-BNC-0. According to Al-Haik et al. (2020),

the thermal stability of bio-nano composites with the addition of 1%, 2%, and 3

% CNC on the PP matrix showed a higher value when compared to pure PP and the

addition of 4% and 5 % CNC. It showed that the addition

of 3 % CNC has the highest thermal

stability. CNC particles were thought to increase the thermal

resistance of AS-BNC by inhibiting the diffusion of volatile decomposition

products or by forming a charred CNC surface that

dissipates heat by absorbing it in the inorganic phase (Thomas et al., 2018; Ng et al.,

2017).

In addition, the presence of M-DAG can inhibit the thermal degradation of

AS-BNC. The reduced thermal resistance in AS-BNC with 2% M-DAG and 0.5% CNC may have been due to the non-uniform dispersion of the CNC particles (Ng et al.,

2017).

Figure 3

XRD diffractogram (A), FT-IR spectra (B), and DSC thermogram of AS-BNC

3.5. Mechanical Properties Analysis

Analysis of mechanical properties of AS-BNC includes

tensile properties (Table 4) and flexural, impact strength, and surface

resistivity properties (Table 5). The best AS-BNC was AS-BNC-2.5

with 11.071 MPa flexural modulus, 30.376 MPa tensile strength, 23.796% tensile

elongation, 1.659 J/m2 impact strength, and 1010 – 1012 /sq resistivity, which was higher than that of pure PP. However, AS-BNC-2.5 has 207.244 MPa modulus,

32.092 MPa highest tensile strength, 29.120% tensile

elongation, and 90.6950 Pa

flexural strength, which was smaller than pure PP. The higher the degree of

crystallinity of the antistatic bio-nano composites, the higher the tensile

strength, but It’s not for other mechanical properties of antistatic bio-nano

composites. According to Shojaeiarani, Bajwa, and

Chanda (2021), CNC has a large surface-to-volume ratio, high tensile strength (

10 GPa), high

stiffness (

110–130 GPa), and high flexibility. Incorporating CNC in composites influenced their mechanical properties by improving

filler-matrix compatibility and forming a filler network. Using CNC as a

reinforcement agent improved the stress-transfer efficiency of the composites

and the overall mechanical properties Shojaeiarani, Bajwa, and Chanda (2021).

Based on the results of the electrical resistivity of

AS-BNC, the values were in the range of antistatic values of 1010 –

1012 /sq. In

addition, the surface resistivity value of AS-BNC was in the static dissipative

value range of 106 – 1012

/sq,

which has the potential to be used for electrostatic discharge prevention or

the presence of a sudden electric current caused by an electric short circuit,

a dielectric fault, or the contact between two electrically charged objects (Pang et al., 2014).

In general, the polymer matrix is highly insulated. Therefore, the presence of

electrically conductive nanomaterials with a large aspect ratio dispersed in

small quantities can drastically increase the electrical conductivity to a

level that can support used for electrostatic discharge protection (Kumar et

al., 2019).

Table 4 Tensile properties of antistatic

bio-nano composites

Based on the results

of mechanical properties, several test sub-parameters showed different

tendencies compared to the results of the thermal properties test, except for

yield strength and impact strength. This can occur due to uneven distribution

of CNC particles in the PP matrix, excessive MAPP concentration, and

preparation of the tensile test sample. It has been reported that using high

concentrations of MAPP will provide many opportunities for the reinforcement

material to bond to the polymer matrix. However, when MAPP completely covered

the surface of the PP matrix, it did not produce better adhesion and decreased

the mechanical properties of composites (Hassanabadi, Alemdar,

and Rodrigue, 2015). Therefore, it was necessary to optimize the use of MAPP on CNC concentration.

The impact strength of AS-BNC decreased with increasing CNC

concentration because the rigid nanoparticles increased the interfacial area

between the matrix and fiber and aided the possibility of crack initiation and

propagation (Yousefian and Rodrigue 2016; 2015). However, in the AS-BNC-2.5, the impact strength was still higher than

Pure PP. This result indicated the presence of antistatic properties of M-DAG

in line with resistivity analysis which was in the static dissipative range

of 106 – 1012 /sq (Pang et al., 2014).

The yield strength of AS-BNC increased with increasing CNC

concentration. According to Al-Haik et al. (2020), adding CNC to the PP matrix leads to a slight increase in yield

strength (8%). However, the concentration of CNC above 2% indicated yield

strength which tends to decrease to lower than Pure PP due to poor dispersion

of CNC in the PP matrix and the weak chemical bonding between CNC and PP

matrix.

Based on the results of SEM

analysis on the cross-section, it was found that M-DAG and CNC agglomerations

were found on the PP matrix. The XRD

diffractogram pattern of AS-BNC showed peaks representing the diffraction

structure of glycerol monostearate and cellulose I. It

was observed that the particle size increased with an increase in CNC

concentration in AS-BNC. The degree

of crystallinity of AS-BNC-2.5 was

higher than pure PP. The FTIR spectrum of each treatment was very similar to the characteristic

peaks of PP and showed three distinct peaks of AS-BNC compared to pure PP. The melting temperature of AS-BNC-0 was

176.54oC, which was higher than pure PP at 175.44 oC. The thermal stability of

AS-BNC-0,

AS-BNC-0.5, and AS-BNC-2.5 was

472.07oC, 470.25oC, and 475.15oC, respectively, which was higher than that

of pure PP at 468.27oC. Furthermore, the MFI of AS-BNC-0 was lower than pure PP, while AS-BNC-0.5 and AS-BNC-2.5 had a higher

MFI value than pure PP, with an increase of 32.0% and 43.9%, respectively. The mechanical properties results showed that the best formulation was

AS-BNC-2.5 with 11.071 MPa flexural modulus, 30.376 MPa yield strength,

23.796% yield

elongation,

1.659 J/m2 impact strength, which was higher than pure PP, and

antistatic at 1010 – 1012 /sq

resistivity. Further identification is needed to improve the characteristics of

antistatic bio-nano composites. Optimization of the conditions for the

synthesis of antistatic bio-nano composites so that it does not easily cause

clogging of the twin-screw extruder and injection molding machine and

modification of the molding machine is needed to minimize the blockages during

the synthesis of antistatic bio-nano composites.

Much appreciation goes to Palm Oil Plantation Fund

Management Agency (POPFMA/BPDPKS) – Ministry of Finance RI for supporting this

research trough Grant Research Sawit (GRS K18) No. PENG-1/DPKS.4/2018.

Adriana,

Jalal, R., Thamrin, Wirjosentono, B., Gea, S., 2014. Mechanical

Properties of Nanocrystal Cellulose Reinforced Polystyrene with Glycerol

Monostearic as Antistatic Agent. International Journal of ChemTech Research,

Volume 6(4), pp. 2421–2426

Al-Haik, M.Y., Aldajah, S.,

Siddique, W., Kabir, M.M., Haik, Y., 2020. Mechanical and Thermal

Characterization of Polypropylene-reinforced Nanocrystalline Cellulose

Nano-composites. Journal of Thermoplastic Composite Materials, Volume

20(10), pp. 1–12

Bhatnagar, N., Asija, N., 2016.

Durability of High-performance Ballistic Composites. In: Lightweight

Ballistic Composites: Military and Law-Enforcement Applications, Bhatnagar,

A. (Eds.), Woodhead Publishing, Inc. Sawston, Cambridge, United Kingdom, pp.

231–283

Brinkmann, A., Chen, M.,

Couillard, M., Jakubek, Z.J., Leng, T., Johnston, L.J., 2016. Correlating

Cellulose Nanocrystal Particle Size and Surface Area. Langmuir, Volume 32(24),

pp. 6105?6114

Chakraborty, B.C., Ratna, D.,

2020. Experimental Techniques and Instruments for Vibration Damping. In: Polymers

for Vibration Damping Applications, Chakraborty, B.C., Ratna, D. (Eds.),

Elsevier Inc., Amsterdam, The Netherlands, pp. 281–325

Clemons, C., Rick, R., 2020.

Preparation of Cellulose Nanocrystal-polyoropylene Masterbatches by

Water-assisted Thermokinetic Mixing. In: ANTEC 2020: The Virtual

Edition, pp. 1–6

Couret, L., Irle, M., Belloncle,

C., Cathala, B., 2017. Extraction and Characterization of Cellulose

Nanocrystals from Post-consumer Wood Fiberboard Waste. Cellulose, Volume

24(5), pp. 1–13

Fang, J., Zhang, L., Sutton, D.,

Wang, X., Lin, T., 2012. Needleless Melt-electrospinning of Polypropylene

Nanofibres. Journal of Nanomaterials, Volume 2012, pp. 1–9

Guerra, V., Wan, C., McNally, T.,

2019. Nucleation of the ?-polymorph in Composites of Poly(Propylene) and

Graphene Nanoplatelets. Journal of Composites Science, Volume 3(38), pp.

1–11

Gwon, J.G., Cho, H.J., Lee, D.,

Choi, D.H., Lee, S., Wu, Q., Lee, S.Y., 2018. Physicochemical and Mechanical

Properties of Polypropylene-cellulose Nanocrystal Nanocomposites: Effects of

Manufacturing Process and Chemical Grafting. BioResources, Volume 13(1),

pp. 1619–1636

Hassanabadi, H.M., Alemdar, A.,

Rodrigue, D., 2015. Polypropylene Reinforced with Nanocrystalline Cellulose:

Coupling Agent Optimization. Journal of Applied Polymer Science, Volume

132(34), p. 42438

Hejna, A., Kirpluks, M., Kosmela,

P., Cabulis, U., Haponiuk, J., Piszczyk, ?., 2017. The Influence of Crude

Glycerol and Castor Oil-based Polyol on the Structure and Performance of Rigid

Polyurethane-polyisocyanurate Foams. Industrial Crops and Products,

Volume 95(1), pp. 113–125

Hobuss, C.B., Da Silva, F.A., Dos

Santos, M.A.Z., De Pereira, C.M.P., Schulz, G.A.S., Bianchini, D., 2020.

Synthesis and Characterization of Monoacylglycerols through Glycerolysis of

Ethyl Esters Derived from Linseed Oil by Green Processes. RSC Advances,

Volume 10, pp. 2327–2336

Jain, R., Tiwari, A., 2015.

Biosynthesis of Planet Friendly Bioplastics using Renewable Carbon Source. Journal

of Environmental Health Science and Engineering, Volume 13(11), pp. 1–5

Kafy, A., Kim, H.C., Zhai, L.,

Kim, J.W., Hai, L. Van, Kang, T.J., Kim, J., 2017. Cellulose Long Fibers

Fabricated from Cellulose Nanofibers and Its Strong and Tough Characteristics. Scientific

Reports, Volume 7, p. 17683

Kumar, P., Narayan Maiti, U.,

Sikdar, A., Kumar Das, T., Kumar, A., Sudarsan, V., 2019. Recent Advances in

Polymer and Polymer Composites for Electromagnetic Interference Shielding:

Review and Future Prospects. Polymer Reviews, Volume 59(4), pp. 687–738

Maryniak,

W.A., Uehara, T., Noras, M.A., 2003. Surface Resistivity and Surface

Resistance Measurements. Trek Application Note, Volume 2003(1005), pp.

195–209

McKeen, L.W., 2014. Introduction

to Plastics, Polymers, and Their Properties. In: The Effect of Temperature

and other Factors on Plastics and Elastomers, McKeen, L.W. (Eds.), William

Andrew, Inc. Norwich, New York, pp. 1–45

Moser, C., Henriksson, G.,

Lindström, M.E., 2016. Specific Surface Area Increase During Cellulose

Nanofiber Manufacturing Related to Energy Input. BioResources, Volume

11(3), pp. 7124–7132

Ng, H.M., Sin, L.T., Bee, S.T.,

Tee, T.T., Rahmat, A.R., 2017. Review of Nanocellulose Polymer Composite

Characteristics and Challenges. Polymer – Plastics Technology and

Engineering, Volume 56(7), pp. 687–731

Pang, H., Xu, L., Yan, D.X., Li,

Z.M., 2014. Conductive Polymer Composites with Segregated Structures. Progress

in Polymer Science, Volume 39(11), pp. 1908–1933

Park, S., Baker, J.O., Himmel,

M.E., Parilla, P.A., Johnson, D.K., 2010. Cellulose Crystallinity Index:

Measurement Techniques and Their Impact on Interpreting Cellulase Performance. Biotechnology

for Biofuels, Volume 3(1), pp. 1–10

Purnomo,

H., Baskoro, H., Muslim, F., 2021. Stress and Strain Behavior of

Confined Lightweight Concrete using Sand Coated Polypropylene Coarse Aggregate.

International Journal of Technology, Volume 12(6), pp. 1261–1272

Rahman,

N.A., Hassan, A., Heidarian, J., 2018. Effect of

Compatibiliser on the Properties of Polypropylene/Glass Fibre/Nanoclay

Composites. Polimeros, Volume 28(2), pp. 1–9

Rochardjo, H.S.B., Fatkhurrohman,

Kusumaatmaja, A., Yudhanto, F., 2021. Fabrication of Nanofiltration Membrane

based on Polyvinyl Alcohol Nanofibers Reinforced with Cellulose Nanocrystal

using Electrospinning Techniques. International Journal of Technology,

Volume 12(2), pp. 329–338

Sabaruddin, F.A., Md-Tahir, P.,

Lee, S.H., 2019. Mechanical Properties of PP/Kenaf Core Nanocomposites Made

from Nanocrystalline Cellulose as An Additive. Journal of Reinforced

Plastics and Composites, Volume 38(2), pp. 88–95

Saleh, T.A., 2021. Structural

Characterization of Hybrid Materials. In: Polymer Hybrid Materials and

Nanocomposites, Saleh, T.A. (Eds.), William Andrew, Inc. Norwich, New York,

pp. 213-240

Salsabila, S., Setyaningsih, D.,

Jannah, Q.R., Muna, N., 2021. Formulation of Mono-diacylglycerol from Palm

Fatty Acid Distillate and Glycerol as Antistatic Agents on Plastics. In:

IOP Conference Series: Earth and Environmental Science, Volume 749, p. 012069

Sandri, G., Bonferoni, M.C.,

Rossi, S., Ferrari, F., Aguzzi, C., Viseras, C., Caramella, C., 2016. Clay

Minerals for Tissue Regeneration, Repair, and Engineering. In: Wound

Healing Biomaterials, Ågren, M.S. (Eds.), Woodhead Publishing, Inc. Sawston,

Cambridge, United Kingdom, pp. 385–402

Sarfat, M.S., Setyaningsih, D.,

Fahma, F., Indrasti, N.S., Sudirman, 2022. Characterization of

Mono-diacylglycerols, Cellulose Nanocrystals, Polypropylene, and Supporting

Materials as raw Materials for Synthesis of Antistatic Bionanocomposites.

In: IOP Conference Series: Earth and Environmental Science, Volume 1034,

pp. 012009

Setyaningsih, D., Suwarna, M.A.,

Muna, N., 2020. The effect of Solvent Type and Temperature on

Mono-diacylglycerol Purification. In: IOP Conference Series: Earth and

Environmental Science, Volume 460, p. 012037

Setyaningsih, D., Warsiki, E.,

Ulfa, S.F., Muna, N., 2020b. The Effect of Sodium Carbonate and Saccharides on

Mono-diacylglycerol (M-DAG) Purification. In: IOP Conference Series: Earth and

Environmental Science, Volume 460, pp. 012038

Shieddieque, A.D., Mardiyati,

Suratman, R., Widyanto, B., 2021. Preparation and Characterization of

Sansevieria Trifasciata Fiber/High-Impact Polypropylene and Sansevieria

Trifasciata Fiber/Vinyl Ester Biocomposites for Automotive Applications. International

Journal of Technology, Volume 12(3), pp. 549–560

Shojaeiarani, J., Bajwa, D.S.,

Chanda, S., 2021. Cellulose Nanocrystal Based Composites: A Review. Composites

Part C: Open Access, Volume 5, p. 100164

Shubhra, Q.T.H., Alam, A.K.M.M.,

Quaiyyum, M.A., 2013. Mechanical Properties of Polypropylene Composites: A

Review. Journal of Thermoplastic Composite Materials, Volume 26, pp.

362–391

Tang, J., Sisler, J.,

Grishkewich, N., Tam, K.C., 2017. Functionalization of Cellulose Nanocrystals

for Advanced Applications. Journal of Colloid and Interface Science,

Volume 494, pp. 397–409

Thomas, B., Raj, M.C., Athira,

B.K., Rubiyah, H.M., Joy, J., Moores, A., Drisko, G.L., Sanchez, C., 2018.

Nanocellulose, a Versatile Green Platform: From Biosources to Materials and

Their Applications. Chemical Reviews, Volume 118(24), pp. 11575–11625

Yousefian, H., Rodrigue, D.,

2015. Nano-crystalline Cellulose, Chemical Blowing Agent, and Mold Temperature

Effect on Morphological, Physical/Mechanical Properties of Polypropylene.

Journal of Applied Polymer Science, Volume 132(47), pp. 428–445

Yousefian, H., Rodrigue, D.,

2016. Effect of Nanocrystalline Cellulose on Morphological, Thermal, and

Mechanical Properties of Nylon 6 Composites. Polymer Composites, Volume

37, pp. 1473–1479

Yusuf, M., Khan, M., Khan, R.A.,

Ahmed, B., 2013. Preparation, Characterization, In Vivo and Biochemical

Evaluation of Brain Targeted Piperine Solid Lipid Nanoparticles in an

Experimentally Induced Alzheimer’s Disease Model. Journal of Drug Targeting,

Volume 21(3), pp. 300–311

Zhou, X., Yu, Y., Lin, Q., Chen,

L., 2013. Effects of Maleic Anhydride-grafted Polypropylene (MAPP) on the

Physico-mechanical Properties and Rheological Behavior of Bamboo

Powder-polypropylene Foamed Composites. BioResources, Volume 8(4), pp.

6263–6279