Extractive Fed-Batch Bioacetone Fermentation with Free Cell and Immobilized Clostridium Saccharoperbutylacetonicum N1-4 in a Large Extractant Volume

Corresponding email: r.f.darmayanti@gmail.com

Published at : 10 Jul 2024

Volume : IJtech

Vol 15, No 4 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i4.5735

Darmayanti, R.F., Muharja, M., Airlangga, B., Widjaja, A., Nalawati, A.N., 2024. Extractive Fed-Batch Bioacetone Fermentation with Free Cell and Immobilized Clostridium Saccharoperbutylacetonicum N1-4 in a Large Extractant Volume. International Journal of Technology. Volume 15(4), pp. 890-902

| Rizki Fitria Darmayanti | Department of Agro-industrial Technology, Faculty of Agriculture, University of Muhammadiyah Jember, Jalan Karimata 49, 68124 Jember, Indonesia |

| Maktum Muharja | Department of Chemical Engineering, Faculty of Industrial Technology and System Engineering, Institut Teknologi Sepuluh Nopember, Surabaya 60111, Indonesia |

| Bramantyo Airlangga | Department of Chemical Engineering, Faculty of Industrial Technology and System Engineering, Institut Teknologi Sepuluh Nopember, Surabaya 60111, Indonesia |

| Arief Widjaja | Department of Chemical Engineering, Faculty of Industrial Technology and System Engineering, Institut Teknologi Sepuluh Nopember, Surabaya 60111, Indonesia |

| Ara Nugrahayu Nalawati | Department of Agro-industrial Technology, Faculty of Agriculture, University of Muhammadiyah Jember, Jalan Karimata 49, 68124 Jember, Indonesia |

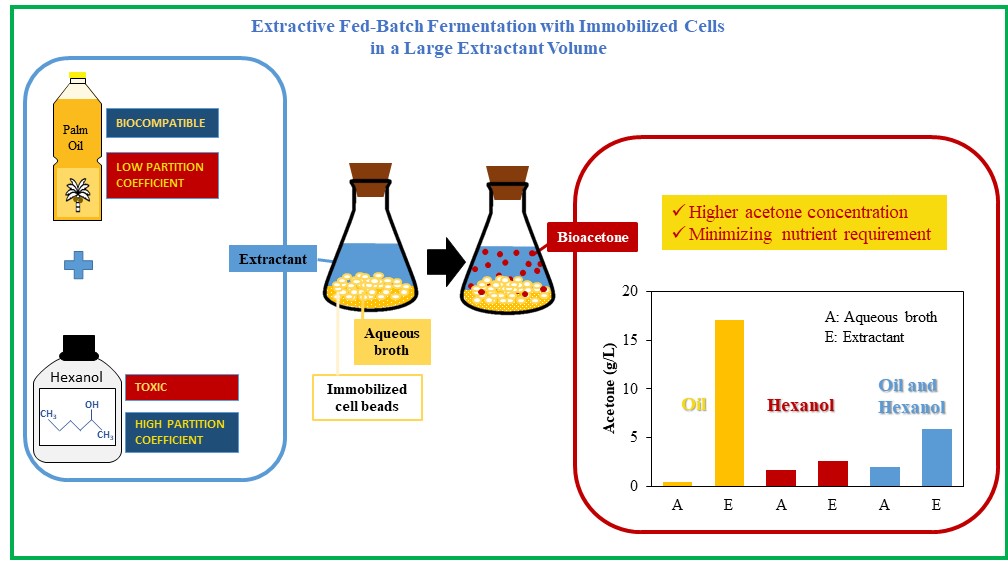

This study compared free and immobilized cells with

palm oil and hexanol as an extractant in a large volume ratio of extractant to

the broth. Fermentation was conducted using TYA (Tryptone-Yeast-Acetate) media,

glucose as the substrate and the palm oil, hexanol, and a mixture of hexanol

and palm oil with a composition of 1:1 v/v as an extractant in the fermentation

with a large volume ratio of extractant to broth of 5. The strain was

inoculated as free-suspended cells of C. saccharoperbutylacetonicum N1-4

and immobilized cells in calcium alginate. The best extractant results for the

acetone fermentation process in the ratio of extractive fermentation of free

cells and immobilized cells were using palm oil as extractants. This extractant

harvested acetone well, with the acetone concentration in the extractant at

18.41 g/L in free cell fermentation and 17.07 g/L in immobilized cell

fermentation. The maximum total acetone concentration was up to 93.72 g/L

broth. Using palm oil as an extractant in a large extractant volume combined

with immobilization is an alternative to enhance bioacetone production by

effectively reducing the toxicity effect of the products and minimizing

nutrient requirements.

Bioacetone; Cell immobilization; Clostridium saccharoperbutylacetonicum N1-4; Extractive fermentation; Free cell fermentation

Most commodity

chemicals and fuels are originated from non-renewable fossil reserves (Alimny et al., 2019). As one of the

products, acetone has a global market of about US$4 billion in 2021 (Amezquita-Ortiz et al., 2022). In

industry, acetone was utilized as a solvent and platform chemical to generate

materials such as acrylic glass and polypropylene. Moreover, in the fuel

sector, acetone was employed to boost the fuel's performance (Aguado-Deblas et al., 2020). Acetone is

generally manufactured via the cumene process as a by-product of phenol

production (Kökdemir and Acarali, 2021). The process involves propene

cracking, which is an energy-intensive and hazardous process (Liew et al., 2022). Acetone can also be

obtained from renewable resources such as lignocellulosic biomass, algae, waste

streams, industrial by-products, etc., through an

C.

saccharoperbutylacetonicum

grows at the optimum temperature of 30 oC, relatively close to

ambient temperature compared with other strains, which are mostly optimum at a

higher temperature of 37 oC, reducing the energy requirement during

fermentation. C. saccharoperbutylacetonicum N1-4 (ATCC 13564) was proven

to be able to convert many kinds of substrates to ABE, such as glucose, lactic

acid (Oshiro et al., 2011), xylose (Zheng et al., 2013), cellobiose (Noguchi et al., 2013), xylan (Al-Shorgani, Kalil, and Yusoff, 2011), hydrolyzed

agricultural waste (Wu et al., 2021; Qureshi

et al., 2008), and wood (Zheng et

al., 2013).

The major

limitation of the ABE fermentation process is the complex composition of

products with low concentrations, which resulted in the high energy demand of

downstream separation of the ABE fermentation from broth (Cai et al., 2022). In addition, the

inhibition of ABE products (i.e., butanol and acetone) limits product titer

because of the toxicity to the producer strain. This condition challenges the

economic viability of the whole ABE process (Sarangi

and Nanda, 2018). The proposed solution is the acetone recovery as fast

as it is generated, thus preventing the acetone concentration under the

inhibition threshold. Some investigated options are adsorption, gas stripping, pervaporation,

liquid-liquid extraction (LLE), etc. (Rathour et

al., 2018). The integration of ABE fermentation with LLE is an

alternative method that is under great challenge to be developed (Al-Shorgani et al., 2019; Jang et al.,

2012). Process with simpler configuration and lower energy consumption

is more preferable (Muharja et al., 2023a;

2022; 2020a). The LLE method has several astonishing advantages: it uses

a simple setup and equipment, easy to recover the products from the extractant,

and it has low energy use (Zhao et al.,

2019). Previous studies found that a large extractant volume of 5 – 10

to broth ratio significantly improved total ABE fermentation by diminishing

butanol toxicity, led to high product yield and high cell density (Darmayanti et al., 2019, 2021; Zhao et al., 2019). Enhanced acetone to

butanol product ratio in ABE fermentation up to 5:7 could be obtained by

increasing the fermentation temperature to 43.5 oC (Wu et al., 2021).

Another common

method to enhance ABE fermentation product yield by protecting the cells from

the product's harmfulness is the cell immobilization technique (Abo et al., 2019). Various cell

immobilization techniques have also been found to improve yield through the use

of high cell density in continuous fermentation mode (Menchavez

and Ha, 2019; Chang et al., 2016). Al-Shorgani

et al. (2019) reported an improvement in fermentation

productivity and stability by using an immobilized cell of Clostridium sp.

in continuous fermentation systems. Cell immobilization prevents bleeding

during the process. There are many methods for cell immobilization, namely

self-aggregation, entrapment, adsorption, or biofilm (Liu

et al., 2019). Cell immobilization via the gel entrapment method

is extensively employed due to its high mechanical properties and flexible

support structure (Gao et al., 2021).

Although research on the improvement of ABE productivity via LLE and cell

immobilization has been progressively conducted, from the literature studies,

there has been no publication focusing on the application of acetone

production.

From the aforementioned background, this study aims to develop acetone production via the ABE fermentation process with a large volume ratio of extractant to the broth. As a result, a high level of acetone production was attained by utilizing immobilized C. saccharoperbutylacetonicum N1-4 in a fed-batch system.

2.1. Materials

The chemicals used for

this experiment are hexanol (Merck, Darmstadt, Germany), palm oil, glucose,

CaCO3, (NH4)2SO4, CH3COONH4,

MgSO4.7H2O, FeSO4 -7H2O, KH2PO4,

NaCl, CaCl2, HCl and KOH (Pudak Scientific, Bandung, Indonesia),

yeast extract and tryptone (Himedia, Mumbai, India).

2.2. Microorganism Refresh

The first process is

mixing distilled water with 15 g/L of grated potato, 10 g/L of glucose, 0.5 g/L

of ammonium sulfate, and 3 g/L of CaCO3. The mixture was then heated

in boiled water for 1 hour, then cooled to room temperature. The solid was

filtered, and the suspension was sterilized and used for Potato-Glucose media.

Five spoons of C. saccharoperbutylacetonicum N1-4 ATCC 13564 sand stock

bacteria were added to 10 ml media, then heat shocked in boiling water for 1

minute. Then, it was cooled and set at room temperature for 24 hours

anaerobically.

2.3. Preculture

Media was made of

tryptone (Himedia, Mumbai, India) 6 g/L, yeast extract (Himedia, Mumbai, India)

2 g/L, CH3COONH4 3 g/L, MgSO4.7H2O

0.3 g/L, FeSO4 -7H2O 0.01 g/L, KH2PO4

0.5 g/L, and glucose 20 g/L. The pH of the solution was adjusted to 6.5 (HCl

and KOH were used as pH-adjusting agents). Refreshed media was inoculated at

10% v/v and then placed at room temperature anaerobically.

2.4. Free Cell Extractive Fermentation

The TYA media

contained tryptone 6 g/L, yeast extract 2 g/L, CH3COONH4

3 g/L, MgSO4 – 7H2O 0.3 g/L, FeSO4 -7H2O

0.01 g/L, KH2PO4 0.5 g/L, and glucose 50 g/L (Darmayanti et al., 2020). The pH of the solution was adjusted to

6.5. Palm oil, hexanol, a mixture of hexanol, and palm oil with a ratio of 1:1

was used as extractants, with an extractant-to-broth volume ratio of 5. The

working volume of fermentation was 30 mL of broth and 150 mL of extractant

(Figure 1A). It was in an incubator shaker at 160 rpm at 50°C. At the 12, 24,

48, and 72 hours, each sample was fed with 2 mL of 120 g/L glucose solution.

2.5. Extractive Fermentation with Immobilized Cells

The working volume of the fermentation was 30 mL of

broth, 30 mL of immobilized cells beads, and 150 mL of extractant (Figure 1B).

Immobilized cell beads were prepared by making sodium alginate gel (3% w/v)

containing NaCl (0.85% w/v) and preculture media of 10% v/v. The gel mixture

was then dropped in CaCl2 solution (3% w/v) to form calcium alginate

beads. The beads were filtered and used for fermentation.

Figure 1 Extractive fermentation with (a) free and (b) immobilized cells

2.6. Analysis

The reducing sugar in

the broth was measured using DNS (dinitrosalicylic acid) method (Muharja et al., 2019; 2020b). The cell density of C.

saccharoperbutylacetonicum was analyzed by measuring absorbance at 562 nm

using a UV-vis spectrophotometer; one unit of absorbance is equal to 0.246 g/L

dry cell weight. Acetone, ethanol, acetic acid, and butanol were analyzed using

gas chromatography (Darmayanti et al., 2021).

3.1. Free Cell Extractive Fermentation

This study used palm oil

and hexanol as representative natural and synthetic extractants because they

have not been reported in previous studies for bioacetone fermentation. Acetone

dissolves well in both of these organic solvents, so they were used as the

extractant for acetone in this experiment. The initial pH was adjusted at 6.5

as this is the optimum acidity for the strain to form organic acid. The pH for

free cell extractive fermentation with palm oil extractant decreased to around

5-6 (Figure 2A), while the pH in hexanol extractants and hexanol-palm oil

mixtures was at pH around 6. During the acidogenesis phase, the pH tends to

decrease due to the formation of acids, namely acetic acid, in the fermentation

with palm oil extractant. The influence of external pH is one of the key

factors involved in triggering the transition from the acidogenesis phase to

the solventogenesis phase (Capilla et al., 2024).

The addition of CaCO3

(calcium carbonate), which is a reagent that serves to buffer the degree of

acidity that can maintain the pH in the fermentation process. To achieve

optimum conditions for the growth and metabolism of acetic acid bacteria, the

environment and the state of the fermentation medium are well maintained. In

this study, the effect of the use of CaCO3 is very influential

because it maintains the pH value of each extractant. The pH in this

fermentation should not be below 5 to prevent the acid crash, which may cause

death to the strain (Capilla et al., 2022). Its low

solubility in water can cause it to neutralize acids such as acetic acid and

maintain pH at a certain level automatically (Valles

et al., 2020). For good ABE

production, the pH should be buffered between 5-6 (Han

et al., 2013), as occurred in the

extractive fermentation with palm oil as an extractant. However, using hexanol

as an extractant caused low cell growth, which consequently formed a lower acid

product and no significant pH change during fermentation.

Figure 2 Free cell extractive

fermentation pH test curve (a), cell density (b), glucose concentration (c),

and acetone concentration (d) with palm oil,

hexanol, and

hexanol-palm oil mixture as extractant. O is oil, H is hexanol, A is the aqueous phase,

and E is the extractant phase

Figure 2D shows that the

concentration of acetone in the free cell extractive fermentation was the

highest using palm oil as extractant with a value of 18.414 g/L, with a high

distribution coefficient of acetone in the palm oil–water mixture of 11.2. This

study attempted a higher temperature of 50 oC to enhance the acetone

product than butanol. As reported in the previous study with SSF of corn

stover, a higher temperature of 43.5 oC could improve the

acetone-to-butanol product ratio (Wu et al.,

2021). The substrate and nutrients in the free-cell extractive

fermentation using palm oil were directly consumed by the free cells and no

toxic barriers. Hence, the value obtained was relatively high. As the palm oil

reduced the acetone concentration effectively from the media, the acetone was

produced in a higher amount compared with the other extractant (Cai et al., 2022).

3.2. Immobilized Cell

Fermentation

Figure 3 Immobilized cell fermentation pH (a), cell density (b), glucose concentration (c), and acetone concentration (d) with

Fermentation using palm oil extractant

demonstrated a high cell concentration increase (Figure 3B); namely, the

maximum cell density is obtained at the 96th hour of 0.354 g/L.

Compared to the cell growth using free cell extractive fermentation (0.246

g/L), immobilization increased the growth. Immobilization protected the cells

inside the alginate matrix, resulting in more accumulated cells entrapped in

the beads, more than the density of free cells (Darmayanti et al., 2018). In the previous study using a low ratio

of toxic extractant to broth volume, immobilization could promote cell growth

in the alginate beads (Ye et al., 2018). In this study, a high-volume ratio of

toxic extractant to broth exposed the cells to a more extreme condition, so

they could not grow even entrapped in the calcium alginate.

Figure 3C shows that

the glucose concentration curve for immobilized cell fermentation had a stable

increase and decrease in all fermentation. The highest sugar consumption was

47.01 g/L, using palm oil as the extractant. The decrease in glucose concentration

in the hexanol extractant and the mixture of hexanol with palm oil occurred

because the bacteria were protected by the alginate and required a substrate

for growth (Muharja et al., 2023b). Although hexanol is a toxic substance,

sugar consumption was more stable than fermentation with free cells. The role

of immobilized cells in the fermentation of acetone products is to increase the

resistance of microbial cells from the influence of environmental conditions

such as pH, temperature, organic solvents, and toxic substances, thus causing

the viability of the cells to be maintained better (Ye et al., 2018).

Figure 3D shows that the

acetone concentration curve in the extractive fermentation of immobilized cells

has increased in the palm oil extractant, which is 17.069 g/L, so the palm oil

extractant is the best extractant to produce acetone products in the extractive

fermentation using immobilized cells. Cell immobilization aims to make the cell

immobile or reduce its space to move so that it inhibits its growth outside the

beads, and the substrate is used only to produce products (Hastuti et al.,

2019).

3.3. Comparison of Free

Cells and Immobilized Cells in Extractive Fermentation

Figure

4 shows the total acetone concentration to the volume of the medium based on

the method of adding glucose to food nutrients in each fermentation obtained a

high enough value for the palm oil extractant with free cell extractive

fermentation, which was 93.72 g/L. This is because the free cells are in direct

contact with the glucose substrate in the media cells. The second highest value

was found in the palm oil extractant with extractive fermentation of

immobilized cells, which was 85.81 g/L. This is because the immobilized cells

were entrapped in the alginate matrix, so the substrate mass transfer to the

immobilized cells was decelerated compared to free cells, which directly

contacted the substrate with no hindrance. However, the difference was insignificant

if immobilized cells were considered for the ease of recycling and eliminating

the nutrient requirement for the preculture of the next fermentation batch (Zhao et al., 2019). A previous study had

proven the reusability of calcium alginate for Abe fermentation with stable

results in three consecutive cycles (Kheyrandish et

al., 2015).

According

to this study's result, the extractant's biocompatibility played a stronger

role than the immobilization. In the previous study using octanol as the

extractant with a low extractant-to-broth volume ratio of 0.33, entrapment in

calcium alginate protected the cells from the toxic effect of the solvent (Ye et al., 2018). In this study, the

hexanol extractant in immobilized cells with a large volume-to-broth ratio of 5

contacted the beads in a high concentration of solvents, hampered the cell's

growth, and consequently resulted in a low acetone concentration. The use of a

biocompatible extractant (palm oil) in a large extractant-to-broth volume ratio

favored the fed-batch fermentation by eliminating the toxic effect of the

produced solvent in broth (Da-Costa-Nogueira et

al., 2021). The viability of the cells was maintained in a

productive condition, giving a high total acetone concentration reaching 93.72

g/L and 85.81 g/L.

Figure 4 Total acetone concentration per media (broth) volume. O is oil, H is

hexanol, A is the aqueous phase, and E is the extractant phase. Total acetone

concentration is the total mass of the acetone produced in the aqueous and extractant

phase divided by the total volume of broth (aqueous phase)

The data in Table 1 shows that in the

extractant and aqueous phases, there are acetone, butanol, and ethanol which

are the end products of the solventogenesis stage, and acetic acid, which is an

intermediate product of the acidogenesis stage. The fermentation in this study

using a fermentation temperature of 50 oC and acetone selective

extractant succeeded in producing acetone selectively rather than the other

products.

Table 1 Concentration of

fermentation products in each phase

|

Sample Name |

Acetone (g/L) |

Ethanol (g/L) |

Butanol (g/L) |

Acetic Acid (g/L) |

|

O-A (F) |

1.652 |

- |

- |

- |

|

O-A (I) |

0.461 |

- |

- |

- |

|

H-A (F) |

0.965 |

0.706 |

- |

0.559 |

|

H-A (I) |

1.671 |

0.212 |

0.075 |

6.492 |

|

HO-A (F) |

1.580 |

- |

- |

0.800 |

|

HO-A (I) |

2.006 |

- |

- |

- |

|

O-E (F) |

18.414 |

- |

- |

1.262 |

|

O-E (I) |

17.069 |

0.337 |

- |

- |

|

H-E (F) |

3.424 |

- |

- |

- |

|

H-E (I) |

2.566 |

- |

0.117 |

- |

|

HO-E (F) |

1.170 |

- |

0.099 |

- |

|

HO-E (I) |

5.836 |

0.155 |

- |

4.629 |

|

Information: O = Fermentation with palm

oil H = Fermentation with

hexanol HO = Fermentation with

palm oil-hexanol mixture |

A = Aqueous phase E = Extractant phase F = Fermentation with free cells I = Fermentation with immobilized cells | |||

Table 2 Comparison of acetone-enhanced ABE

fermentation

|

Fermen-tation |

Process modification |

Strain |

Tempe-rature (oC) |

Total acetone

concentration (g/L broth) |

References |

|

Batch |

Extraction using octanol with extractant to broth

ratio of 0.33 |

C. acetobutylicum |

37 |

3.33 |

(Ye et al., 2018) |

|

Batch |

Acetate addition |

C. acetobutylicum and S. cerevisiae |

37 |

7.0 |

(Luo et al., 2016) |

|

Batch |

Acetate addition |

C. acetobutylicum and S. cerevisiae |

37 |

10.5 |

(Luo et al., 2017) |

|

Fed-batch |

pH-stat with acetate and glucose co-feeding |

C.

saccharoper-butylacetonicum |

30 |

8.74 |

(Gao et al., 2016) |

|

Batch |

SSF of corn stover using thermotolerant strain |

C. acetobutylicum |

43.5 |

5.0 |

(Wu et al., 2021) |

|

Fed-batch |

Extraction using oleyl alcohol and tributyrin

mixture with extractant to broth ratio of 5 |

C.

saccharoper-butylacetonicum |

30 |

13.0 |

(Darmayanti et al., 2018) |

|

Fed-batch |

Extraction using palm oil with extractant to broth

ratio of 5 |

C.

saccharoper-butylacetonicum |

50 |

93.72 with free cells and 85.81 with immobilized

cells |

This study. |

Several studies enhancing acetone production in ABE

fermentation were reported but in a limited number (Table 2). This study using

high temperature and palm oil extractant in a large extractant-to-broth volume

ratio reached the highest total acetone concentration compared with the other

reported research. The total concentration of produced acetone was calculated

using the volume of broth as the basis because broth or media requires costly

nutrient ingredients. Besides, in industrial applications, the extractant is

recyclable, while the nutrient in the broth is consumable. A large

extractant-to-broth ratio led to a higher capacity of the broth to produce six

times more than the fermentation without extraction. High acetone concentration

was produced by the strain because of the toxicity-eliminating effect from the

use of biocompatible acetone selective extractant in a large volume. Using

extractants in a large volume is a novel option to enhance the total

concentration of product per broth so that the required nutrient during

fermentation can be minimized (Darmayanti et al., 2023). It was combined with the immobilization

of cells to ease the reuse of the cells beads to remove the preculture step

during long operations, so the nutrient required for the preculture step could

also be eliminated. These advantages are solutions to overcome the issues of

bringing ABE fermentation to a largescale production, improving the economic

feasibility of bioacetone production.

The best extractant

results for the acetone fermentation process were using free cells extractive

fermentation with palm oil extractants with a total acetone concentration of

93.72 g/L broth. The large volume of biocompatible acetone selective extractant

favored fermentation by reducing the toxicity effects of the products.

Combining the use of a large volume of extractant and immobilization is a

promising method for conducting fermentation with minimized nutrient

requirements. The research could be further investigated for the purification

of products and larger-scale applications.

The

author acknowledged the Ministry of Education, Culture, Research, and

Technology, Indonesia. We have no conflicts of interest to declare.

| Filename | Description |

|---|---|

| R1-CE-5735-20220805112242.PNG | Figure 1 |

| R1-CE-5735-20220805112439.PNG | Figure 2 |

| R1-CE-5735-20220805112458.PNG | Figure 3 |

| R1-CE-5735-20220805112704.png | Figure 4 |

Abo, B.O., Gao, M., Wang, Y., Wu, C., Wang, Q.,

Ma, H., 2019. Production of Butanol from Biomass: Recent Advances and Future Prospects.

Environmental Science and Pollution Research, Volume 26, pp. 20164–20182

Aguado-Deblas, L., Estevez, R., Hidalgo-Carrillo,

J., Bautista, F.M., Luna, C., Calero, J., Posadillo, A., Romero, A.A., Luna,

D., 2020. Acetone Prospect as an Additive to Allow the Use of Castor and

Sunflower Oils as Drop-In Biofuels in Diesel/Acetone/Vegetable Oil Triple

Blends for Application in Diesel Engines. Molecules, Volume 25(12), p.

2935.

Aisyah, A.N., Ni’maturrohmah, D., Putra, R.,

Ichsan, S., Kadja, G.T.M., Lestari, W.W., 2023. Nickel Supported on MIL-96(Al)

as an Efficient Catalyst for Biodiesel and Green Diesel Production from Crude

Palm Oil. International Journal of Technology, Volume 14(2), pp. 276–289

Alimny,

A.N., Muharja, M., Widjaja, A., 2019. Kinetics of Reducing Sugar Formation from

Coconut Husk by Subcritical Water Hydrolysis. Journal of Physics: Conference

Series, Volume 1373(012006), pp. 1-8

Al-Shorgani, N.K.N., Al-Tabib, A.I., Kadier, A.,

Zanil, M.F., Lee, K.M., Kalil, M.S., 2019. Continuous Butanol Fermentation of

Dilute Acid-Pretreated De-oiled Rice Bran by Clostridium acetobutylicum YM1. Scientific

Reports, Volume 9(1), pp. 1–13

Al-Shorgani, N.K.N., Kalil, M.S., Yusoff, W.M.W.,

2011. The Effect Of Different Carbon Sources on Biobutanol Production Using Clostridium

saccharoperbutylacetonicum N1-4. Biotechnology, Volume 10(3), pp. 1–6

Amezquita-Ortiz, J.M., Alcocer-Garcia, H.,

Contreras-Zarazua, G., Fontalvo, J., Segovia-Hernandez, J.G., 2022. Sustainable

Process Design for Acetone Purification Produced via Dehydrogenation of

2-Propanol. Industrial and Engineering Chemistry Research, Volume

61(10), pp. 3660–3671

Cai, D., Wen, J., Zhuang, Y., Huang, T., Si, Z.,

Qin, P., Chen, H. 2022. Review of Alternative Technologies for Acetone-butanol-ethanol

Separation: Principles, State-of-the-art, and Development Trends. Separation

and Purification Technology, Volume 298, pp. 121244

Capilla, Miguel, Silvestre, C., Valles, A.,

Álvarez-Hornos, F. J., San-Valero, P., Gabaldón, C., 2022. The Influence of

Sugar Composition and pH Regulation in Batch and Continuous

Acetone–Butanol–Ethanol Fermentation. Fermentation, Volume 8(5), pp. 226

Capilla, Miguel, Valles, A., San, P., Francisco,

V., Álvarez, J., Carmen, H., 2024. Solvent Production from Rice Straw by a Co -

culture of Clostridium Acetobutylicum and Saccharomyces Cerevisiae: effect of

pH control. Biomass Conversion and Biorefinery, pp. 1–13

Chang, Z., Cai, D., Wang, Y., Chen, C., Fu, C., Wang, G., Qin,

P., Wang, Z., Tan, T., 2016. Effective Multiple

Stages Continuous Acetone-butanol-ethanol Fermentation by Immobilized Bioreactors:

Making Full use of Fresh Corn Stalk. Bioresource Technology, Volume 205,

pp. 82–89

Da-Costa-Nogueira, C., de-Araújo-Padilha, C.E.,

de-Medeiros-Dantas, J.M., de-Medeiros, F.G. M., de-Araújo-Guilherme, A.,

de-Santana-Souza, D.F., dos-Santos, E.S., 2021. In-situ Detoxification

Strategies to Boost Bioalcohol Production from Lignocellulosic Biomass. Renewable

Energy, Volume 180, pp. 914–936

Darmayanti, R.F., Amini, H.W., Rizkiana, M.F.,

Setiawan, F.A., Palupi, B., Rahmawati, I., Susanti, A., Fachri, B.A., 2019.

Lignocellulosic Material from Main Indonesian Plantation Commodity as the Feedstock

for Fermentable Sugar in Biofuel Production. Asian Research Publishing

Network (ARPN) Journal of Engineering and Applied Sciences, Volume 14(20),

pp. 3524–3534

Darmayanti, R.F., Muharja, M., Tashiro, Y.,

Sonomoto, K., Zhao, T., Widjaja, A., Fahmiati, S., Halim, A., 2023. Extractive Biobutanol

Fermentation Using Immobilized Cells With Organic Acid Esters as Novel

Co-Substrates in Large Extractant Volume. Bioresource Technology Reports,

Volume 23 (101538), pp. 1-11

Darmayanti, R.F., Susanti, A., Setiawan, F.A.,

Rizkiana, M.F., Muharja, M., Aji, B.B., Prasiefa, M. G., Dewi, L.T., Yanti,

Z.A., 2021. Exploring Starch Sources for the Refreshment Process of

Acetone-Butanol-Ethanol Fermentation with Clostridium

Saccharoperbutylacetonicum N1-4. International Journal of Technology,

Volume 12(2), pp. 309–319

Darmayanti, R.F., Tashiro, Y., Noguchi, T., Gao,

M., Sakai, K., Sonomoto, K., 2018. Novel Biobutanol Fermentation at a Large Extractant

Volume Ratio Using Immobilized Clostridium Saccharoperbutylacetonicum N1-4. Journal

of Bioscience and Bioengineerinng, Volume 126(6), pp. 750–757

Darmayanti, R.F., Tashiro, Y., Sakai, K.,

Sanomoto, K., Susanti, A., Palupi, B., Rizkiana, M.F., 2020. Biobutanol

Production Using High Cell Density Fermentation in a Large Extractant Volume. International

Journal of Renewable Energy Development, Volume 9(3), pp. 431–437

Etteh, C.C., Ibiyeye, A.O., Jeland, F.B.,

Rasheed, A.A., Ette, O.J., Victor, I., 2021. Production of Biobutanol using

Clostridia Spp Through Novel ABE Continuous Fermentation of Selected Waste Streams

and industrial By-products. Scientific African, volume 12, p. e00744

Gao, H., Lu, J., Jiang, Y., Fang, Y., Tang, Y.,

Yu, Z., Zhang, W., Xin, F., Jiang, M. 2021. Material-Mediated Cell Immobilization

Technology in the Biological Fermentation Process. Biofuels, Bioproducts and

Biorefining, Volume 15(4), pp. 1160–1173

Gao, M., Tashiro, Y., Wang, Q., Sakai, K.,

Sonomoto, K., 2016. High Acetone-butanol-ethanol Production in pH-stat

co-feeding of Acetate and Glucose. Journal of Bioscience and Bioengineering.

Volume 122(2), pp. 176-182

Han, B., Ujor, V., Lai, L.B., Gopalan, V., Ezeji,

T.C., 2013. Use of Proteomic Analysis to Elucidate the Role of Calcium

Inacetone-Butanol-Ethanol Fermentation by Clostridium Beijerinckii NCIMB 8052. Applied

and Environmental Microbiology, Volume 79(1), pp. 282–293

Hastuti, N., Darmayanti, R.F., Hardiningtyas,

S.D., Kanomata, K., Sonomoto, K., Goto, M., Kitaoka, T., 2019. Nanocellulose

from Oil Palm Biomass to Enhance Microbial Fermentation of Butanol for Bioenergy

Applications. BioResources, Volume 14(3), pp. 6936–6957

Hawashi, M., Gunawan, S., Aparamarta, H.W.,

Widjaja, T., 2019. Optimization of Solid-State Fermentation Conditions for

Cyanide Content Reduction in Cassava Leaves using Response Surface Methodology.

International Journal of Technology, Volume 10(3), pp. 291–319

Hossain, M.I., Heng, T.B., Lee, C.L., Ong, T.S.,

Islam, M.T., 2022. Green Human Resource Management, Top Management Commitment,

Green Culture, and Green Performance of Malaysian Palm Oil Companies. International

Journal of Technology, Volume 13(5), pp. 1106–1114

Jang, Y.S., Malaviya, A., Cho, C., Lee, J., Lee,

S.Y., 2012. Butanol Production from Renewable Biomass by Clostridia. Bioresource

Technology, Volume 123, pp. 653–663

Kheyrandish, M., Asadollahi, M.A., Jeihanipour,

A., Doostmohammadi, M., Rismani-Yazdi, H., Karimi, K., 2015. Direct Production

of Acetone–butanol–ethanol from Waste Starch by Free and Immobilized

Clostridium Acetobutylicum. Fuel, Volume 142, pp. 129-133

Kökdemir, B., Acarali, N., 2021. A novel study on

CHEMCAD Simulation of Isopropyl Alcohol Dehydrogenation Process Development.

Journal of the Indian Chemical Society, Volume 98(3), pp. 100035

Liew, F.E., Nogle, R., Abdalla, T., Rasor, B.J.,

Canter, C., Jensen, R.O., Wang, L., Strutz, J., Chirania, P., De Tissera, S.,

Mueller, A.P., Ruan, Z., Gao, A., Tran, L., Engle, N.L., Bromley, J.C.,

Daniell, J., Conrado, R., Tschaplinski, T.J., Köpke, M., 2022. Carbon-negative Production

of Acetone and Isopropanol by Gas Fermentation at Industrial Pilot Scale. Nature

Biotechnology, Volume 40(3), pp. 335–344

Liu, J., Zhou, W., Fan, S., Xiao, Z., 2019. Study

of the Co-production of Butanol and Hydrogen by Immobilizing Clostridium Acetobutylicum

CICC8012. Energy Procedia, Volume 158, pp. 1879–1884

Luo, H., Ge, L., Zhang, J., Ding, J., Chen, R.,

Shi, Z., 2016. Enhancing Acetone Biosynthesis and Acetone-butanol-ethanol Fermentation

Performance by Co-culturing Clostridium Acetobutylicum/Saccharomyces Cerevisiae

Integrated with Exogenous Acetate Addition. Bioresource Technology,

Volume 200, pp. 111–120

Luo, H., Zhang, J., Wang, H., Chen, R., Shi, Z.,

Li, X., Ding, J. 2017. Effectively Enhancing Acetone Concentration and Acetone/butanol

Ratio in ABE Fermentation by a Glucose/acetate co-substrate System Incorporating

with Glucose Limitation and C. Acetobutylicum/S. Cerevisiae Co-culturing. Biochemical

Engineering Journal, Volume 118, pp. 132–142

Menchavez, R.N., Ha, S.H., 2019. Fed-batch Acetone-butanol-ethanol

Fermentation using Immobilized Clostridium Acetobutylicum in Calcium Alginate Beads.

Korean Journal of Chemical Engineering, Volume 36(6), pp. 909–913

Muharja, M., Darmayanti, R.F., Fachri, B.A.,

Palupi, B., Rahmawati, I., Rizkiana, M.F., Amini, H.W., Putri, D.K.Y.,

Setiawan, F.A., Asrofi, M., Widjaja, A., Halim, A., 2023b. Biobutanol

Production from Cocoa Pod Husk Through a Sequential Green Method: Depectination,

Delignification, Enzymatic Hydrolysis, and Extractive Fermentation. Bioresource Technology Reports, Volume 21, pp.

101298

Muharja, M., Fadhilah, N., Darmayanti, R.F.,

Sangian, H.F., Nurtono, T., Widjaja, A., 2020a. Effect of Severity Factor on

The Subcritical Water and Enzymatic Hydrolysis Of Coconut Husk For Reducing

Sugar Production. Bulletin of Chemical Reaction Engineering and Catalysis,

Volume 15, pp. 786–797

Muharja, M., Fadhilah, N., Nurtono, T., Widjaja,

A., 2020b. Enhancing Enzymatic Digestibility Of Coconut Husk Using

Nitrogen-Assisted Subcritical Water For Sugar Production. Bulletin of Chemical Reaction Engineering and Catalysis,

Volume 15(1), pp. 84–95

Muharja, M., Widjaja, A., Darmayanti, R. F.,

Airlangga, B., Anugraha, R.P., Fauziyah, M., Wijanarto, E., holehuddin, M.,

Khamil, A.I., 2023a. Heat Exchanger Network Analysis of The Power Plant

Industry Using Aspen Energy Analyzer Software. ASEAN Journal of Chemical

Engineering, Volume 23(1), pp. 14–27

Muharja, M., Widjaja, A., Darmayanti, R. F.,

Fadhilah, N., Airlangga, B., Halim, A., Fadilah, S.K., Arimbawa, I.M., 2022.

Subcritical Water Process for Reducing Sugar Production from Biomass:

Optimization and Kinetics. Bulletin of Chemical Reaction Engineering and

Catalysis, Volume 17(4), pp. 839–849

Muharja, M., Umam, D.K., Pertiwi, D., Zuhdan, J.,

Nurtono, T., Widjaja, A., 2019. Enhancement of Sugar Production from Coconut Husk

Based on the Impact of the Combination of Surfactant-assisted Subcritical Water

and Enzymatic Hydrolysis. Bioresource Technology, Volume 274, pp. 89–96

Niglio, S., Marzocchella, A., Rehmann, L., 2019.

Clostridial Conversion of Corn Syrup to Acetone-Butanol-Ethanol (ABE) via Batch

and Fed-batch Fermentation. Heliyon, Volume 5(3), pp. e01401

Noguchi, T., Tashiro, Y., Yoshida, T., Zheng, J.,

Sakai, K., Sonomoto, K., 2013. Efficient Butanol Production without Carbon Catabolite

Repression from Mixed Sugars with Clostridium Saccharoperbutylacetonicum N1-4. Journal

of Bioscience and Bioengineering, Volume 116(6), pp. 716–721

Oshiro, M., Hanada, K., Tashiro, Y., Sonomoto, K.,

2010. Efficient Conversion of Lactic Acid to Butanol with pH-stat Continuous Lactic

Acid and Glucose Feeding Method by Clostridium Saccharoperbutylacetonicum. Applied

Microbiology and Biotechnology, Volume 87, pp. 1177–1185

Qureshi, N., 2008. Banking on Biobutanol. Agricultural

Research, Volume 10, pp. 8–9

Rathour, R.K., Ahuja, V., Bhatia, RK., Bhatt,

A.K., 2018. Biobutanol: New era of biofuels. International Journal of Energy

Research, Volume 42(15), pp. 4532–4545

Sarangi, P.K., Nanda, S., 2018. Recent Developments

and Challenges of Acetone-butanol-ethanol fermentation. Recent Advancements in

Biofuels and Bioenergy Utilization, PP. 111-123

Su, Z., Wang, F., Xie, Y., Xie, H., Mao, G.,

Zhang, H., Song, A., Zhang, Z., 2020. Reassessment of the Role of CaCO3

in n-butanol Production from Pretreated Lignocellulosic Biomass by Clostridium Acetobutylicum.

Scientific Reports, Volume 10(1), pp. 1–10

Valles, A., Álvarez-Hornos, F.J., Martínez-Soria,

V., Marzal, P., Gabaldón, C., 2020. Comparison of Simultaneous Saccharification

and Fermentation and Separate Hydrolysis and Fermentation Processes for Butanol

Production from Rice Straw. Fuel, Volume 282, p. 118831

Veza, I., Said, M.F., Latiff, Z.A., 2021. Recent Advances

in Butanol Production by Scetone-butanol-ethanol (ABE) Fermentation. Biomass

and Bioenergy, Volume 144, pp. 105919

Wu, Y., Wang, Z., Ma, X., Xue, C., 2021. High Temperature

Simultaneous Saccharification and Fermentation of Corn Stover for Efficient Butanol

Production by a Thermotolerant Clostridium Acetobutylicum. Process

Biochemistry, Volume 100, pp. 20–25

Ye, Z., Song, J., Zhu, E., Song, X., Chen, X.,

Hong, X., 2018. Alginate Adsorbent Immobilization Technique Promotes Biobutanol

Production by Clostridium Acetobutylicum Under Extreme Condition of High Concentration

of Organic Solvent. Frontiers in Microbiology, Volume 9, pp. 1–7

Zhao, T., Tashiro, Y., Sonomoto, K., 2019. Smart Fermentation

Engineering for Butanol Production: Designed Biomass and Consolidated Bioprocessing

Systems. Applied Microbiology and Biotechnology, Volume 103, pp.

9359–9371

Zhao, T., Yasuda, K., Tashiro, Y., Darmayanti,

R.F., Sakai, K., Sonomoto, K., 2019. Semi-hydrolysate of Paper Pulp Without Pretreatment

Enables a Consolidated Fermentation System with in Situ Product Recovery for

the Production of Butanol. Bioresource Technology, Volume 278, pp. 57–65

Zheng, J., Tashiro, Y., Yoshida, T., Gao, M.,

Wang, Q., Sonomoto, K., 2013. Continuous Butanol Fermentation from Xylose with High

Cell Density by Cell Recycling System. Bioresource Technology, Volume

129, pp. 360–365